Gear shifting handle

A technology for shifting handles and gears, applied to components with teeth, belts/chains/gears, mechanical equipment, etc., can solve problems such as complexity, inflexibility, and complex structure, and achieve simple mechanical structure and reasonable design , Increase the effect of application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

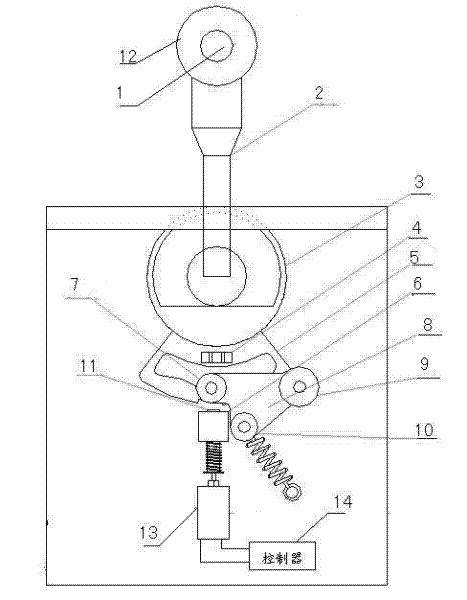

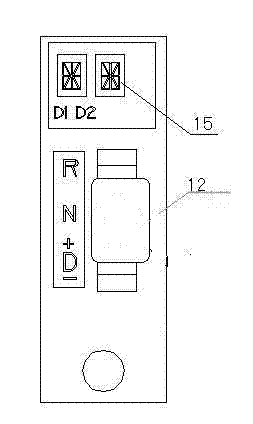

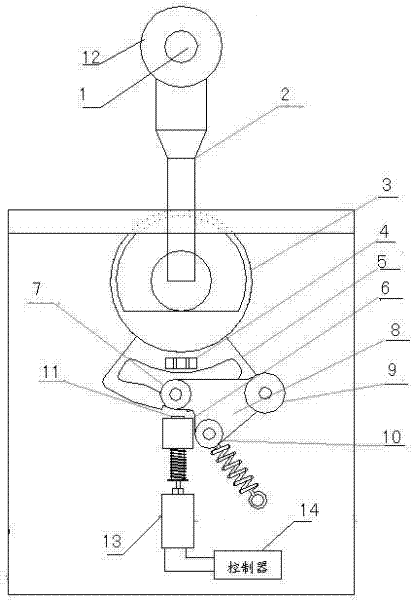

[0013] a shift lever such as figure 1 and figure 2 As shown, it includes a controller 14 and an operating mechanical unit. The controller 14 issues control instructions to assist in controlling the operation of the operating mechanical unit; the operating mechanical unit includes an unlock button 1, an operating rod 2, a round handle block 3, a magnet block 4, and a gear position Limiting block 5, fixed block 6, gear position limiting spring block 8, iron post 11, operating rod handle 12, electromagnet 13. Among them, the three ends of the gear limit spring block are respectively provided with a fixed wheel 9, a spring tension wheel 10, and an embedded wheel 7; On the lower end side of the operating rod 1 is connected with the round handle block 3, the center of the round handle block 3 is fixed, the gear limit block 5 and the round handle block 3 are connected together, the gear limit block 5 has three grooves, the corresponding The handle 12 of the operating rod is provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com