Touch Point Adjusting Method For Dct

An adjustment method and contact point technology, applied in the direction of elements with teeth, non-mechanical drive clutches, clutches, etc., can solve the problem of no reliable adjustment, and achieve the effects of reliable control, durability improvement, and value enhancement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Reference will now be made in detail to various embodiments of the invention, examples of which are illustrated in the accompanying drawings and described below. While the invention has been described in conjunction with exemplary embodiments, it will be understood that present description is not intended to limit the invention to those exemplary embodiments. On the contrary, the invention is intended to cover not only the exemplary embodiments, but also alterations, modifications, equivalents and other embodiments as included within the spirit and scope of the invention as defined by the claims.

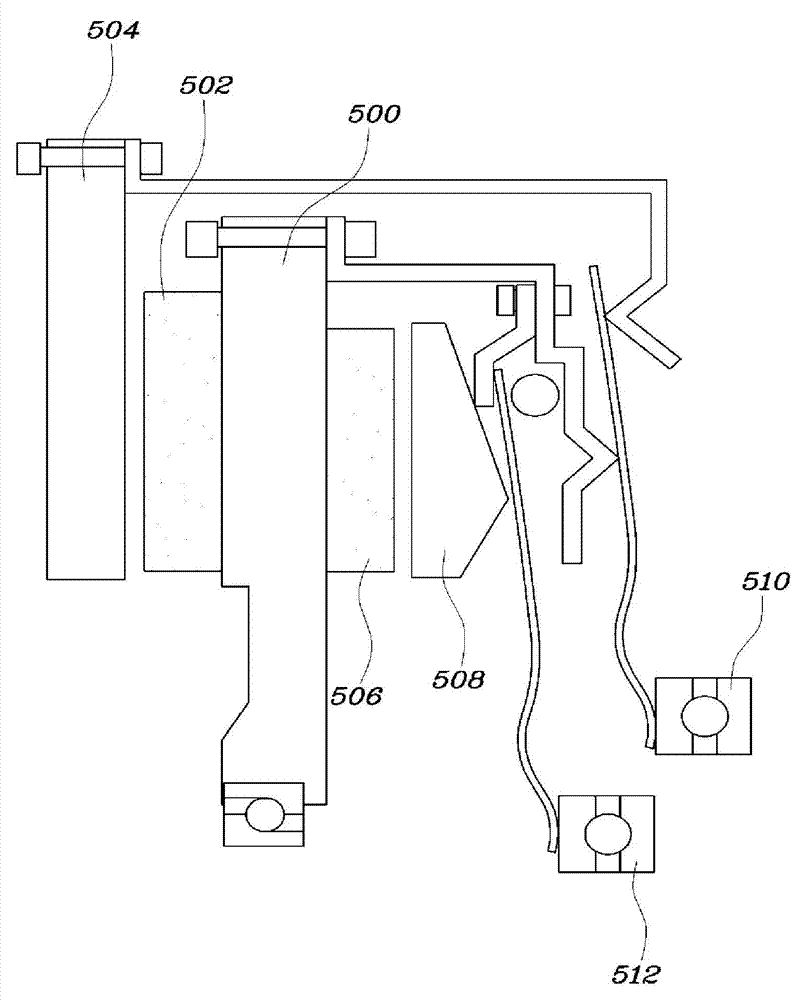

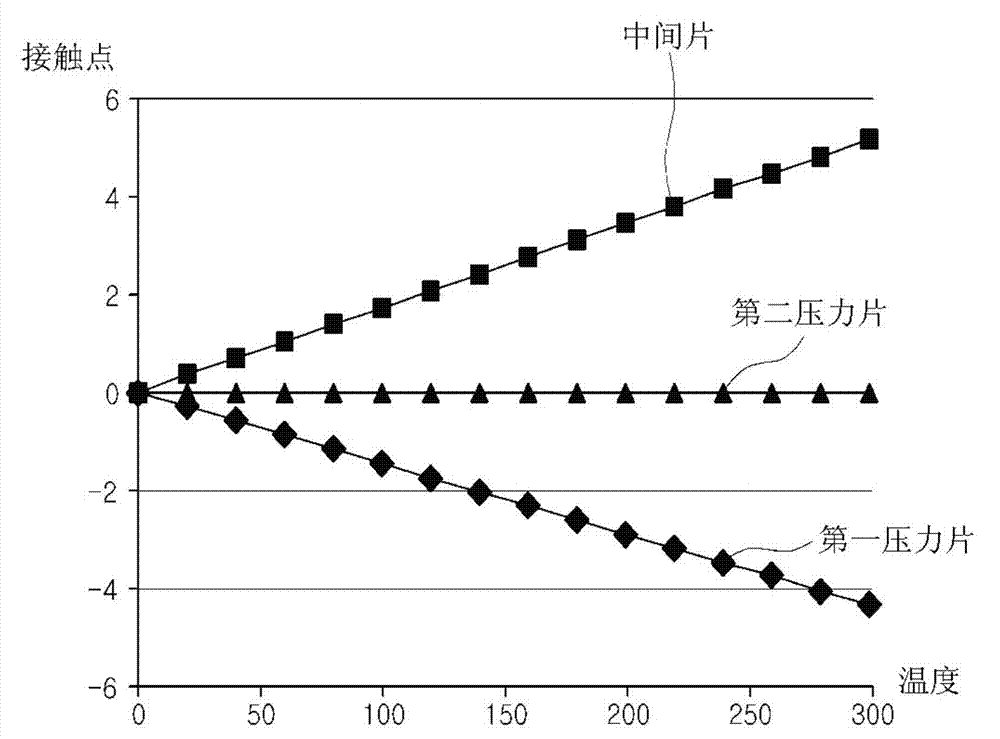

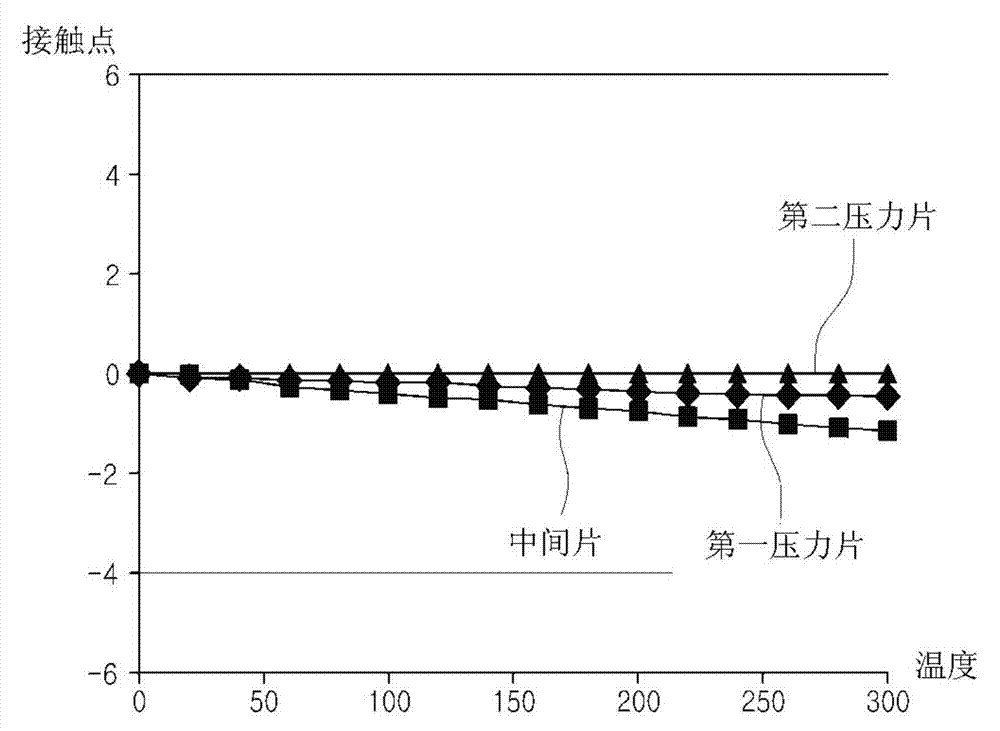

[0028] refer to Figure 4 with Figure 5 , according to an exemplary embodiment of the present invention, an exemplary embodiment of a contact point adjustment method for a dual clutch transmission (DCT) includes: an individual adjustment calculation step S10, an overall adjustment calculation step S40, and an adjustment step S50, the individual adjustment calculation step ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com