Long rubber barrel packer for oil field water exclusion production

A technology of long rubber cartridges and packers, which is applied in the directions of sealing/isolation, earthwork drilling, wellbore/well parts, etc., and can solve problems such as complex construction technology, short compression stroke, and poor isolation effect, and achieve sealing The effect is good, the strength of the body is guaranteed, and the effect of improving the success rate of sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

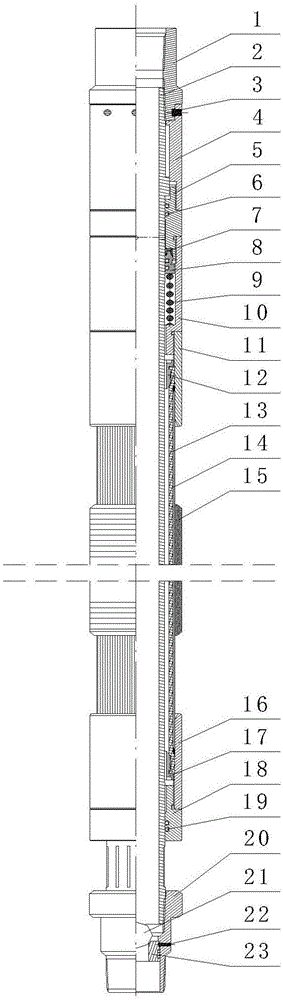

[0026] Such as figure 1 As shown, the present invention provides a long rubber cartridge packer for oil field intervals, which at least includes an upper joint 1, a central pipe 2, a connecting sleeve 4, a connecting head 5, a piston switch 8, a spring seat cover 10, and an intermediate rubber cartridge assembly , sliding sleeve 18, lower joint 20, setting shear nail 22, ball seat 23, the upper end of the central pipe 2 is connected with the upper joint 1, the lower end of the central pipe 2 is connected with the lower joint 20, and the central pipe 2 is connected from the top And the bottom is sequentially connected with connecting sleeve 4, connecting head 5, spring seat cover 10, intermediate rubber tube assembly and sliding sleeve 18. The circular surface is connected, the inner circular surface of the lower end of the connector 5 is connected with the piston switch 8, the outer circular surface of the lower end of the connector 5 is connected with the inner circular surfa...

Embodiment 2

[0029] On the basis of Example 1, the present invention provides a long rubber cartridge packer for oil field intervals, which at least includes an upper joint 1, a central pipe 2, a connecting sleeve 4, a connecting head 5, a piston switch 8, and a spring seat sleeve 10 , intermediate rubber tube assembly, sliding sleeve 18, lower joint 20, setting shear nail 22, ball seat 23, the upper end of the central pipe 2 is connected with the upper joint 1 through thread, and the lower end of the central pipe 2 is connected with the lower joint through thread. The joint 20, the central tube 2 is sequentially sleeved with a connecting sleeve 4, a connecting head 5, a spring seat cover 10, an intermediate rubber tube assembly and a sliding sleeve 18 from top to bottom, and the connecting sleeve 4 and the upper joint 1 are unsealed The shear pin 3 is connected, the lower end of the connecting sleeve 4 is connected with the outer surface of the upper end of the connecting head 5, the conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com