Multi-stage accelerated rotational flow cavitation device

An acceleration tube and acceleration section technology, which is applied in transportation and packaging, chemical instruments and methods, chemical/physical processes, etc., can solve problems such as channel blockage, impurity accumulation, and oil and water well production reduction, so as to improve flow velocity, formation and No pollution to the environment and high energy conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below with reference to the specific embodiments and the accompanying drawings. The examples are only used to explain the present invention, and are not intended to limit the scope of the present invention.

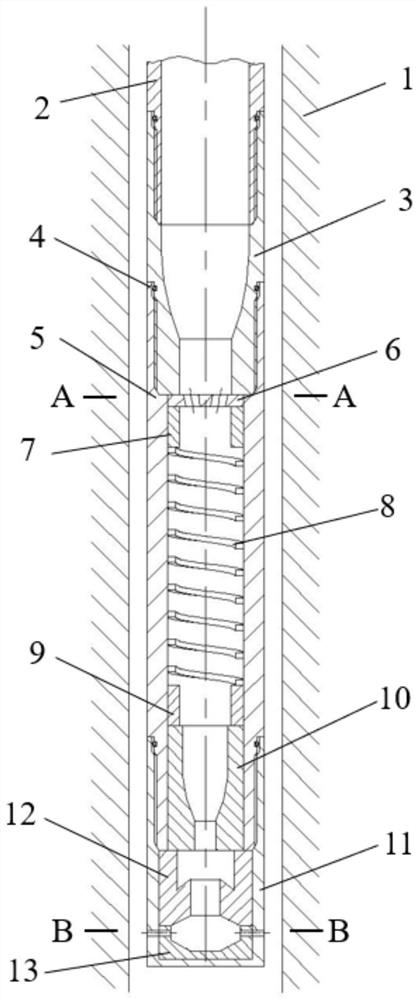

[0028] like figure 1 As shown, a multi-stage accelerated swirl cavitation device includes a first-stage shrinking tube 3, an accelerating tube 5, a mixed flow plate 6, a swirl acceleration section 8, a second-stage shrinking tube 10, a nozzle tube 11, and a self-vibrating cavitation cavity. 12. Conductive body 13;

[0029] The first-stage shrinking tube 3 is located above the accelerating tube 5, the two are connected by threads, and an O-ring is installed at the root of the thread;

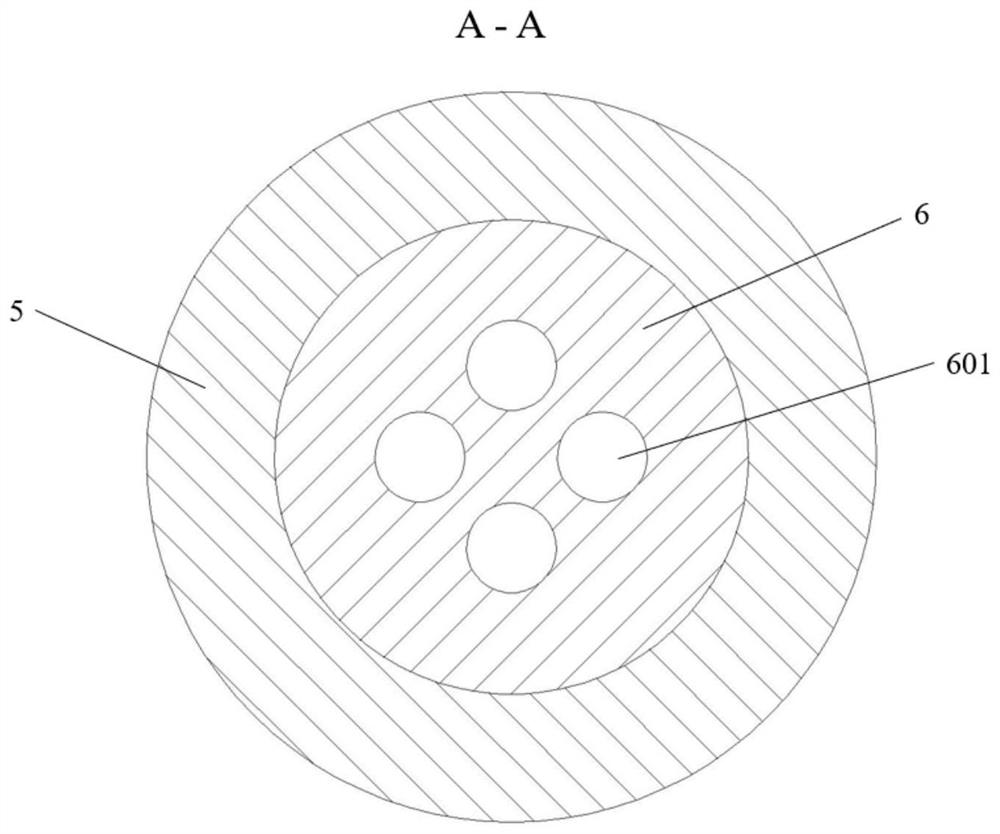

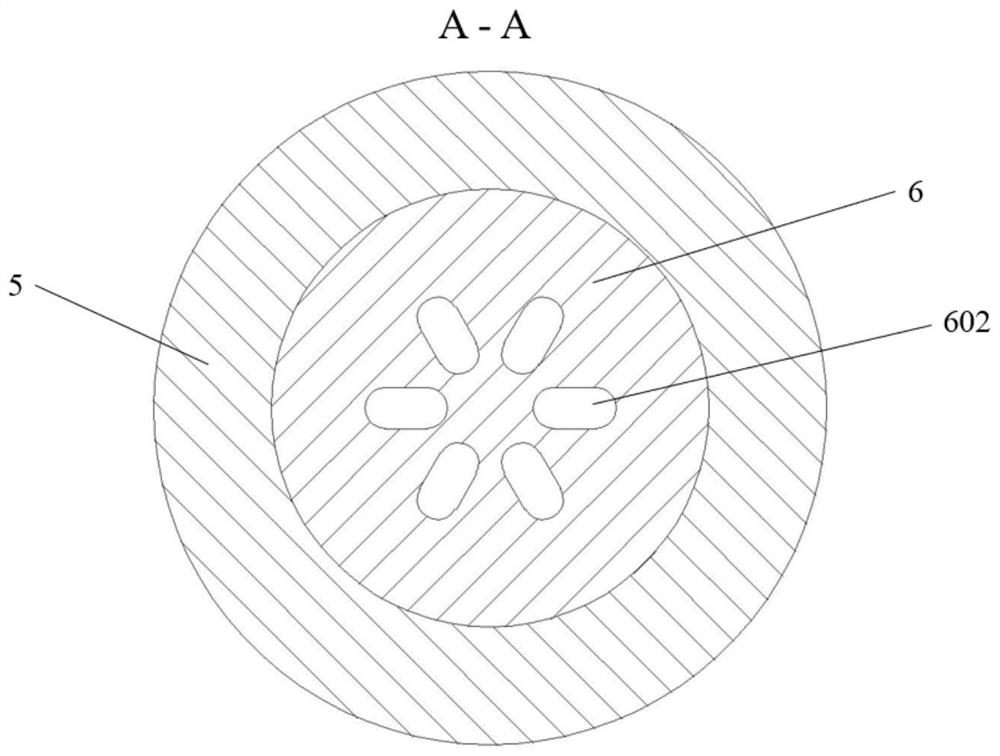

[0030] like figure 2 As shown, the mixed flow plate 6 is installed at the uppermost end of the acceleration tube 5, and the mixed flow plate 6 is provided with inclined through holes, the through holes are circular through holes 601, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com