Non-oxidizing polymer cracking agent

A non-oxidative, polymer technology, used in drilling compositions, chemical instruments and methods, etc., can solve problems such as deteriorating water quality, corroding pipe strings, increasing iron ion concentration, etc., achieving good blocking effect and corrosion resistance. strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

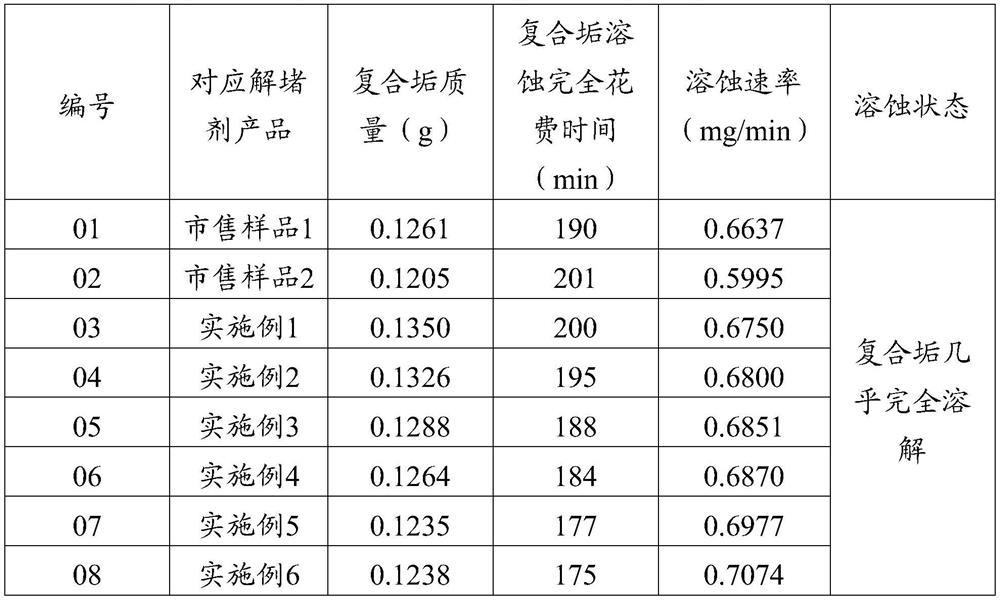

Examples

Embodiment 1

[0029] A non-oxidative polymer cracking agent, which comprises the following components by mass percentage: 0.5% cracking main agent, 0.2% cracking auxiliary agent, 0.5% clay stabilizer, 0.5% corrosion inhibitor, 0.5% surfactant and the remaining amount of water.

[0030] Specifically, the cracking main agent is glutaraldehyde, the cracking auxiliary agent is sodium nitrite, the clay stabilizer is EDTA, the corrosion inhibitor is propynyl alcohol, and the surfactant is fatty alcohol polyoxyethylene ether.

Embodiment 2

[0032] A non-oxidative polymer splitting agent, by mass percentage, comprising the following components: 1% cracking main agent, 0.5% cracking auxiliary agent, 1% clay stabilizer, 1% corrosion inhibitor, 1% surfactant and the rest amount of water.

[0033] Specifically, the cracking main agent is acetone, the cracking auxiliary agent is potassium nitrite, the clay stabilizer is EDTA, the corrosion inhibitor is 7-octynyl alcohol, and the surfactant is AEO-9.

Embodiment 3

[0035] A non-oxidizing polymer splitting agent, by mass percentage, comprising the following components: cracking main agent 1%, cracking auxiliary agent 1%, clay stabilizer 1%, corrosion inhibitor 2%, surfactant 2% and the rest amount of water.

[0036] Specifically, the cracking main agent is vinyl ether, the cracking auxiliary agent is sodium nitrite, and the clay stabilizer is NH 4 Cl, the corrosion inhibitor is 2-picoline, and the surfactant is Tween 60.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com