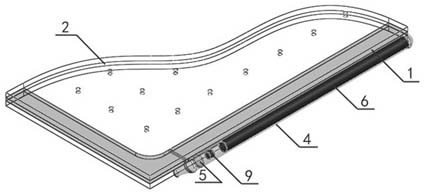

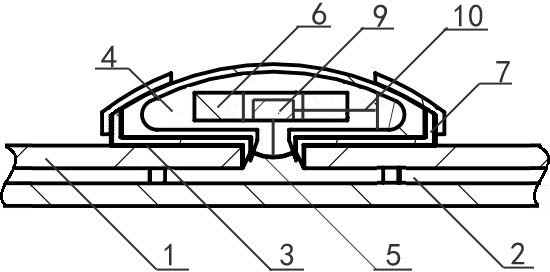

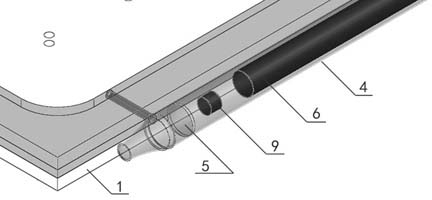

Vacuum glass panel with external cavity

A vacuum glass and glass panel technology, applied in glass forming, glass reshaping, glass manufacturing equipment, etc., can solve the problem that the getter cannot be replaced, achieve extended life, wide selection of materials, and long-term maintenance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The present invention is not limited to the specific description disclosed, and the terminology used herein is for the purpose of specific description only, and is not limiting. The following description of the present invention is provided to disclose the contents of the present invention as currently known embodiments. Those skilled in the relevant art will know and understand that many variations and combinations of the various aspects of the invention can be made while still obtaining the beneficial results of the invention. The following description is provided as an illustration of the principles of the invention and not as a limitation of the invention.

[0054] The selection of the material of the cavity (4) mainly requires as low a permeability coefficient and an outgassing rate as possible so that the vacuum can be maintained for a longer period of time. Glass, ceramics, oxygen-free copper, stainless steel, aluminum, etc. are preferable.

[0055] For a cavi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com