Piston cylinder system, control method, AMT gear shifting system and control method

A control method and piston cylinder technology, which are applied in the directions of transmission control, servo motor, servo motor assembly, etc., can solve the problems of the AMT shift system failing to pick up the gear, the piston is easy to get stuck, the piston is stuck, etc., to solve the problem of gear picking The effect of failure, removal of stuck, and prevention of shift shock

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

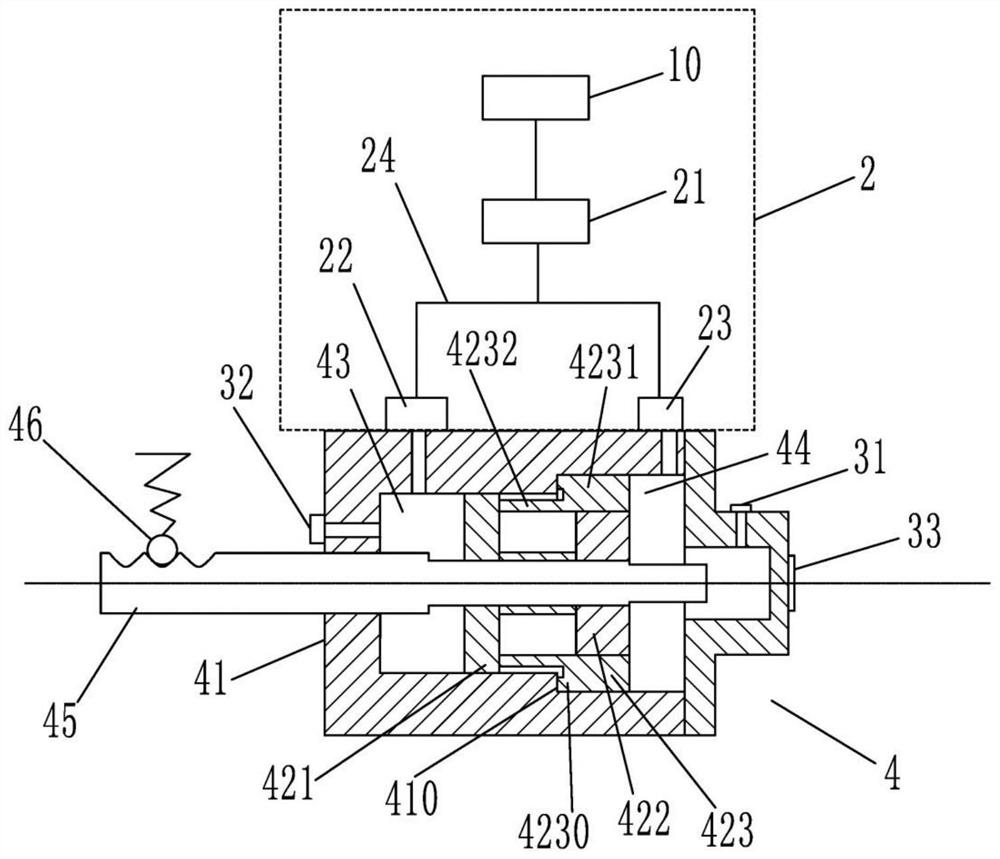

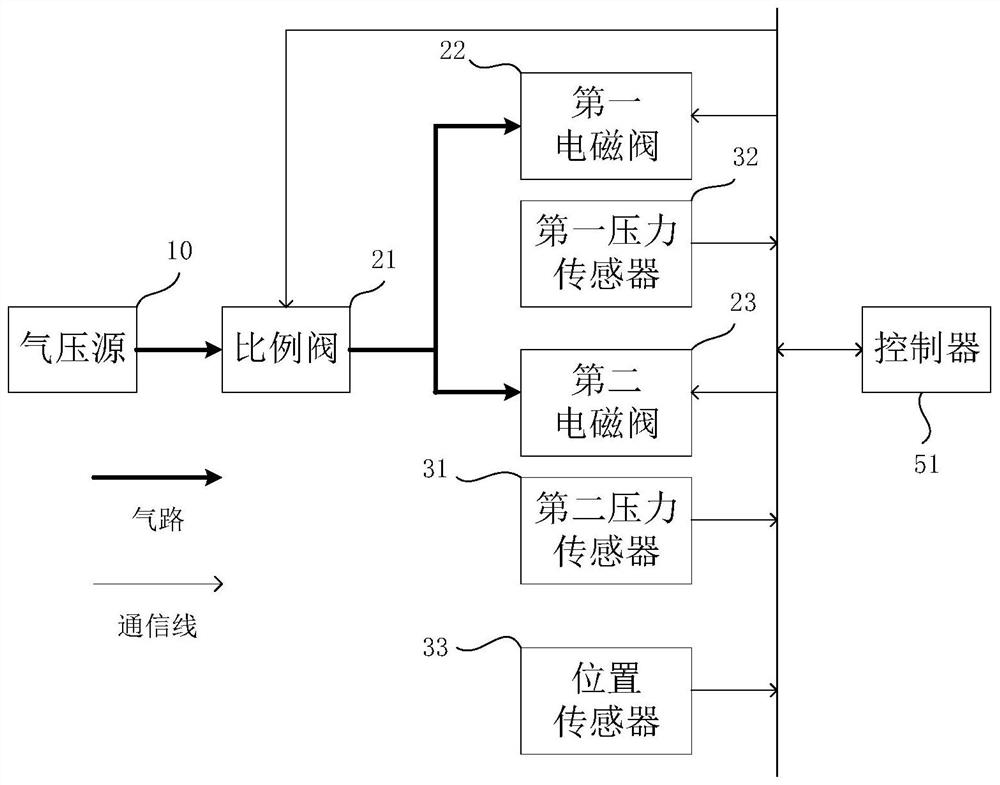

[0036] The piston-cylinder system and the piston-cylinder of the present invention are applied to an embodiment of an AMT shift system, and are used to drive a shift actuator of an AMT (automatic transmission) of a vehicle to complete the shift action. AMT includes a shift actuator and a piston-cylinder system. The shift controller of an automatic transmission can have the function of a cylinder controller, or use an independent cylinder controller, which is controlled and connected by the shift controller. The piston rod transmission of the piston cylinder is connected to the shift actuator, the shift controller or an independent cylinder controller (such as figure 2 Shown, namely piston-cylinder controller 51) sampling connects the sensor on the piston-cylinder in the piston-cylinder system and the piston-cylinder drive unit (as figure 2 As shown, the first pressure sensor 32, the second pressure sensor 31 and the position sensor 33) also control the fluid control elements...

Embodiment 2

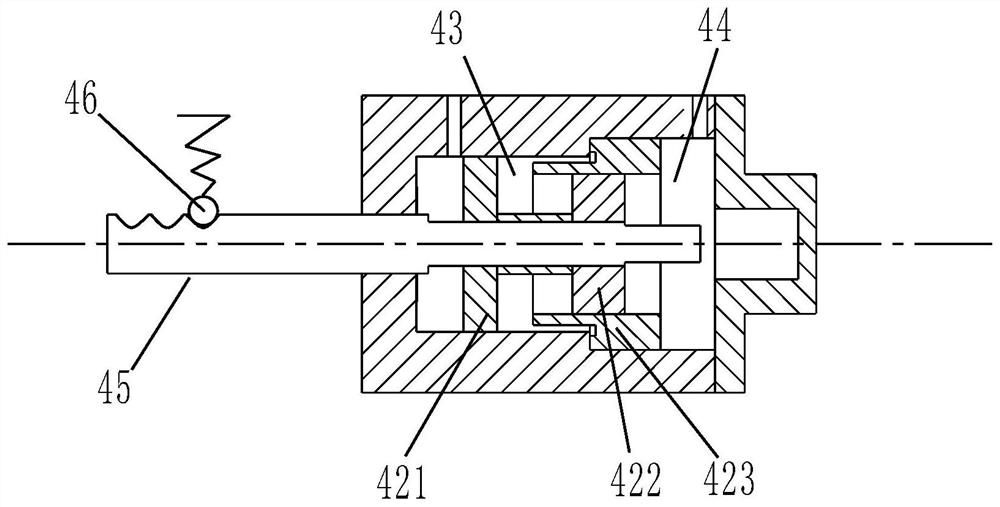

[0065] Another embodiment of the piston cylinder of the present invention differs from the piston cylinder in the above-mentioned embodiment 1 only in that, as Figure 6 As shown, its piston 42 is a single structure, the left end face of the piston 42 is the first force bearing surface, the right end face is the second force bearing surface, the cross section of the right part of the piston 42 is smaller than the cross section of the left part, in fact respectively The first piston and the second piston, the right part of the piston 42 is inserted into the third piston. Therefore, it should be pointed out that the "first piston and second piston" in the present invention can be two pistons on the piston rod, or two parts of one piston on the piston rod.

[0066] The embodiment of the piston-cylinder system and the embodiment of the control method of the piston-cylinder system of the present invention adopt the piston-cylinder and control method in the above-mentioned shift sys...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com