Patents

Literature

36results about How to "Avoid shift shock" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

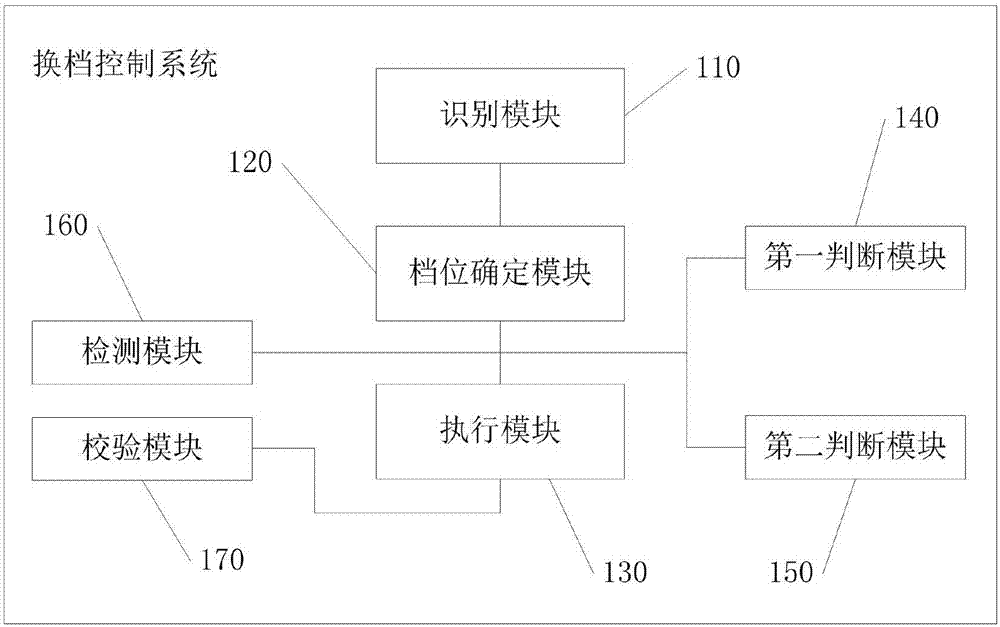

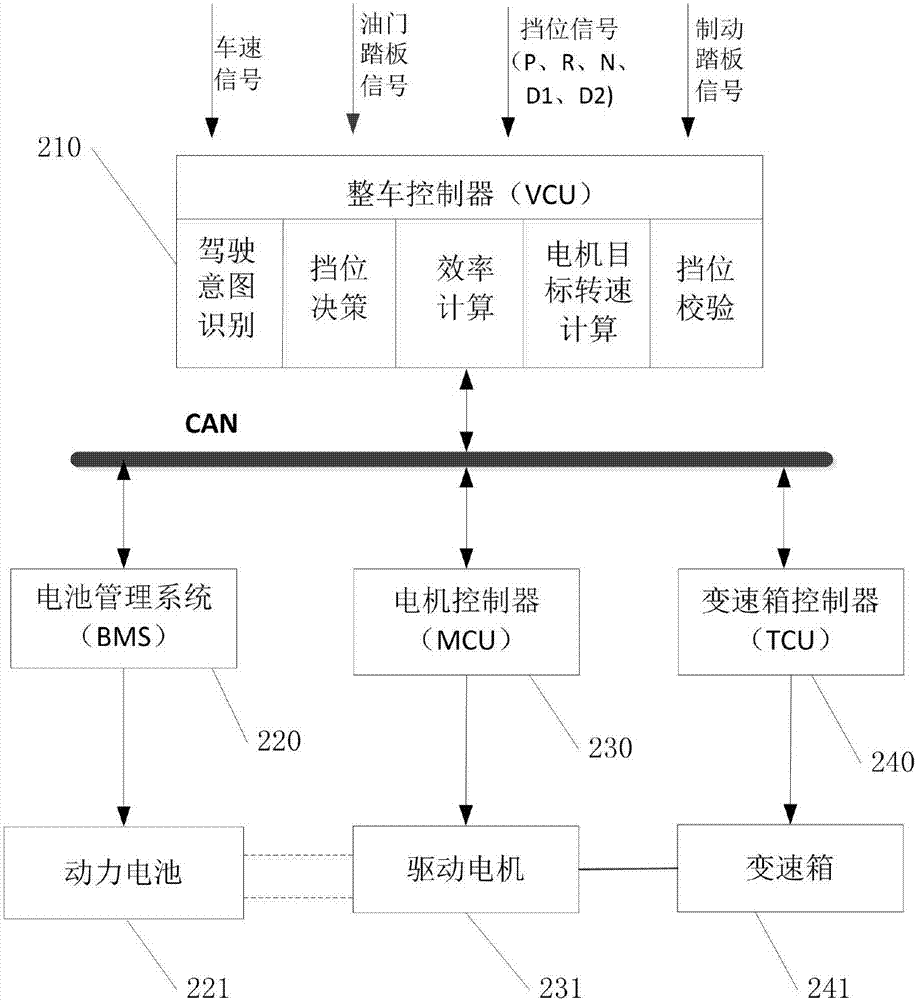

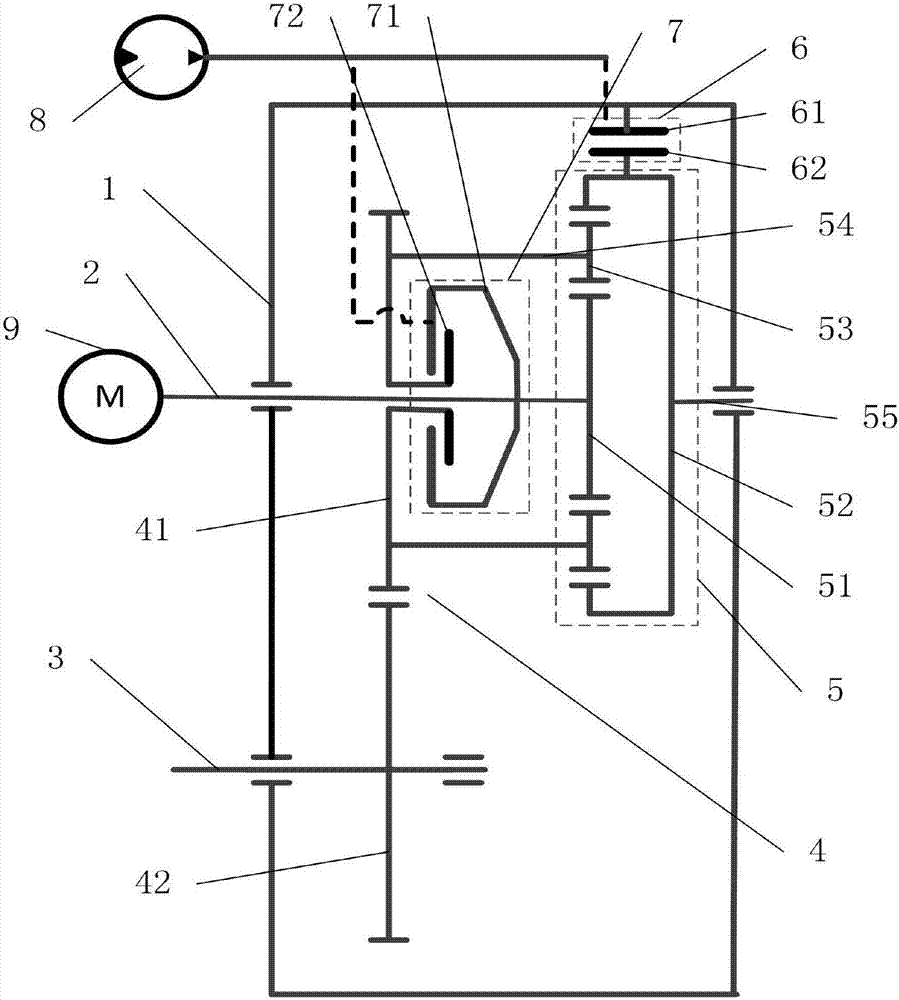

Gear shifting control method and system of two-gear automatic gearbox

InactiveCN107255159ASatisfy the driving feelingMeet energy consumption requirementsGearing controlDriver/operatorControl system

The invention belongs to the field of automobile transmission systems and particularly provides a gear shifting control method and system of a two-gear automatic gearbox. The method and system are used for solving the problem that gear shifting impact exists during gear shifting of a two-gear automatic gearbox in the prior art. For solving the problem, the gear shifting control method provided by the invention comprises the following steps that the driving intention of a driver is identified; a target gear is determined according to the driving intention; and a first clutch and a second clutch are closed or disengaged according to a set mode, and accordingly the current gear of an automobile is shifted to the target gear. Through the gear shifting control method provided by the invention, the sliding friction degree between the first clutch and the second clutch can be controlled in a coordinated mode, that is, when one clutch is closed, the other clutch is slowly disengaged; and the gear shifting process of the two-gear gearbox can be smooth and free of gear shifting impact.

Owner:NIO CO LTD

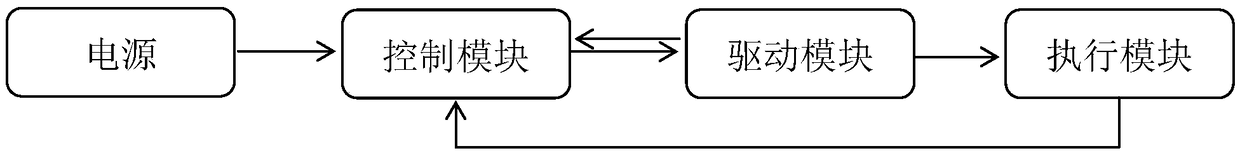

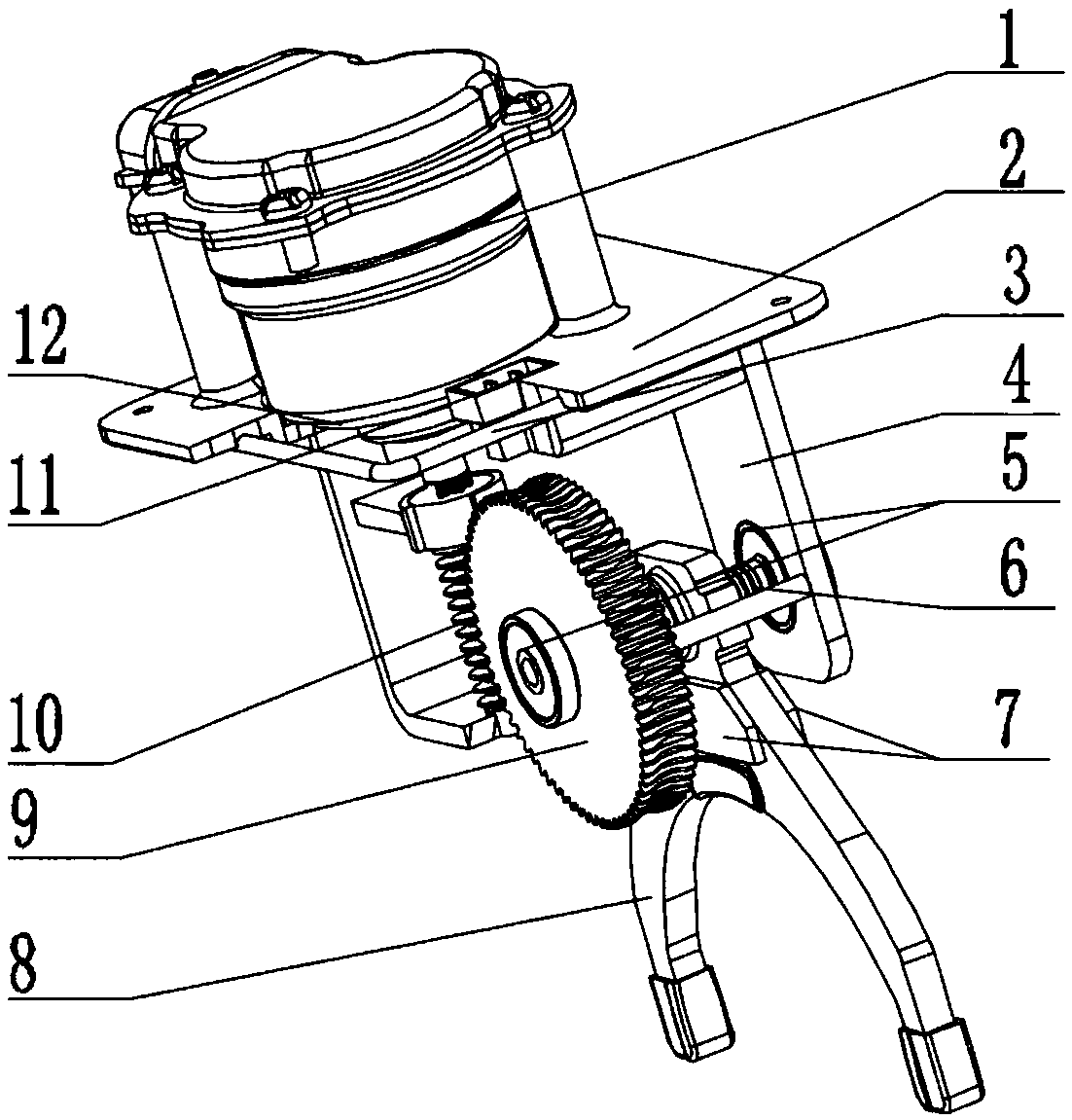

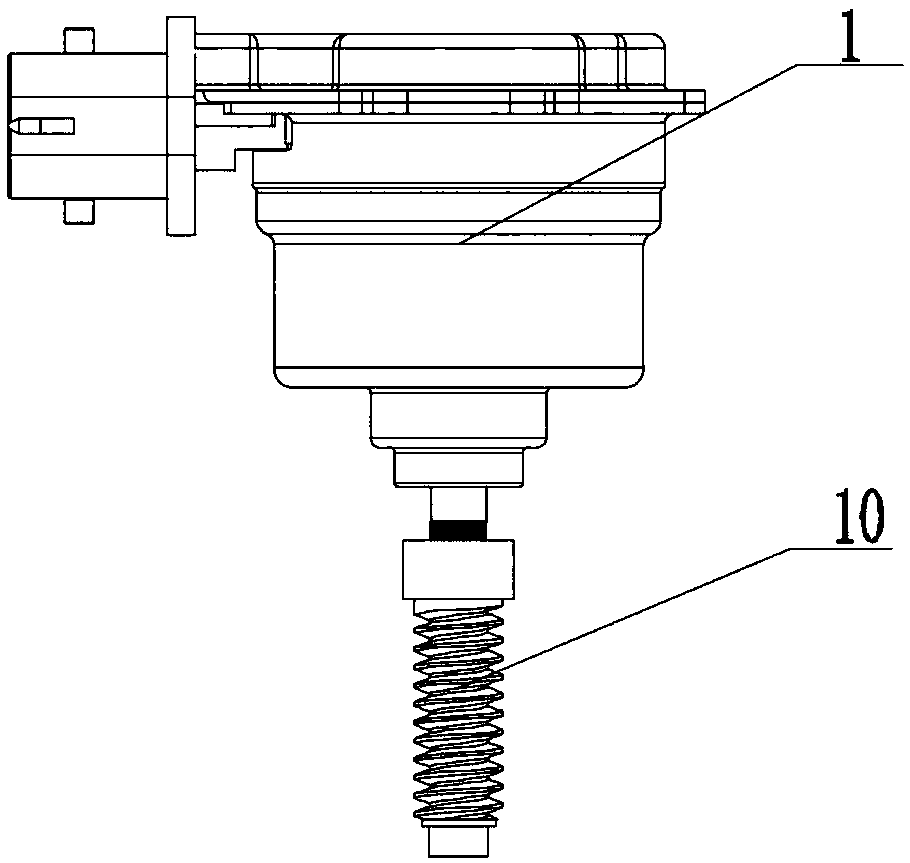

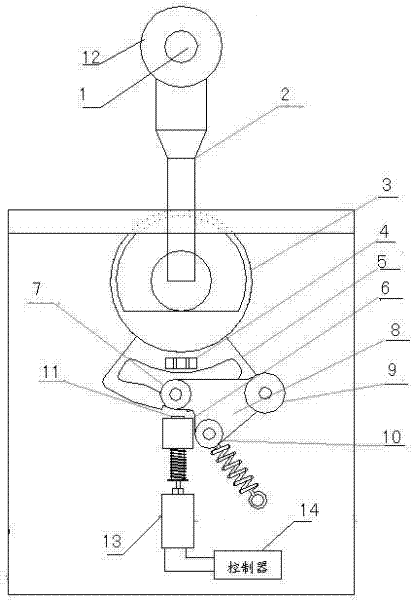

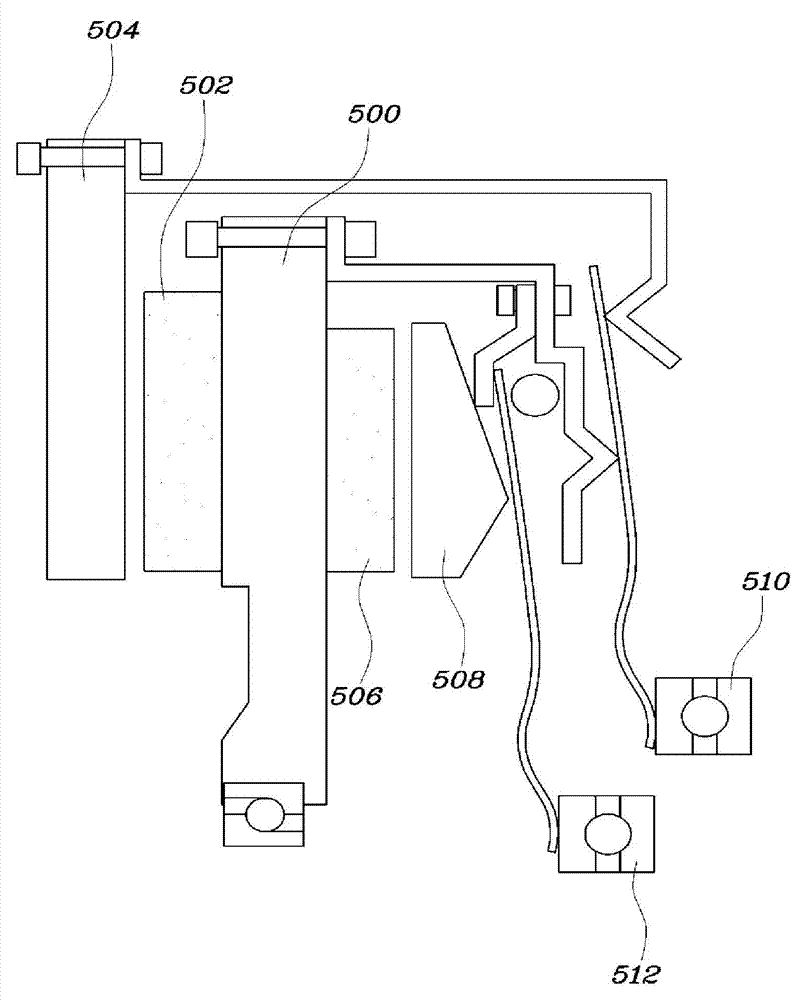

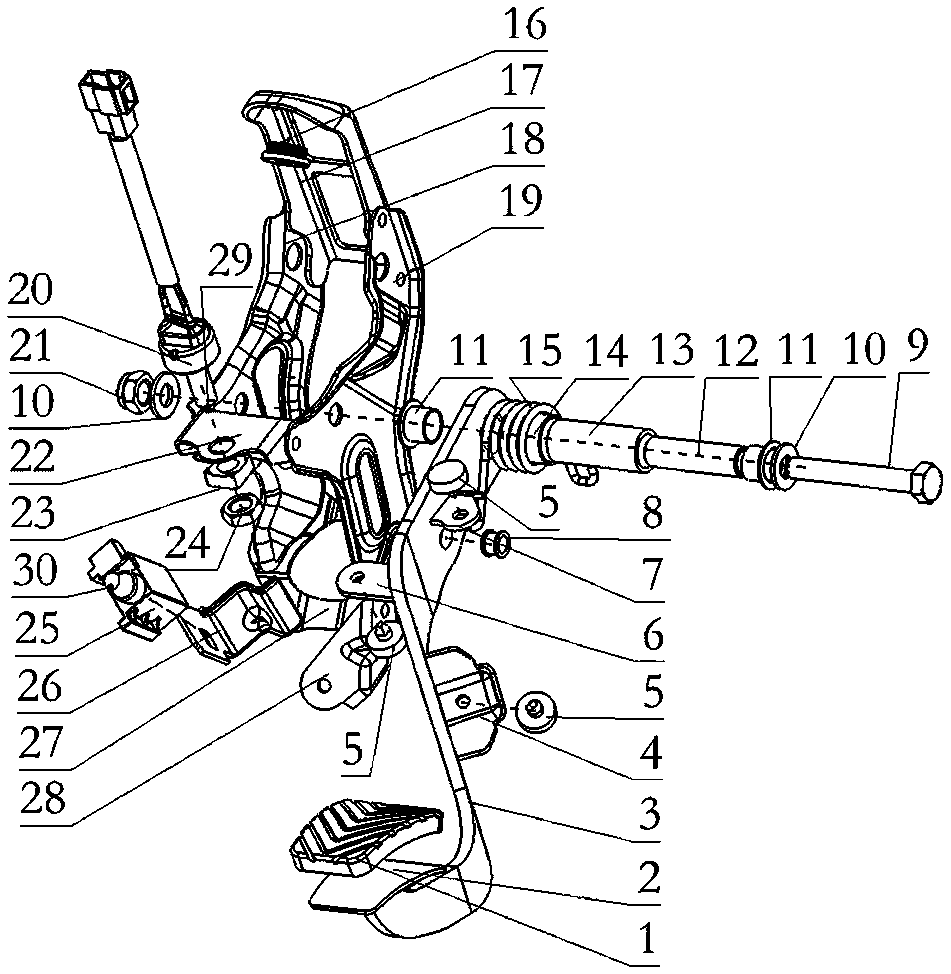

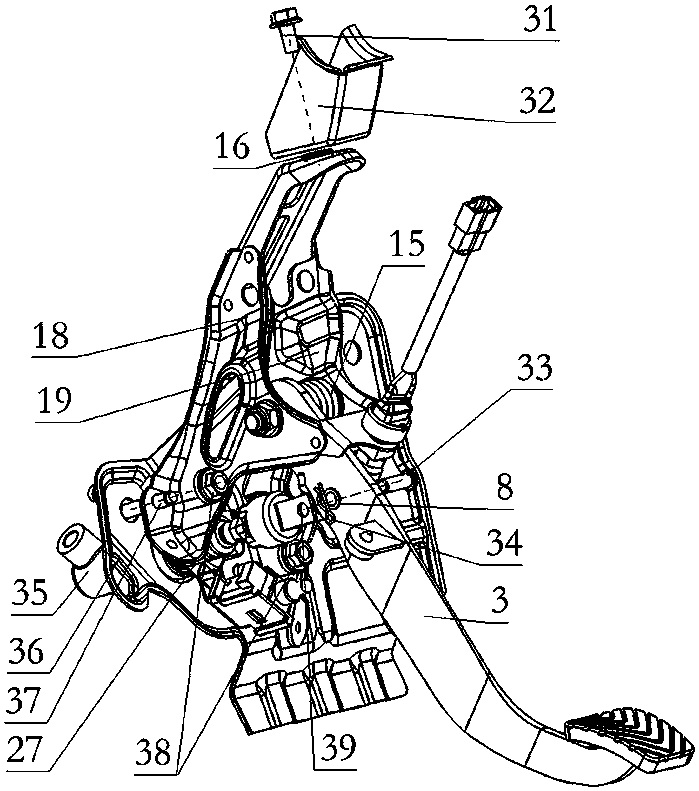

Transmission electric gear selecting and shifting system and car

InactiveCN109163088AAvoid shift shockReduce shift noiseControlled membersGearing controlVariatorEngineering

The invention discloses a transmission electric gear selecting and shifting system and a car. The transmission electric gear selecting and shifting system comprises a control module, a drive module and an execution module. The control module is connected with the drive module and the execution module for monitoring the gear shifting force and a gear shifting stroke actually output by the executionmodule and transmitting an instruction for adjusting the gear shifting force to the drive module in real time. The drive module is used for receiving the instruction of the control module, and driving the execution module to perform gear selecting and shifting operations. The execution module includes a gear shifting poking fork, and the gear shifting poking fork moves left and right to push a synchronizer to complete the gear engaging and gear removing actions. The transmission electric gear selecting and shifting system can realize the precise adjustment of the gear shifting force and the gear shifting stroke in real time, ensures that the synchronizer always works in the optimal state, avoids the gear shifting shock problem caused by the excessive gear shifting force, effectively reduces the gear shifting noise, prolongs the life of the synchronizer, and avoids the problem that the gear engaging cannot be performed in time due to too small gear shifting force at the same time.

Owner:NINGBO SHANGZHONGXIA AUTOMATIC TRANSMISSION +1

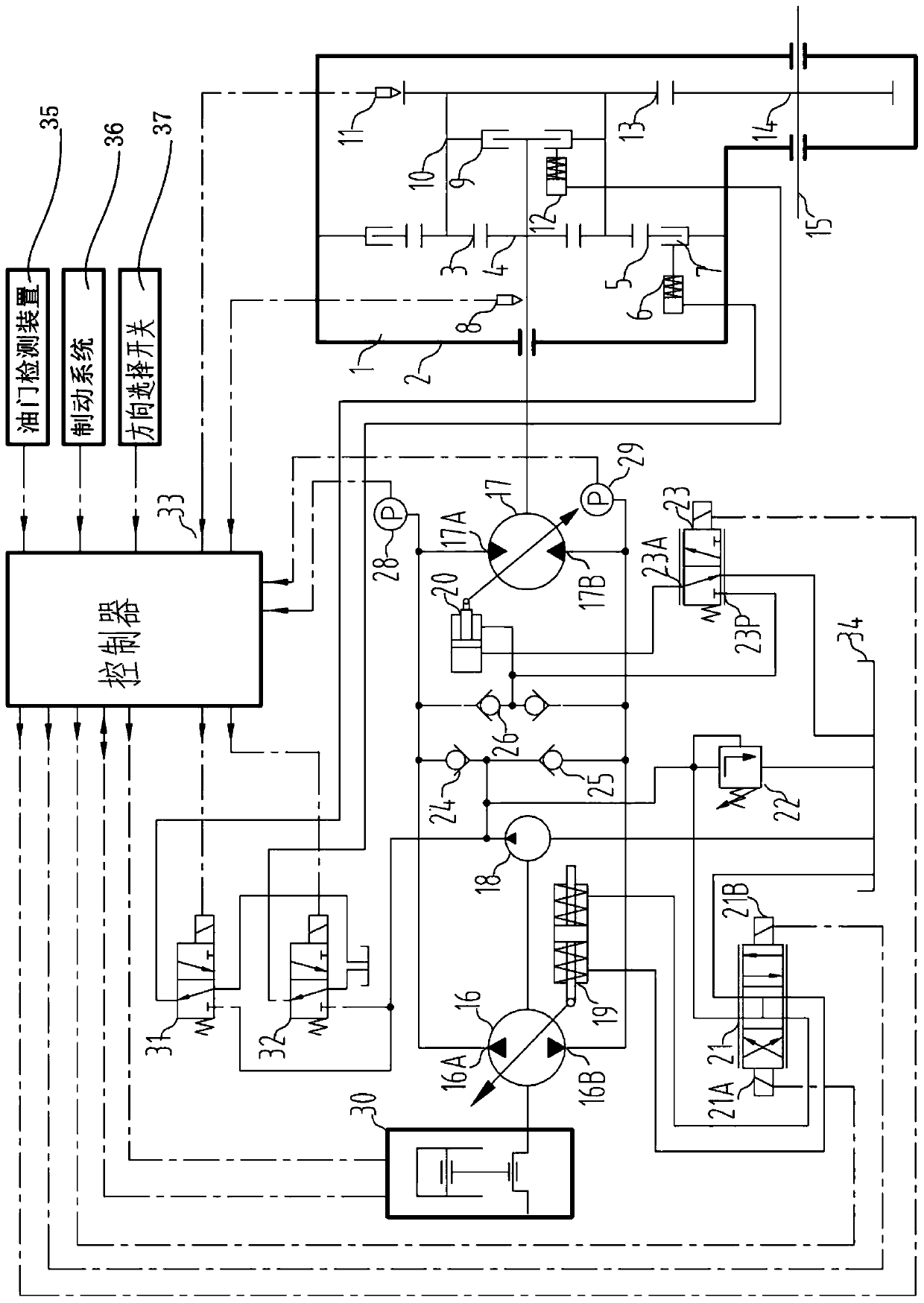

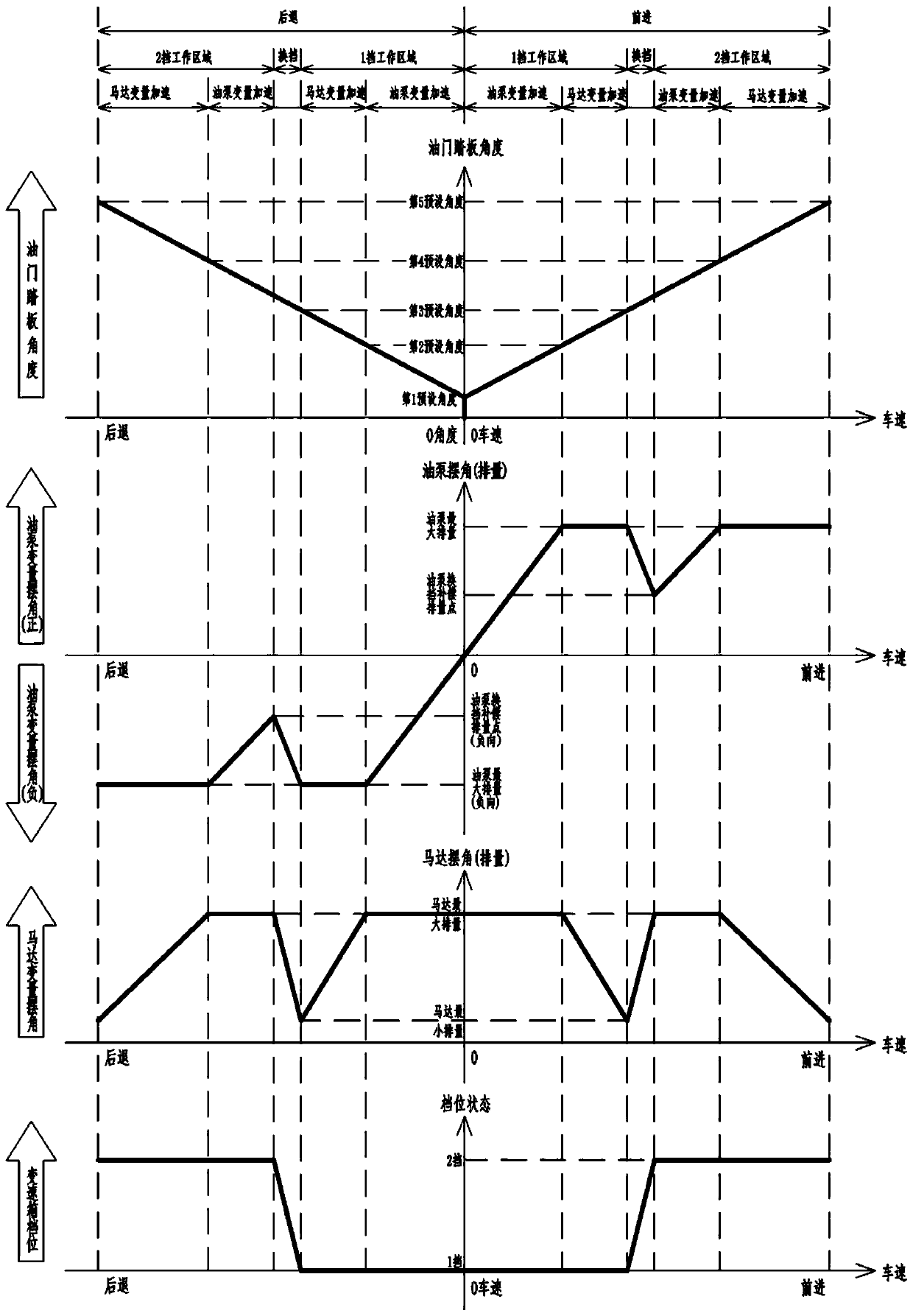

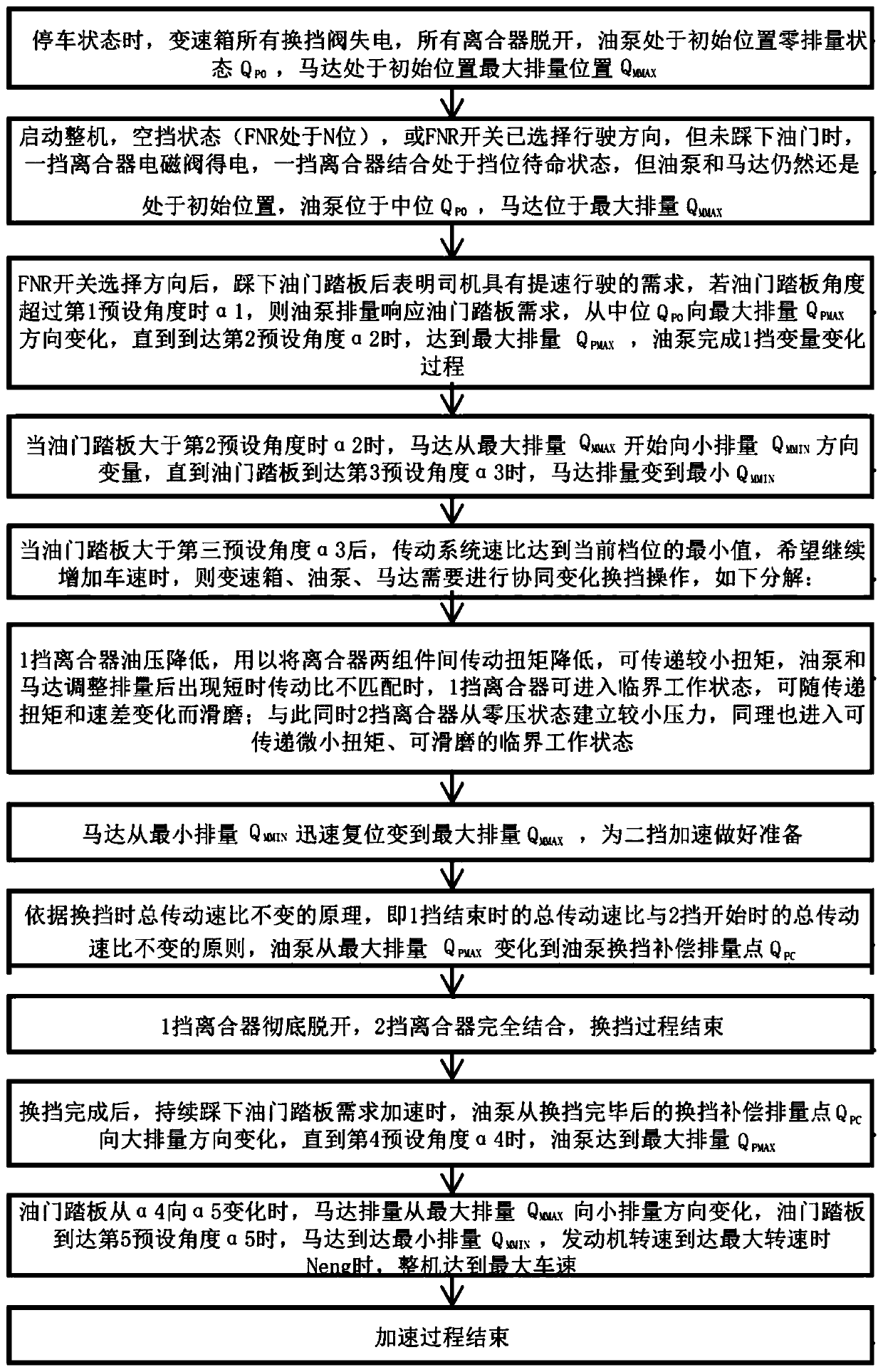

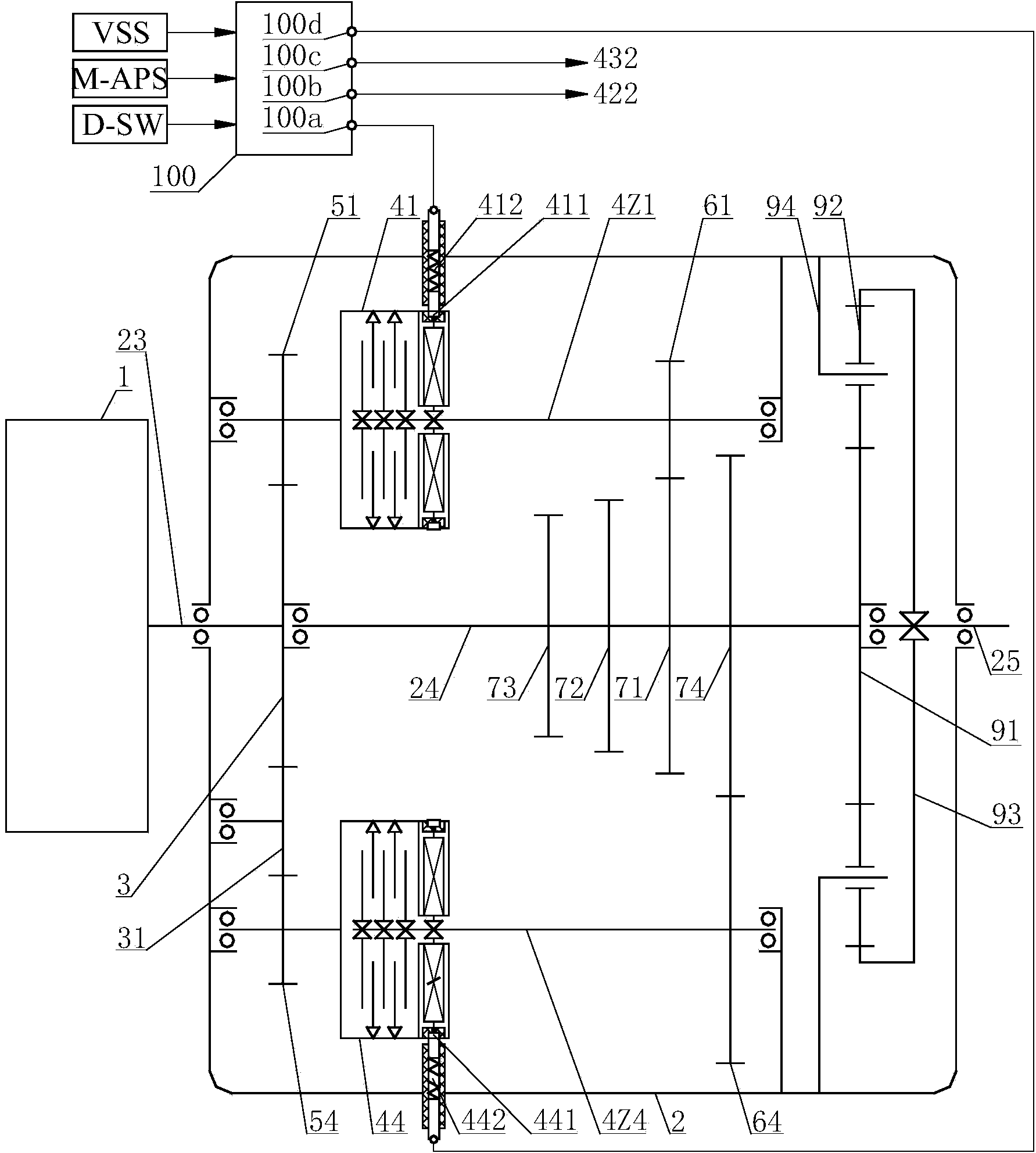

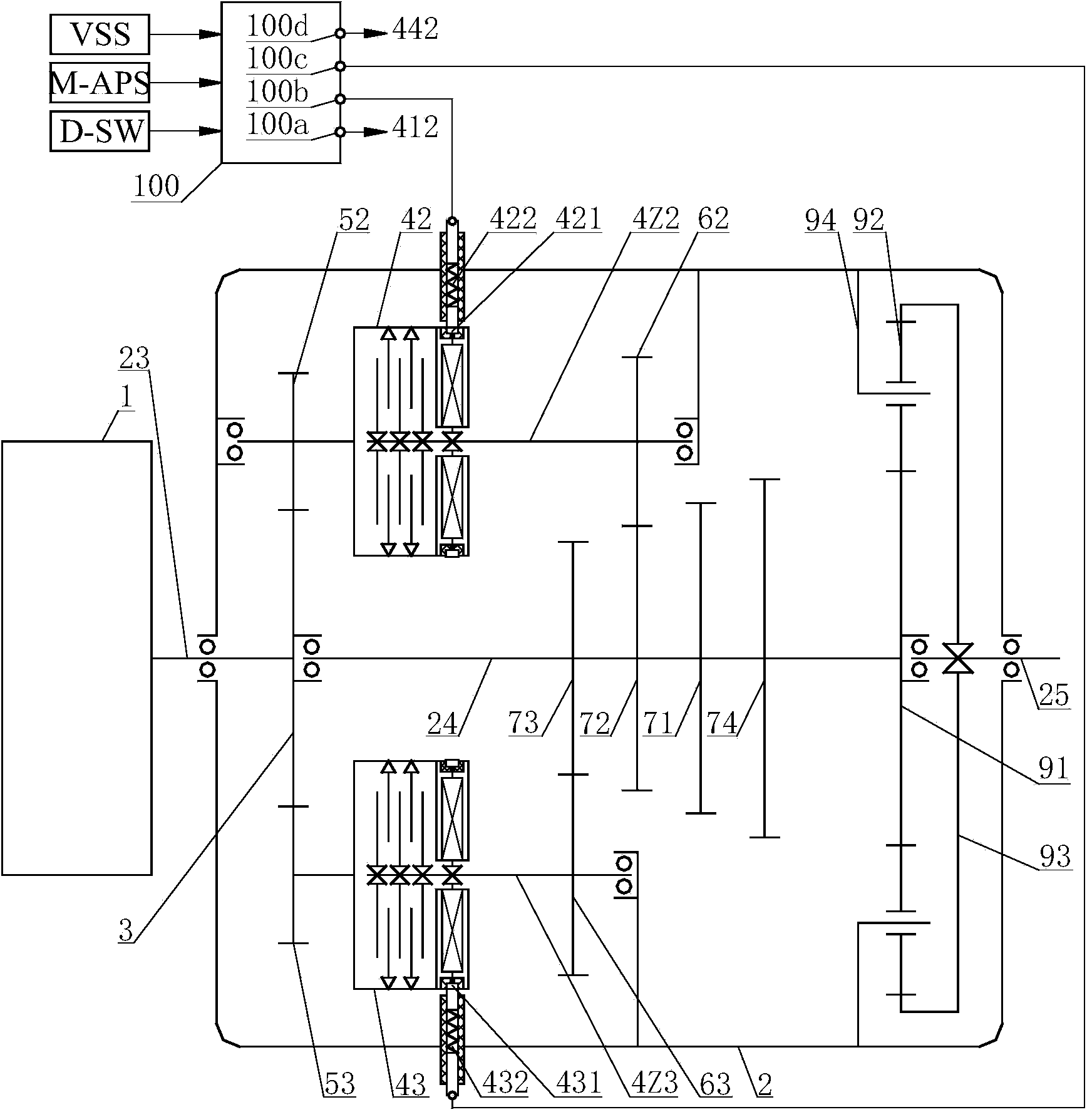

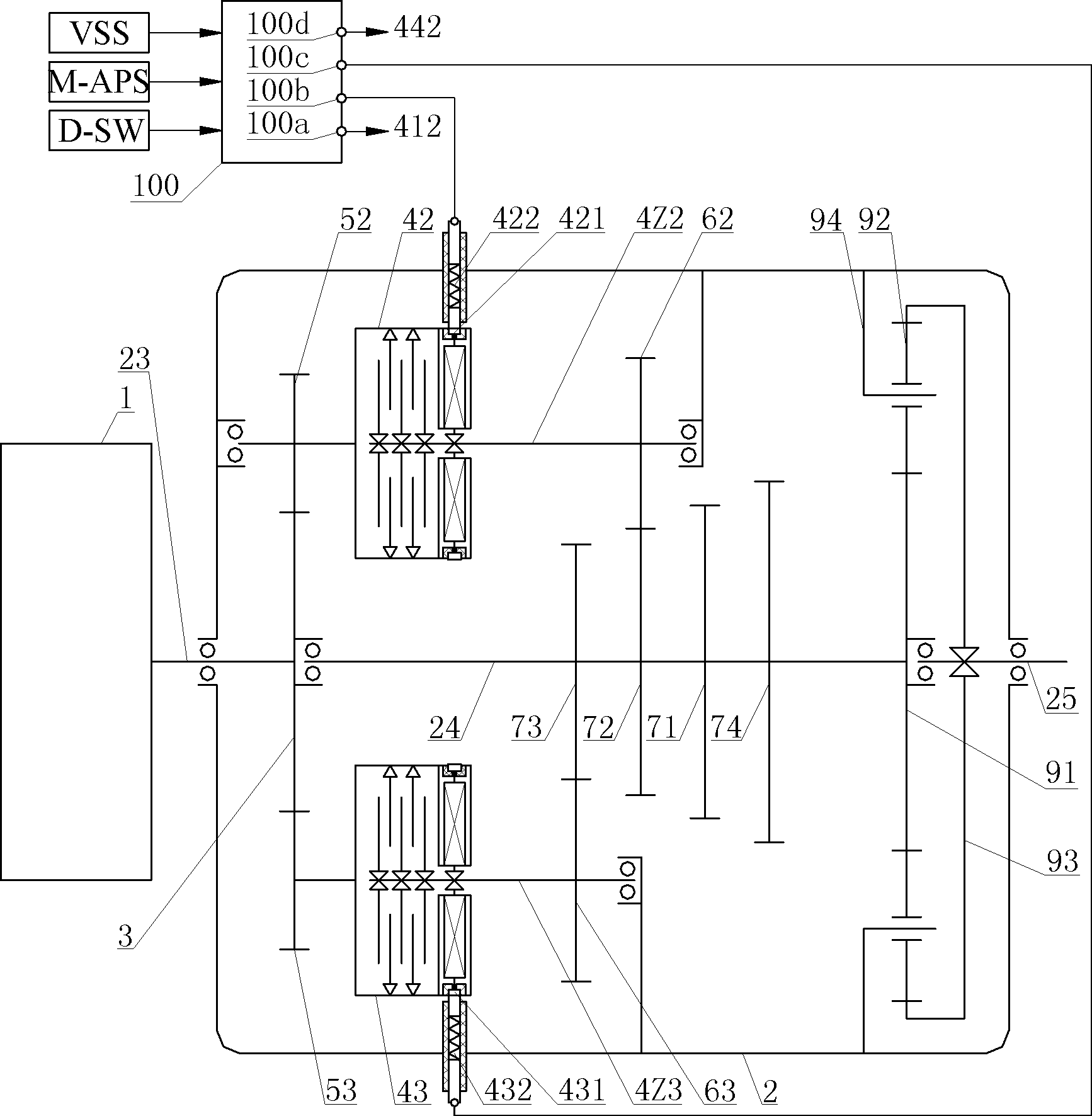

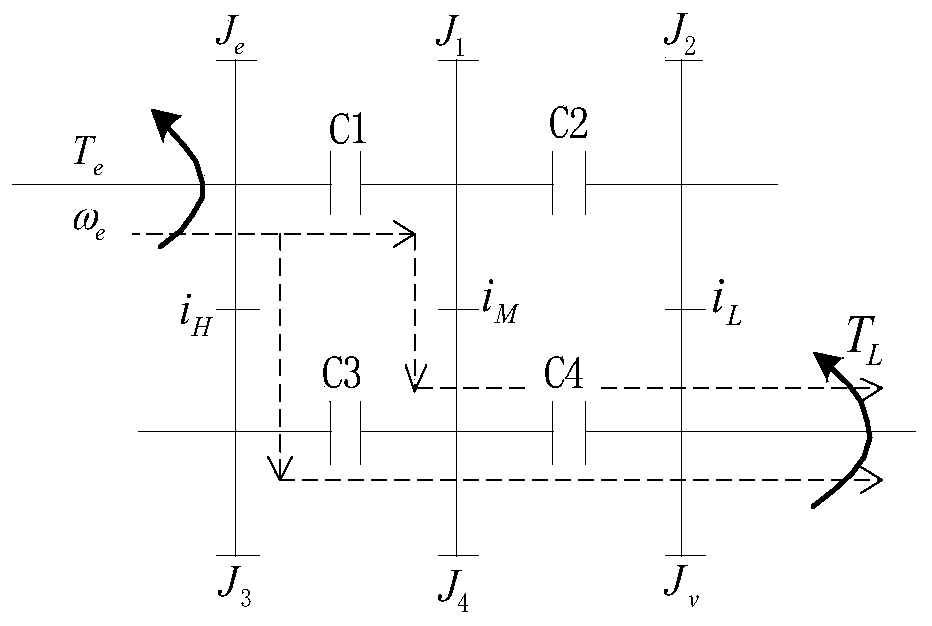

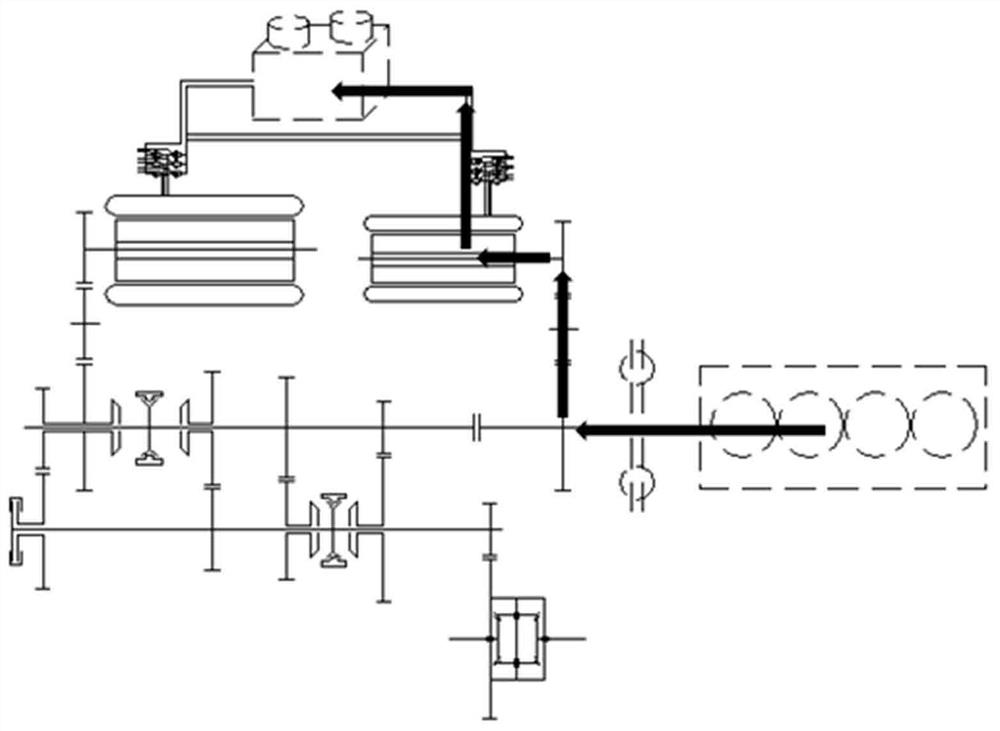

Hydrostatic drive transmission system, variable speed control method and loader

The invention relates to a hydrostatic drive transmission system, aims to solve the problem that an existing hydrostatic drive system needs to stop during shifting gears, and provides the hydrostaticdrive transmission system, a variable speed control method and a loader. In the hydrostatic drive transmission system, a variable pump is in closed-loop connection with a variable motor, the variablemotor is connected with a gearbox, and a controller outputs control signals used for controlling a pump displacement control solenoid valve, a motor displacement control solenoid valve, a first gear solenoid valve and a second gear solenoid valve correspondingly according to the throttle degree, the gearbox output rotating speed and a direction selection switch signal. The hydrostatic drive transmission system is of single-motor hydrostatic drive, and does not need to stop for shifting gears, during gear shifting, the system has pump displacement compensation control, and gear shifting impactcan be avoided.

Owner:GUANGXI LIUGONG MASCH CO LTD

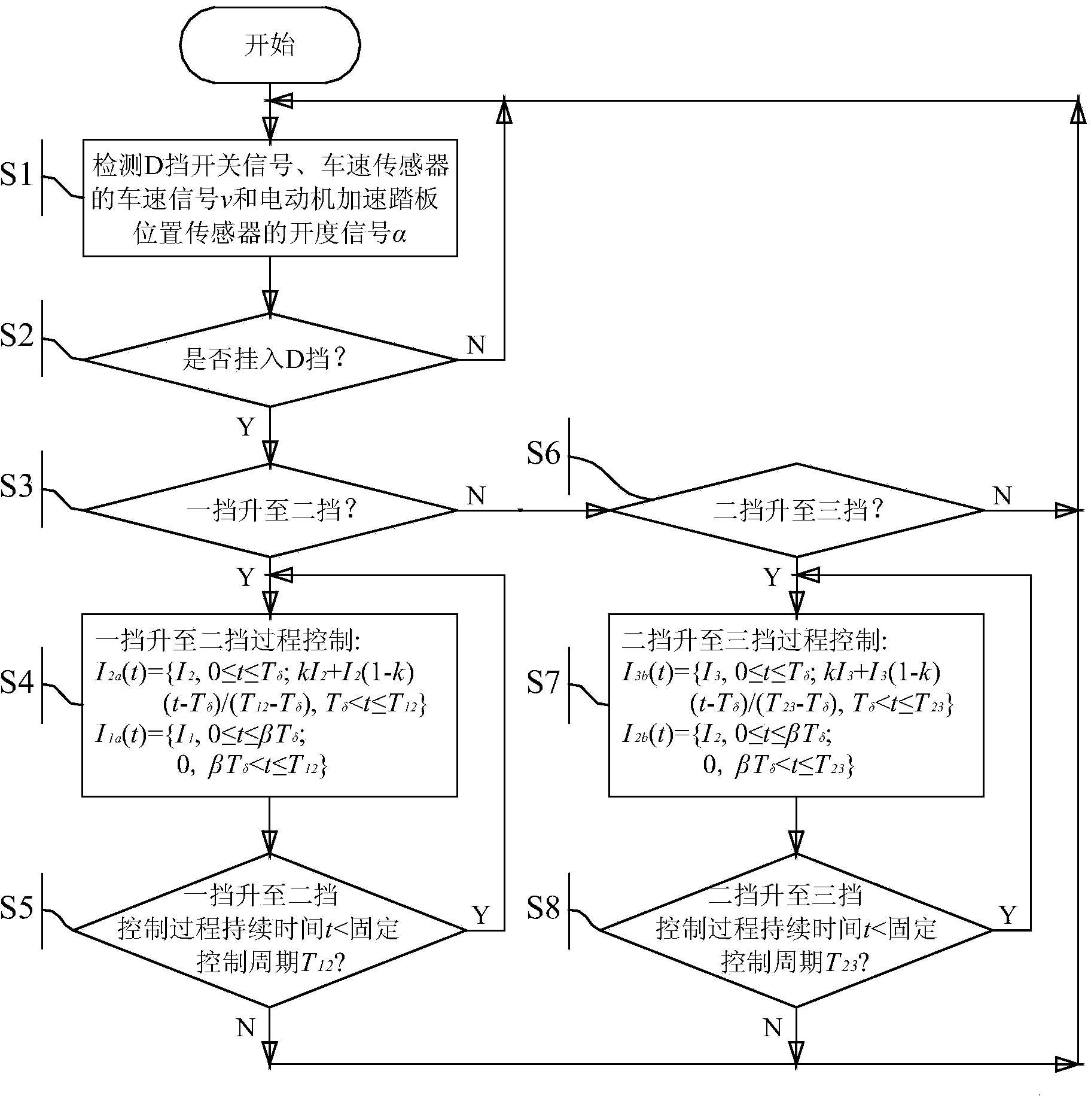

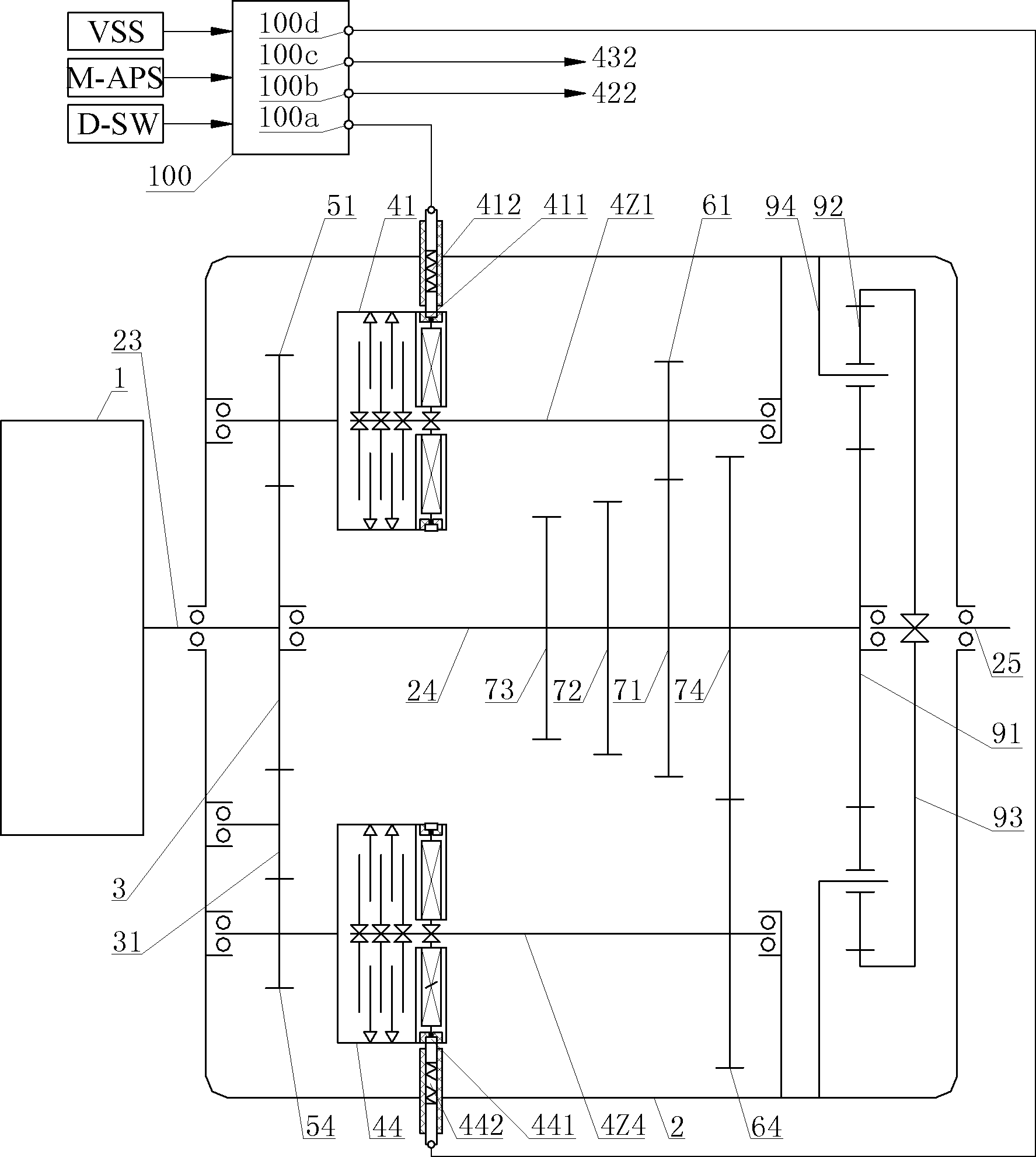

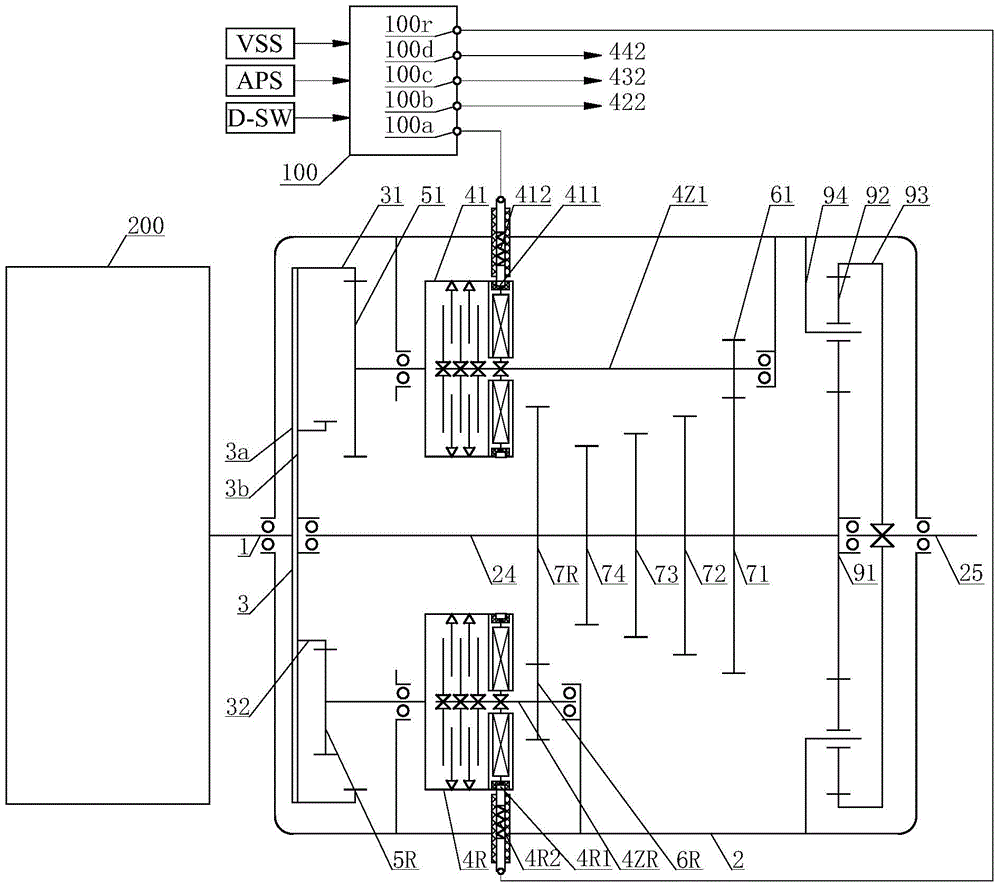

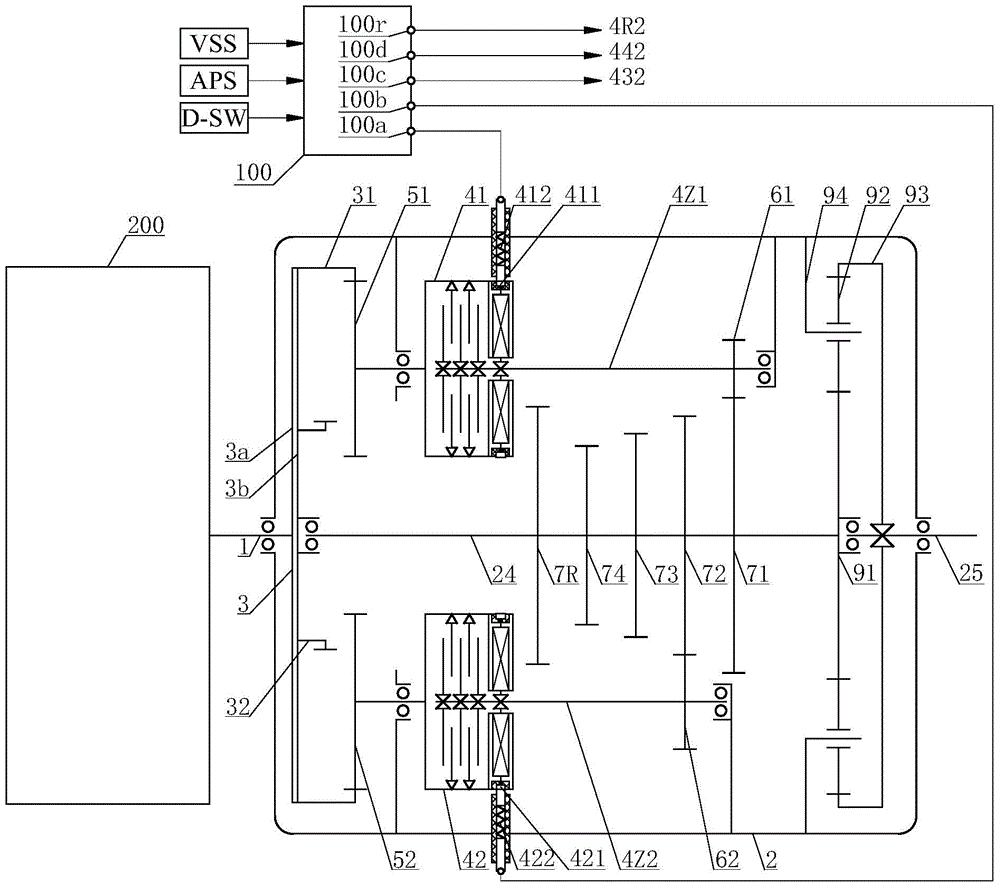

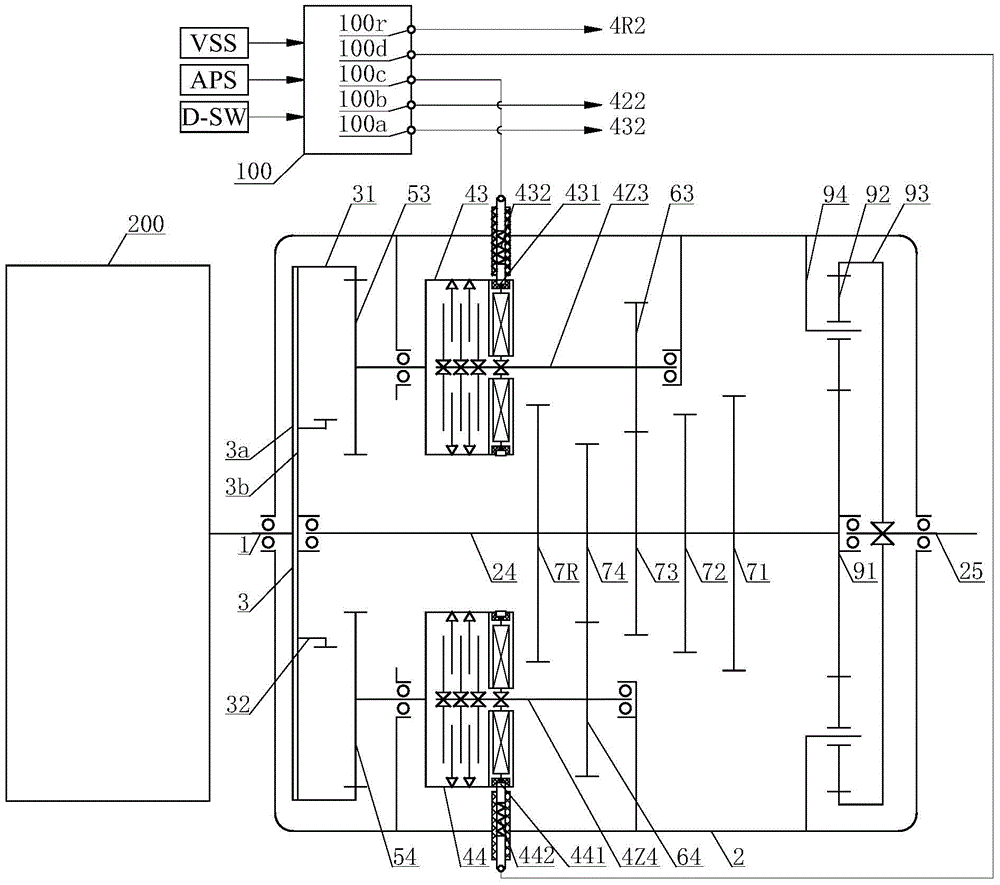

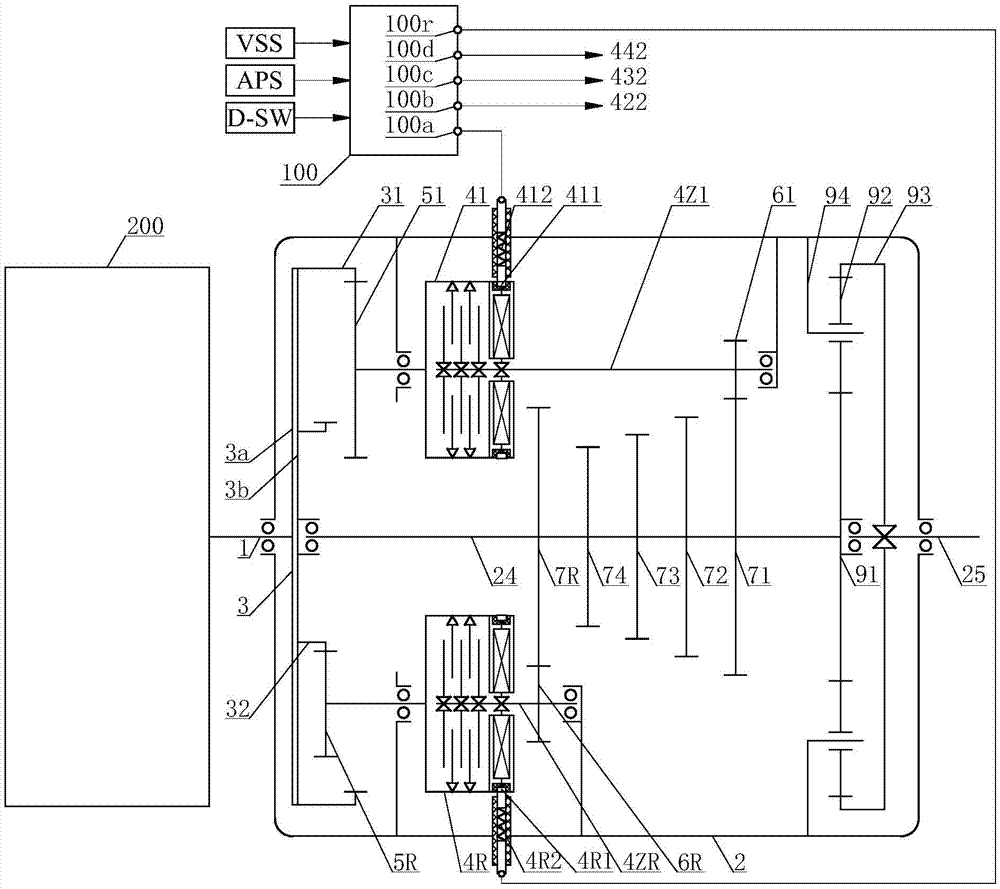

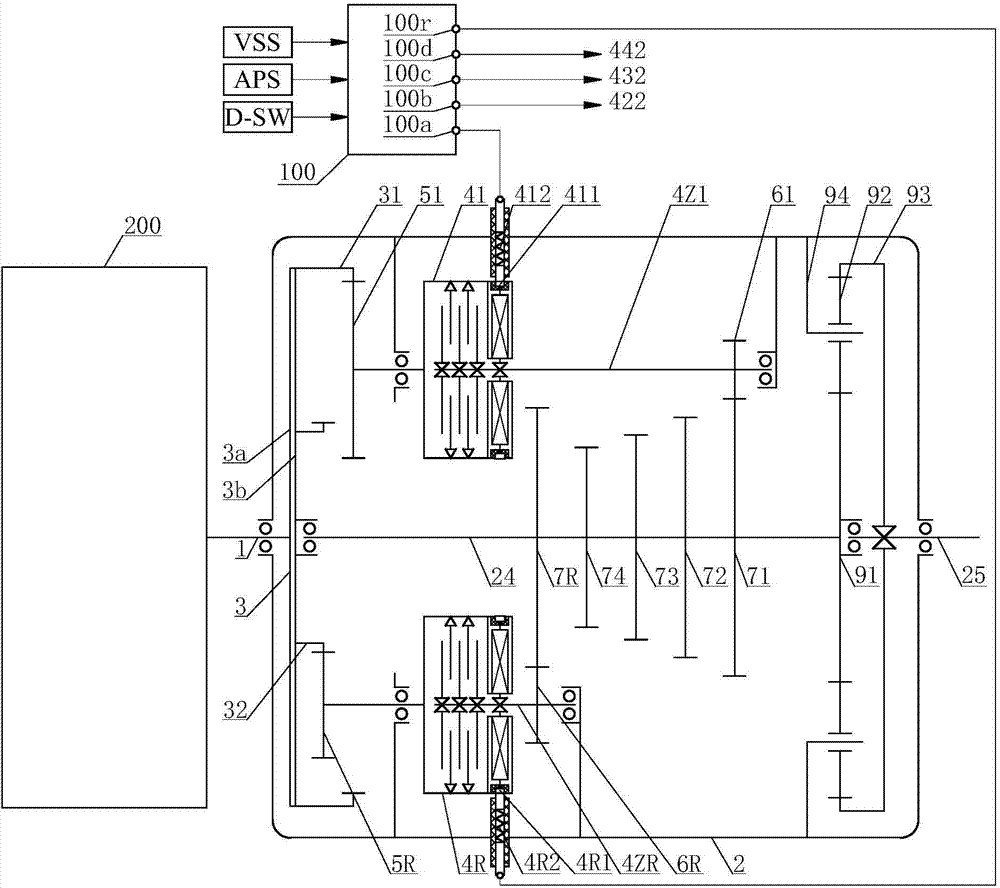

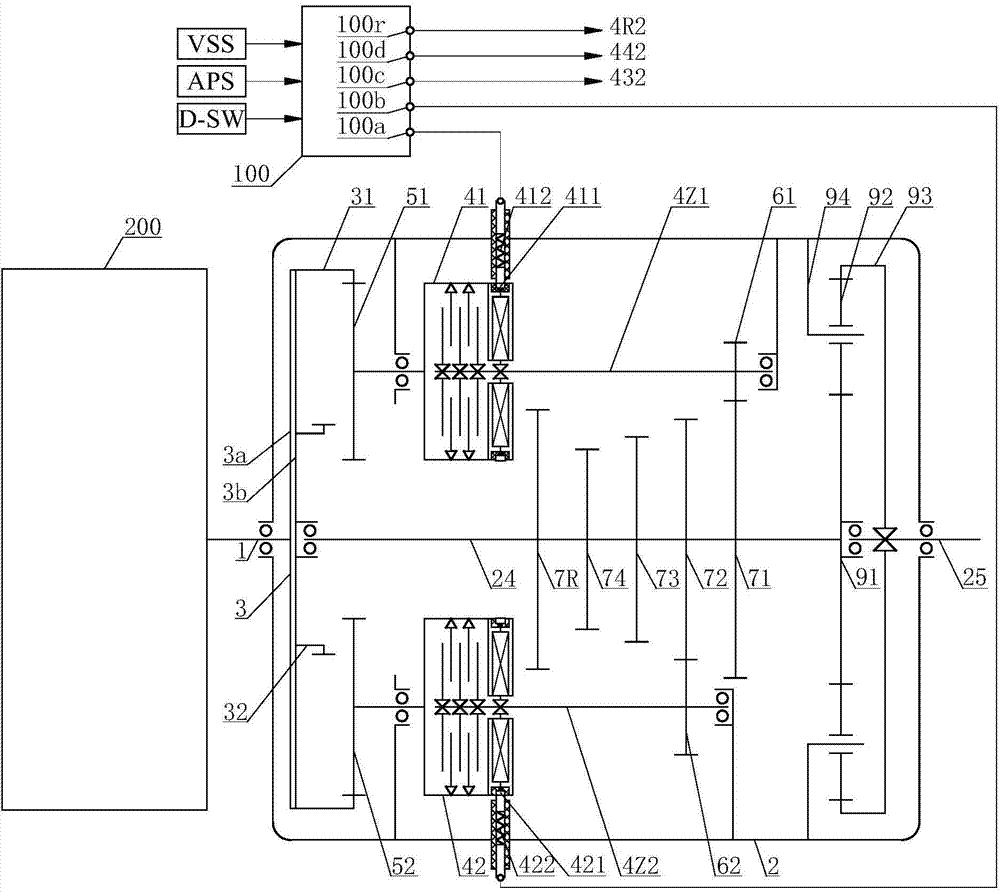

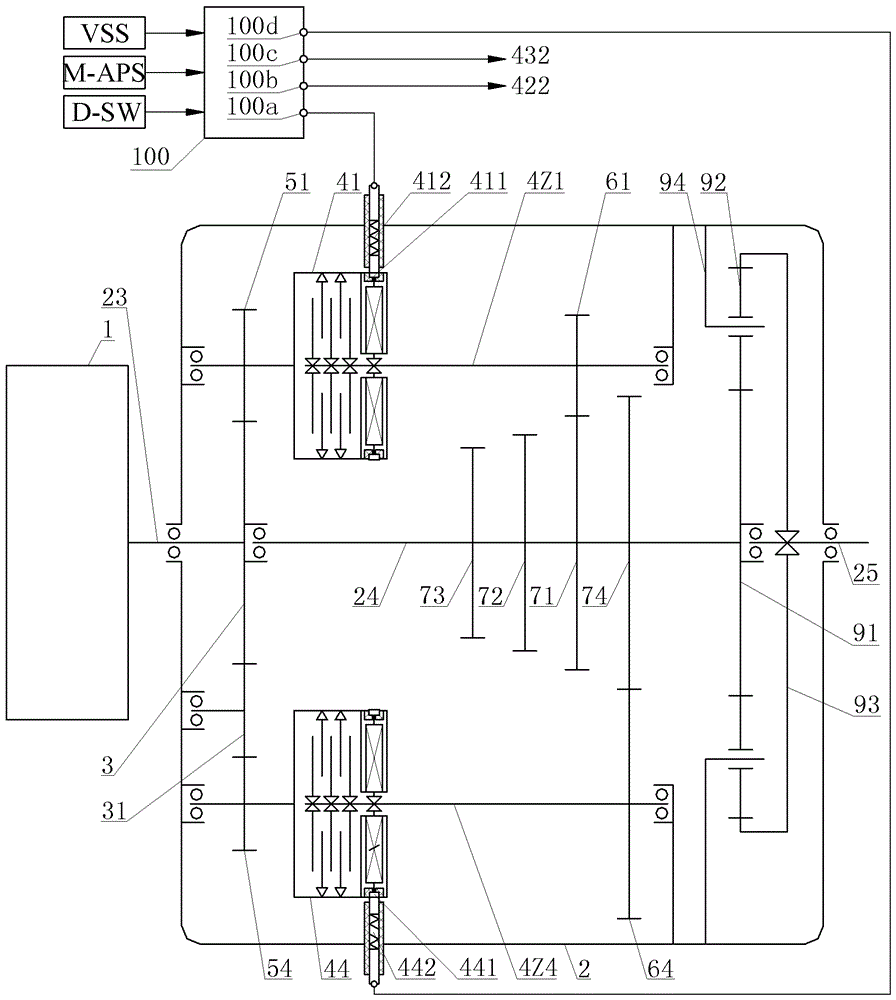

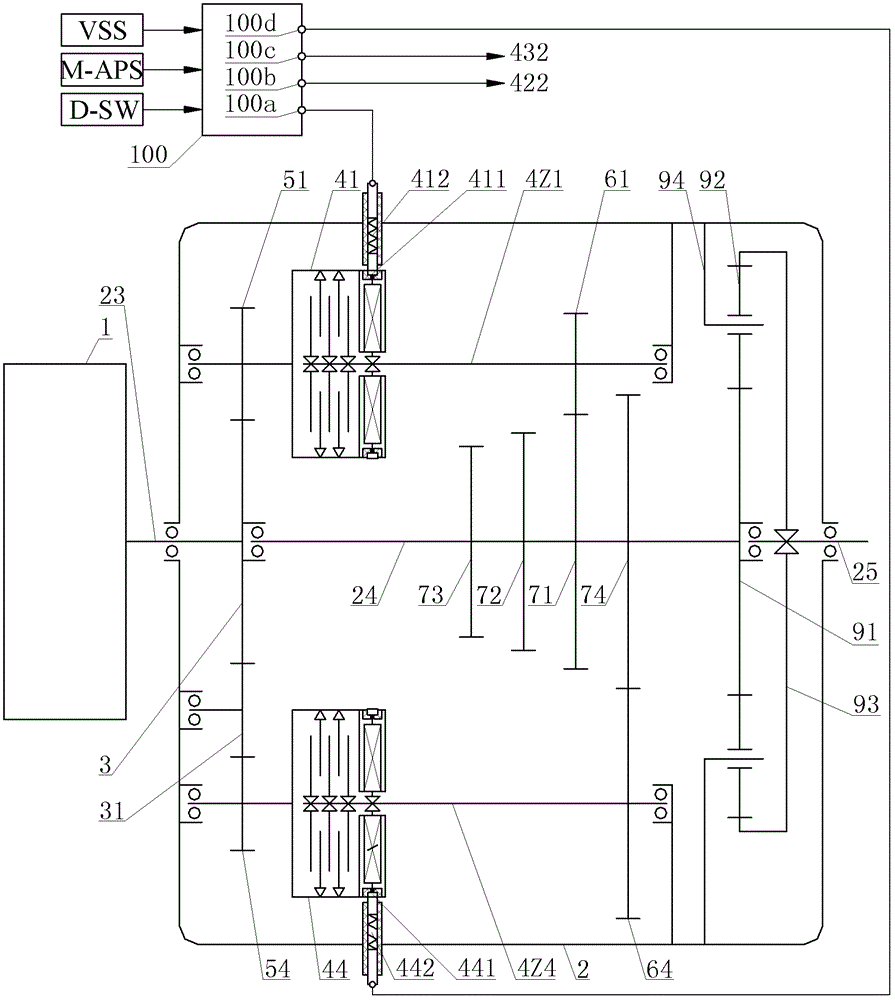

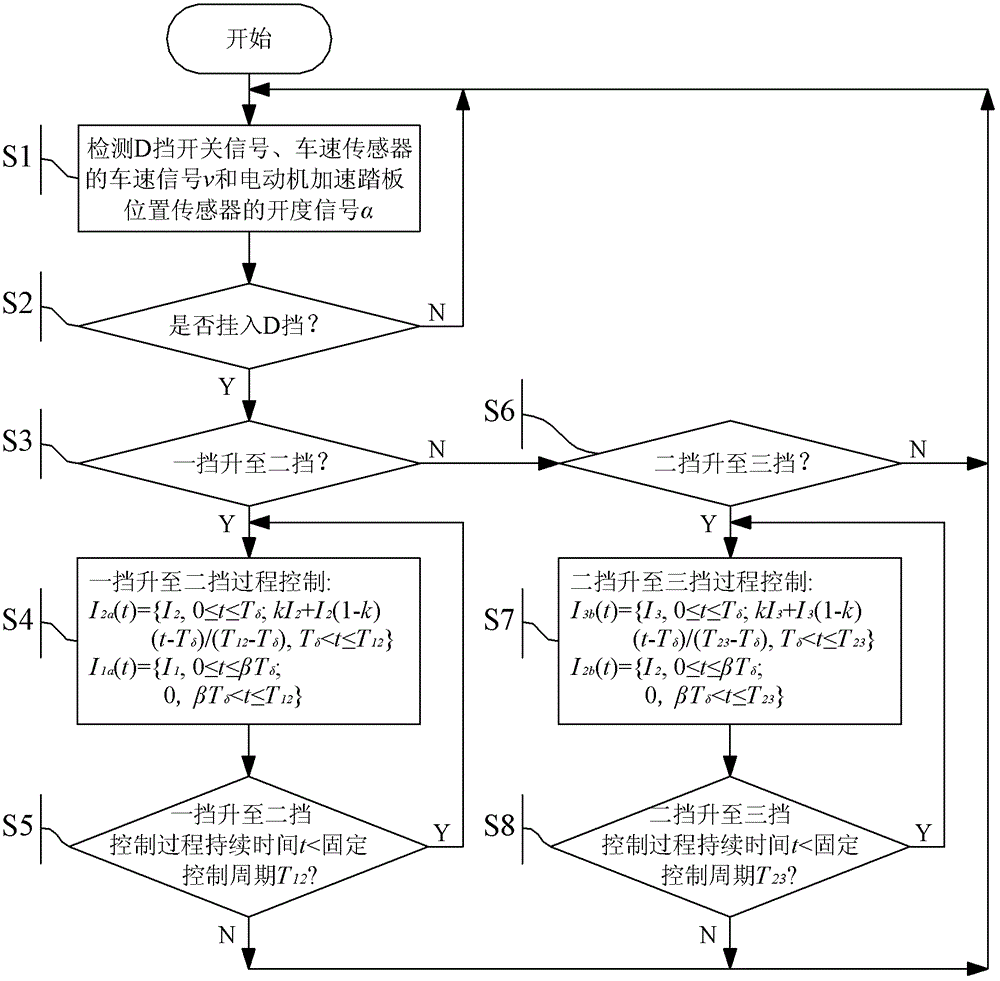

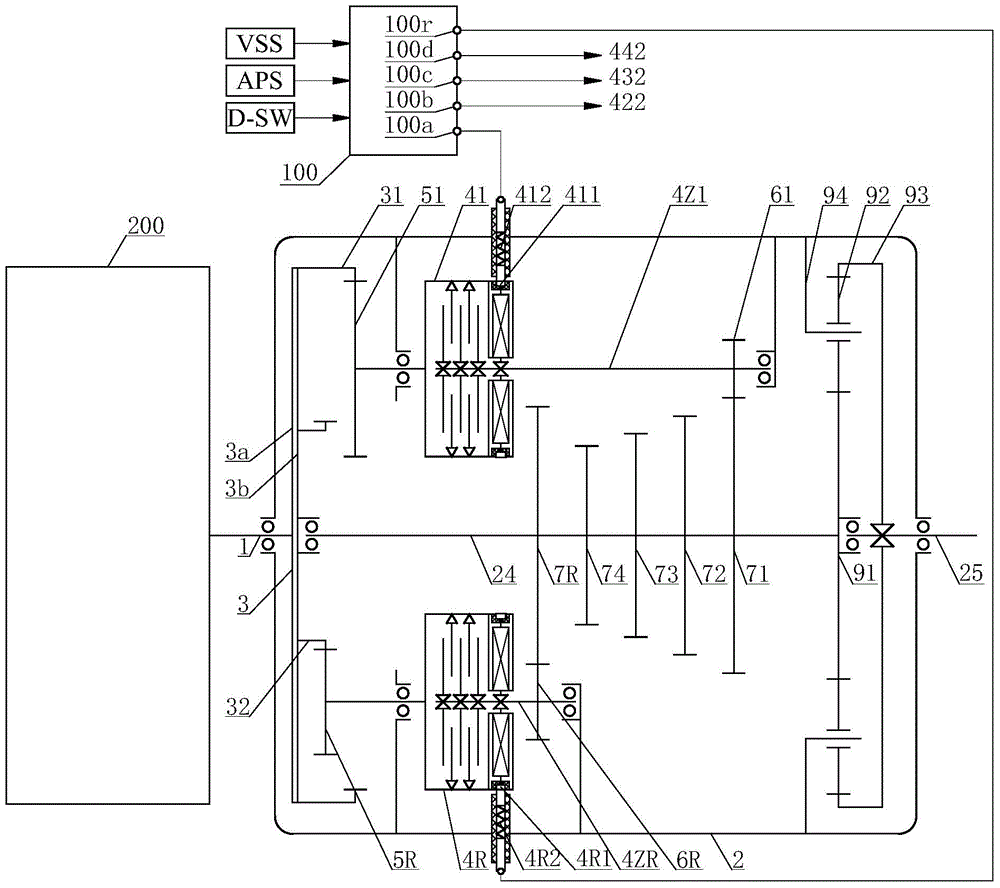

Upshift process control method of three-gear wire control automatic transmission of electric vehicle

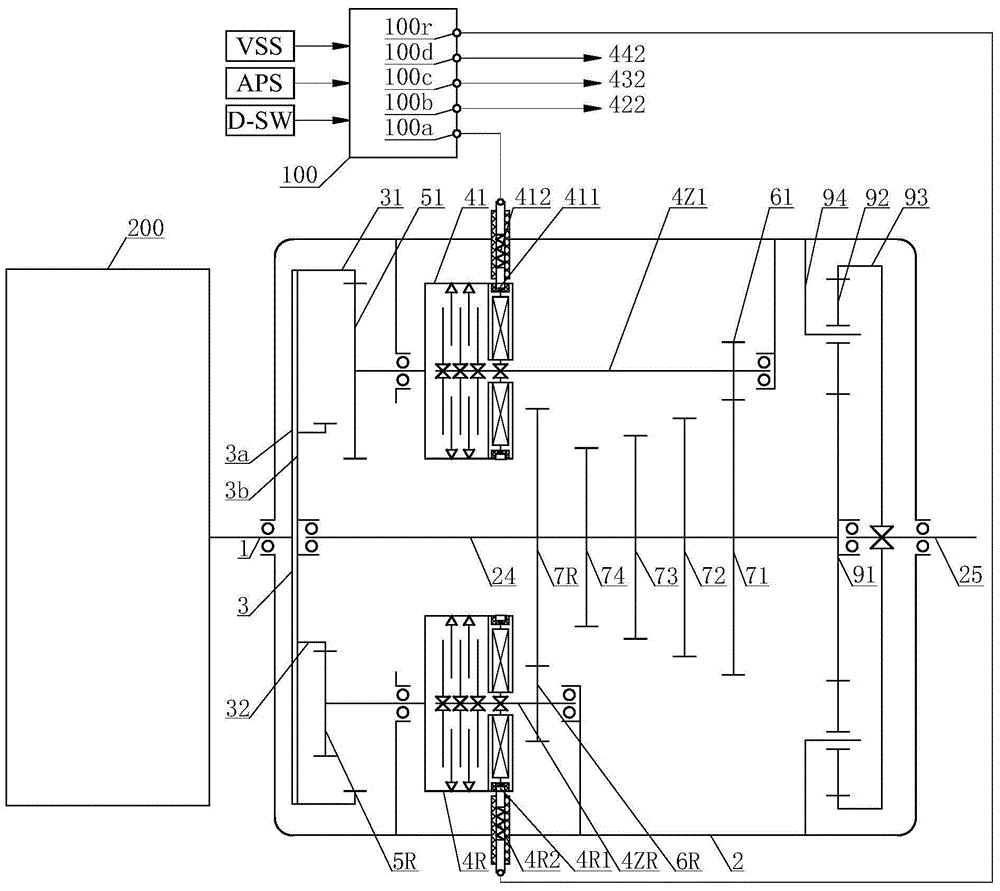

InactiveCN104389997AEliminate separation gapsLarge currentGearing controlEngineeringElectric vehicle

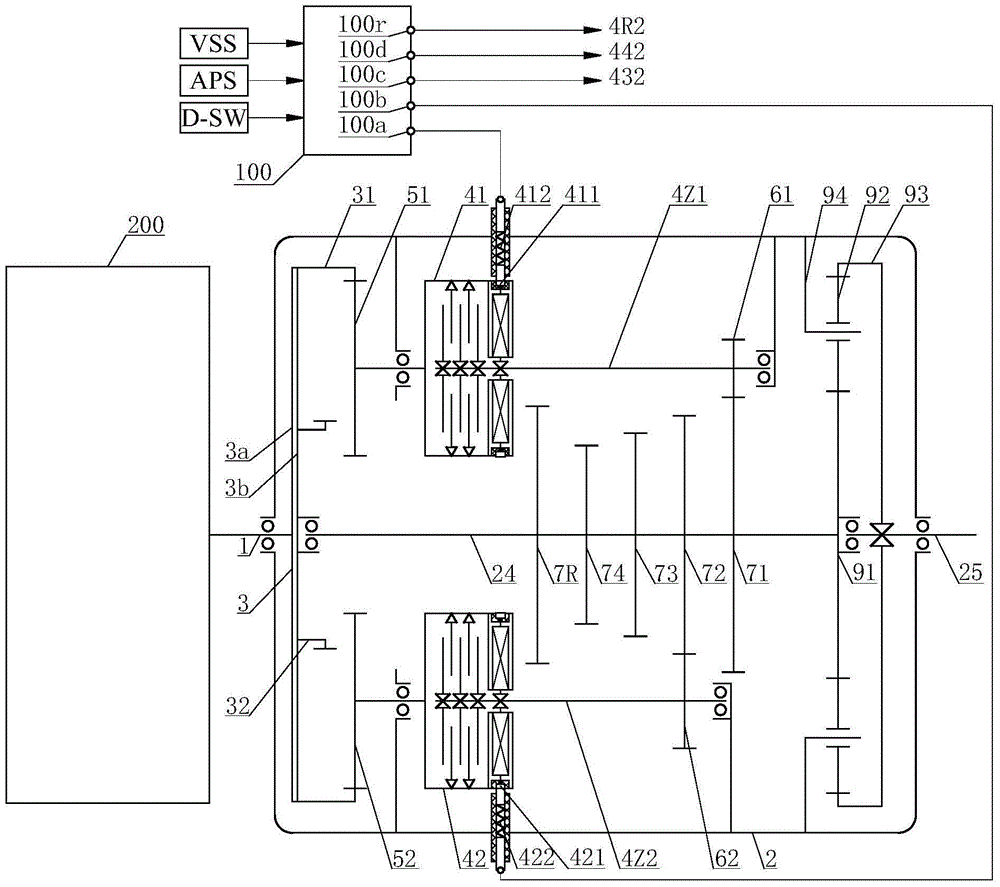

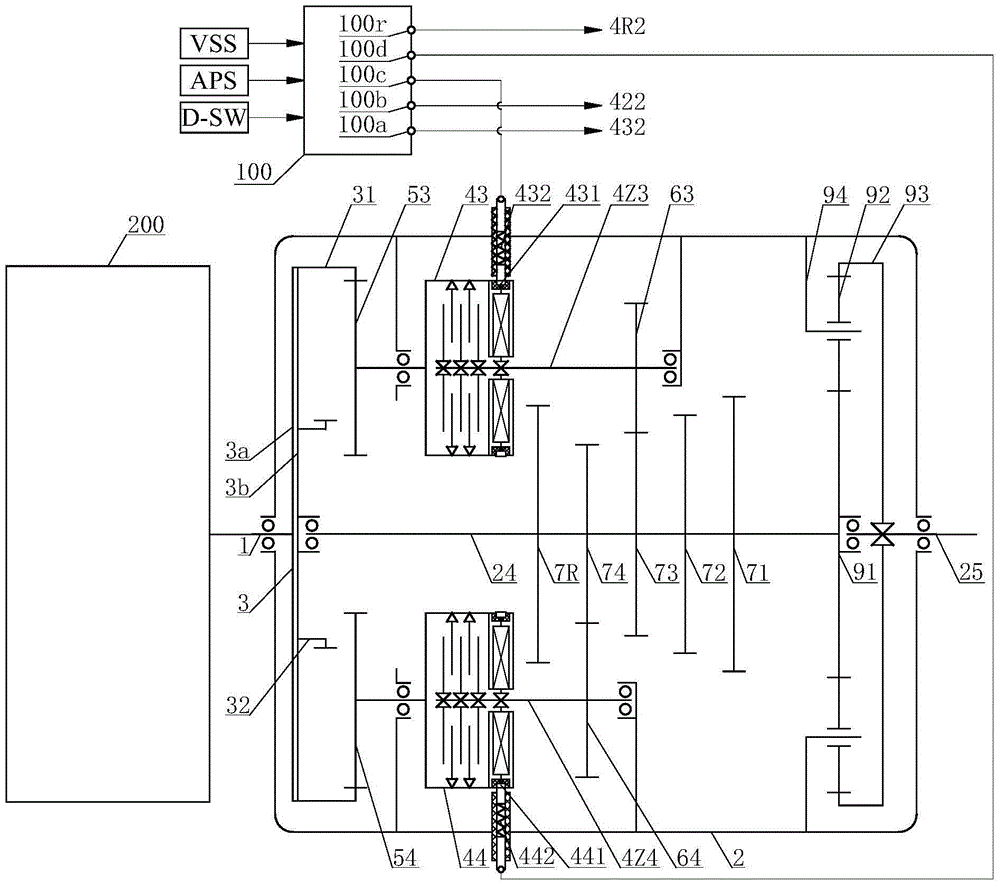

The invention discloses a upshift process control method of a three-gear wire control automatic transmission of an electric vehicle. The method uses an electric control unit for judging if a first gear is required to be risen to a second gear and the second gear is required to be risen to a third gear through detecting a signal of a D-gear switch, a vehicle speed signal (v) of a vehicle speed sensor and an openness signal (a) of a motor acceleration pedal position sensor, and controls the electrification current of electromagnetic clutches in each upshift process. Taking the rising from the second gear to the third gear as an example, the electric control unit controls the electrification current of a third-gear electromagnetic clutch according to an electrification current function I3b(t)={I3, t is not smaller than 0 and not greater than T delta; kI3+I3(1-k)(t- T delta) / (T23-T delta), t is greater than T delta and not greater than T23} of the third-gear electromagnetic clutch in a fixed control period T23, and controls the electrification current of a second-gear electromagnetic clutch according to an electrification current function I2b(t)={I2, t is not smaller than 0 and not greater than b T delta; 0, t is greater than b T delta and not greater than T23} of the second-gear electromagnetic clutch, so as to realize the upshift process control of the wire control automatic transmission. The upshift process control method not only can prevent the interruption of input power of the motor in the upshift process, but also can prevent the gear shift impact to realize smooth upshift of the wire control automatic transmission.

Owner:SHANDONG UNIV OF TECH

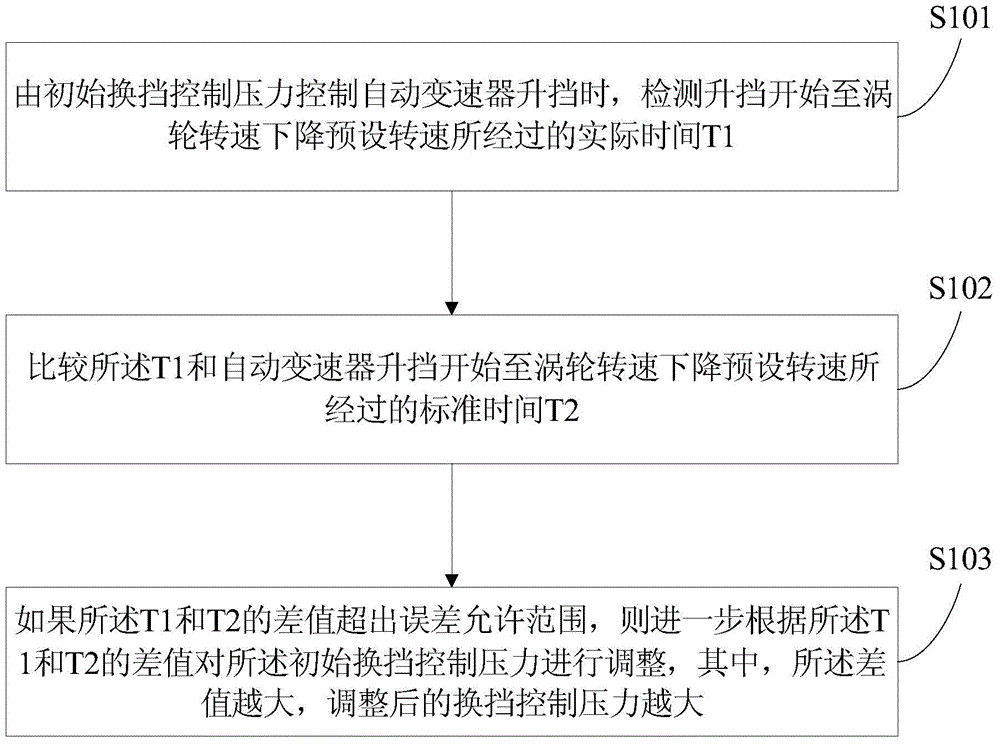

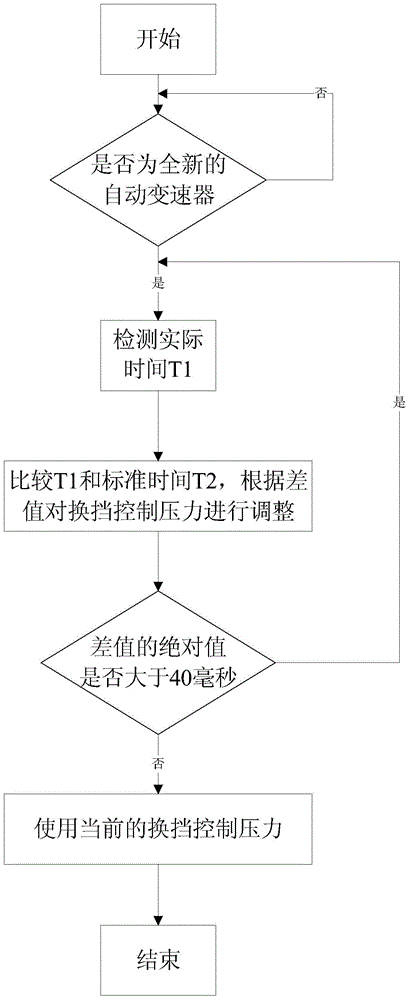

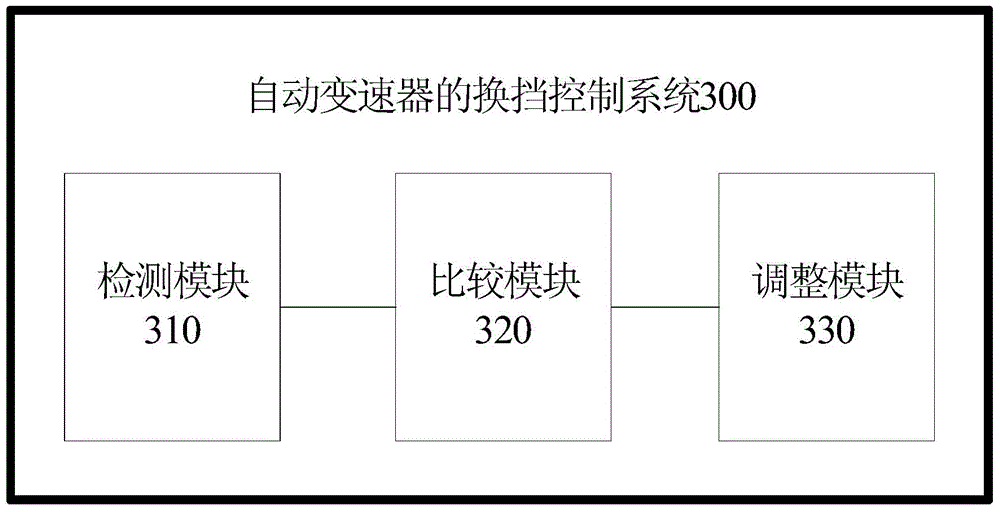

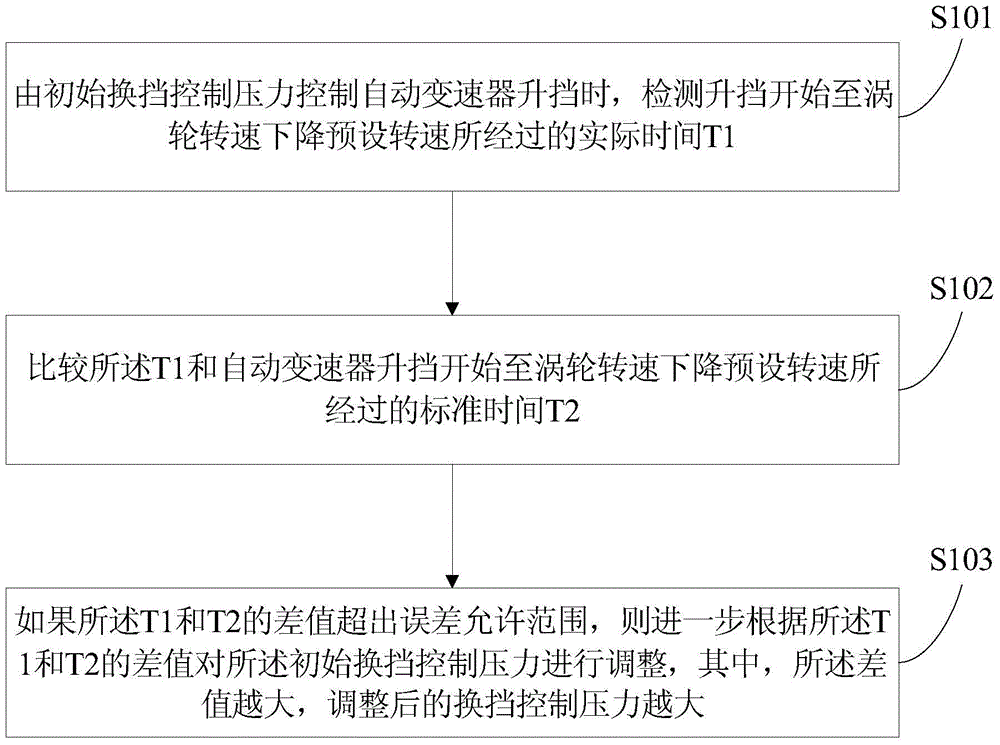

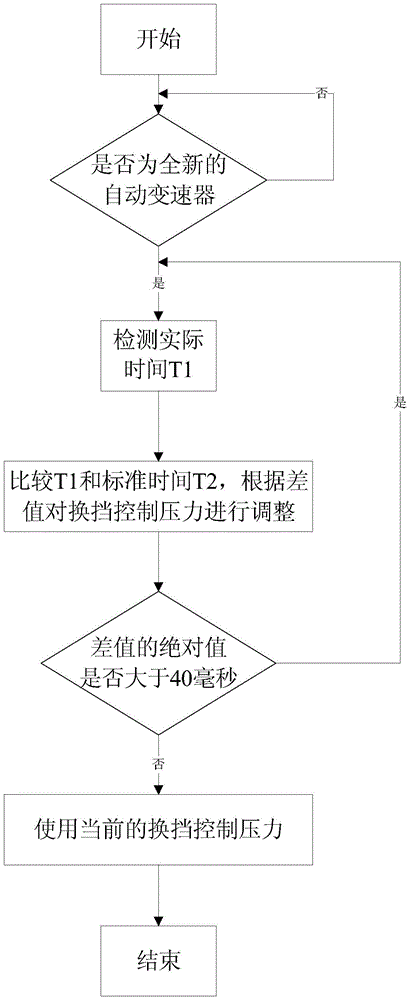

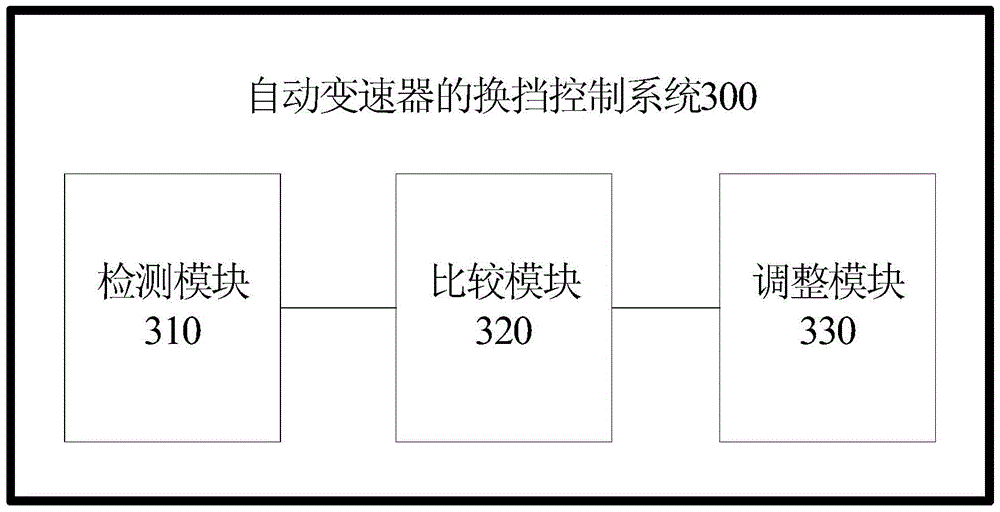

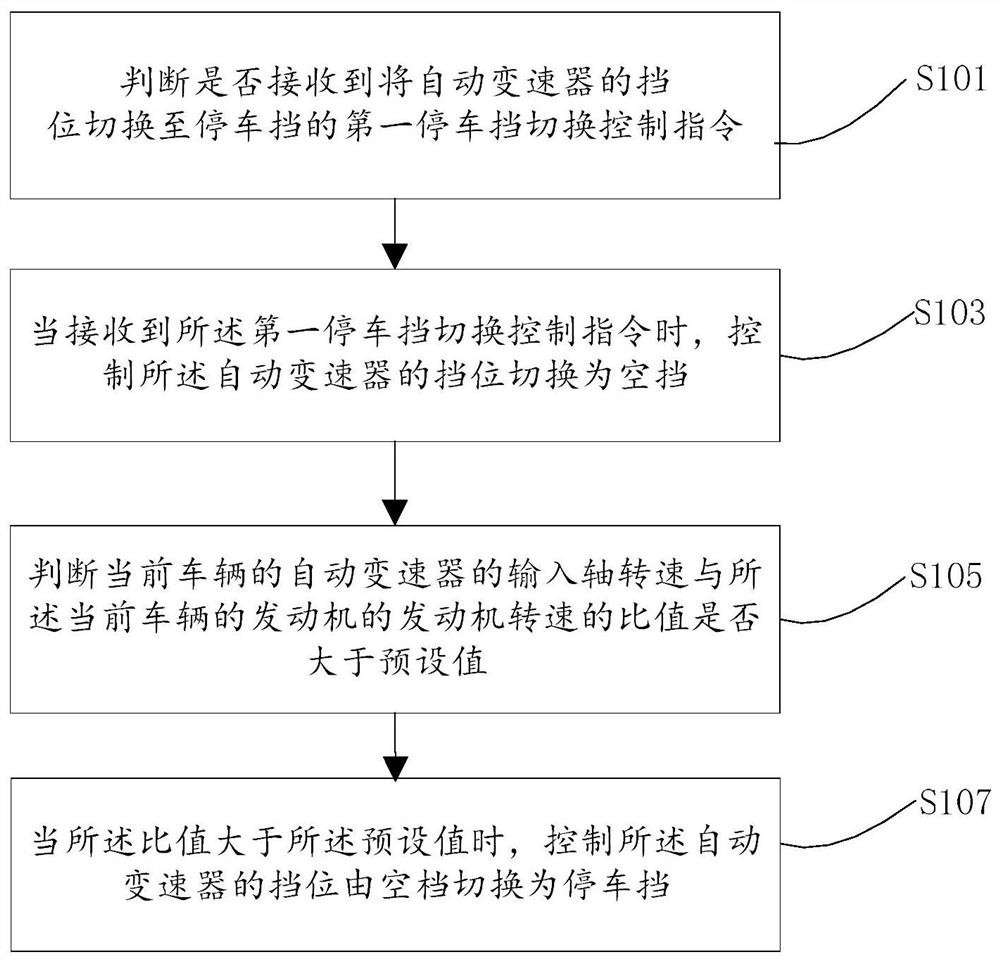

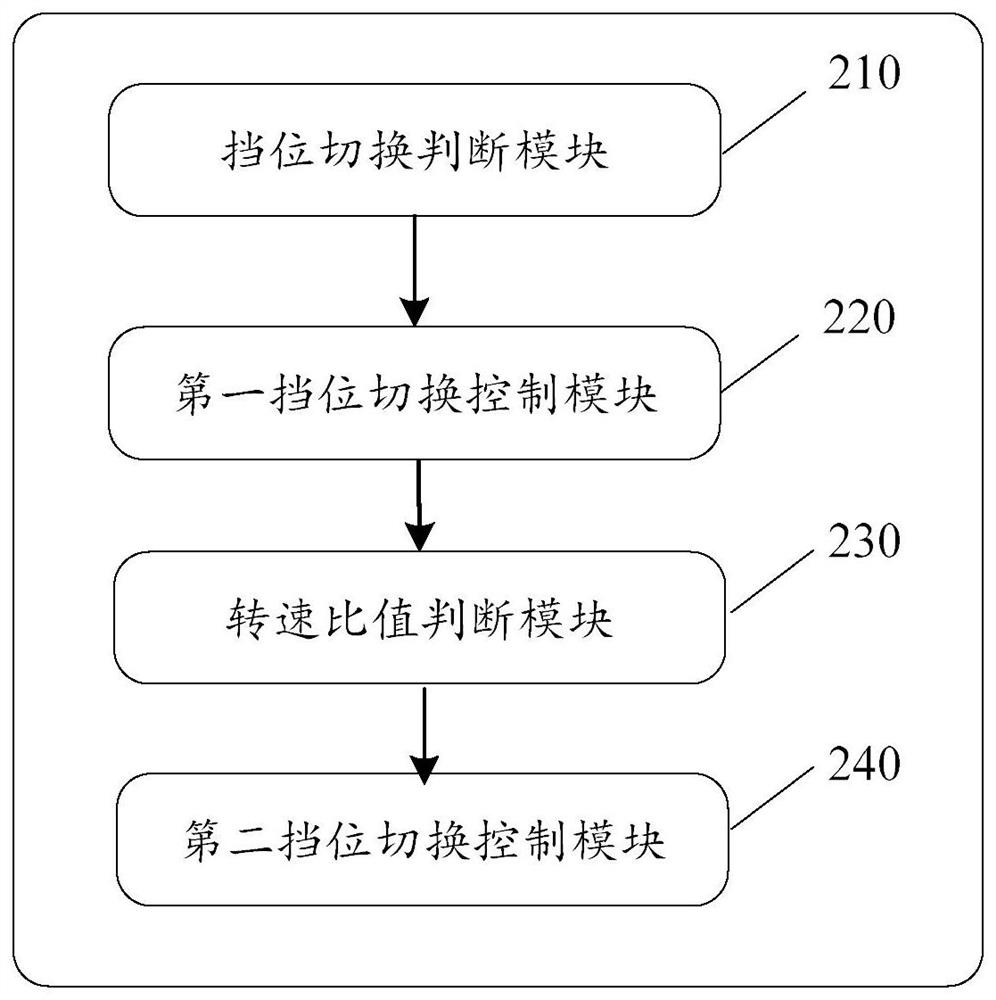

Gear shifting control method and system of automatic gearbox and vehicle

The invention provides a gear shifting control method and system of an automatic gearbox and a vehicle. The method comprises the steps that when up-shift of the automatic gearbox is controlled through initial gear shifting control pressure, the actual time T1 from the up-shift starting time to the time when the rotating speed of a turbine is reduced by the preset rotating speed is detected; the T1 is compared with the standard time T2 from the up-shift starting time of the automatic gearbox to the time when the rotating speed of the turbine is reduced by the preset rotating speed; if the difference value of the T1 and the T2 exceeds an error allowance range, the initial gear shifting control force is adjusted according to the difference value of the T1 and the T2, wherein the larger the difference value, the larger the adjusted gear shifting control pressure is. By means of the gear shifting control method of the automatic gearbox, the gear shifting impact can be lowered or avoided, gear shifting can be smoother, the abruptness occurring in the gear shift process can be reduced and even eliminated, and the riding comfort is improved.

Owner:GREAT WALL MOTOR CO LTD

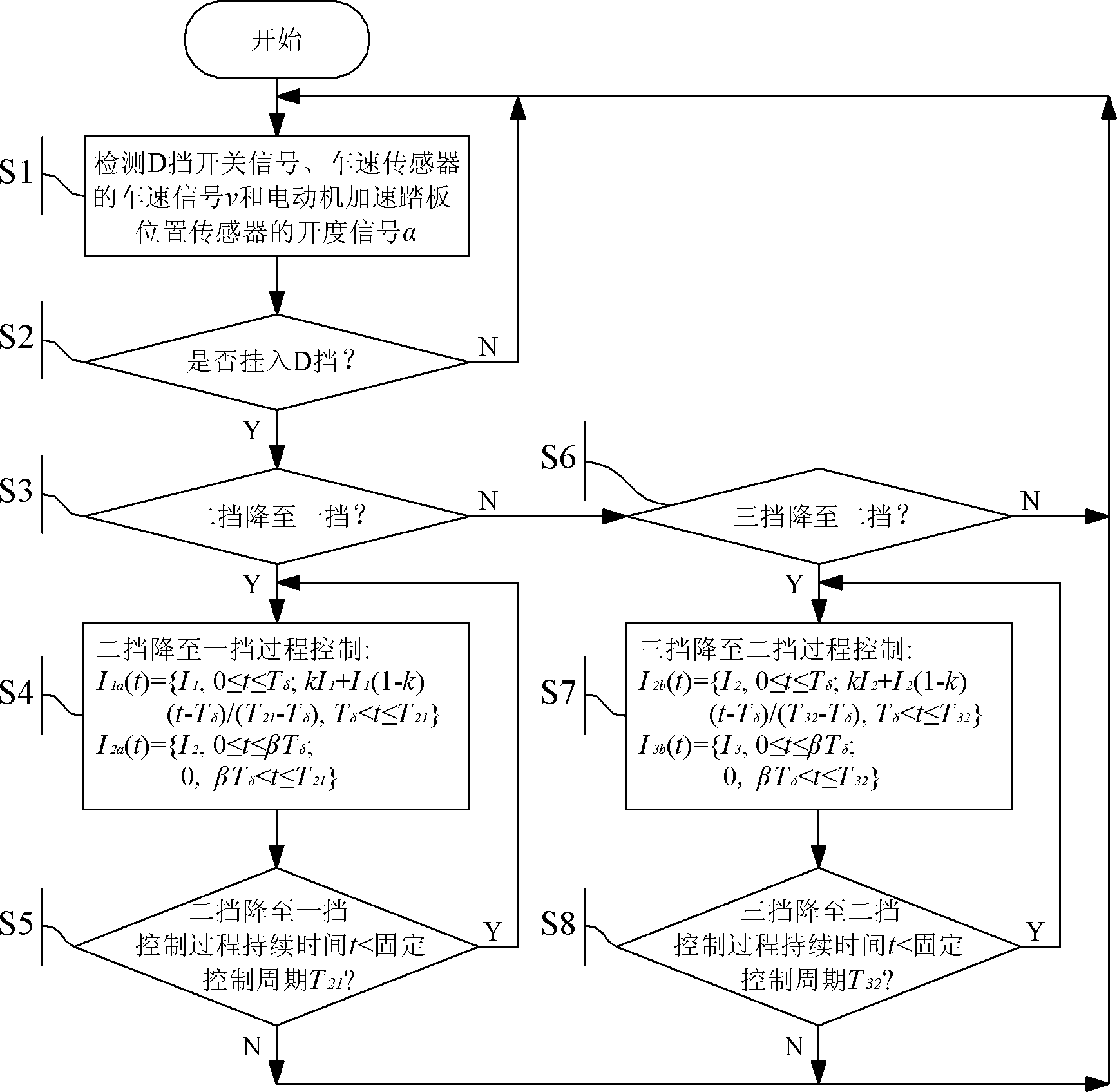

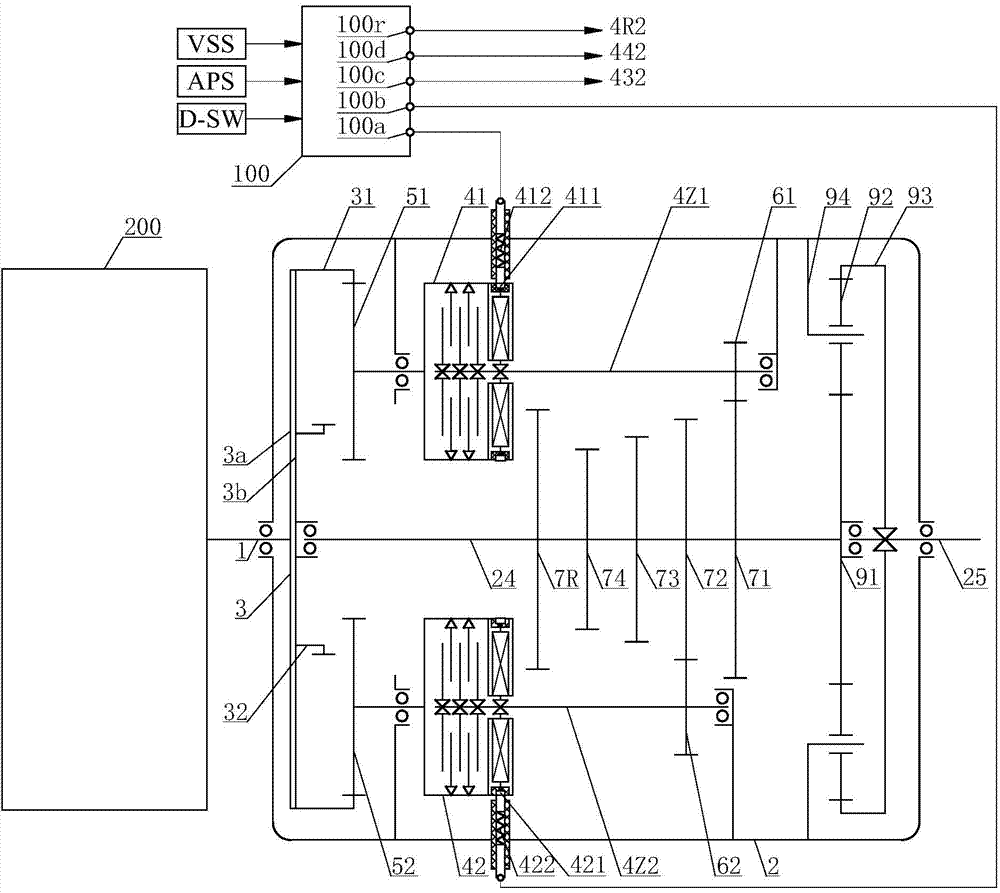

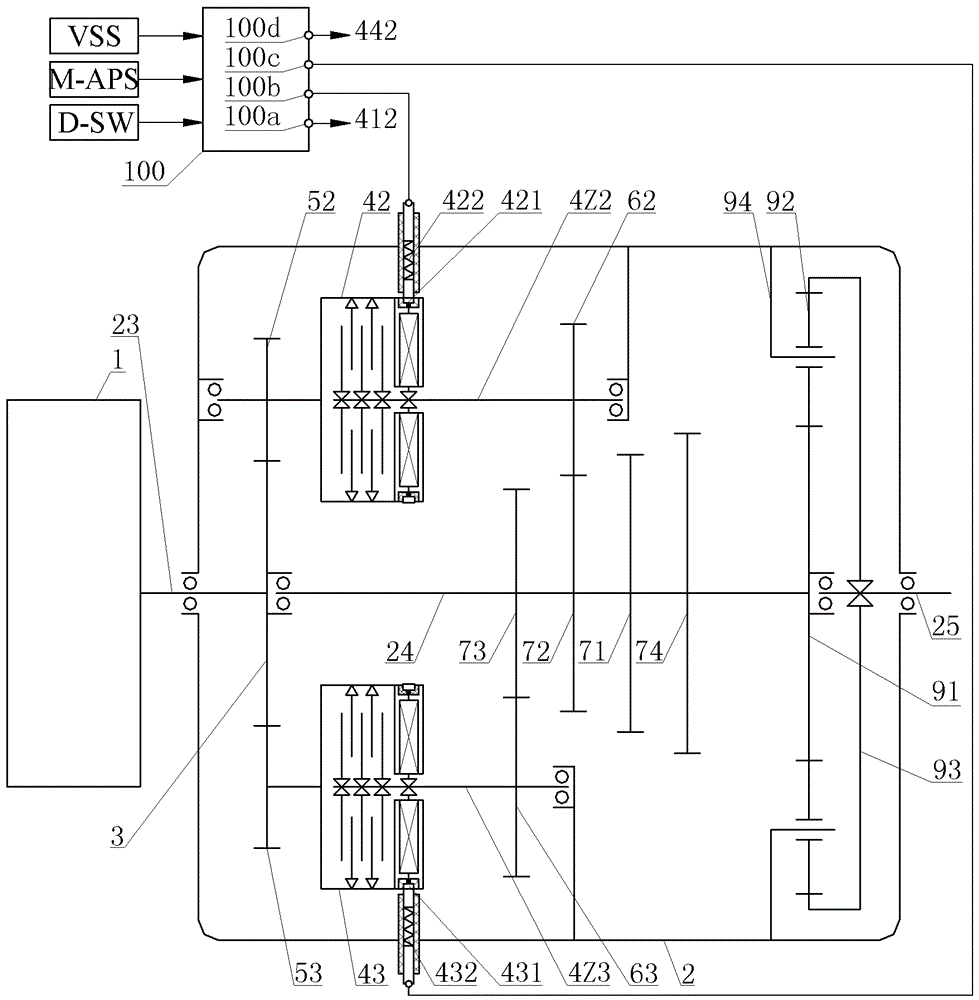

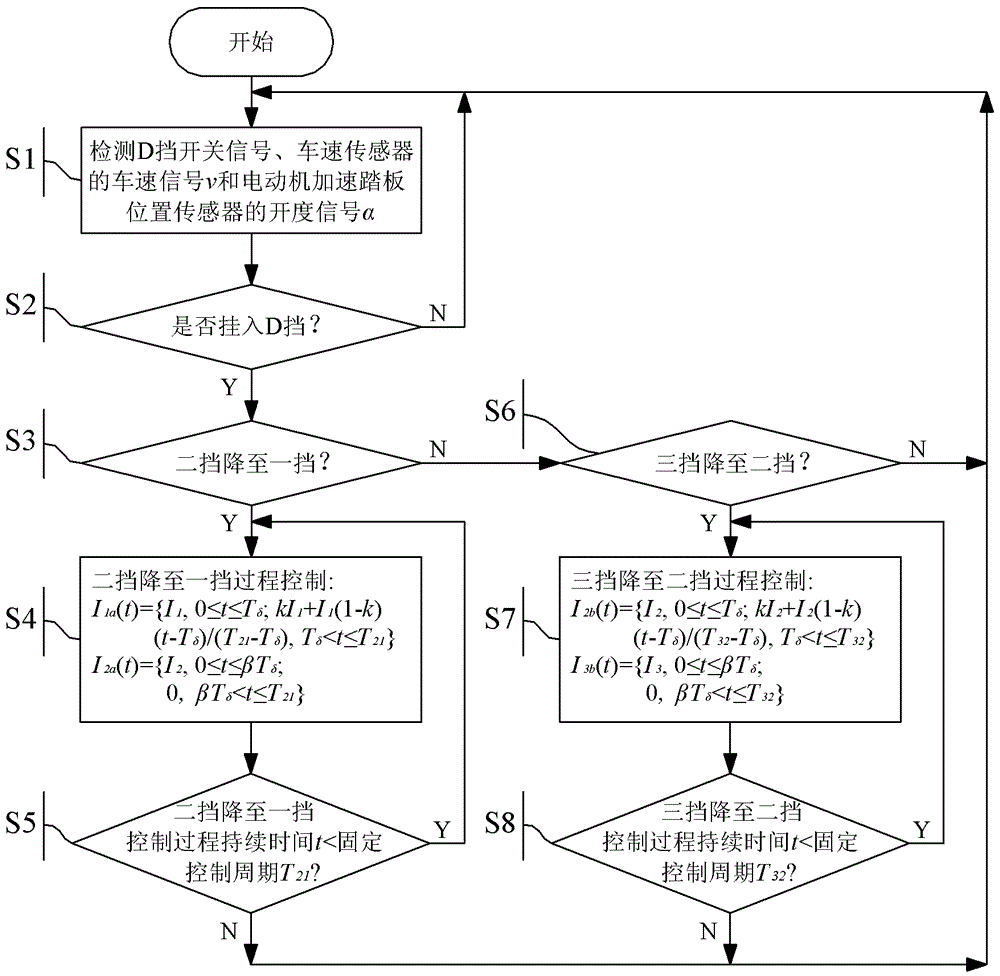

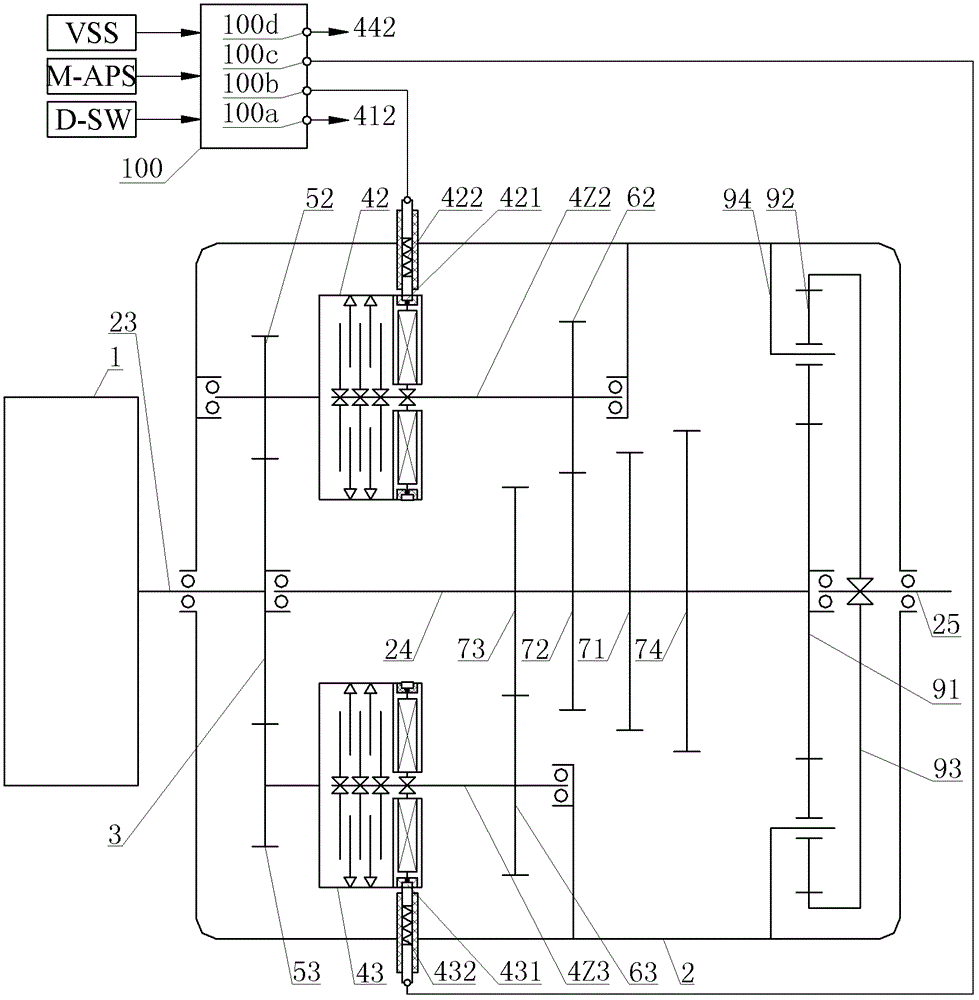

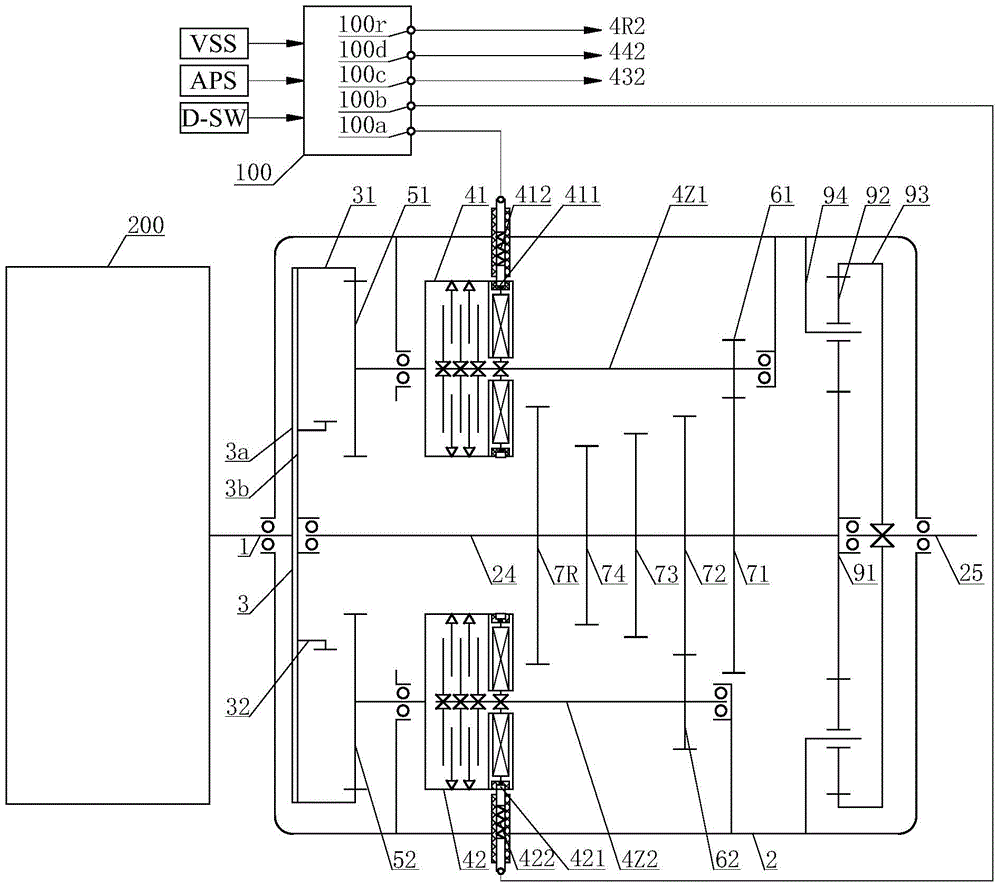

Downshift process control method of three-gear wire control automatic transmission of electric vehicle

InactiveCN104390000AEliminate separation gapsLarge currentGearing controlEngineeringElectric vehicle

The invention discloses a downshift process control method of a three-gear wire control automatic transmission of an electric vehicle. The method uses an electric control unit for judging if a second gear is required to be reduced to a first gear and a third gear is required to be reduced to the second gear through detecting a signal of a D-gear switch, a vehicle speed signal (v) of a vehicle speed sensor and an openness signal (a) of a motor acceleration pedal position sensor, and controls the electrification current of electromagnetic clutches in each downshift process. Taking the reduction from the third gear to the second gear as an example, the electric control unit controls the electrification current of a second-gear electromagnetic clutch according to an electrification current function I2b(t)={I2, t is not smaller than 0 and not greater than T delta; kI2+I2(1-k)(t-T delta) / (T32-T delta), t is greater than T delta and not greater than T32} of the second-gear electromagnetic clutch in a fixed control period T32, and controls the electrification current of a third-gear electromagnetic clutch according to an electrification current function I3b(t)={I3, t is not smaller than 0 and not greater than b T delta; 0, t is greater than b T delta and not greater than T32} of the third-gear electromagnetic clutch, so as to realize the downshift process control of the wire control automatic transmission. The downshift process control method not only can prevent the interruption of input power of the motor in the downshift process, but also can prevent the gear shift impact to realize smooth downshift of the wire control automatic transmission.

Owner:SHANDONG UNIV OF TECH

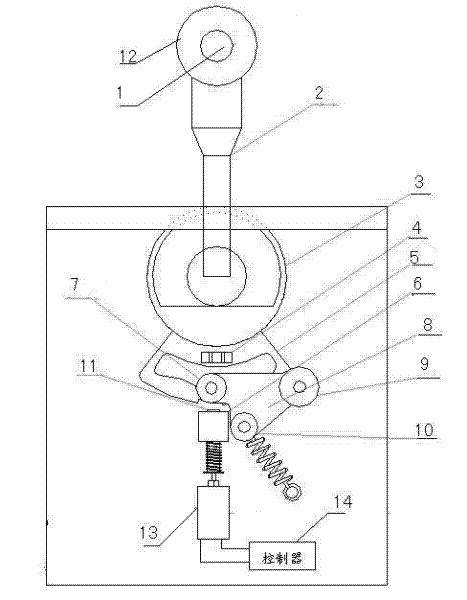

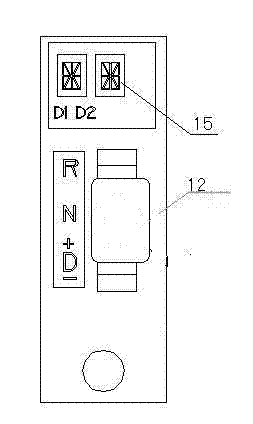

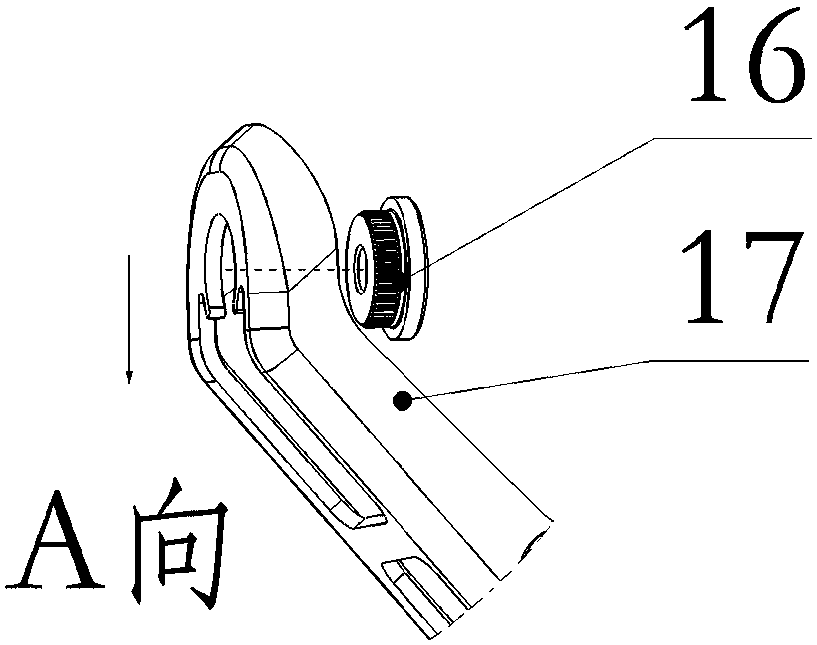

Gear shifting handle

ActiveCN102345729ASimple mechanical structureReasonable designGearing controlAutomatic transmissionAgricultural engineering

The invention belongs to the technical field of a vehicle automatic transmission gearshift, and in particular relates to a gear shifting handle. The gear shifting handle comprises a controller and an operating machine unit, wherein a fixed pulley, a spring tension wheel, and an embeded wheel are arranged at three ends of a gear limiting move spring block in the operating machine unit; the upper end of an operating arm is provided with an operating arm grab handle, an unlock button is arranged on the operating arm grab handle, one side of the lower end of the operating arm is connected with a circle handle block, and a gear limiting block is connected with the circle handle block; the gear limiting block is provided with three grooves, a magnet block is fixed on the gear limiting block, and the gear limiting move spring block is arranged on the lower end of the gear limiting block; the embedded wheel is embedded in the gear limiting block, and the fixed pulley is used for fixing one end of the gear limiting block; and an iron prop is arranged below the gear limiting move spring block, and the lower end of the iron prop is connected with an electromagnet. The gear shifting handle provided by the invention has the advantages of simple mechanism unit structure, reasonable design, and practical function.

Owner:SPECIAL VEHICLE TECH CENT OF HUBEI AEROSPACE TECH RES INST

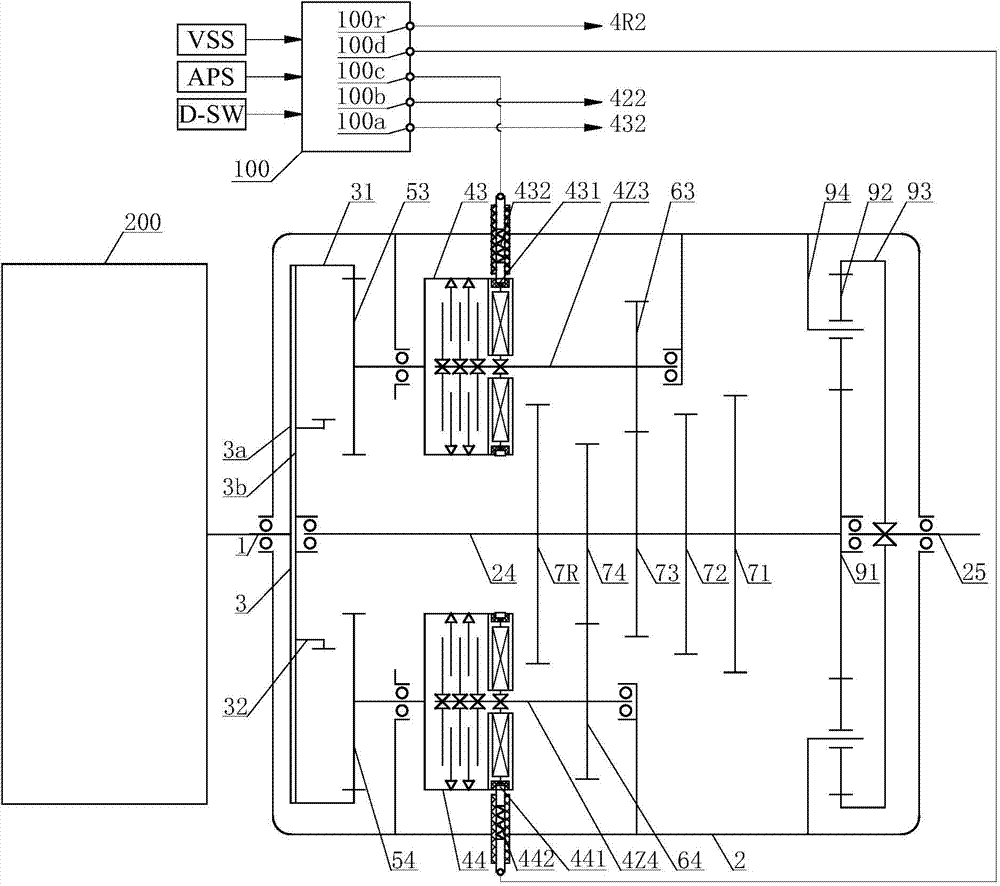

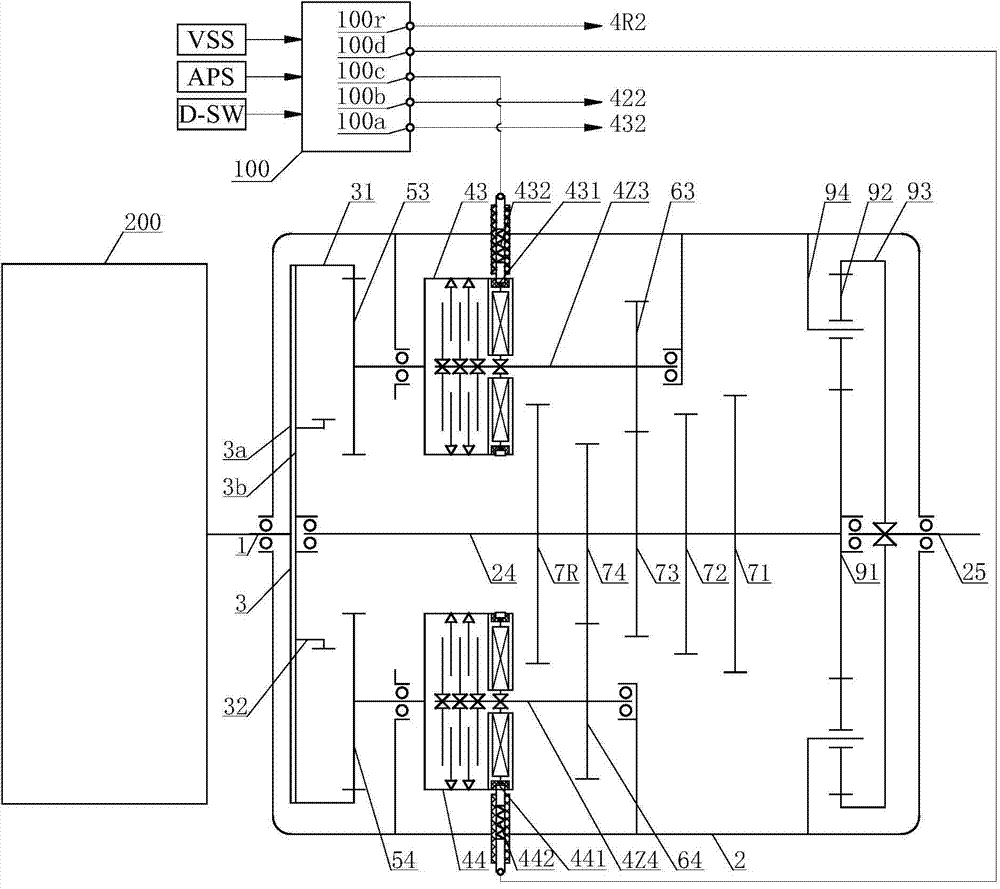

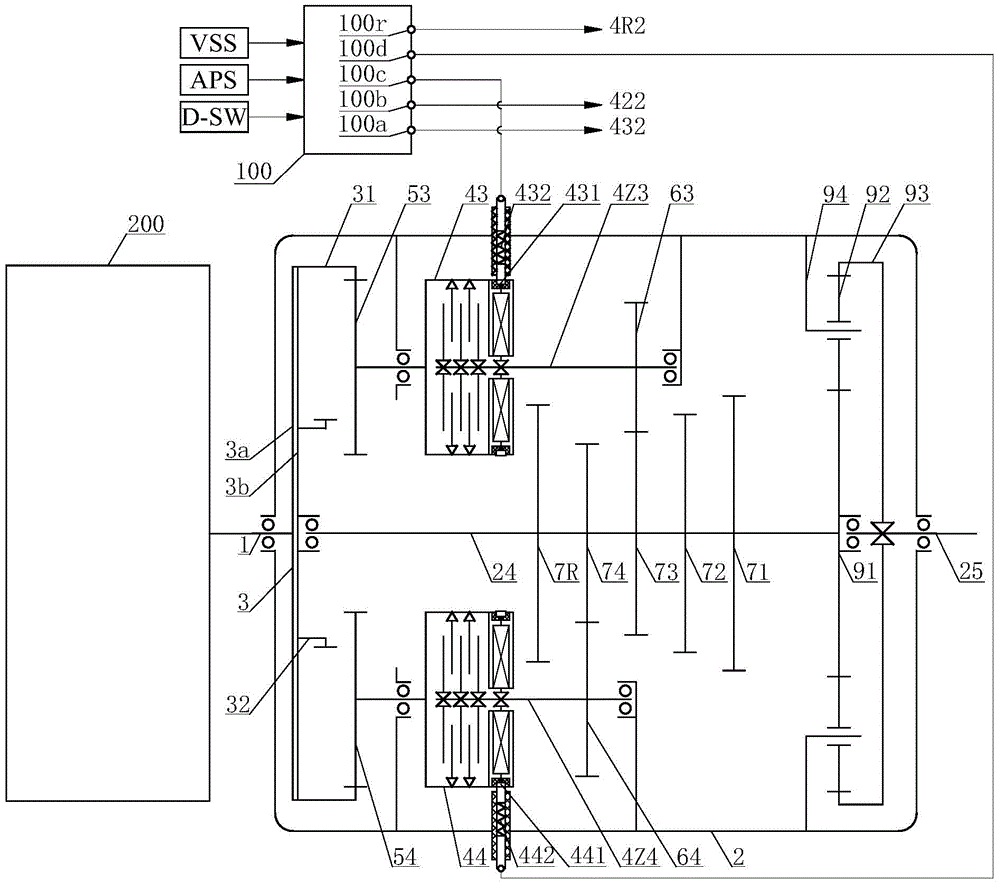

Variable-cycle upshift process control method for multi-gear wire control automatic transmission

ActiveCN104315135APrecise time controlMeet the requirements of upshift control cycleGearing controlTransmission elementsAutomatic transmissionElectromagnetic clutch

The invention discloses a variable-cycle upshift process control method for a multi-gear wire control automatic transmission. The method comprises the following steps: judging whether the first gear is shifted to the second gear, the second gear is shifted to the third gear and the third gear is shifted to the fourth gear by detecting a D-gear switch signal, a vehicle speed signal v of a vehicle speed sensor and an opening signal alpha of an accelerator pedal position sensor by an electrical control unit, and controlling the power-on current of an electromagnetic clutch in each upshift process; taking the process of shifting the second gear to the third gear as an example, by a variable cycle function T(v), controlling the power-on current of a third-gear electromagnetic clutch according to a power-on current function I3b(t) (I3b(t)={I3, t is not less than 0 and not more than T[delta]; kI3+I3(1-k)(t-T[delta]) / (T23-T[delta]), t is more than T[delta] and not more than T23}) of the third-gear electromagnetic clutch, and controlling the power-on current of a second-gear electromagnetic clutch according to a power-on current function I2b(t) (I2b(t)={I2, t is not less than 0 and not more than IT[delta]; 0, t is more than IT[delta] and not more than T23}) of the second-gear electromagnetic clutch by the electrical control unit, so that the control on the upshift process of the wire control automatic transmission is finished. According to the method, the interruption of input power of an engine in the upshift process and the impact of shifting can be avoided, and the upshift process of the wire control automatic transmission is stable.

Owner:SHANDONG UNIV OF TECH

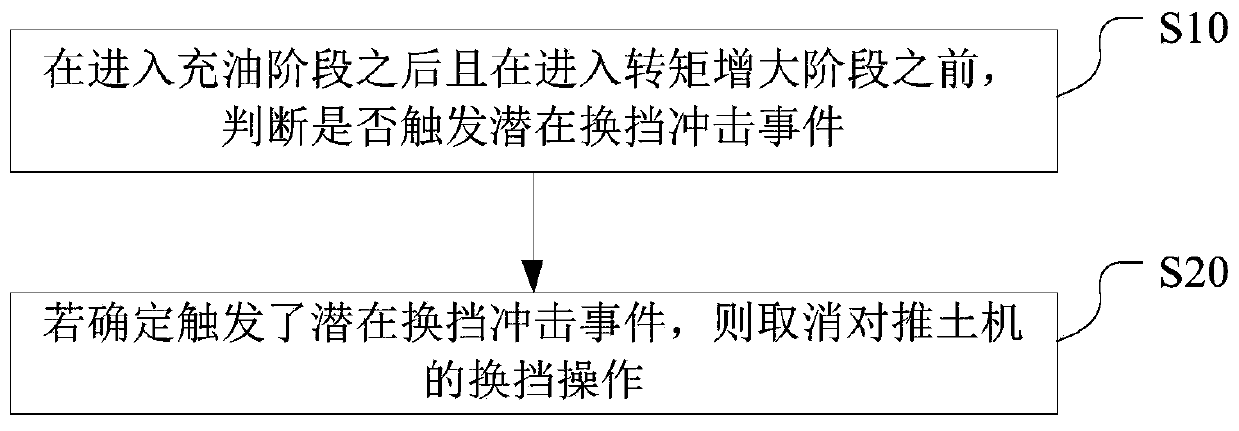

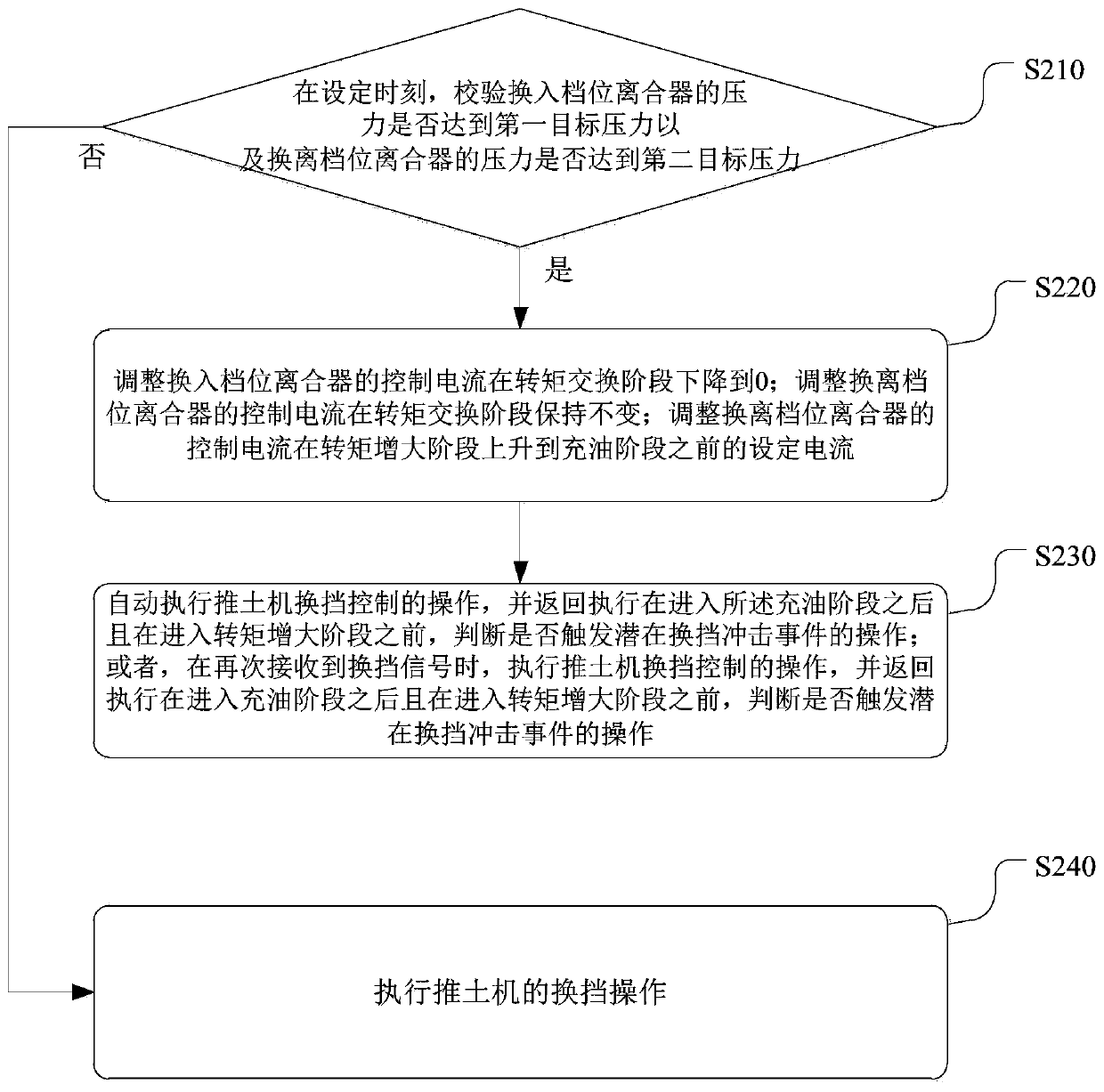

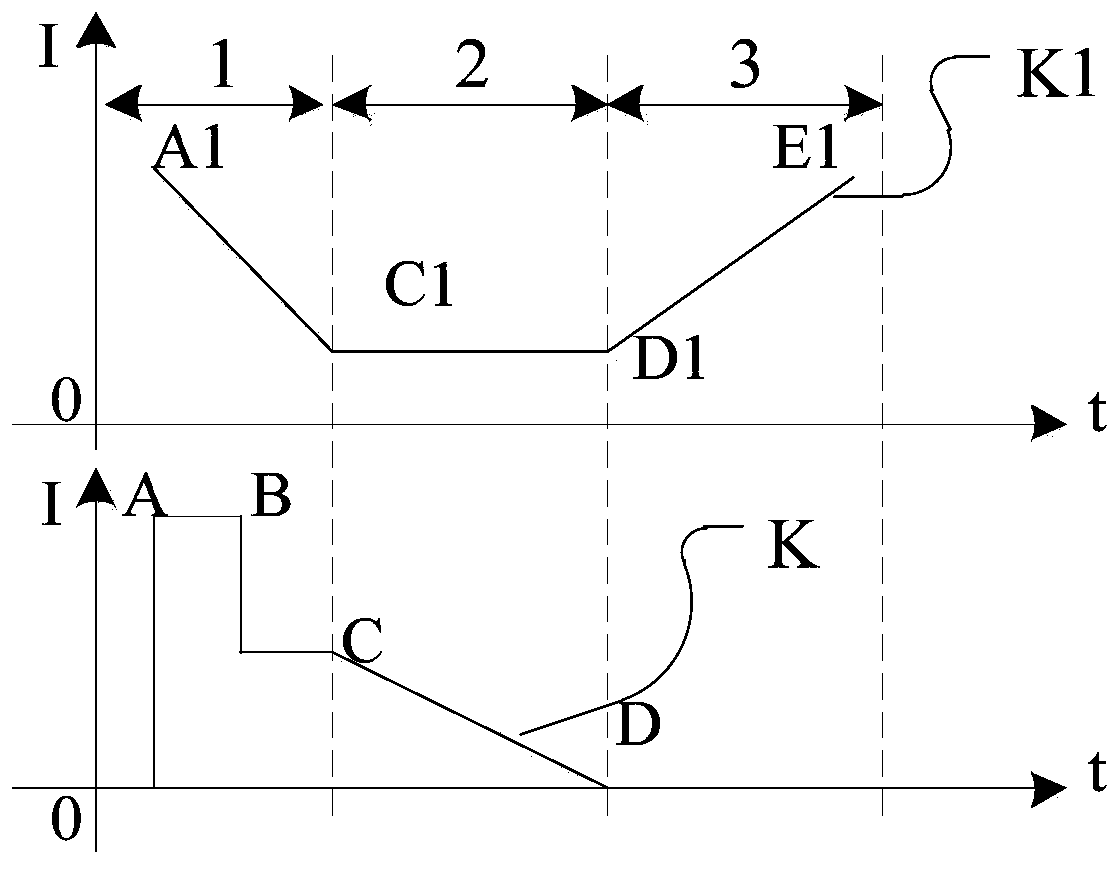

Bulldozer gear shifting control method and device and computer storage medium

ActiveCN110886839AShift control is effectiveAvoid damageGearing controlControl engineeringMechanical engineering

The embodiment of the invention discloses a bulldozer gear shifting control method and device and a computer storage medium. The bulldozer gear shifting control method comprises the steps of: judgingwhether to trigger a potential gear shifting impact event or not after entering an oil charging stage and before entering a torque increasing stage, and cancelling gear shifting operation on the bulldozer if the potential gear shifting impact event is determined to be triggered. By means of the control method, the bulldozer can effectively conduct gear shifting control, and the problem of gear impact during gear shifting is avoided.

Owner:SHANTUI CONSTR MASCH CO LTD

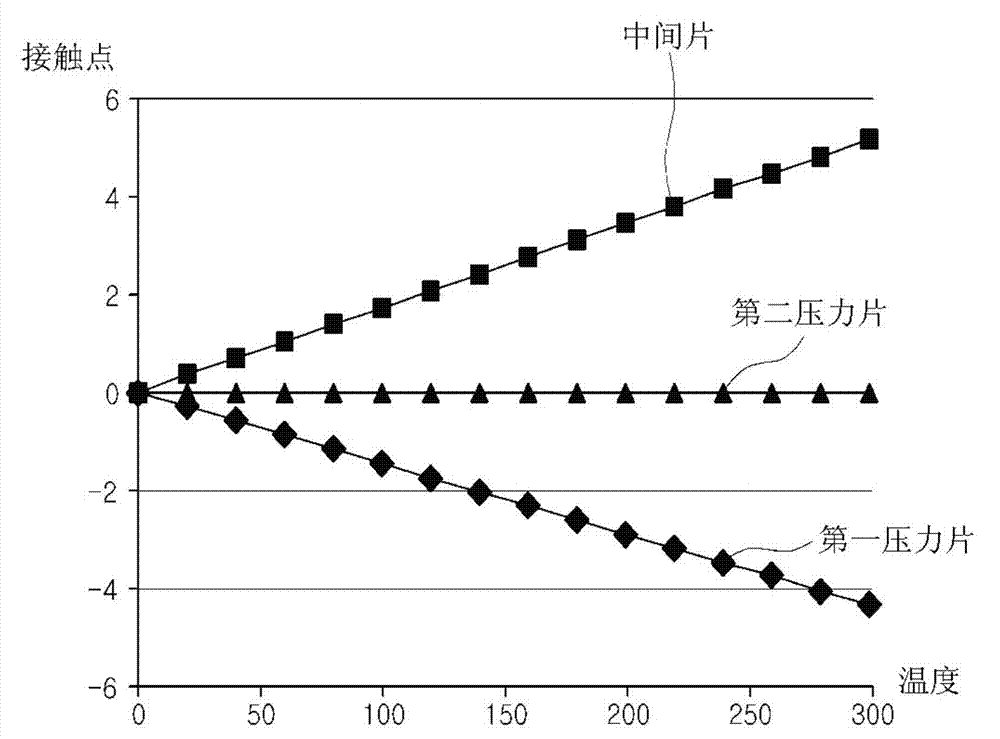

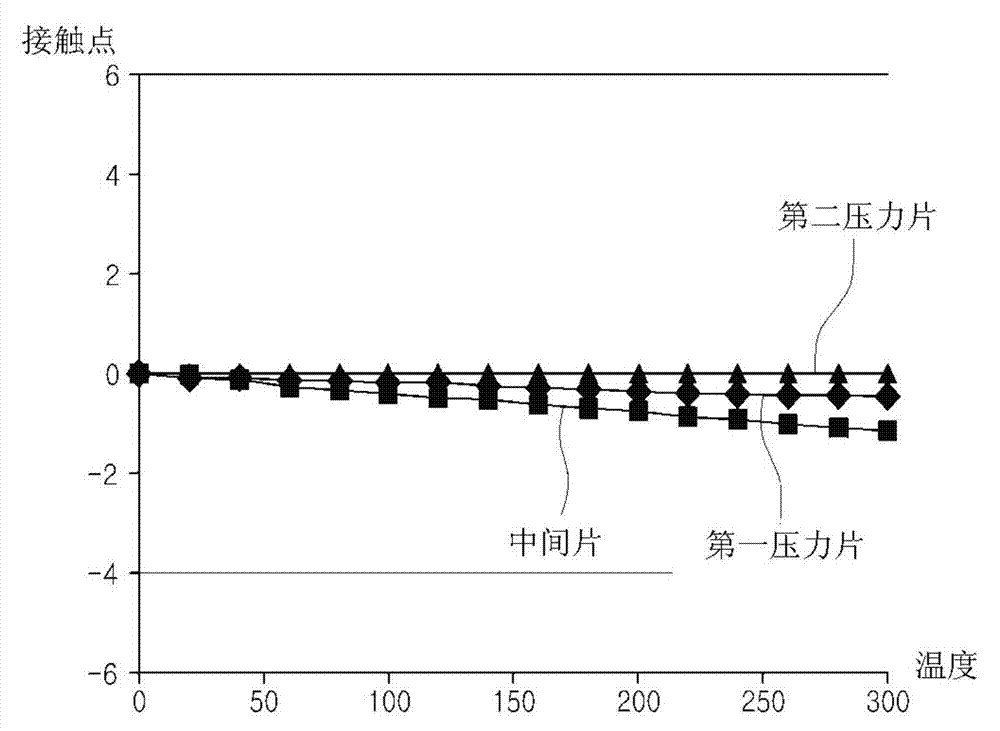

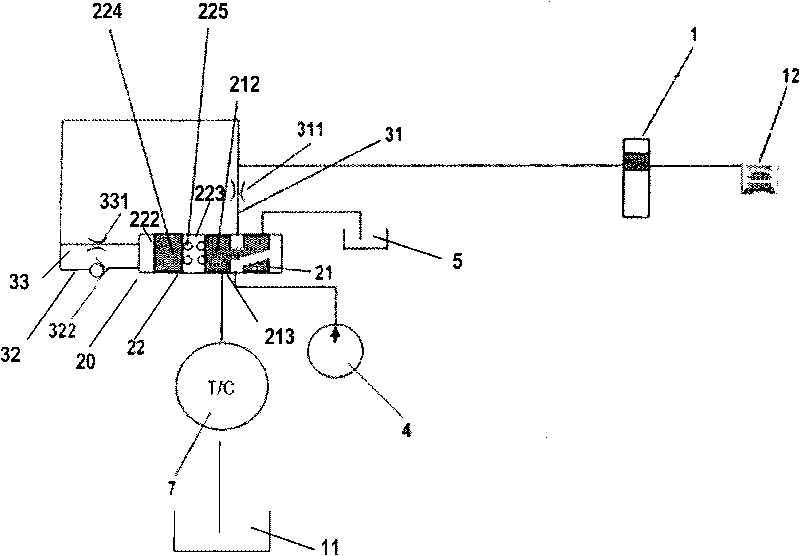

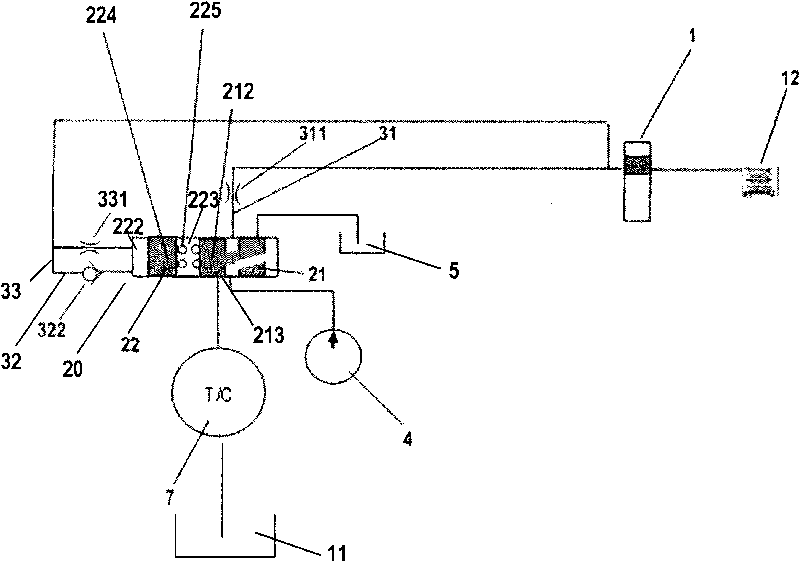

Touch Point Adjusting Method For Dct

InactiveCN104728311AIncreased durabilityIncrease valueFluid actuated clutchesGearing controlControl theoryIndividual Adjustment

A touch point adjusting method for a double clutch transmission, may include determining amounts of individual adjustment of first and second pressure plates and a center plate depending on temperature, determining an amount of final adjustment of a touch point in consideration of the amounts of the individual adjustment determined at the process of determining the amounts of the individual adjustment, and adjusting the touch point of a corresponding clutch based on the amount of the final adjustment of the touch point determined at the process of determining the amount of the final adjustment of the touch point.

Owner:HYUNDAI MOTOR CO LTD +1

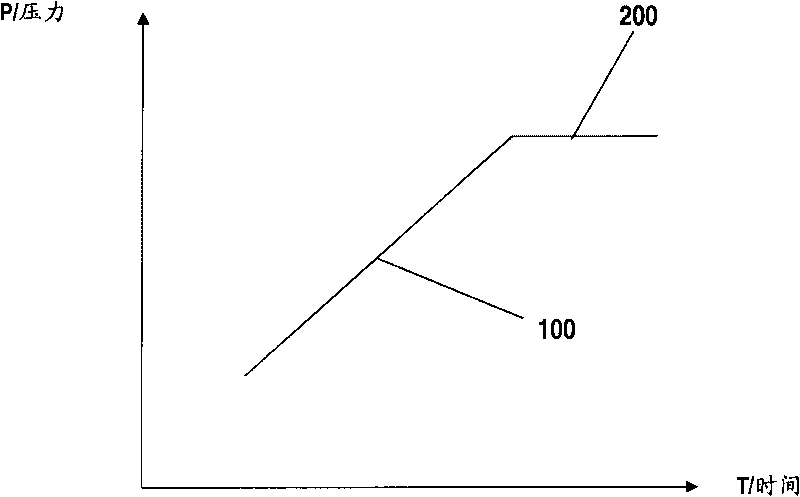

Pressure regulating system and method for working machine

InactiveCN101749295AQuick breakAvoid shift shockServomotor componentsFluid gearingsEngineeringMachine

The invention provides a pressure regulating system for a working machine, comprising an oil tank in response to operation of a control valve, an actuating mechanism which does actuating actions, a first pressure regulating valve and a second pressure regulating valve, wherein fluid flows through the first pressure regulating valve and is output to the actuating mechanism from the oil tank, the second regulating valve and the first pressure regulating valve are connected by the fluid, and pressure buffer is carried out on the fluid which flows to the second pressure regulating valve, thus enabling the pressure of the fluid which is output to the actuating mechanism to be increased stably. The invention also provides a pressure regulating method for the working machine, comprising the following steps: a part of the fluid which flows through the first pressure regulating valve from the oil tank is output to the actuating mechanism of the working machine; a part of the fluid which flows through the first pressure regulating valve is output to the second pressure regulating valve which is connected with the first pressure regulating valve by the fluid, wherein pressure buffer is carried out on the fluid which flows to the second pressure regulating valve, thus enabling the pressure of the fluid which is output to the actuating mechanism to be increased stably and avoiding pressure shock.

Owner:CATERPILLAR INC

Damping hydraulic clutch planetary gear automatic transmission and gear shifting method thereof

PendingCN111795128AReasonable structural designImprove stabilityGear lubrication/coolingGearing controlAutomatic transmissionGear wheel

The invention relates to a damping hydraulic clutch planetary gear automatic transmission and a gear shifting method thereof, and belongs to the technical field of transmissions. The damping hydraulicclutch planetary gear automatic transmission specifically comprises an input shaft and an output shaft which are installed in a transmission shell, a plurality of low-speed gear mechanisms, a plurality of high-speed gear mechanisms and a reverse gear mechanism are installed on the input shaft, a plurality of first speed regulating gears which are correspondingly meshed with the low-speed gear mechanisms, the high-speed gear mechanisms and the reverse gear mechanisms are installed on the output shaft, an electronic synchronizer is arranged between the first speed regulating gears and the output shaft. The damping hydraulic clutch planetary gear automatic transmission and the gear shifting method thereof are reasonable in structural design, good in stability and long in service life, and power transmission does not need a friction piece.

Owner:白俊彪

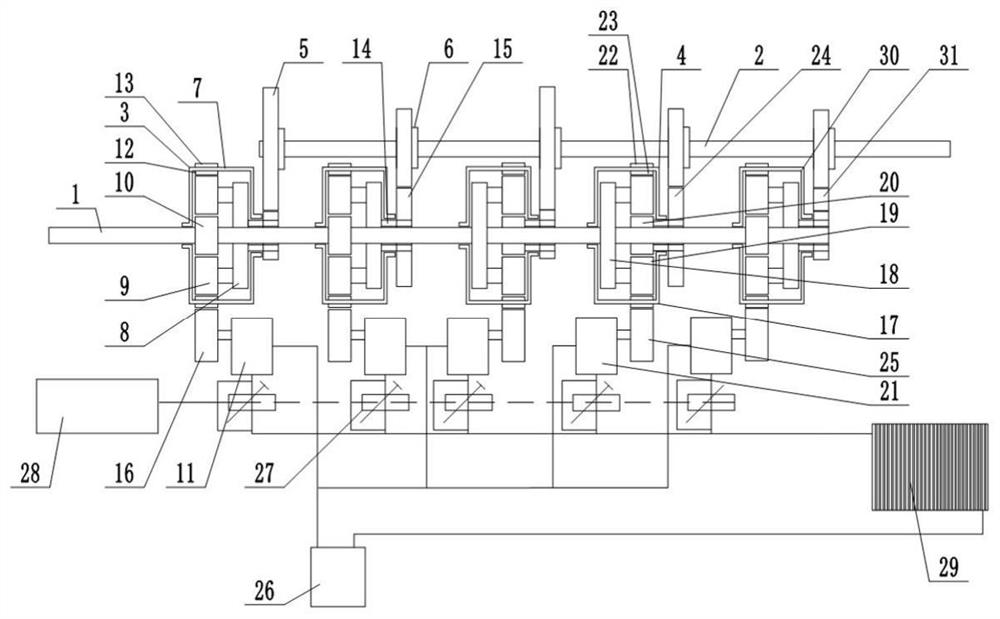

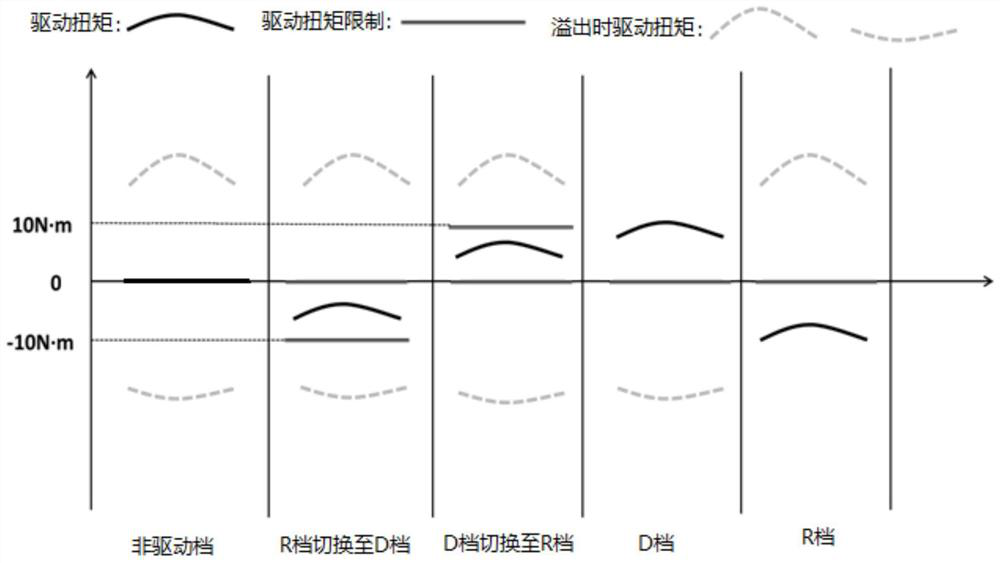

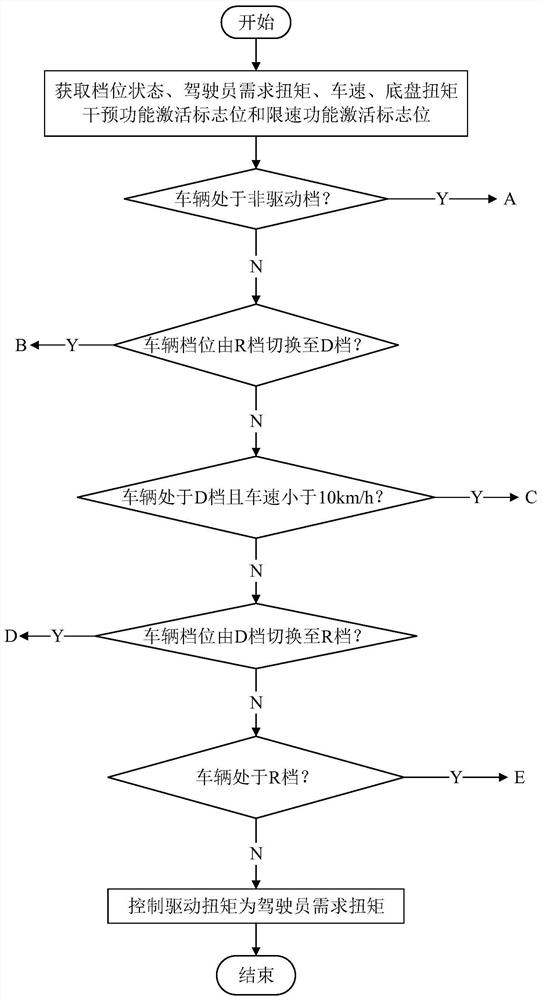

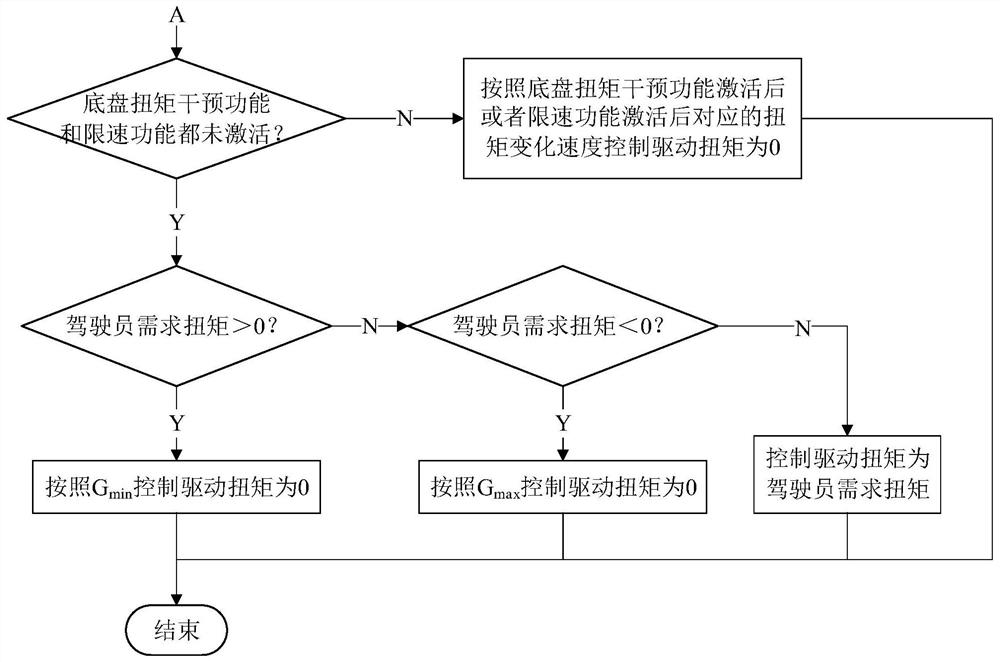

Control method for driving torque of pure electric vehicle

ActiveCN112644296AAvoid turningAvoid shift shockSpeed controllerElectric energy managementDriver/operatorSpeed limit

The invention discloses acontrol method for the driving torque of a pure electric vehicle. The driving torque is limited according to the gear condition of a vehicle, the driver demand torque, the vehicle speed, the chassis torque intervention function activation condition and the speed limiting function activation condition, generation of large unexpected acceleration when controller software data overflows is avoided, the vehicle driving risk is reduced, and the safety threat to a driver is reduced.

Owner:重庆长安新能源汽车科技有限公司

A Method for Determining Semi-coupling Point of Wet Dual Clutch Transmission

ActiveCN108708971BImprove adaptabilityImprove the level of intelligenceToothed gearingsGearing controlEngineeringOil temperature

The invention discloses a method for determining the semi-coupling point of a wet dual-clutch transmission. The method for determining the semi-coupling point of the wet dual-clutch transmission comprises the following steps: detecting the oil temperature of the transmission when the wet dual-clutch transmission shifts gears, and when the oil temperature is within the normal range When the oil temperature is low, gradually increase the input pressure of the shift-in clutch, and at the same time judge the pressure of the half-joint point of the clutch according to the change trend of the speed difference between the input shaft and the output shaft of the transmission; when the oil temperature of the transmission is at a low temperature, gradually increase the input pressure of the shift-in clutch , at the same time judge the pressure of the clutch half-engagement point by the speed difference between the transmission input shaft and the output shaft and the change trend of the output shaft torque. It can quickly and efficiently control the pressure of the clutch half-joint point under different oil temperature conditions, effectively avoiding the phenomenon of shifting shock and power cycle.

Owner:HEFEI UNIV OF TECH

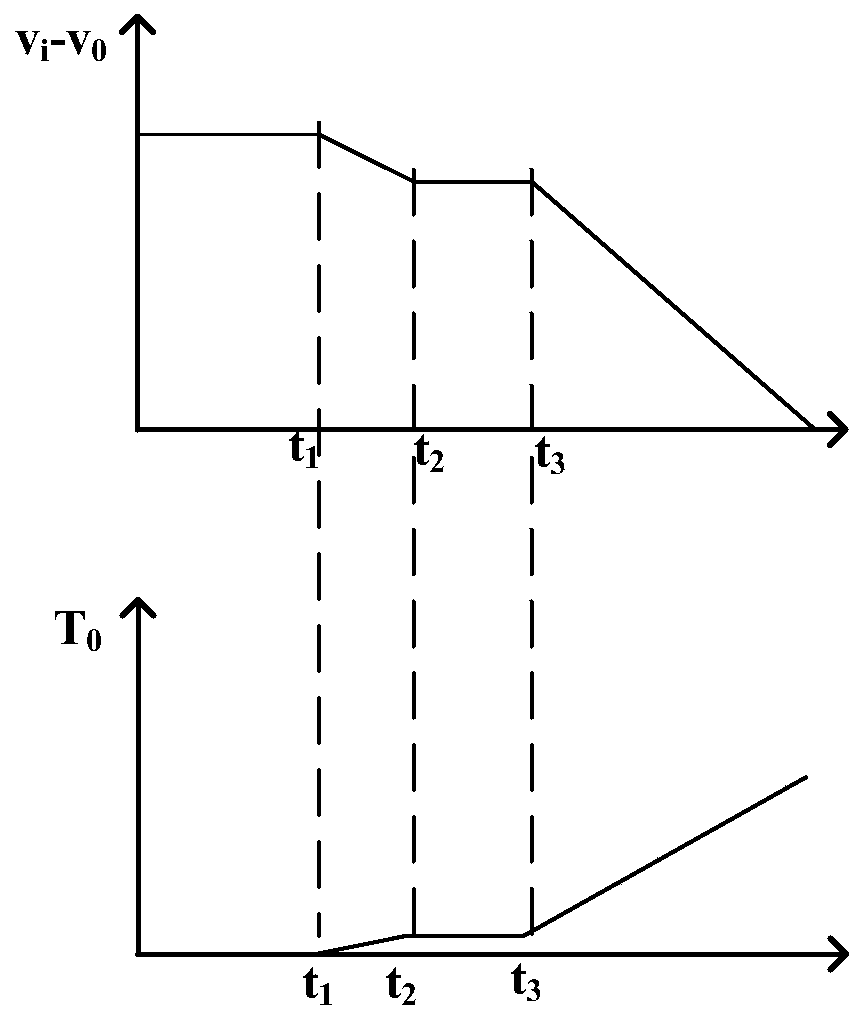

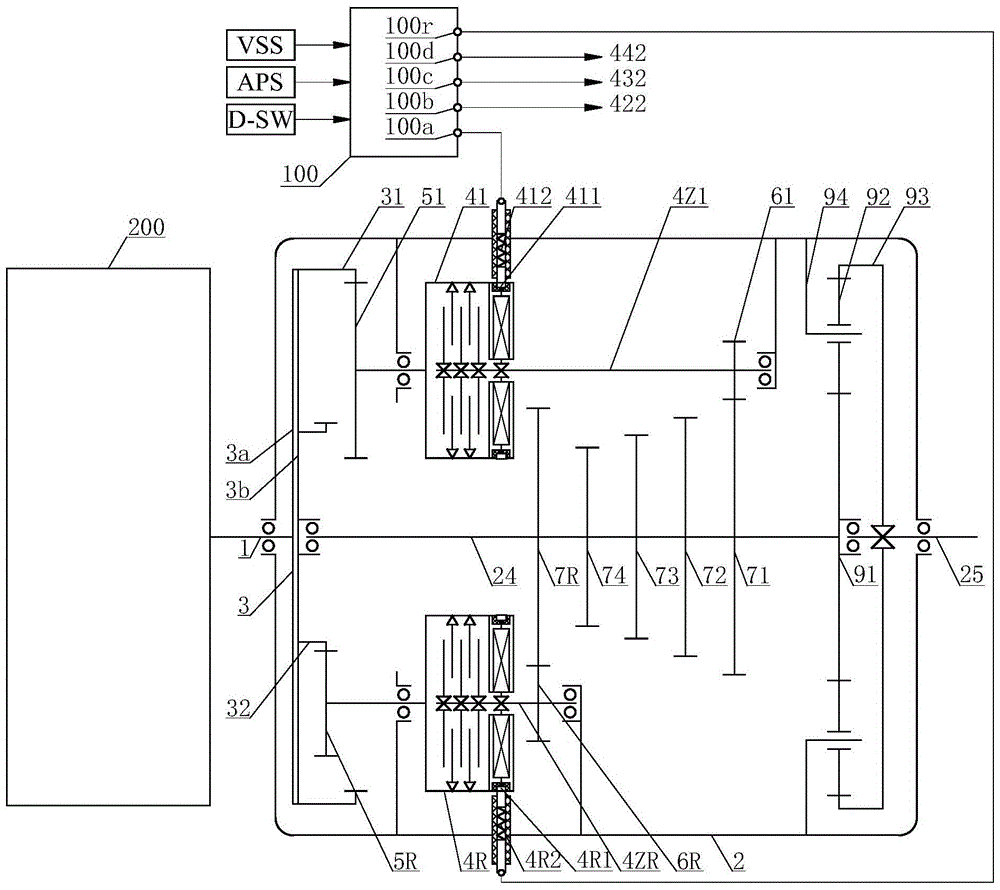

Variable-period downshift process control method of multi-gear wire-controlled automatic gearbox

InactiveCN104279317APrecise time controlMeet the requirements of downshift control cycleGearing controlAutomatic transmissionElectromagnetic clutch

The invention discloses a variable-period downshift process control method of a multi-gear wire-controlled automatic gearbox. According to the method, whether the downshift from the second gear to the first gear, the downshift from the third gear to the second gear or the downshift from the fourth gear to the third gear is needed or not is judged by an electric control unit through detecting a D gear switching signal, a vehicle speed signal v of a vehicle speed sensor and an opening degree signal Alpha of an accelerator pedal position sensor, and the electrification current control of an electromagnetic clutch in each downshift process is carried out. By taking the downshift from the third gear to the second gear as an example, the electrification current of a second gear electromagnetic clutch is controlled by the electric control unit according to a variable control period function T(v) and the electrification current function of the second gear electromagnetic clutch: I<2b>(t) ={I2, t is greater than or equal to 0 but is smaller than or equal to T<delta>; kI2+I2(1-k)(t-T<delta>) / (T<32>-T<delta>), t is greater than or equal to T<delta> but is smaller than or equal to T<32>}, meanwhile, the electrification current of a third gear electromagnetic clutch is controlled according to the electrification current function of the third gear electromagnetic clutch: I<3b>(t)={I3, t is greater than or equal to 0 but is smaller than or equal to IT<delta>; 0, t is greater than or equal to IT<delta> but is smaller than or equal to T<32>}, and the downshift process control of the wire-controlled automatic gearbox is realized. The downshift process control method has the advantages that the input power interrupt of an engine in the downshift process can be avoided, in addition, the gear shifting impact can be avoided, and the stable downshift of the wire-controlled automatic gearbox is realized.

Owner:SHANDONG UNIV OF TECH

Control method for variable-period downshift process of multi-gear-by-wire automatic transmission

InactiveCN104279317BPrecise time controlMeet the requirements of downshift control cycleGearing controlAutomatic transmissionElectromagnetic clutch

Owner:SHANDONG UNIV OF TECH

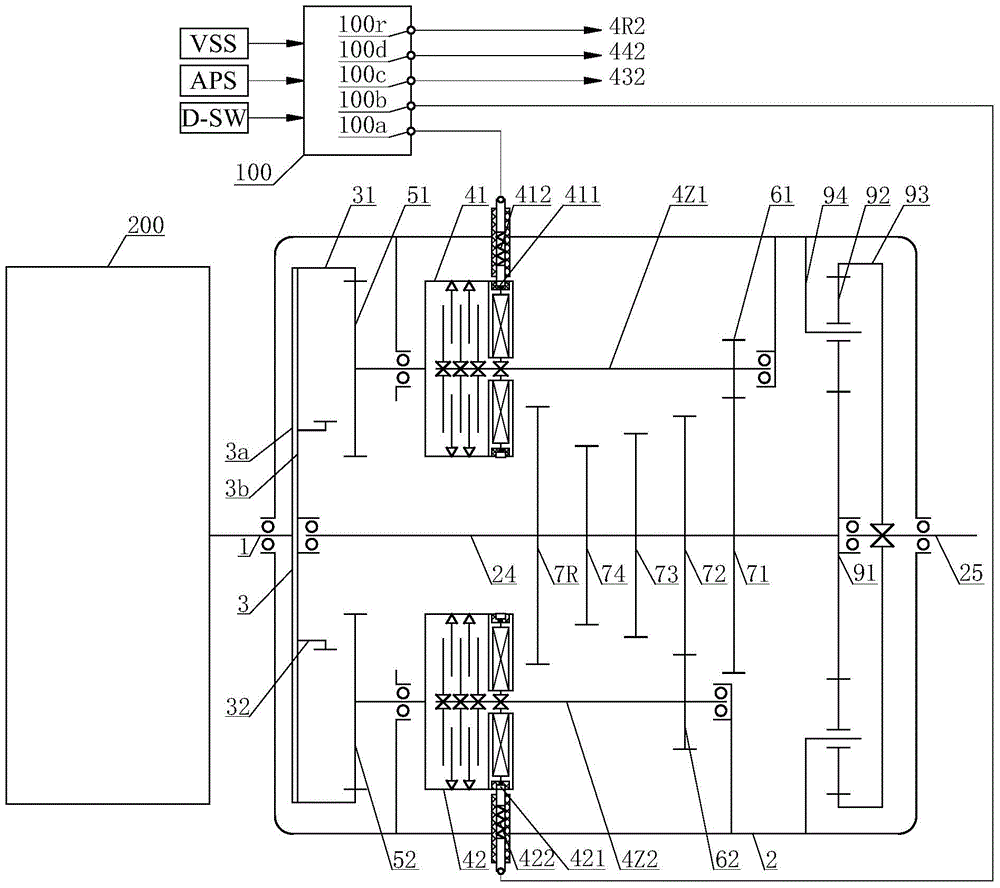

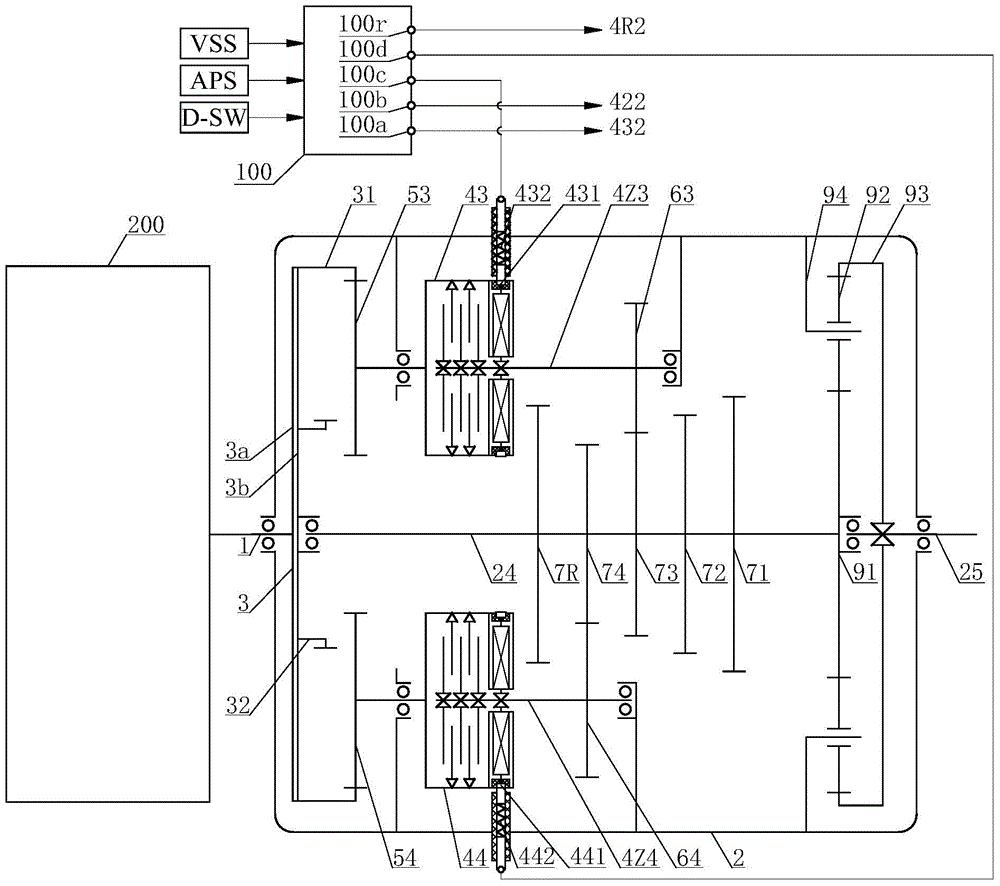

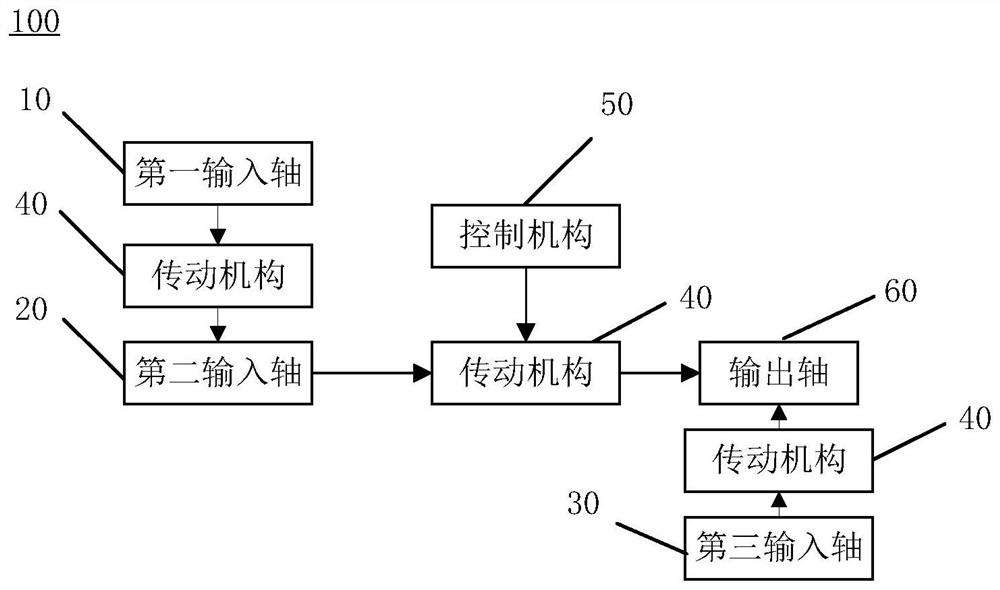

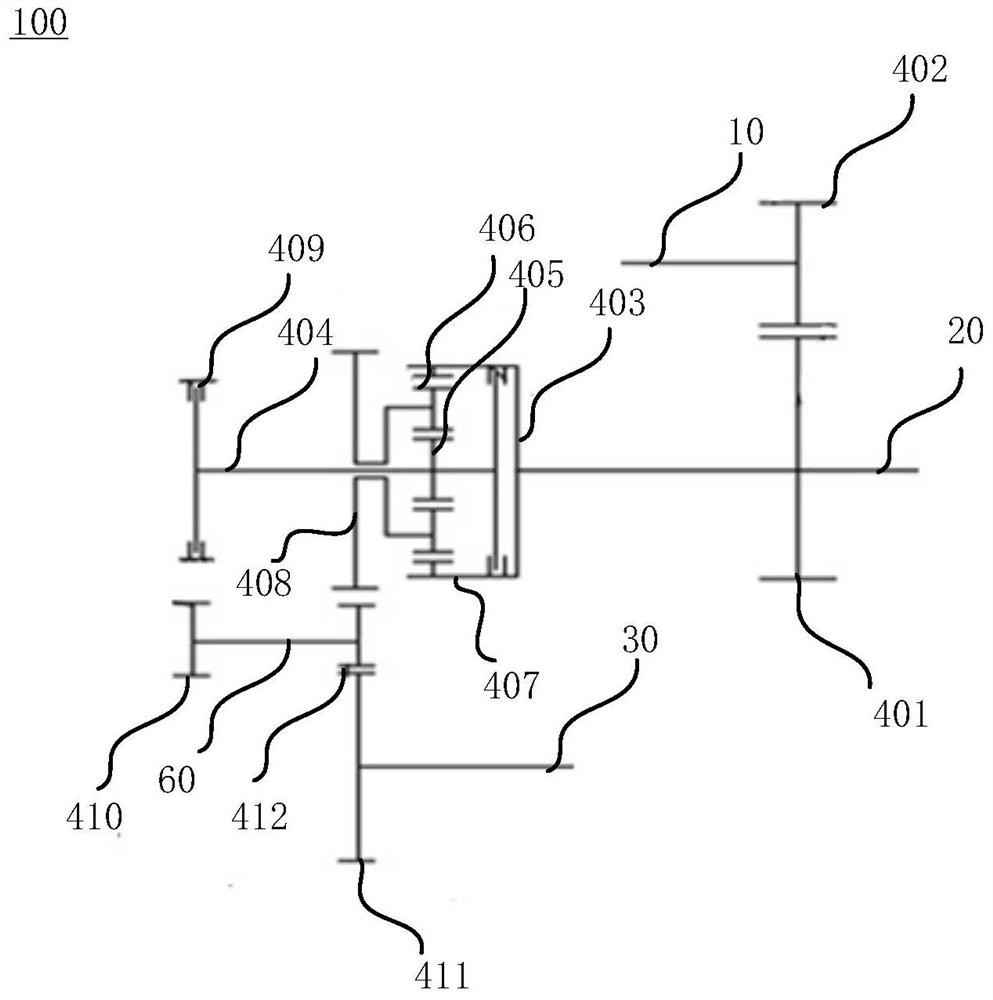

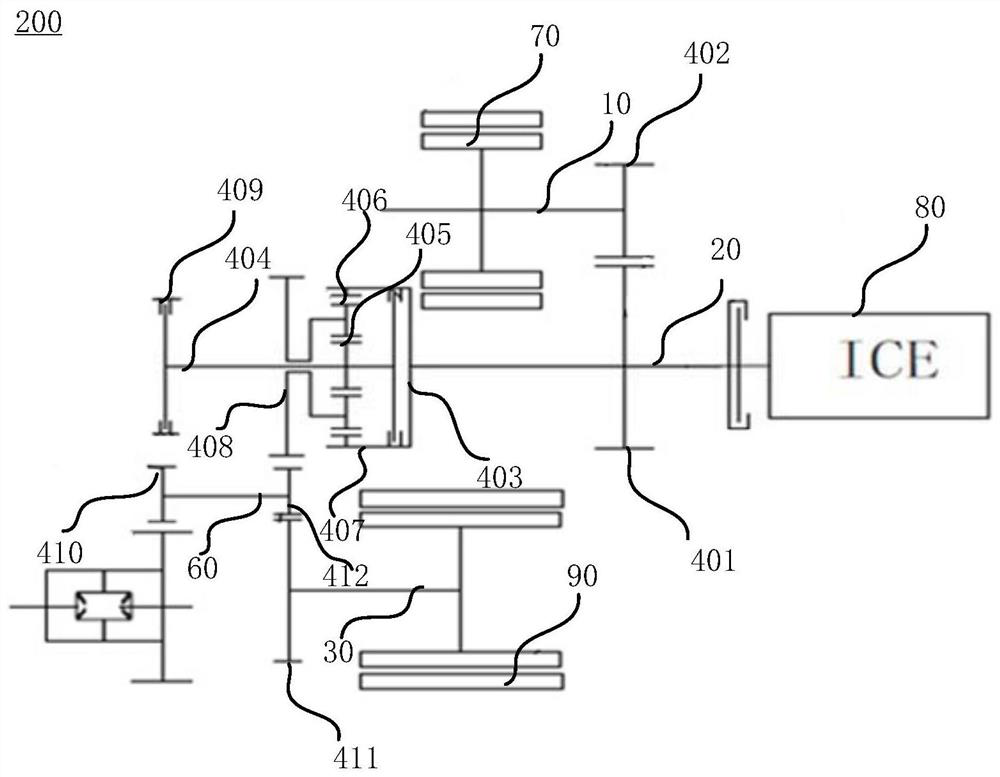

Power transmission device, power assembly and vehicle

ActiveCN112477580AImprove efficiencyAvoid shift shockHybrid vehiclesBraking element arrangementsControl powerControl engineering

The invention provides a power transmission device, a power assembly and a vehicle, and relates to the field of vehicle transmissions. The power transmission device includes a first input shaft, a second input shaft, a third input shaft, an output shaft, a transmission mechanism, and a control mechanism. The transmission mechanism is connected between the first input shaft and the second input shaft, between the second input shaft and the output shaft and between the third input shaft and the output shaft. The control mechanism is used for controlling power transmission paths of the transmission mechanism; the power transmission paths comprises the paths through which power input by the second input shaft is transmitted to the first input shaft and the output shaft at the same time, powerinput by the third input shaft is transmitted to the output shaft, power input by the second input shaft is transmitted to the output shaft, power input by the first input shaft and the second input shaft is transmitted to the output shaft at the same time, and power input by the first input shaft, the second input shaft and the third input shaft is transmitted to the output shaft at the same time. By means of the power transmission device, the efficiency of a vehicle power system can be optimal.

Owner:ZHEJIANG GEELY HLDG GRP CO LTD +3

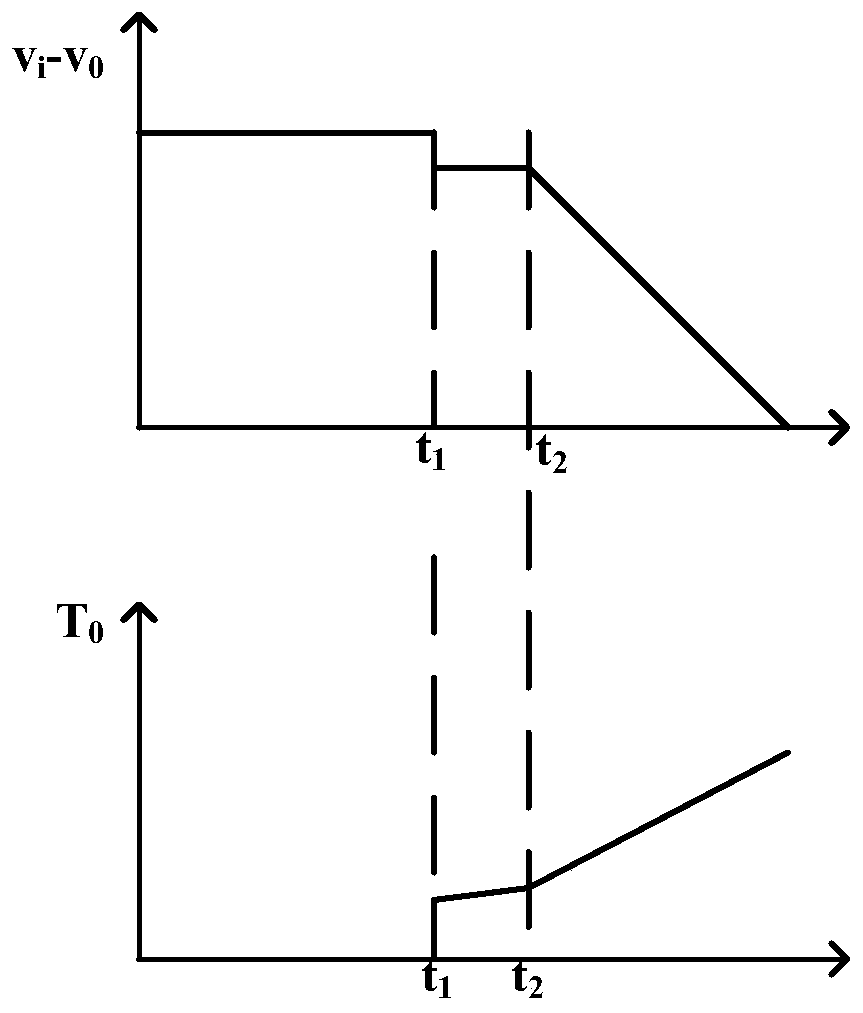

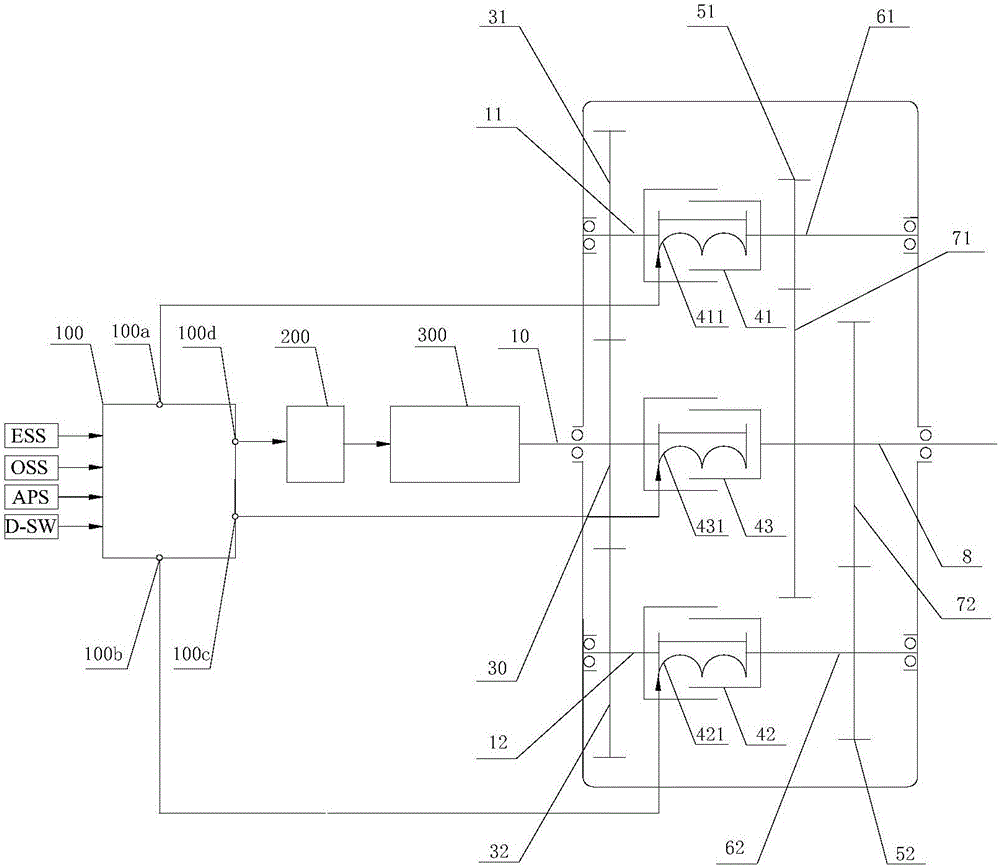

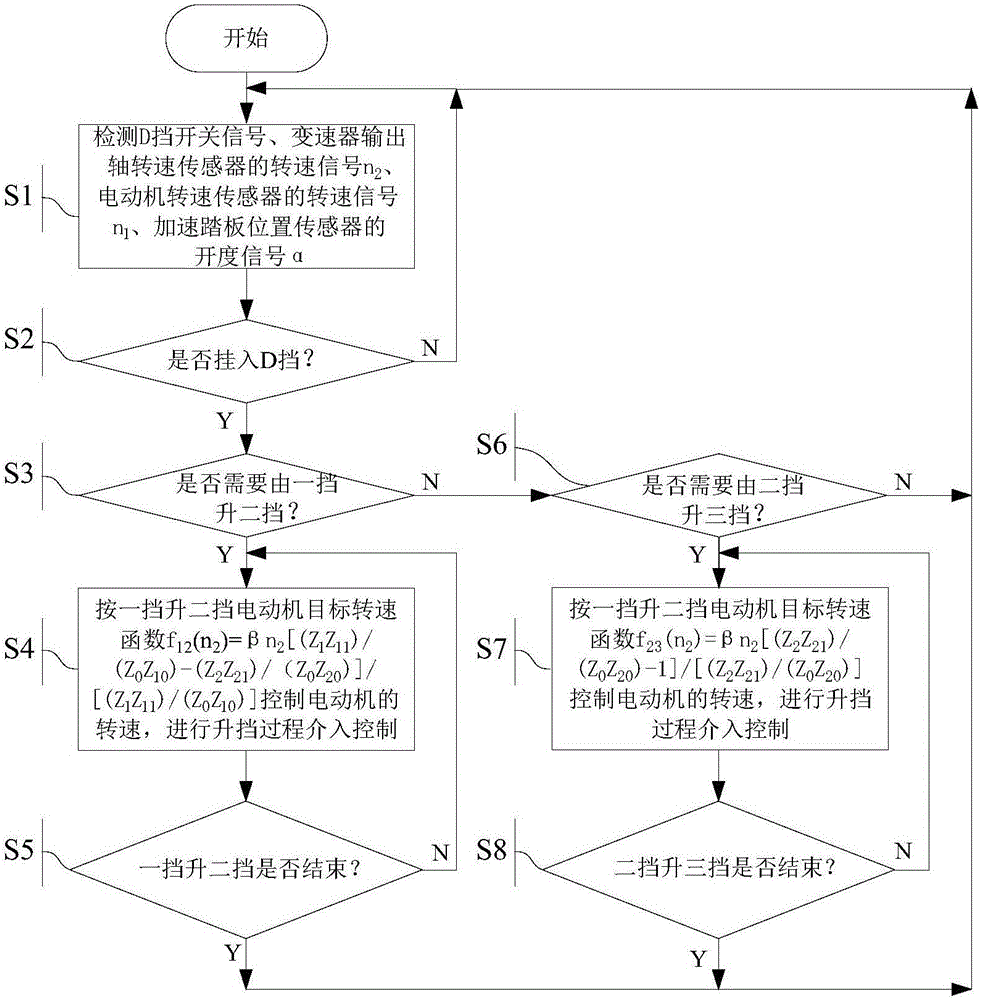

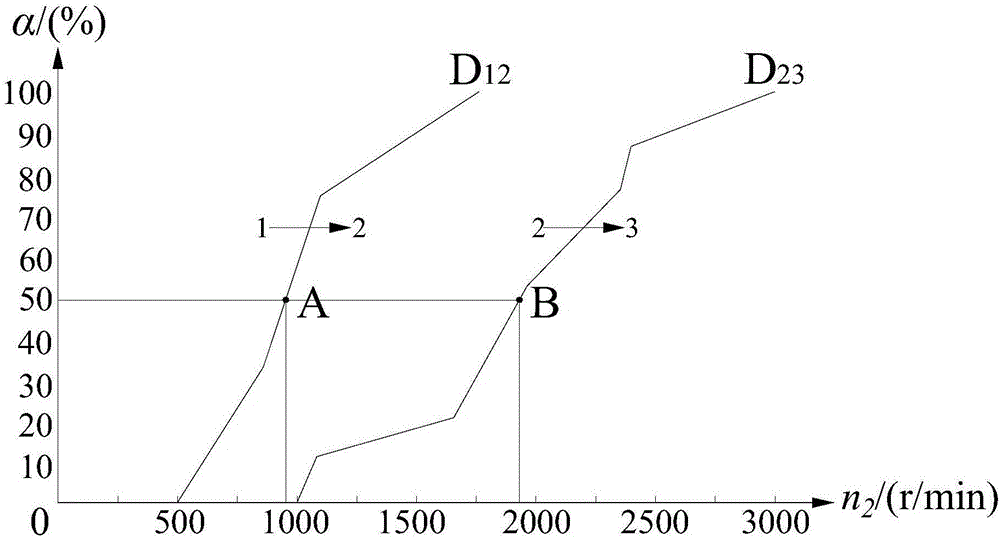

The high-speed step-up intervention control method for three-gear line control automatic transmission of electric car

The invention discloses a high-speed step-up intervention control method for the three-gear line control automatic transmission of an electric car. The method variator detects D switch signal, the rotation speed signal n2 of transmission output shaft speed sensor, the rotation speed signal n1 of motor speed sensor, opening amount signal (i) Alpha ( / i) of accelerator pedal position sensor by TCU, to determine whether there is a need for rising the second gear from first gear, rising the third gear from the second gear, and the motor speed intervention control during each upshift. For example, the first gear up to the second gear, the target rotate speed of the second-speed motor is determined according to the target rotation speed function of the second-gear-up motor, and the electric-control unit of the motor controls the rotation speed of the motor to reach the target rotation speed, carrying out the intervention control of the speed-up process of the wire-controlled automatic transmission to realize the stable speed-up of the wire-controlled automatic transmission.

Owner:SHANDONG UNIV OF TECH

Down-shift process control method of automatic multi-gear linear control speed changer

ActiveCN104500724AEliminate separation gapsLarge currentGearing controlLinear controlElectric control

The invention discloses a down-shift process control method of an automatic multi-gear linear control speed changer. The method comprises the steps of judging whether the speed changer needs to be changed from the second level to the first level, from the third level to the second level and from the fourth level to the third level by detecting a D-gear switch signal, a car speed signal (v) of a car speed sensor and an openness signal (a) of an acceleration pedal position sensor by virtue of an electric control unit, and carrying out the electrification current control of an electromagnetic clutch in each down-shift process. Taking the down shift from third level to the second level as an example, the electrification current of a second-level electromagnetic clutch is controlled by virtue of the electric control unit by taking a fixed control period T<32> according to an electrification current function that I<2b>(t) is equal to {I<1> t is less than or equal to T<theta> and more than or equal to zero; kI<1>+I<1>(1-k)(t-T<theta>) / (T<21>-T<theta>), t is more than T<theta and less than or equal to T<21>}, simultaneously the electrification current of a third-level electromagnetic clutch is controlled according to the third-level electromagnetic clutch electrification current function that I<3b>(t) is equal to {I<3>0 t is more than or equal to 0 and less than or equal to beta T<theta>; 0, t is more than beta T<theta> and less than or equal to T<32>}, so that the down-shift process control of the automatic linear control speed changer is realized; by adopting the down-shift process control method, not only can the interruption of the input power of an engine in the down-shift process be avoided, but also the gear shift impact can be avoided, and the stable down-shift of the automatic linear control speed changer can be realized.

Owner:SHANDONG UNIV OF TECH

Control method for downshift process of three-speed wire-controlled automatic transmission of electric vehicle

InactiveCN104390000BEliminate separation gapsLarge currentGearing controlEngineeringElectric vehicle

The invention discloses a downshift process control method of a three-gear wire control automatic transmission of an electric vehicle. The method uses an electric control unit for judging if a second gear is required to be reduced to a first gear and a third gear is required to be reduced to the second gear through detecting a signal of a D-gear switch, a vehicle speed signal (v) of a vehicle speed sensor and an openness signal (a) of a motor acceleration pedal position sensor, and controls the electrification current of electromagnetic clutches in each downshift process. Taking the reduction from the third gear to the second gear as an example, the electric control unit controls the electrification current of a second-gear electromagnetic clutch according to an electrification current function I2b(t)={I2, t is not smaller than 0 and not greater than T delta; kI2+I2(1-k)(t-T delta) / (T32-T delta), t is greater than T delta and not greater than T32} of the second-gear electromagnetic clutch in a fixed control period T32, and controls the electrification current of a third-gear electromagnetic clutch according to an electrification current function I3b(t)={I3, t is not smaller than 0 and not greater than b T delta; 0, t is greater than b T delta and not greater than T32} of the third-gear electromagnetic clutch, so as to realize the downshift process control of the wire control automatic transmission. The downshift process control method not only can prevent the interruption of input power of the motor in the downshift process, but also can prevent the gear shift impact to realize smooth downshift of the wire control automatic transmission.

Owner:SHANDONG UNIV OF TECH

Upshift process control method of electric vehicle three-speed wire-controlled automatic transmission

InactiveCN104389997BEliminate separation gapsLarge currentGearing controlElectric vehicleElectric control

The invention discloses a upshift process control method of a three-gear wire control automatic transmission of an electric vehicle. The method uses an electric control unit for judging if a first gear is required to be risen to a second gear and the second gear is required to be risen to a third gear through detecting a signal of a D-gear switch, a vehicle speed signal (v) of a vehicle speed sensor and an openness signal (a) of a motor acceleration pedal position sensor, and controls the electrification current of electromagnetic clutches in each upshift process. Taking the rising from the second gear to the third gear as an example, the electric control unit controls the electrification current of a third-gear electromagnetic clutch according to an electrification current function I3b(t)={I3, t is not smaller than 0 and not greater than T delta; kI3+I3(1-k)(t- T delta) / (T23-T delta), t is greater than T delta and not greater than T23} of the third-gear electromagnetic clutch in a fixed control period T23, and controls the electrification current of a second-gear electromagnetic clutch according to an electrification current function I2b(t)={I2, t is not smaller than 0 and not greater than b T delta; 0, t is greater than b T delta and not greater than T23} of the second-gear electromagnetic clutch, so as to realize the upshift process control of the wire control automatic transmission. The upshift process control method not only can prevent the interruption of input power of the motor in the upshift process, but also can prevent the gear shift impact to realize smooth upshift of the wire control automatic transmission.

Owner:SHANDONG UNIV OF TECH

Clutch petal assembly

The invention relates to a vehicle clutch control system or part, in particular to a clutch petal assembly. A clutch petal upper switch, a clutch petal lower switch and a clutch petal self-limiting mechanism are arranged on a clutch support body, a crushing nut is connected to an upper support in a riveted mode, and a return spring is further arranged on a shaft sleeve between the upper support and a lower support. When a clutch is stepped, the upper switch is connected, an engine control unit receives a signal of the upper switch, the ignition advance angle is decreased, the oil spraying amount is decreased, power storage is carried out, the gear shifting impact is avoided, the service life of a clutch system is prolonged, and oil consumption is reduced. When a clutch pedal is stepped tothe bottom, the clutch system is disconnected, the clutch petal lower switch is connected, a clutch system disconnection signal is provided for a keyless entry system, and safe starting of an automobile is ensured. Through the crushing nut, the situations that when the automobile is collided, a clutch main cylinder moves backwards and is disengaged from the upper support, the clutch petal rotatesaround the mounting point of the crushing nut and an instrument cross beam support, and consequently a left shank is hurt can be prevented.

Owner:BRILLIANCE AUTO

Shift control method, system and vehicle of automatic transmission

The invention provides a gear shifting control method and system of an automatic gearbox and a vehicle. The method comprises the steps that when up-shift of the automatic gearbox is controlled through initial gear shifting control pressure, the actual time T1 from the up-shift starting time to the time when the rotating speed of a turbine is reduced by the preset rotating speed is detected; the T1 is compared with the standard time T2 from the up-shift starting time of the automatic gearbox to the time when the rotating speed of the turbine is reduced by the preset rotating speed; if the difference value of the T1 and the T2 exceeds an error allowance range, the initial gear shifting control force is adjusted according to the difference value of the T1 and the T2, wherein the larger the difference value, the larger the adjusted gear shifting control pressure is. By means of the gear shifting control method of the automatic gearbox, the gear shifting impact can be lowered or avoided, gear shifting can be smoother, the abruptness occurring in the gear shift process can be reduced and even eliminated, and the riding comfort is improved.

Owner:GREAT WALL MOTOR CO LTD

Downshift process control method of multi-block automatic transmission by wire

ActiveCN104500724BEliminate separation gapsLarge currentGearing controlLinear controlElectric control

The invention discloses a down-shift process control method of an automatic multi-gear linear control speed changer. The method comprises the steps of judging whether the speed changer needs to be changed from the second level to the first level, from the third level to the second level and from the fourth level to the third level by detecting a D-gear switch signal, a car speed signal (v) of a car speed sensor and an openness signal (a) of an acceleration pedal position sensor by virtue of an electric control unit, and carrying out the electrification current control of an electromagnetic clutch in each down-shift process. Taking the down shift from third level to the second level as an example, the electrification current of a second-level electromagnetic clutch is controlled by virtue of the electric control unit by taking a fixed control period T<32> according to an electrification current function that I<2b>(t) is equal to {I<1> t is less than or equal to T<theta> and more than or equal to zero; kI<1>+I<1>(1-k)(t-T<theta>) / (T<21>-T<theta>), t is more than T<theta and less than or equal to T<21>}, simultaneously the electrification current of a third-level electromagnetic clutch is controlled according to the third-level electromagnetic clutch electrification current function that I<3b>(t) is equal to {I<3>0 t is more than or equal to 0 and less than or equal to beta T<theta>; 0, t is more than beta T<theta> and less than or equal to T<32>}, so that the down-shift process control of the automatic linear control speed changer is realized; by adopting the down-shift process control method, not only can the interruption of the input power of an engine in the down-shift process be avoided, but also the gear shift impact can be avoided, and the stable down-shift of the automatic linear control speed changer can be realized.

Owner:SHANDONG UNIV OF TECH

A gear control method, device and medium

ActiveCN110985660BAvoid shift shockImprove driving experienceGearing controlAutomatic transmissionElectrical and Electronics engineering

Owner:ZHEJIANG GEELY HLDG GRP CO LTD +1

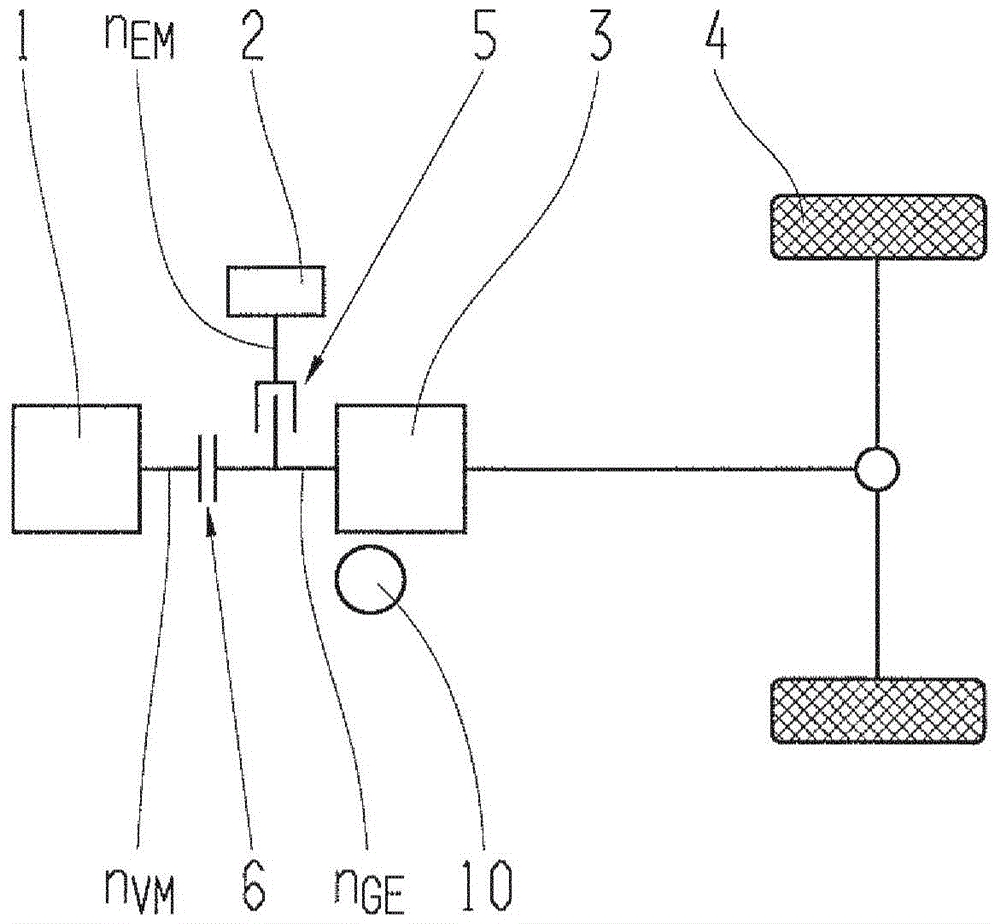

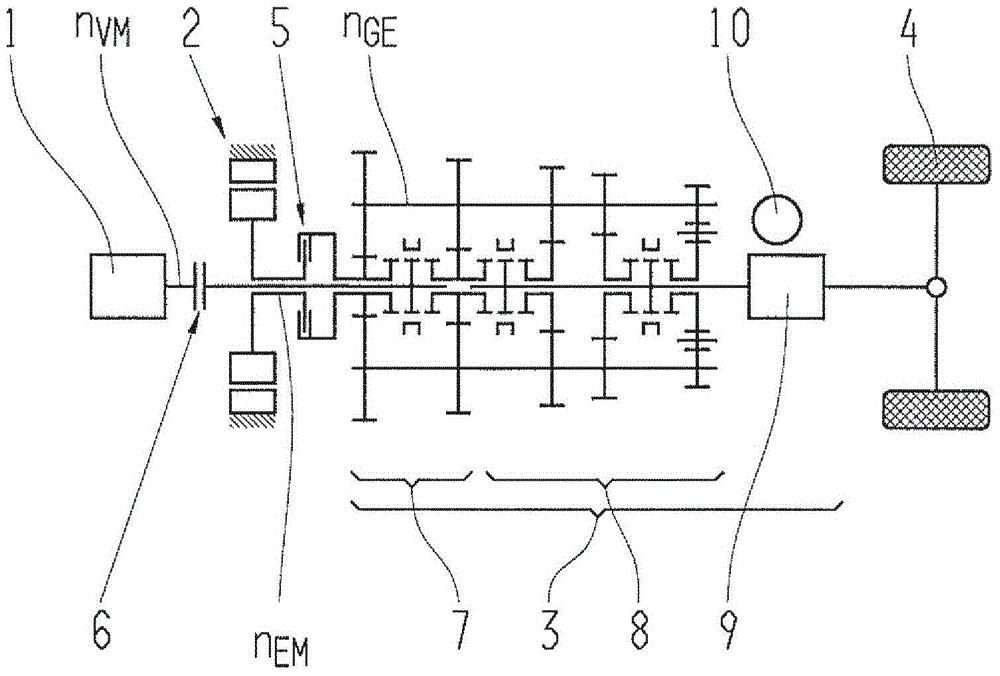

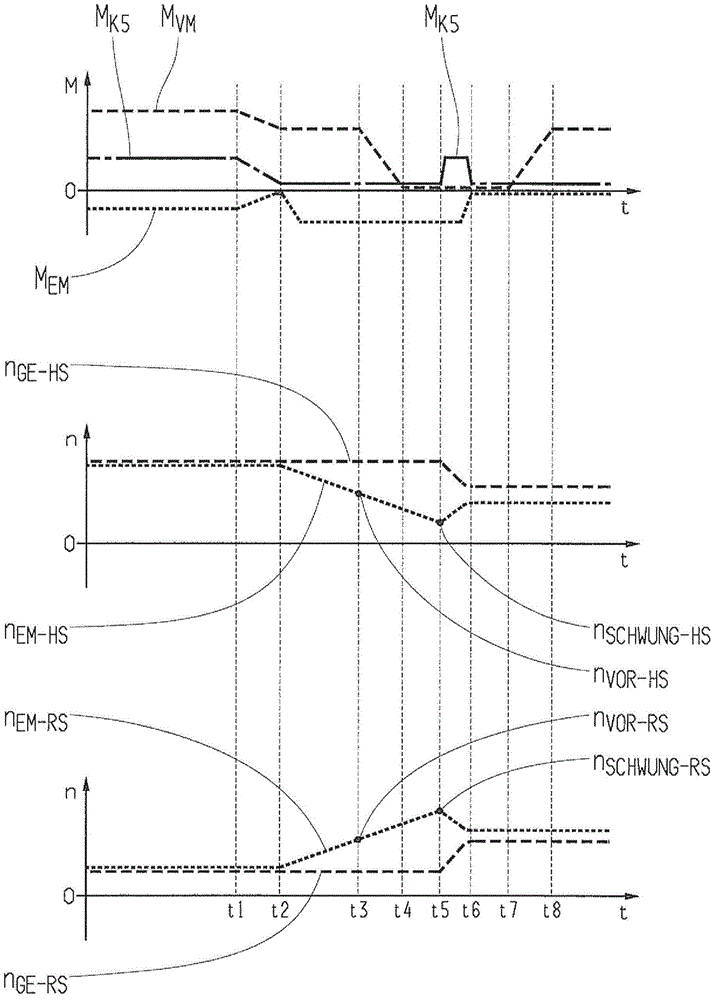

Method for operating drive train and control device

InactiveCN103889806BSmall drive torqueSimple structureHybrid vehiclesToothed gearingsElectric machineOutput device

A method for operating a drive train of a hybrid vehicle having a hybrid drive comprising at least one electric machine (2) and an internal combustion engine (1), wherein an indirect connection between the internal combustion engine (1) and an output device (4) There is an automatic shift transmission (3), wherein the electric motor (2) is coupled to the shaft of the automatic shift transmission (3) via a friction clutch (5), and wherein, in the automatic shift transmission (3), the interruption is made by mixing With the drive torque available at the output, the drive implements a shift in such a way that the drive torque available at the output (4) is first reduced in a first phase and then carried out in a second phase The actual gear change, and then in the third phase, the drive torque is built up again at the output (4), wherein, to carry out the actual gear change, after disengaging the actual gear and before engaging the target gear , the gearshift transmission (3) is synchronized in such a way that the rotational inertial mass of the electric motor is fully utilized, that is, when the friction clutch (5) is opened, the rotational speed of the electric motor (2) is brought to the inertial rotational speed, and subsequently For the rotational inertia synchronization of the gearshift transmission, the friction clutch (5) is first engaged and then at least partially opened again.

Owner:ZF FRIEDRICHSHAFEN AG

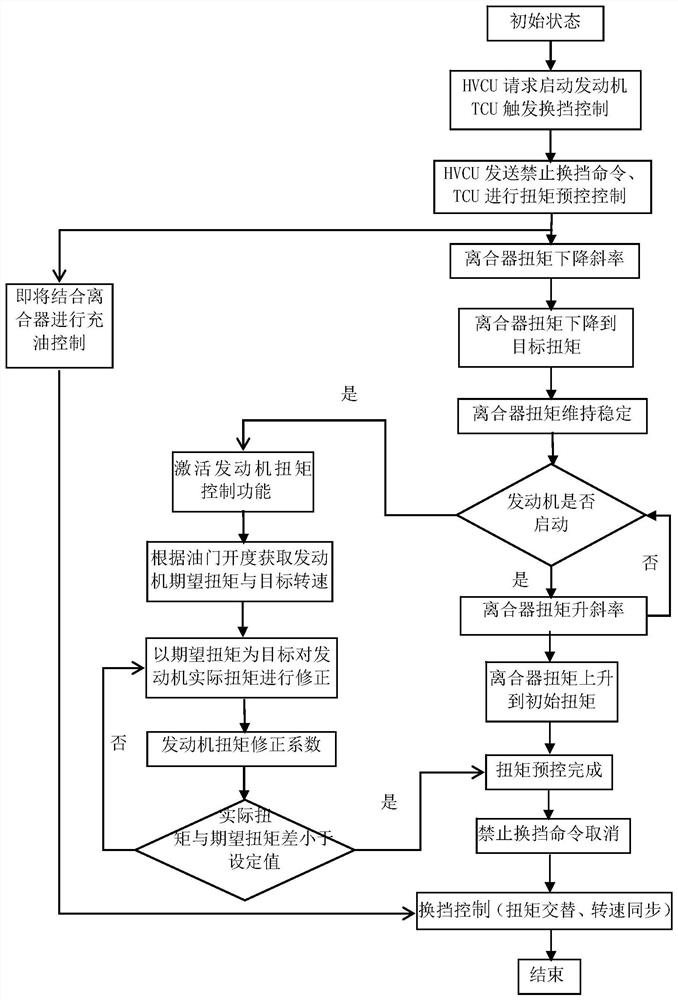

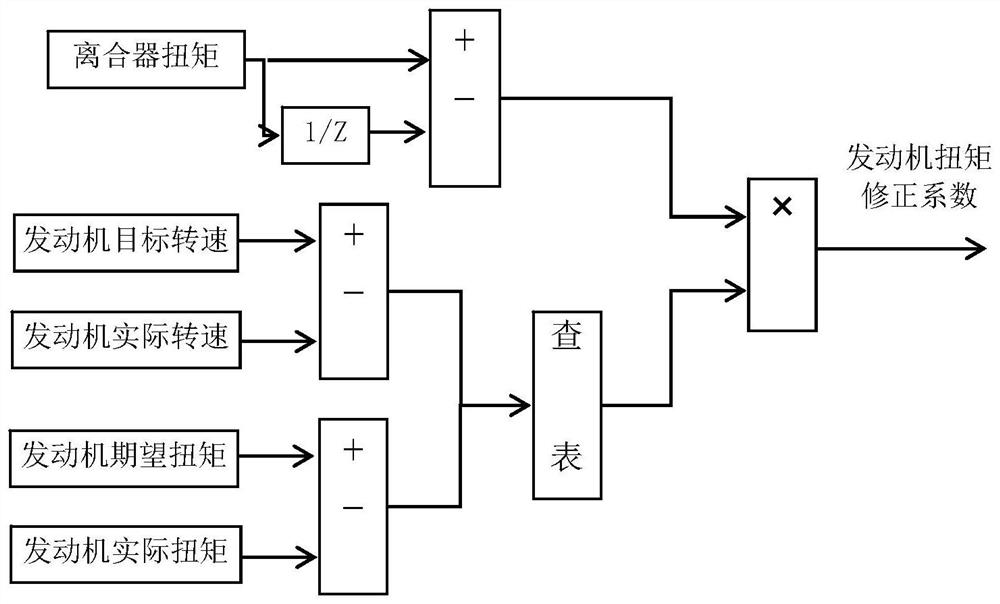

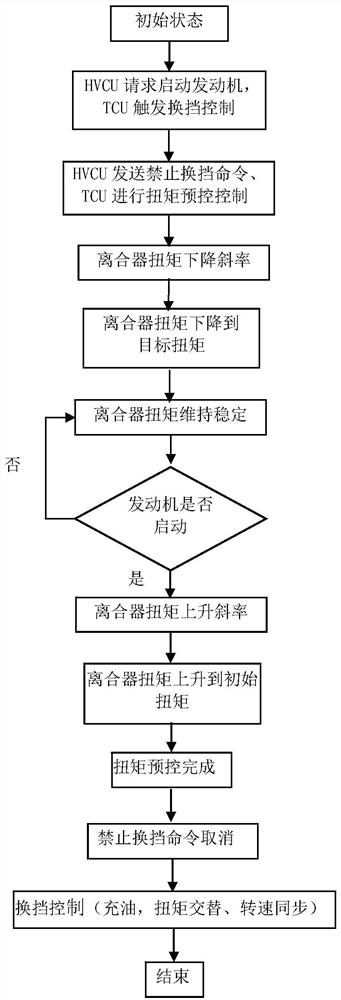

Automatic transmission torque pre-control and shift coordination control method, device and vehicle

ActiveCN112196995BTorque stabilizationIntervention StabilizationClutchesGearing controlAutomatic transmissionControl theory

The invention discloses an automatic gearbox torque pre-control and shift coordination control method, device and automobile. This method optimizes the control logic. If the torque pre-control and shift control are not triggered at the same time, the gearbox will perform normal torque pre-control; The engine torque intervention is carried out during the process, and when the engine torque is stable, the torque pre-control control is exited and the subsequent shift control is entered. The present invention has already completed the clutch oil filling in the torque pre-control, increases the intervention of the engine torque, ensures that both the clutch torque and the engine torque remain stable during the torque pre-control, and proposes a new method when simultaneously triggering shifting and torque pre-control The new strategy, in the process of torque pre-control, the clutch that is about to be combined is controlled by oil filling, which reduces the subsequent shift time, and also avoids the shift shock caused by torque fluctuations when the torque pre-control directly enters the shift control.

Owner:ANHUI UNIVERSITY OF ARCHITECTURE

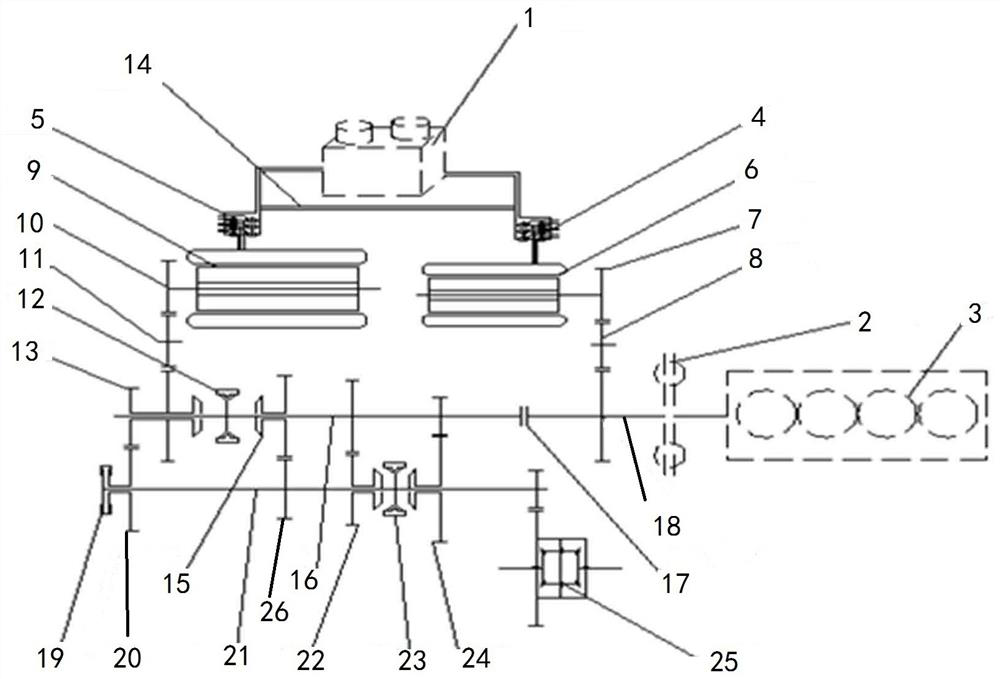

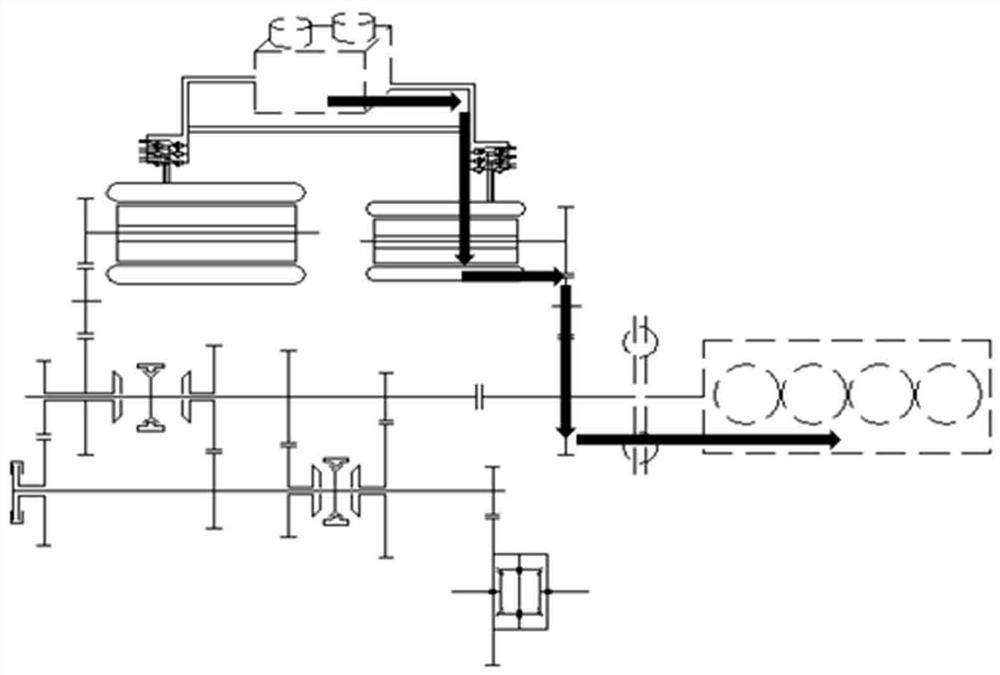

A series-parallel hybrid transmission

ActiveCN111497594BReduce fuel consumptionImprove powerGas pressure propulsion mountingPlural diverse prime-mover propulsion mountingGear wheelElectric machinery

A series-parallel hybrid transmission, including a transmission device, a wiring harness, a shock absorber, an internal combustion engine, and a controller. The transmission device includes a battery and a battery management system, and the battery is connected to the first inverter and the second inverter , the first inverter is connected to the first motor, the output end of the first motor is provided with a first gear, the first gear is connected to the second input shaft through the first idler gear, the second inverter is connected to the second motor, The output end of the second motor is provided with a second gear, and the second gear is connected with the first input shaft through the second idler gear. The first input shaft is provided with a first synchronizer and a fourth-speed main gear. The clutch is connected to the second input shaft, and the second input shaft is connected to the internal combustion engine through the shock absorber. By adopting the above-mentioned structure, the fuel consumption can be reduced as much as possible, the impact of gear shifting can be reduced, and the power performance can be improved.

Owner:CHINA THREE GORGES UNIV

Control method for variable-period upshifting process of multi-gear-by-wire automatic transmission

ActiveCN104315135BPrecise time controlMeet the requirements of upshift control cycleGearing controlTransmission elementsAutomatic transmissionElectromagnetic clutch

The invention discloses a method for controlling the variable-period upshifting process of a multi-gear-by-wire automatic transmission. In the method, the electronic control unit detects the switch signal of the D gear, the vehicle speed signal v of the vehicle speed sensor, and the opening degree signal α of the accelerator pedal position sensor. Determine whether it is necessary to upgrade from the first gear to the second gear, from the second gear to the third gear, and from the third gear to the fourth gear, and carry out the current control of the electromagnetic clutch in each gear up process. Taking the second gear to the third gear as an example, the electronic control unit controls the cycle function T(v) variablely, and at the same time presses the third gear electromagnetic clutch current function I3b(t)={I3,0≤t≤Tδ;kI3+ I3(1‑k)(t‑Tδ) / (T23‑Tδ),Tδ

Owner:SHANDONG UNIV OF TECH

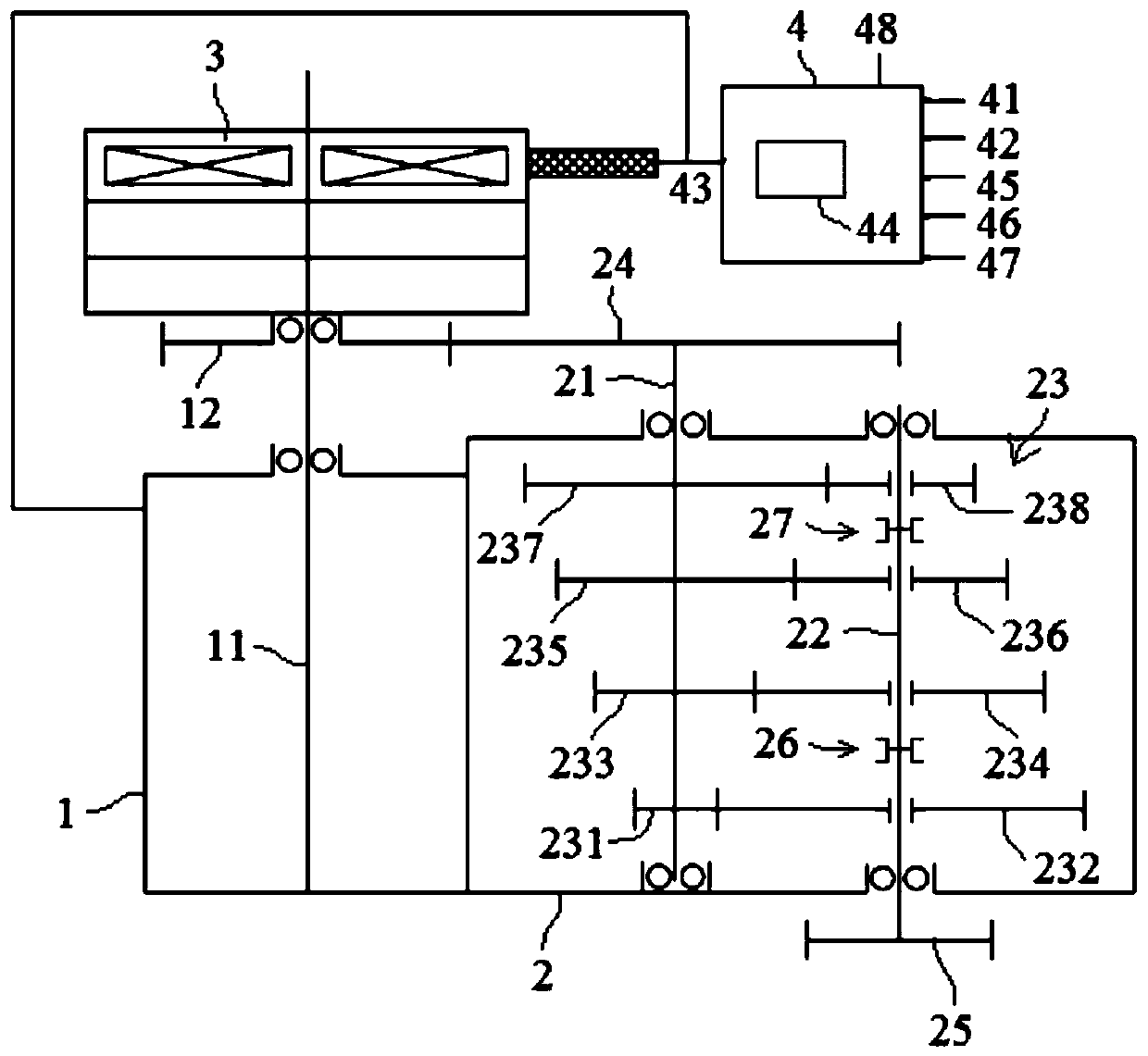

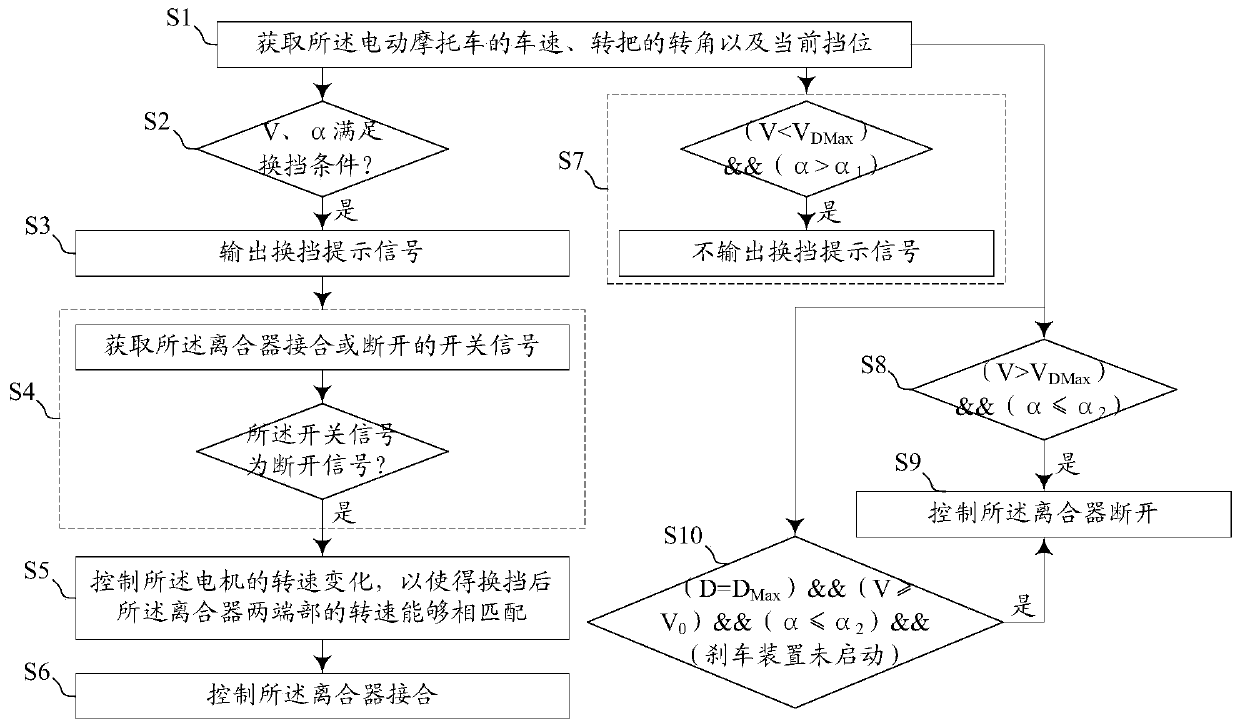

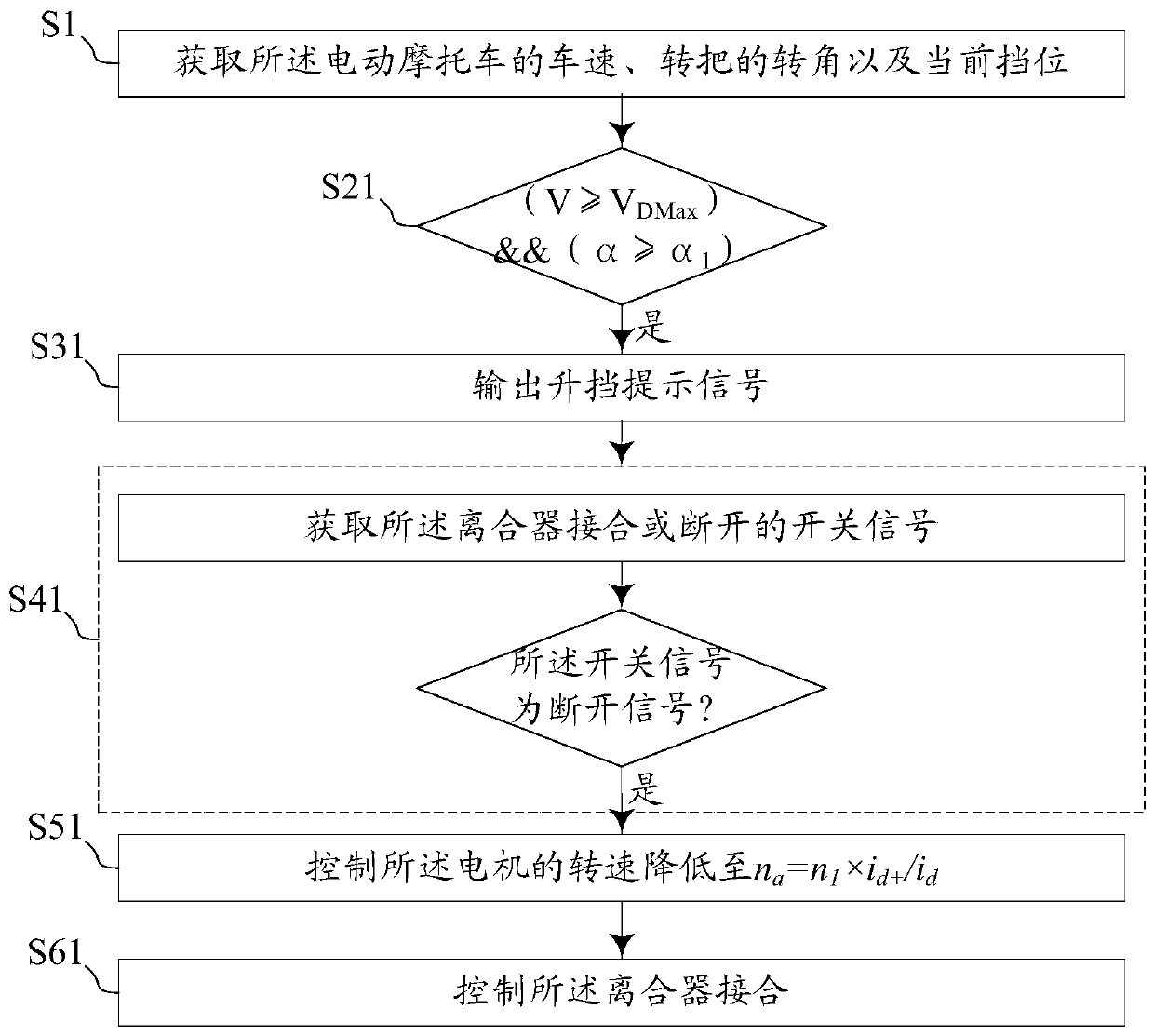

Electric motorcycle and power assembly and control method thereof

PendingCN109703358AEfficient working stateAvoid long workSpeed controllerElectric energy managementPower batteryPower flow

The invention discloses an electric motorcycle as well as a power assembly and a control method thereof, wherein the power assembly comprises a motor, a gearbox and a clutch; the gearbox is provided with a plurality of gears, and the clutch can be connected with a rotating shaft of the motor and an input shaft of the gearbox. The power assembly further comprises the gearbox that is provided with aplurality of gears so as to provide different speed ratios; according to the technical scheme, different speed ratios can be provided; the motor can be kept in an efficient working state in a large vehicle speed interval through gear shifting; the motor can be prevented from working in a limit rotating speed state for a long time to a large extent, the large-current discharging time of a power battery pack can be shortened, and the cruising ability and the service life of the power battery pack can be guaranteed.

Owner:BAFANG ELECTRIC (SUZHOU) CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com