Assembly line type immersion work harmful water treatment device for chemical production

An assembly line, chemical production technology, applied in water/sewage treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve the problem of affecting the service life of ultrafiltration devices, cumbersome operation process, and decreased filtration performance. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

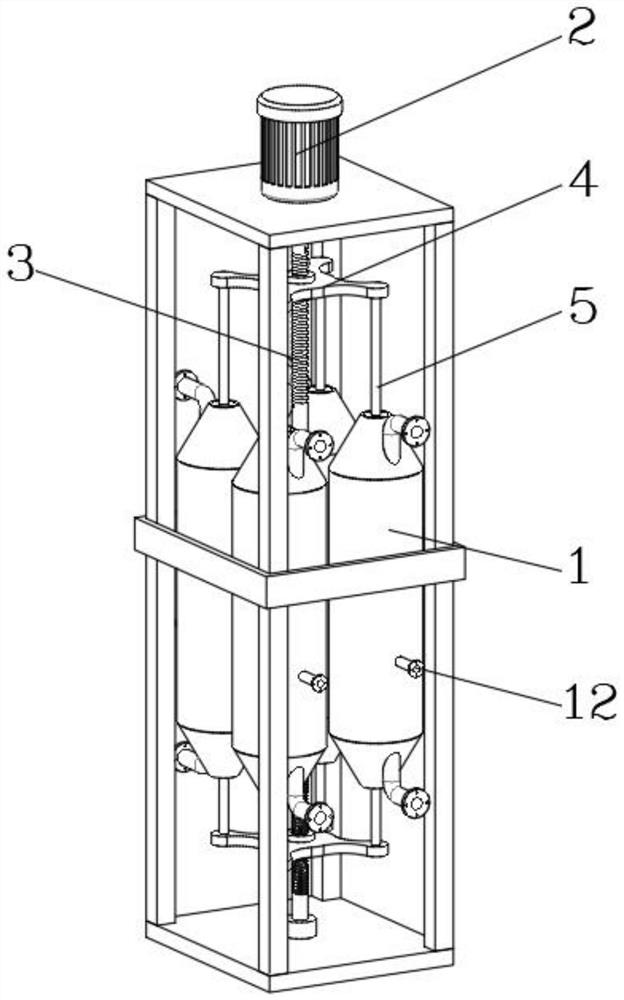

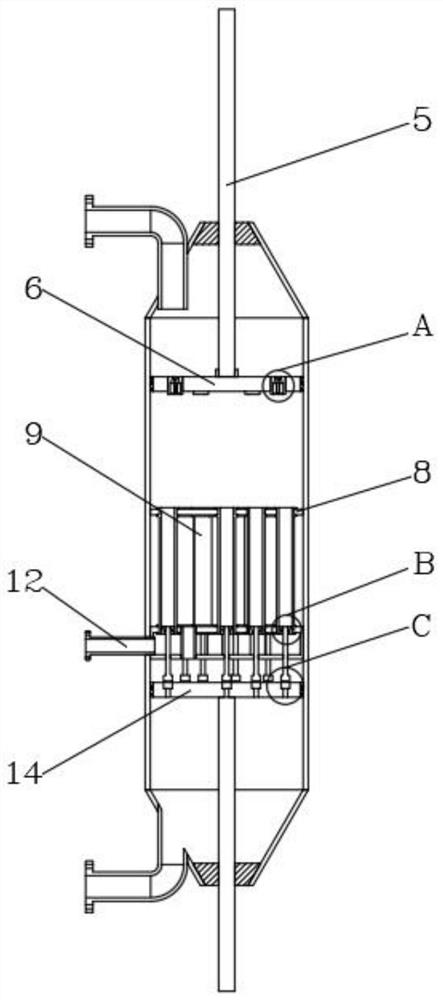

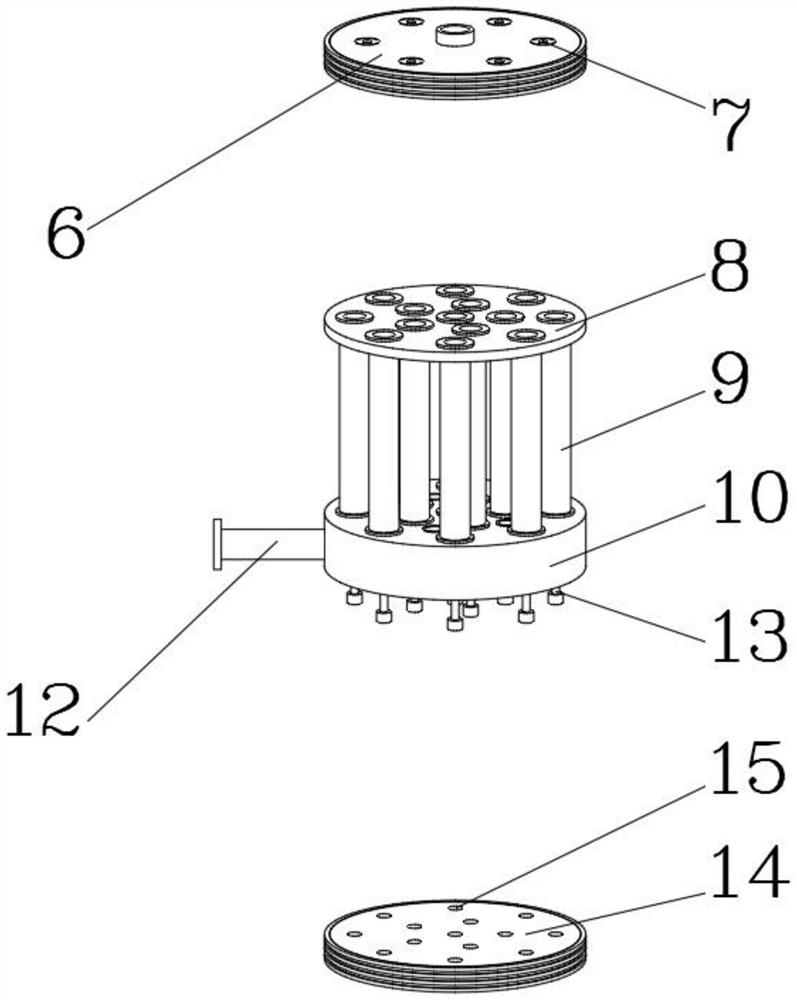

[0034] like Figure 1 to 9 As shown, in the embodiment of the present invention, the harmful water treatment apparatus for chemically producing pipeline immersion operation, including wastewater treatment tank 1, motor 2, ball screw 3, slider 4 and stem 5, motor 2 is disposed in wastewater treatment Above the can 1, the output shaft of the motor 2 is driven with the ball screw 3, and the slider 4 is provided with two and the movable sleeve to the top and bottom of the ball screw 3, and the slider 4 is fixedly connected to the top rod 5. The inner portion of the wastewater treatment tank 1 is provided with a one-way water supply plate 6, the separator 8, the ultrafiltration device 9, the drainage tank 10 and the push plate 14, and the top and push water of the unidirectional water supply plate 6 are provided in the internal portion of the wastewater treatment can 1. The bottom of the plate 14 is connected to the top rod 5 located at the top of the wastewater treatment tank 1 and the...

Embodiment 2

[0054] like Figure 10 to 12 As shown in the present embodiment, the activated carbon filter 17 includes a filtration tank 17-1, a effluent in the bottom of the wastewater treatment tank 1 through the water pipes 2 20-19 and the inlet water provided in the top of the filter tank 17-1. There is a water outlet in the bottom of the filter tank 17-1, and the filter can body 17-1 is provided from top to bottom. Several first separation network 17-2 separates the filter tank 17-1 into a plurality of filler layers, filler layers The internal filled charcoal is provided with a lifting device 19 in the top of the filter tank body 17-1. In the present embodiment, the lifting device adopts an electronically controlled telescopic rod, and the filter can body 17-1 slides and has a vertical rod 17-3, vertical The top end of the rod 17-3 projects out of the filter can body 17-1 and is connected to the lifting device 19, and the vertical rod 17-3 is provided in each layer of the filler layer, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com