Patents

Literature

162results about How to "Limit the range of activities" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

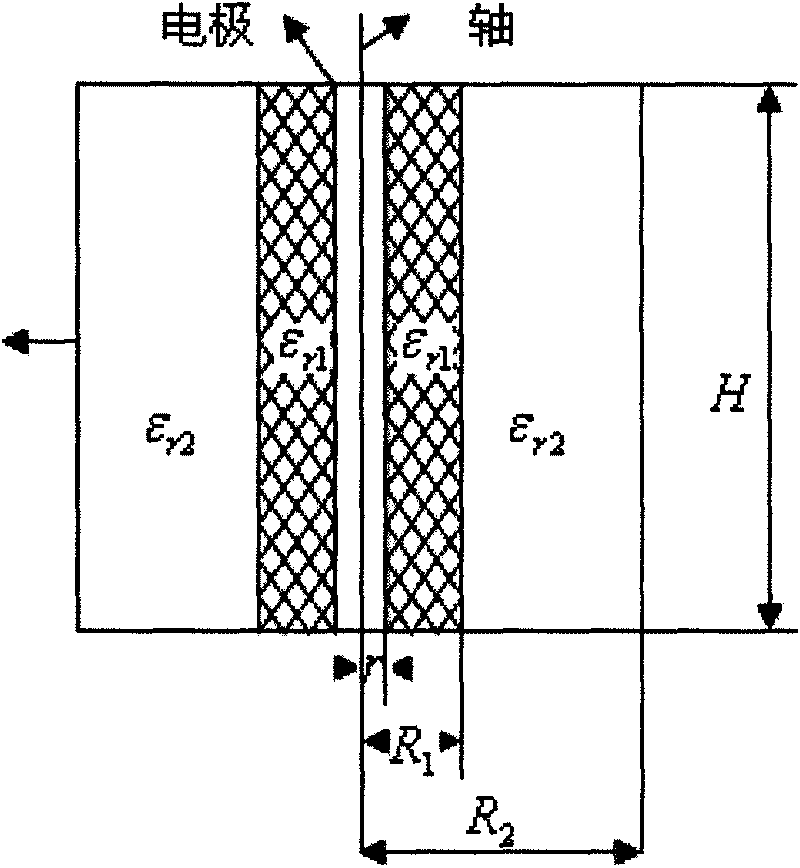

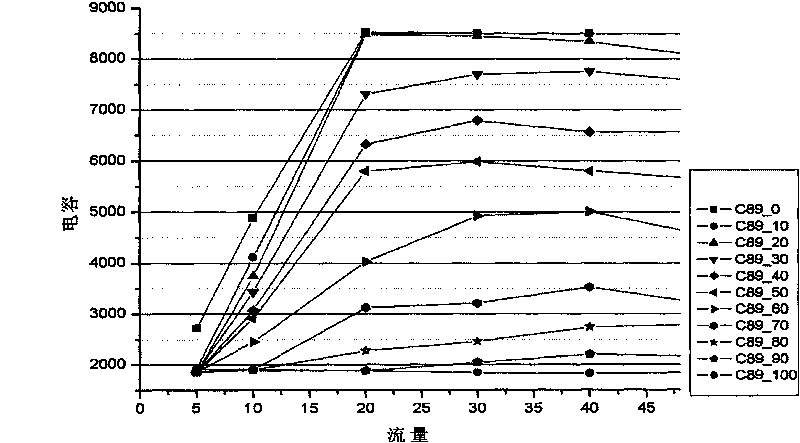

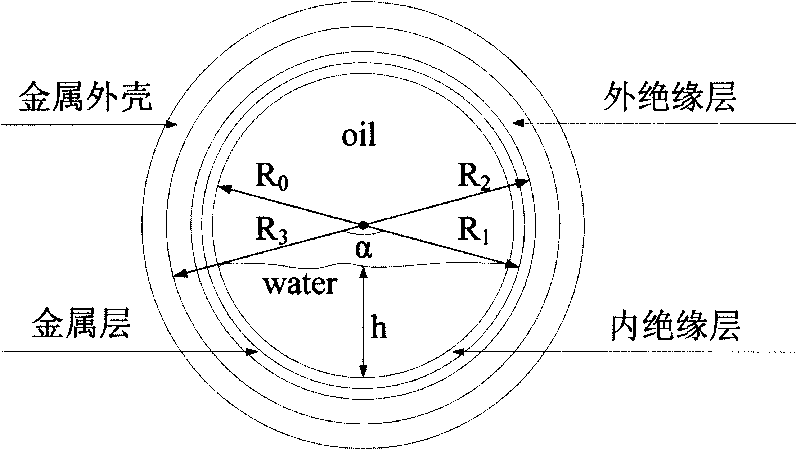

Combined sensor applied to measurement of water ratio in oil well

ActiveCN101737041ABroaden the response rangeIncrease chance of stickingMaterial capacitanceBorehole/well accessoriesImage resolutionOil water

The invention discloses a combined sensor applied to measurement of a water ratio in an oil well and mainly solves the problem that the measurement resolution of common sensors for the water ratio is reduced under the condition of low-flow oil-water stratified flows in the prior art. The combined sensor applied to the measurement of the water ratio in the oil well is characterized in that: an electrode rod of a coaxial capacitance sensor is embedded at the central position of a tubular capacitance sensor; the electrode rod consists of an inserted electrode bar and an insulating layer coated outside thereof; the inserted electrode bar in the electrode rod is connected in parallel with a metal tubular electrode; the two electrodes are subjected to sealing treatment to insulate from a shell, and leads of the two electrodes are led out to connect the same exciter in a parallel connection mode on a circuit; and the metal shell serves as a grounding terminal. Compared with the conventional tubular sensors and coaxial capacitance measurement sensors, the combined sensor has wider response range when the oil water stratified flows flow in the sensor; under the condition of no stratified flows, the structure of the combined sensor increases an effective area in contact with oil bubbles, and limits the range of activity of the oil bubbles, thereby improving the measurement resolution.

Owner:DAQING OILFIELD CO LTD +1

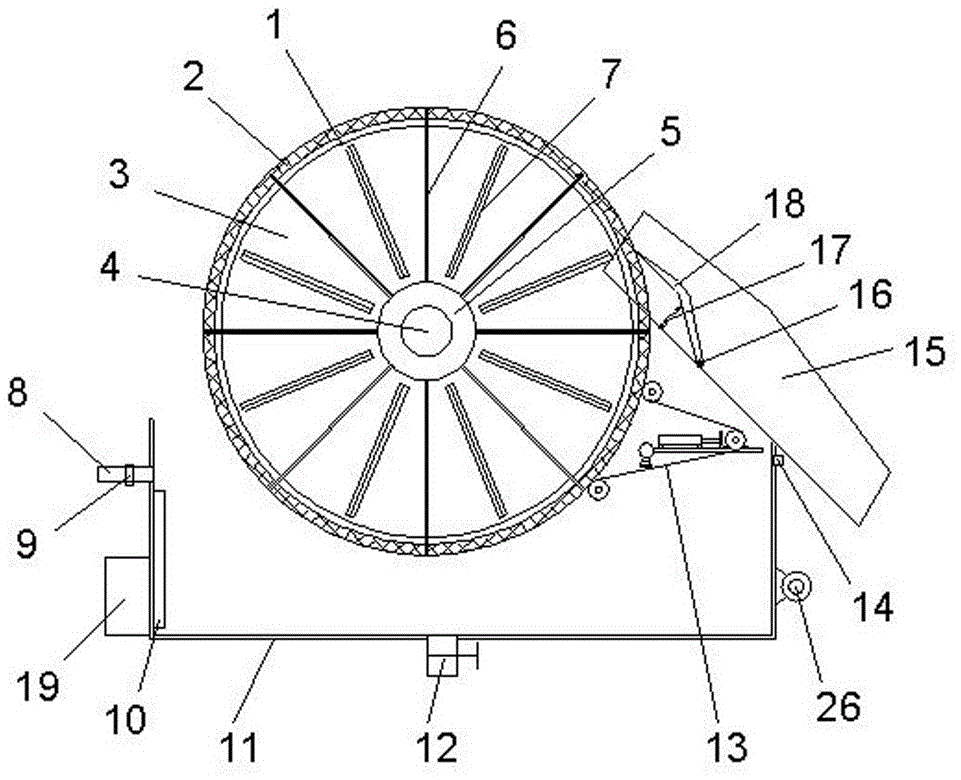

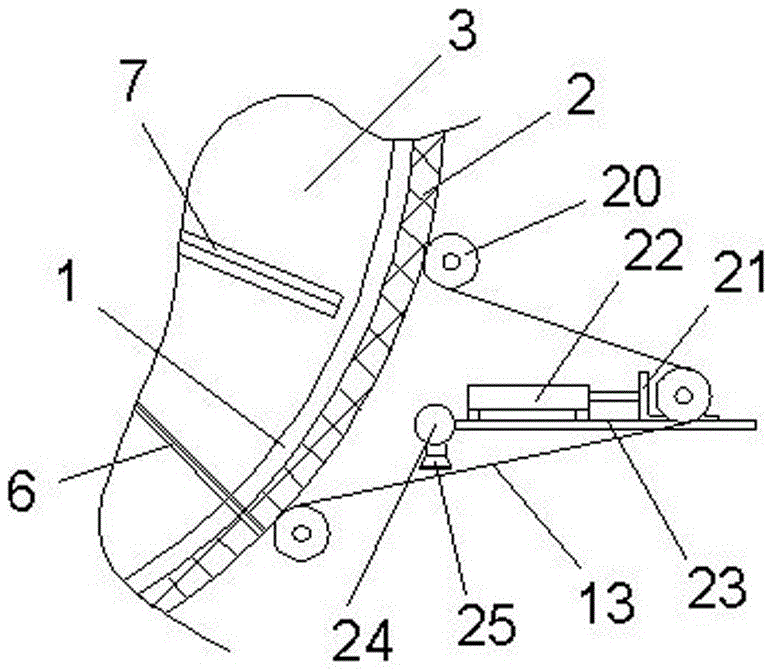

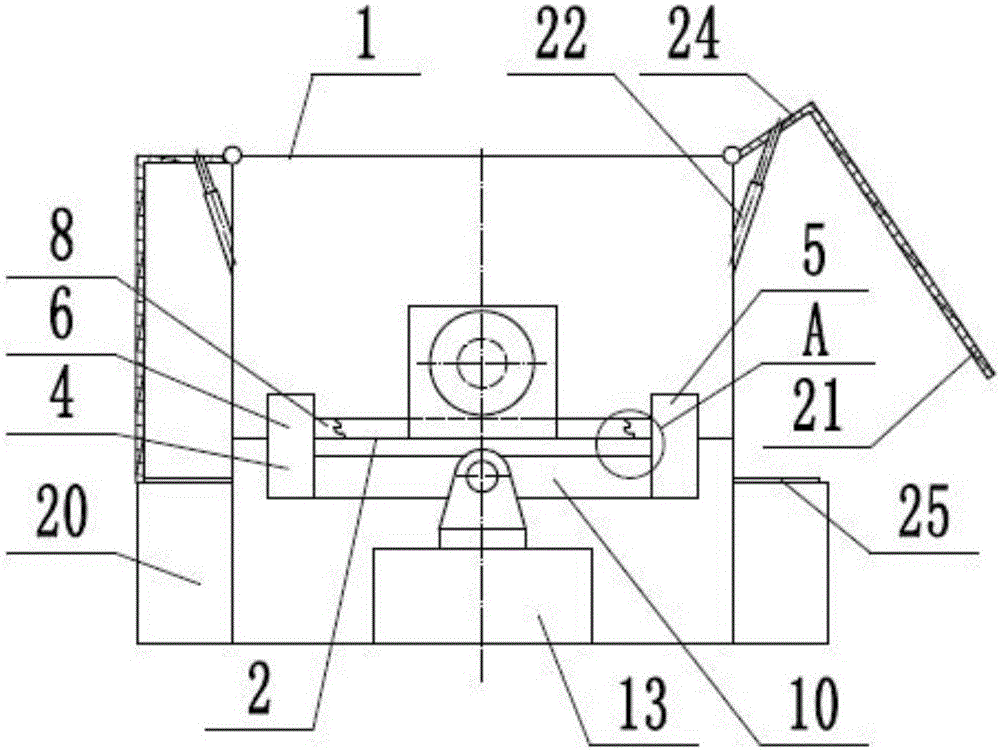

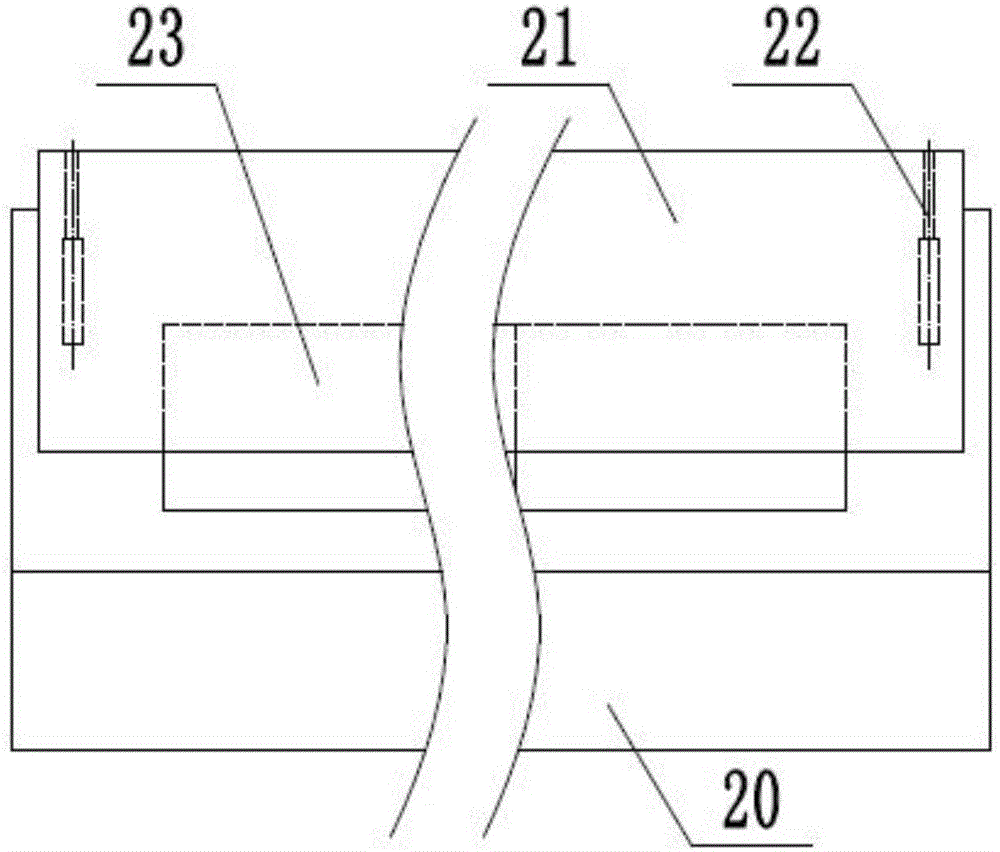

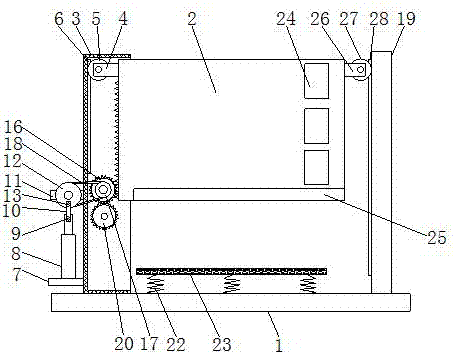

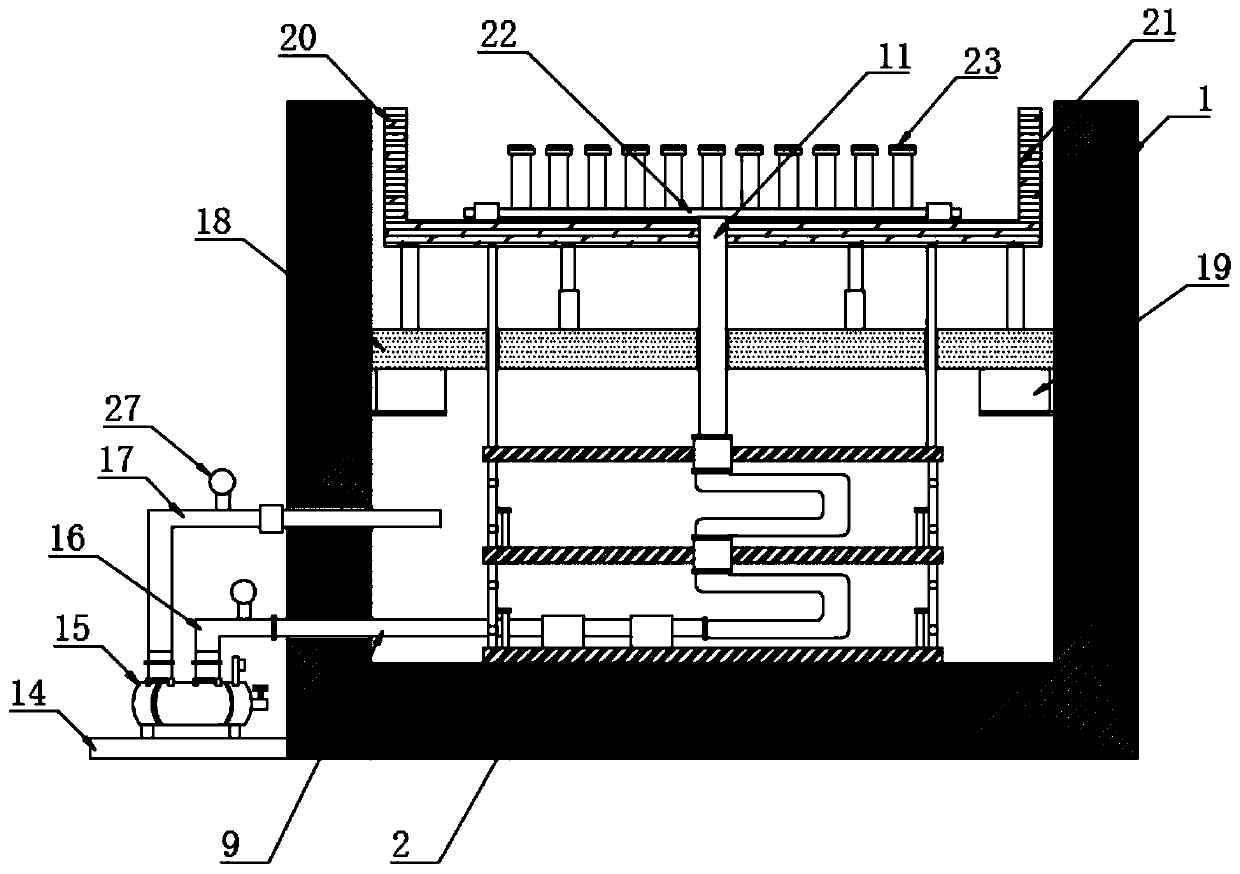

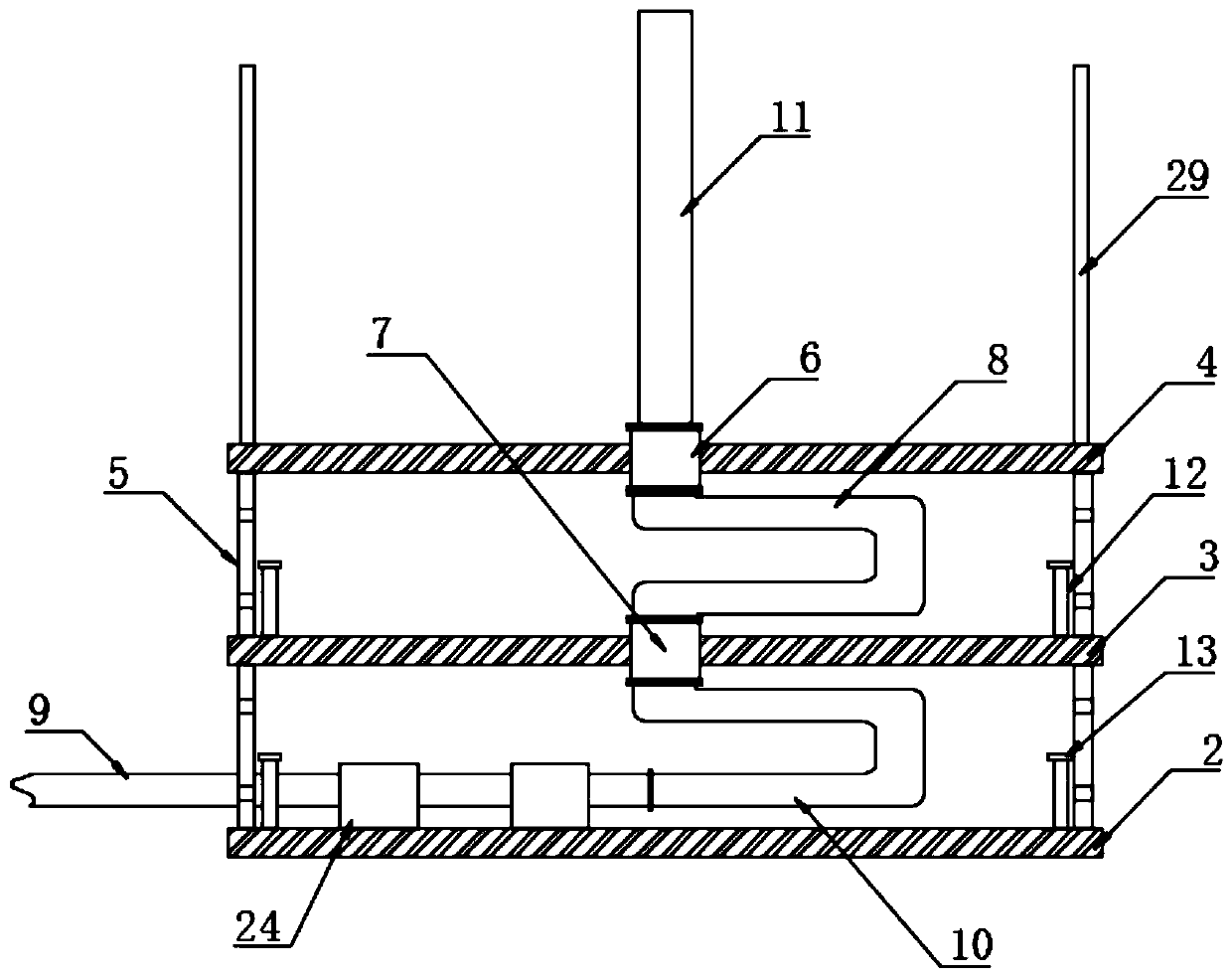

Automation-control rotary drum vacuum filter apparatus

InactiveCN106237696ARealize automatic liquid feedingLimit the range of activitiesMoving filtering element filtersTextileAutomation

The invention discloses an automation-control rotary drum vacuum filter apparatus which comprises a filtering rotary drum on a rack, a distributing head, a transmission apparatus, a stirring apparatus and a material slurry storage tank. The filtering rotary drum includes a cylindrical drum body. A support filter screen is arranged on the outer wall of the drum body. A filter cloth coats the support filter screen through a plurality of guiding rollers which are all mounted on the rack. The rack is also provided with a tensional apparatus for regulating the tension of the filter cloth and a cleaning apparatus for cleaning the filter cloth. A central rotary shaft is installed in the center of the drum body, an input end of the central rotary shaft being connected to the transmission apparatus. With the central rotary shaft as an axis, a plurality of separation boards are arranged radially in the radial direction inside the drum body. A controller is arranged on an outer wall of the material slurry storage tank. The rotary drum vacuum filter apparatus has reasonable structural design, allows automatic slurry inlet and achieves automatic cleaning of the filter cloth, has good filter cloth cleaning effect and effectively ensures filter efficiency.

Owner:HEBI COLLEGE OF VOCATION & TECH

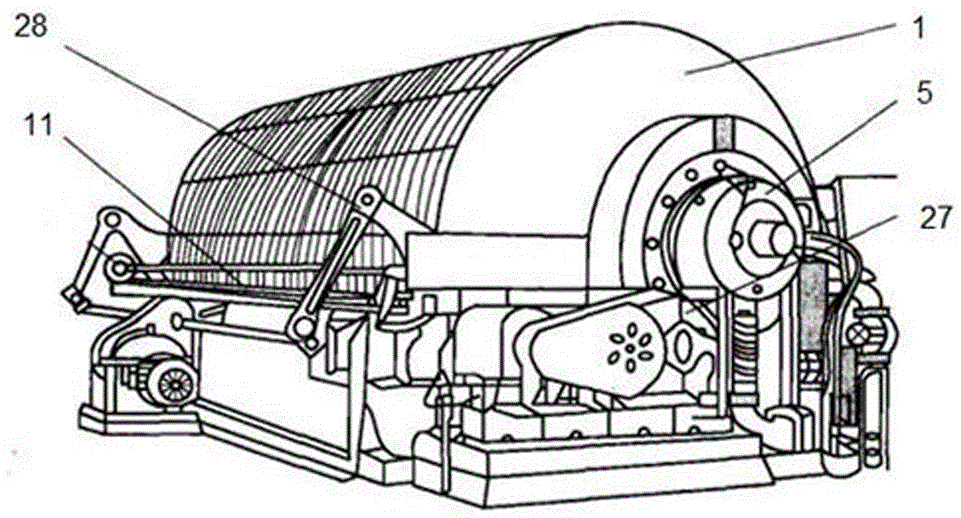

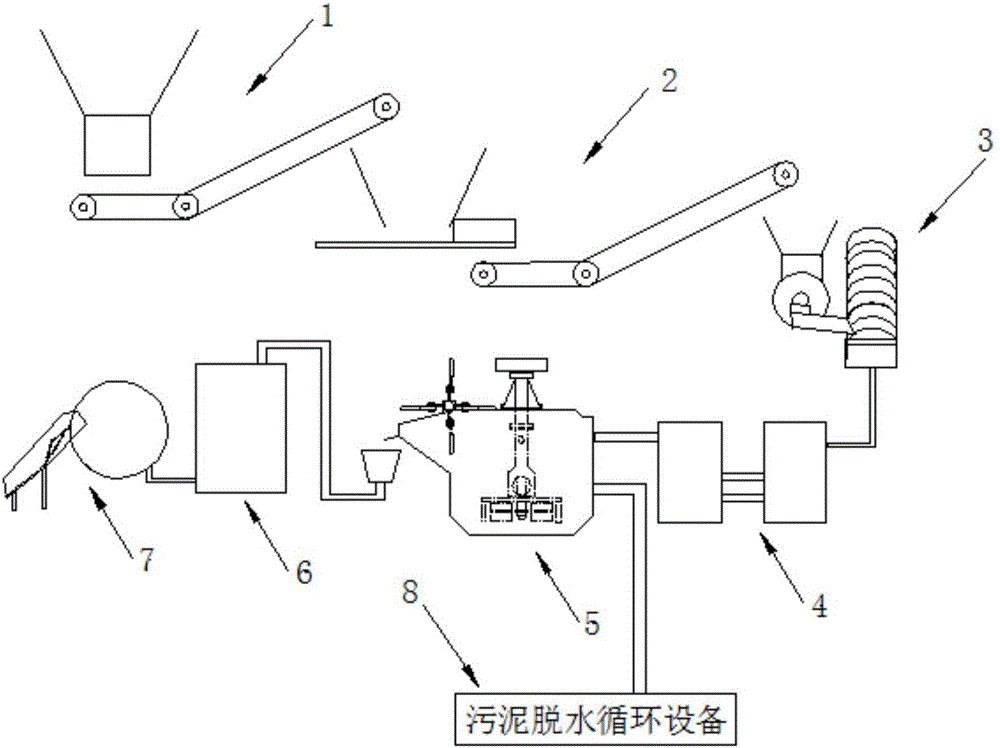

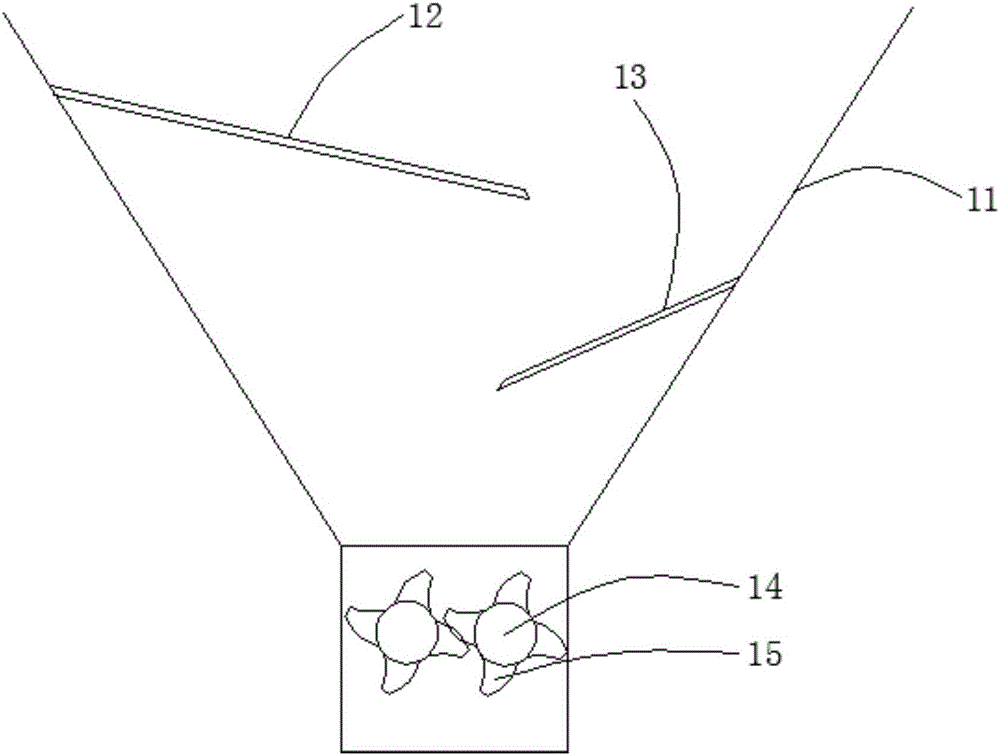

Unit used for machining fluorite mineral aggregate and application thereof

InactiveCN105642432AReduce shockExtend your lifeFlotationGrain treatmentsAfter treatmentEconomic benefits

The invention provides a unit used for machining fluorite mineral aggregate and application thereof. According to the processing route of the mineral aggregate, the unit comprises a crusher, a disk feeder, a levigating device, a stirring device, a flotation machine, a concentration device and a rotary drum vacuum filter in order. By the improved devices provided by the invention, the mineral aggregate is levigated after crushed, and then forms pulp. The pulp forms fine powder foam after treatment and finally forms mineral powder after dewatering and drying. The unit further comprises a sludge dewatering recycling device. Compared with the prior art, the devices provided by the invention are improved in a plurality of places. The improved devices can optimize the machining process, save raw materials, and reduce noise at the same time. Above all, the improved devices are convenient to replace if the parts are damaged so that human and material resource is greatly saved, and the waste can be turned into wealth by a sludge dewatering recycling device so that high economic benefit is achieved.

Owner:JINGDE COUNTY SHENGYU FLUORITE PROCESSING CO LTD

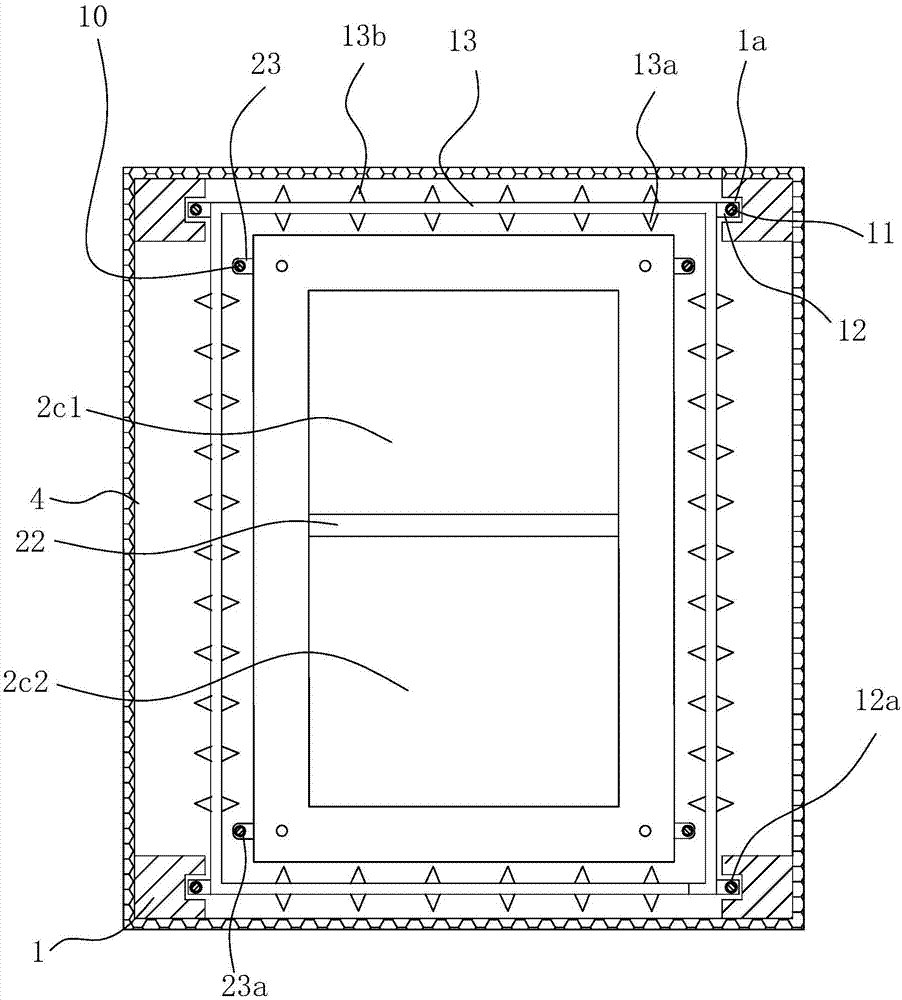

Seawater culture net cage of improved structure

ActiveCN107372261AAvoid cloggingReduce liquidityClimate change adaptationPisciculture and aquariaEngineeringSeawater

The invention provides a seawater culture net cage of an improved structure, and belongs to the technical field of culture equipment. The seawater culture net cage of the improved structure comprises an upper floating body, a base plate, four stand columns, a cleaning pipe and a water pump. A net body is arranged between the upper floating body and the base plate. Each stand column is vertically provided with a guiding rod. The edge of the upper floating body is provided with four first guiding sleeves, the first guiding sleeves are arranged on the corresponding guiding rods in a sliding mode. An outer net body is arranged on the periphery of the outer sides of the four stand columns. A plurality of first nozzles and a plurality of second nozzles are arranged on the cleaning pipe. The first nozzles are right opposite to the net body, the second nozzles are right opposite to the outer net body, the water pump is arranged at the upper end of one stand column, the water pump is communicated with the cleaning pipe through a host, and each stand column is provided with a driving mechanism. The seawater culture net cage has the advantages that the net bodies can be automatically cleaned, and garbage in sea is prevented from being gathered around the net bodies.

Owner:ZHEJIANG OCEAN UNIV

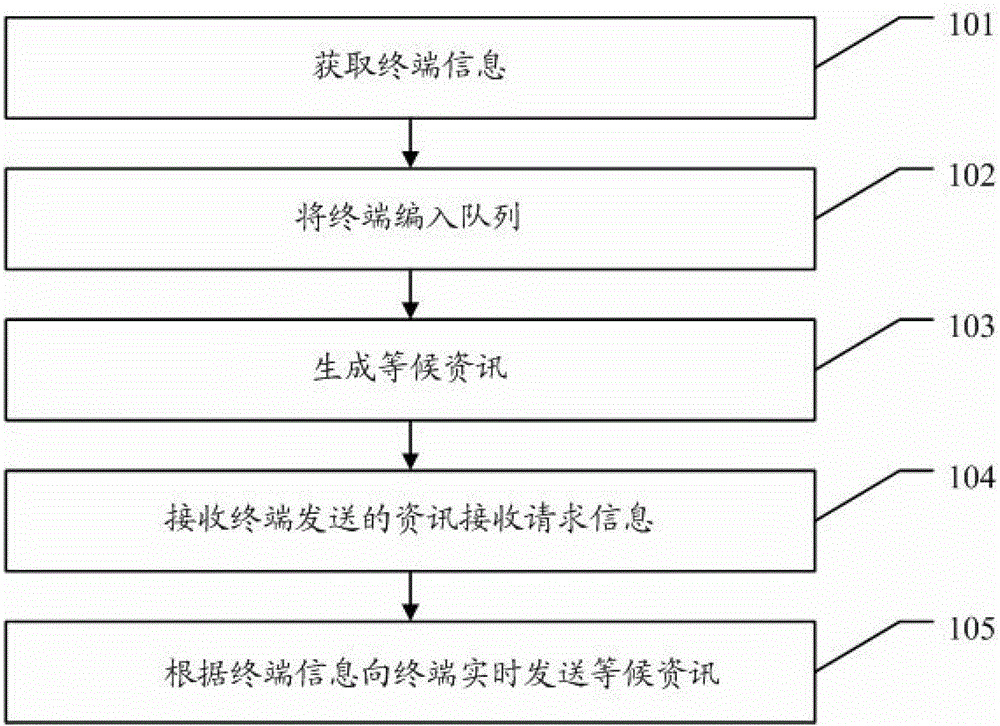

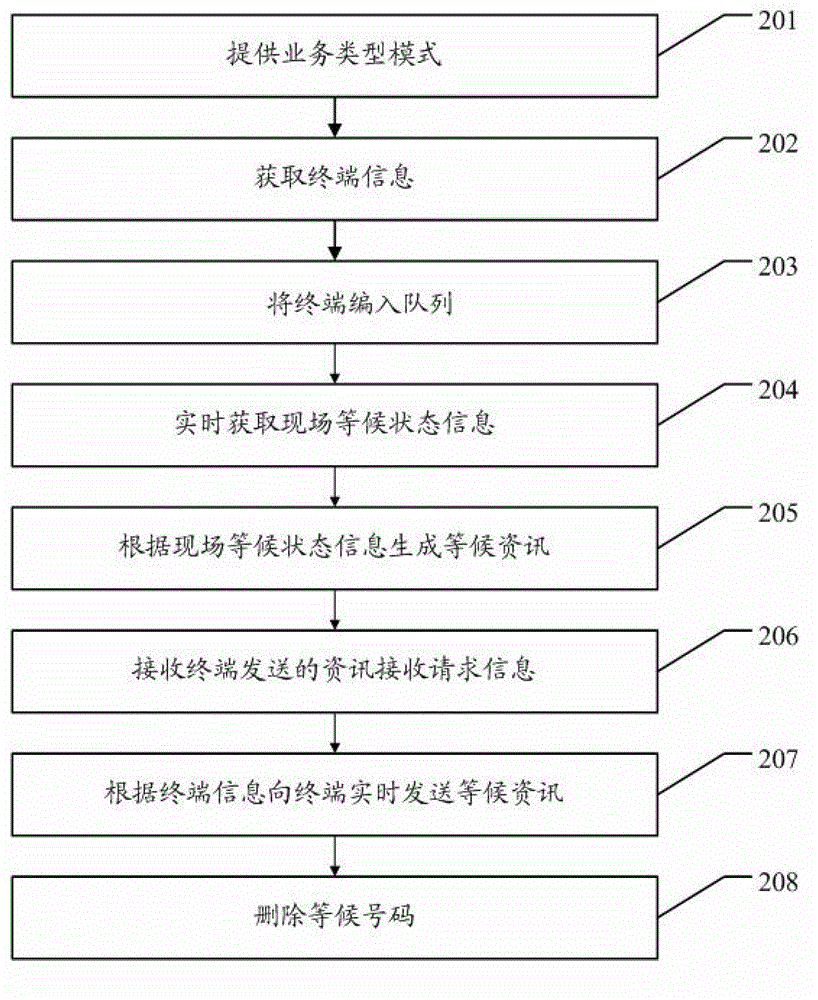

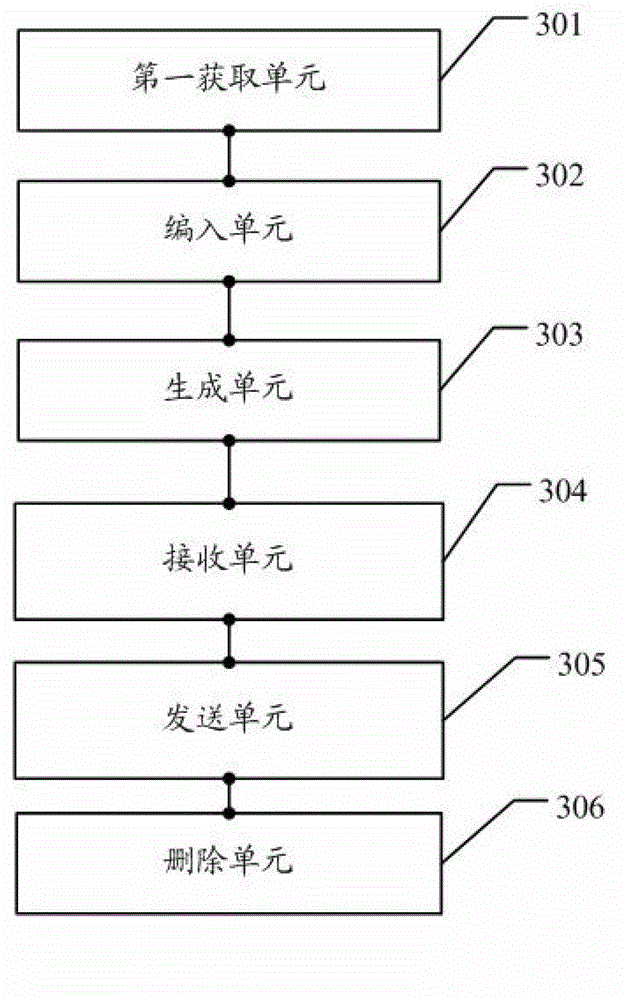

Waiting reminding method and waiting reminding device

The invention discloses a waiting reminding method and a waiting reminding device, and a customer is enabled to be capable of mastering a site queuing situation without the need for staying on site. The waiting reminding method includes obtaining terminal information first, enrolling a terminal into a queue, generating a waiting message then, receiving message-receiving request information sent by the terminal, and sending a waiting message to the terminal in real time according to the terminal information. Therefore, the customer only needs to pay close attention to the waiting message on the terminal to master the site queuing situation, and does not need to be restricted to wait on site.

Owner:陈锡明 +1

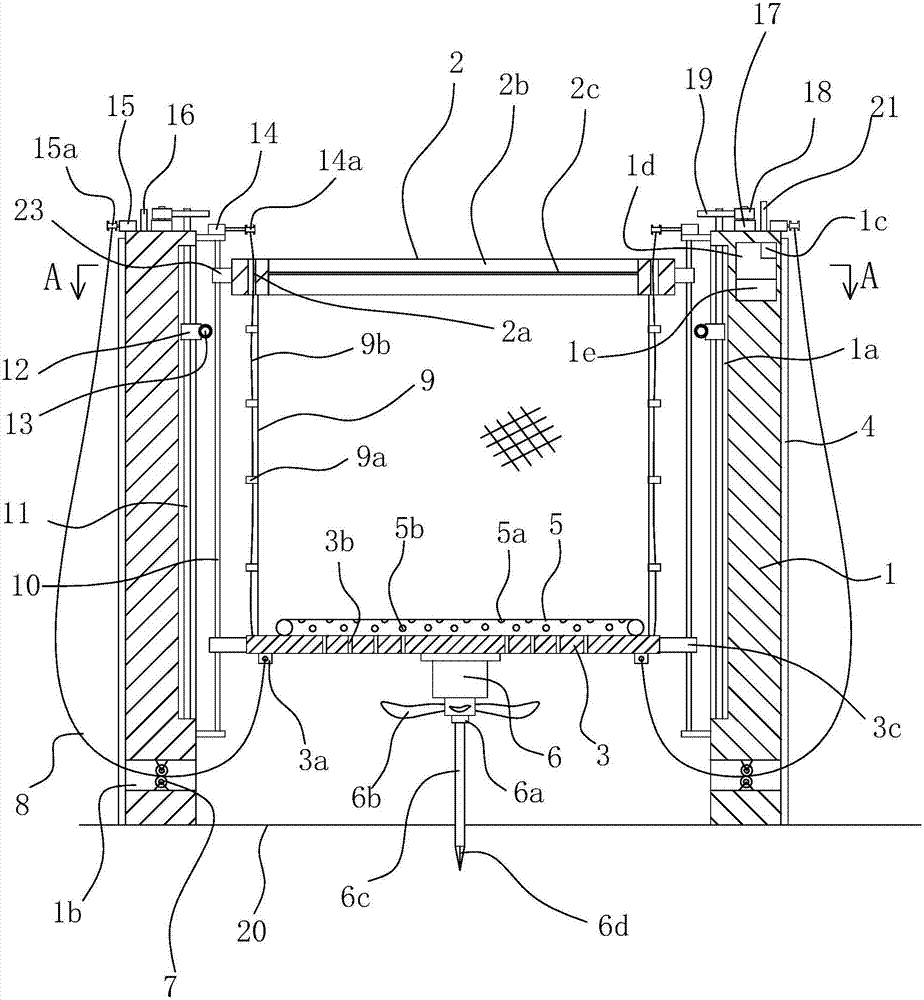

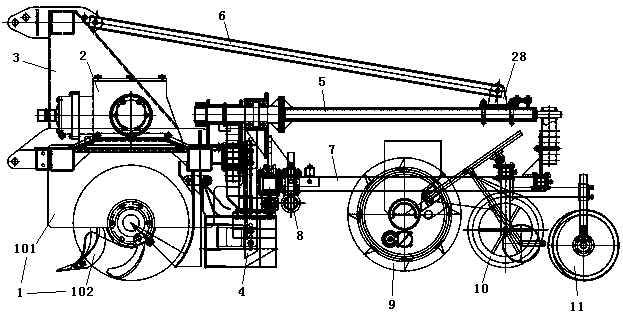

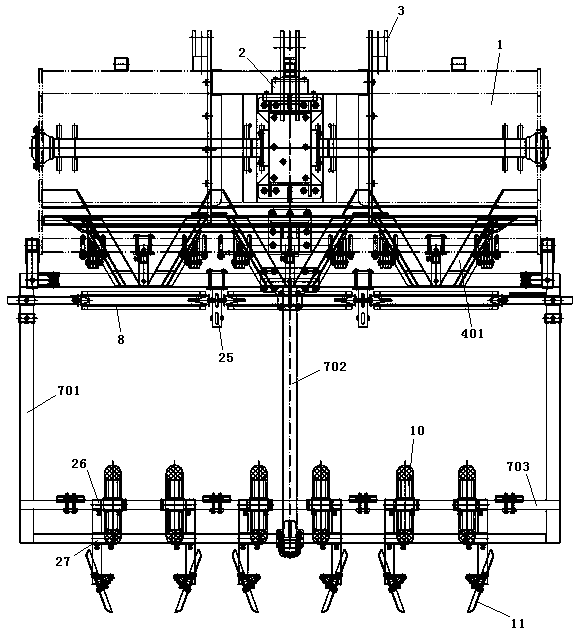

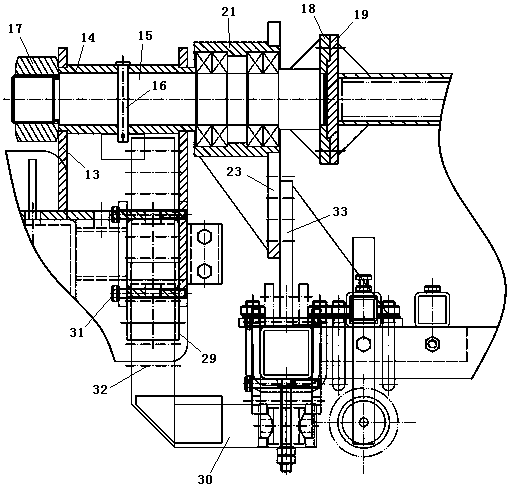

Rotary tillage, ridging and mulching combined operation machine for slope cropland

PendingCN111066399AWith profiling functionSatisfy the needs of flat land operationsSpadesPloughsAgricultural engineeringCantilever

The invention discloses a rotary tillage, ridging and mulching combined operation machine for slope cropland. The operation machine includes a rotary tillage machine; a gear box assembly and a hangingrack assembly are arranged on a frame of the rotary tillage machine; the power output end of the gear box assembly drives a cutter-shaft assembly of the rotary tillage machine; a ridging device is arranged on the rear end of the rotary tillage machine and provided with multiple sets of ridging plates; the operation machine also includes a cantilever, a diagonal draw bar and a mulching frame; thecantilever is arranged on the rotary tillage machine and extends to the rear part of the rotary tillage machine; the two ends of the diagonal draw bar are respectively in hinged joint with the hangingrack assembly and the cantilever; the front and rear ends of the mulching frame are rotatably connected to the cantilever; film rollers are arranged on the front end of the mulching frame; hole-sowing devices, film-pressing wheels and soil-covering disc shovels are successively arranged on the rear end of the mulching frame; and the film rollers, the film-pressing wheels and the soil-covering disc shovels are in front and back correspondence with each set of the ridging plates. The operation machine has a profile modeling function; and the mulching frame can be automatically adjusted according to the ground surface, so that operational requirements of cultivated land with different types can be met.

Owner:NANJING AGRI MECHANIZATION INST MIN OF AGRI +1

Petrochemical engineering oil-water separation device

ActiveCN112408546AIncrease contact areaImprove separation efficiencyFatty/oily/floating substances removal devicesSpecific water treatment objectivesElectric machineryPetrochemical

The invention discloses a petrochemical engineering oil-water separation device, and the device comprises an oil skimming pool and an oil skimming device arranged in the oil skimming pool; the oil skimming device comprises a protective cover and a driving motor arranged on one side of the protective cover; one end of an output shaft of the driving motor is connected with a driving belt wheel, a supporting frame is arranged at the lower end of the protective cover, and two sets of supporting rods are arranged on one side of the supporting frame; a second connecting rod is arranged on one side of the supporting rod; the upper end of the second connecting rod is connected with the protective cover; an oil receiving groove is formed in the protective cover, oil scraping plates are arranged onthe two sides of the upper portion of the oil receiving groove and make contact with the two sides of the oil skimming belt, and an oil receiving box is arranged on one side outside the protective cover. The oil skimming device is arranged in the oil skimming pool, the driven belt wheels are arranged on the frame rods, and the oil skimming belt continuously bypasses the oil skimming belt on the frame rods, so that the contact area between the oil skimming belt and sewage is increased, the oil-water separation efficiency is improved on the premise of not adding an oil-water separation device, and the sewage treatment cost of enterprises is reduced.

Owner:东营启辉石油设备有限责任公司

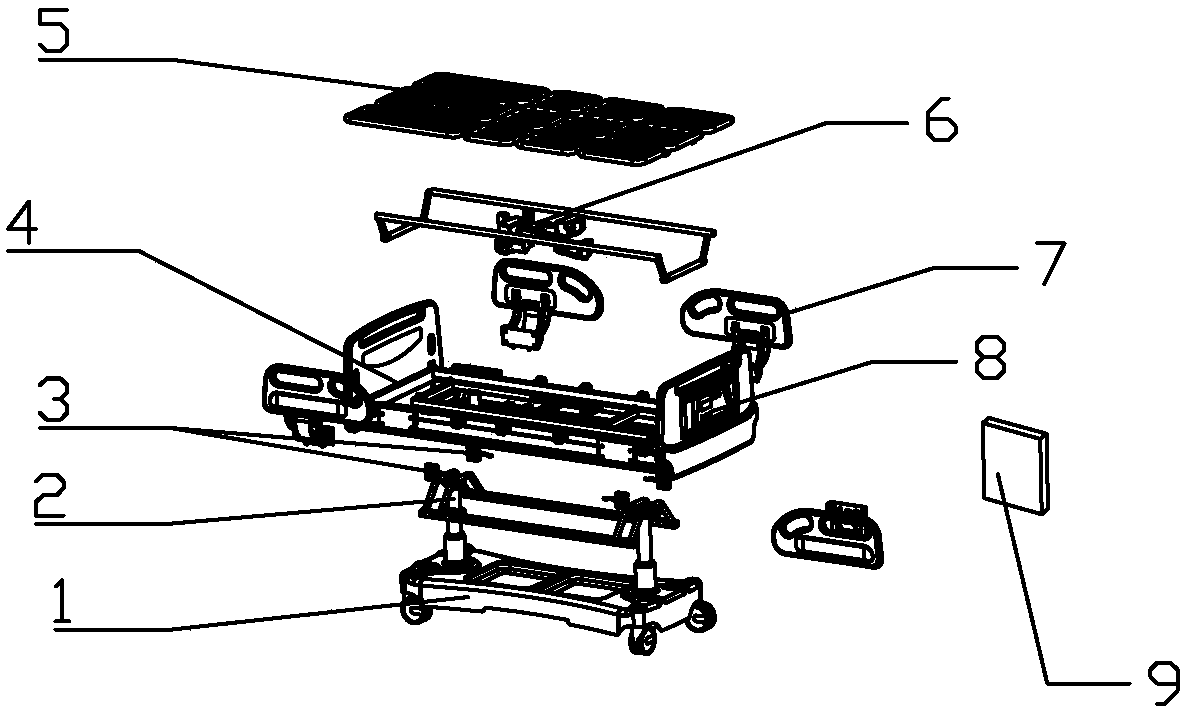

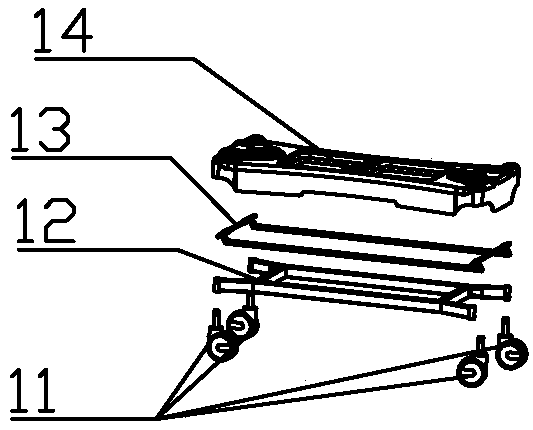

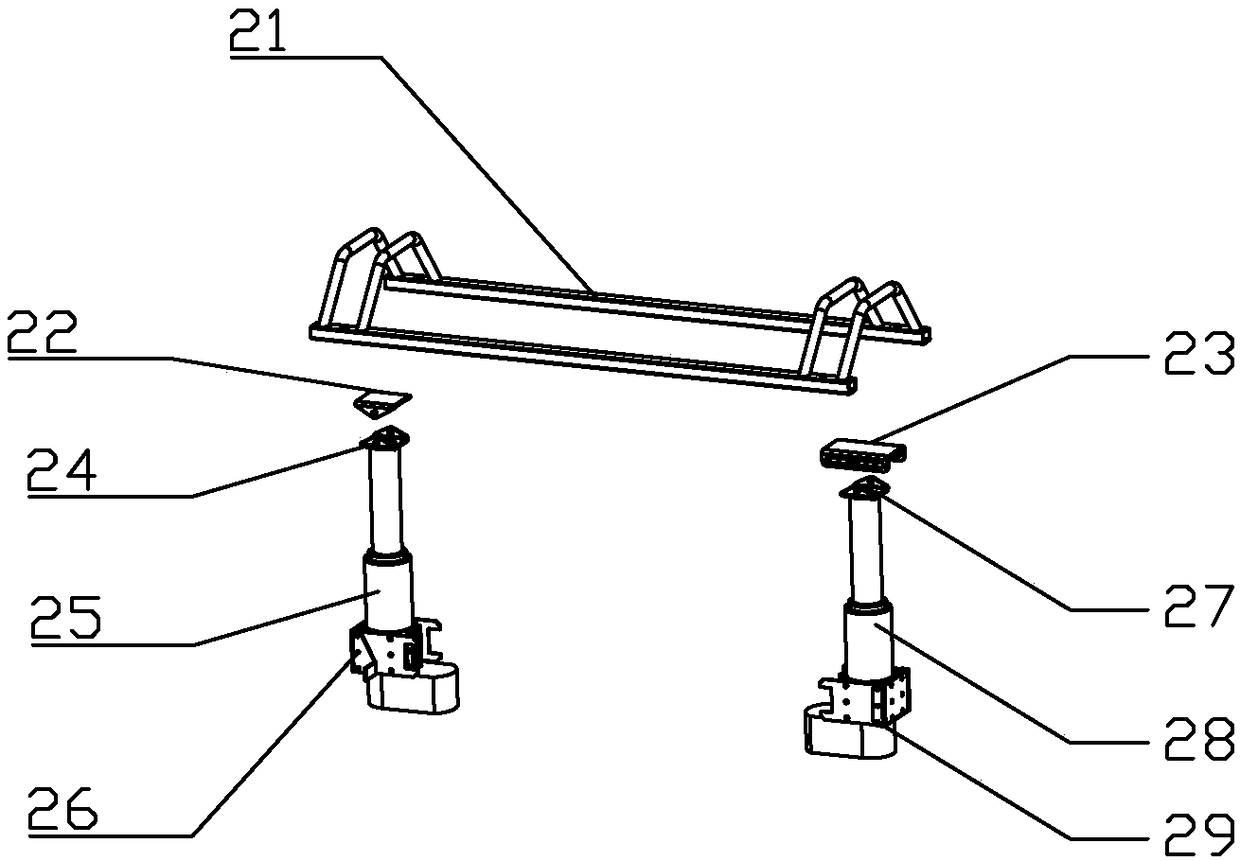

Intelligent hospital bed for assisting patient in turnover by wireless terminal

InactiveCN108324461ALimit the range of activitiesDoes not affect getting in and out of bedNursing bedsAmbulance serviceEngineeringPower apparatus

The invention relates to the field of mobile internet medical instruments, and discloses an intelligent hospital bed for assisting a patient in turnover by a wireless terminal. The intelligent hospital bed comprises a chassis traveling device, a lifting device, a weighing component, bed plate fixing components, modular bed plates, a power device, lifting guard rail devices, a controller and the wireless terminal. The intelligent hospital bed for assisting the patient in turnover by the wireless terminal has the advantages that the overall height of the hospital bed is adjusted, the bed helps the patient to turn over, lift legs and read weighing information and the like which are completed on a nurse station server and the wireless terminal, and the bed is convenient to use.

Owner:柯文光

Access control opening method and system, control center, visited end and readable storage medium

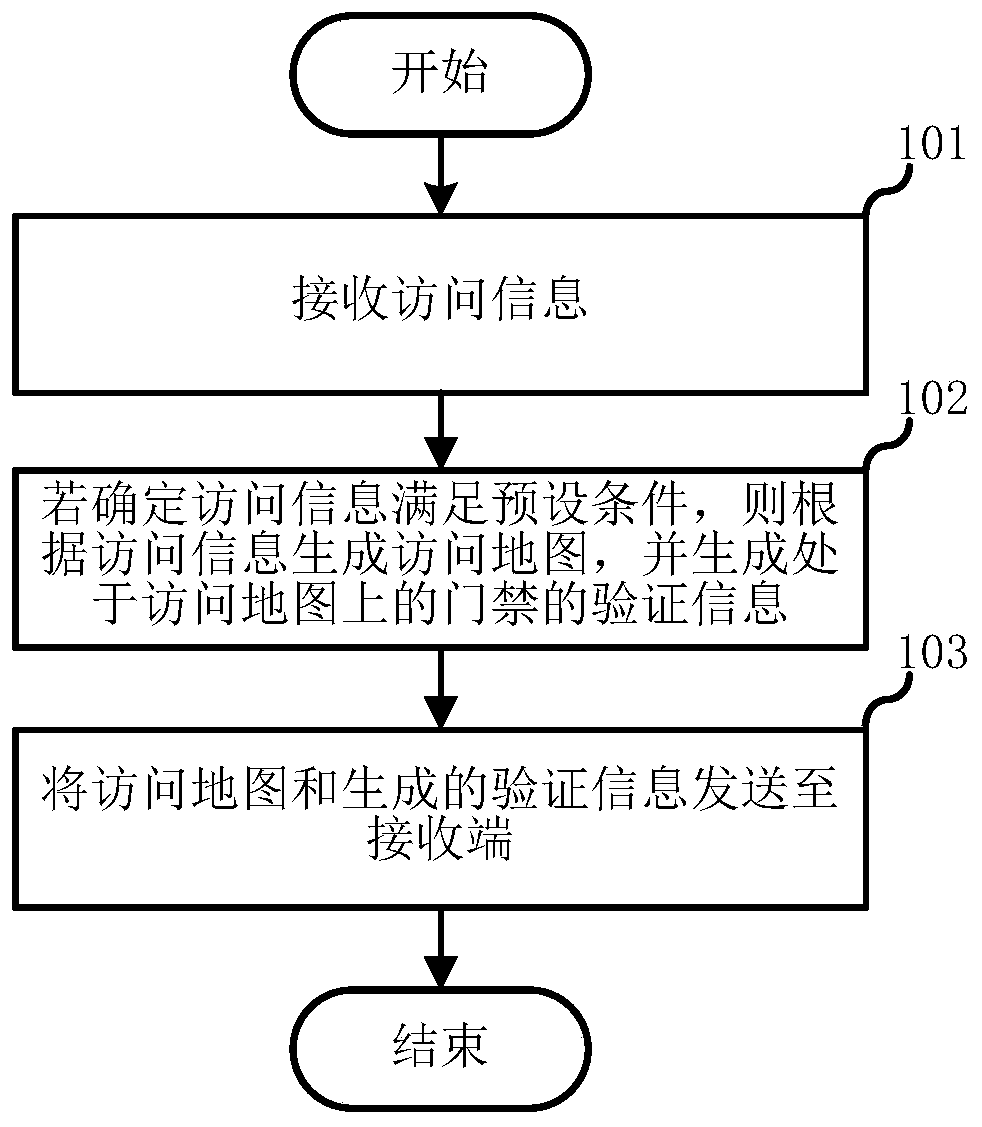

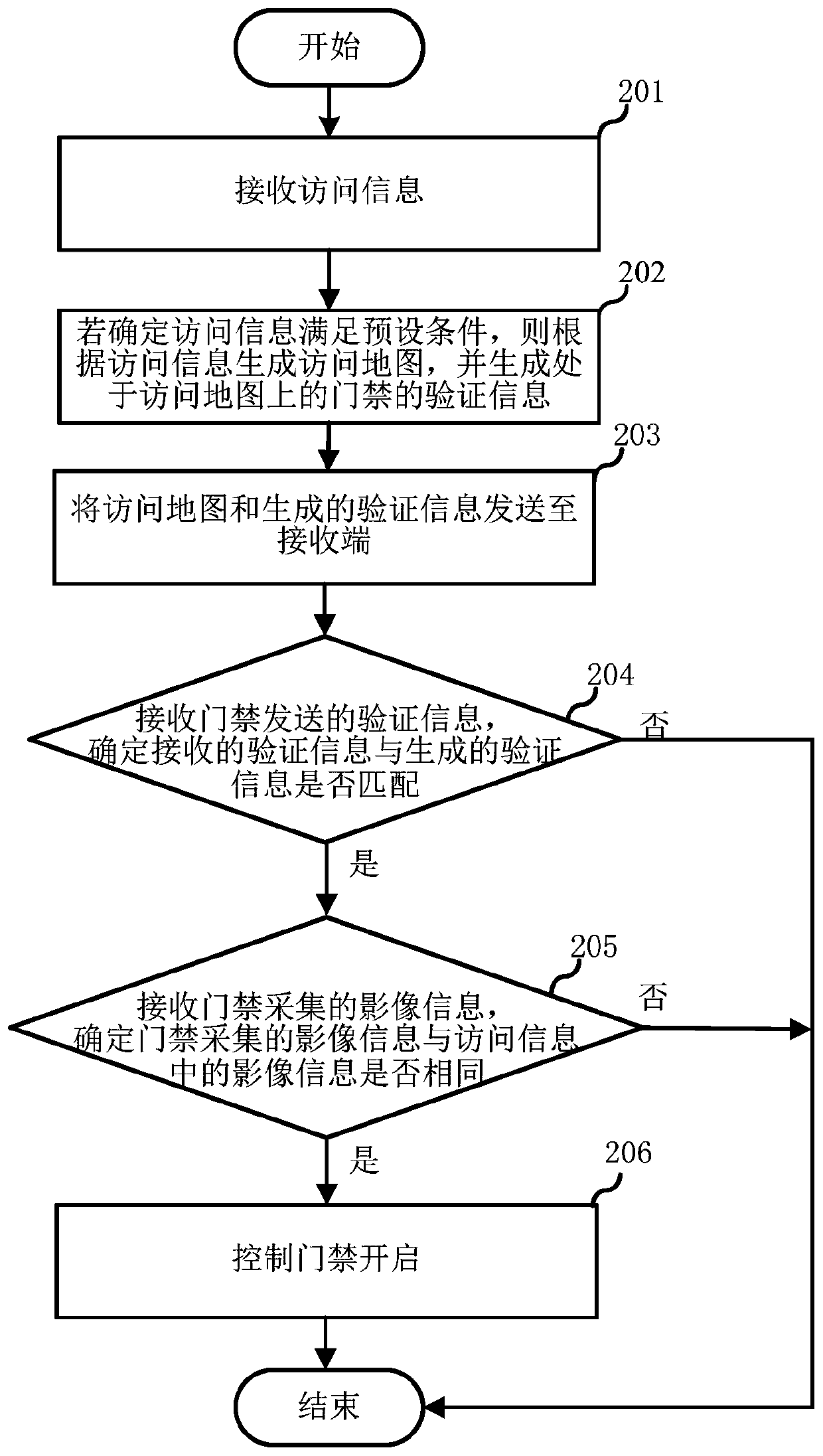

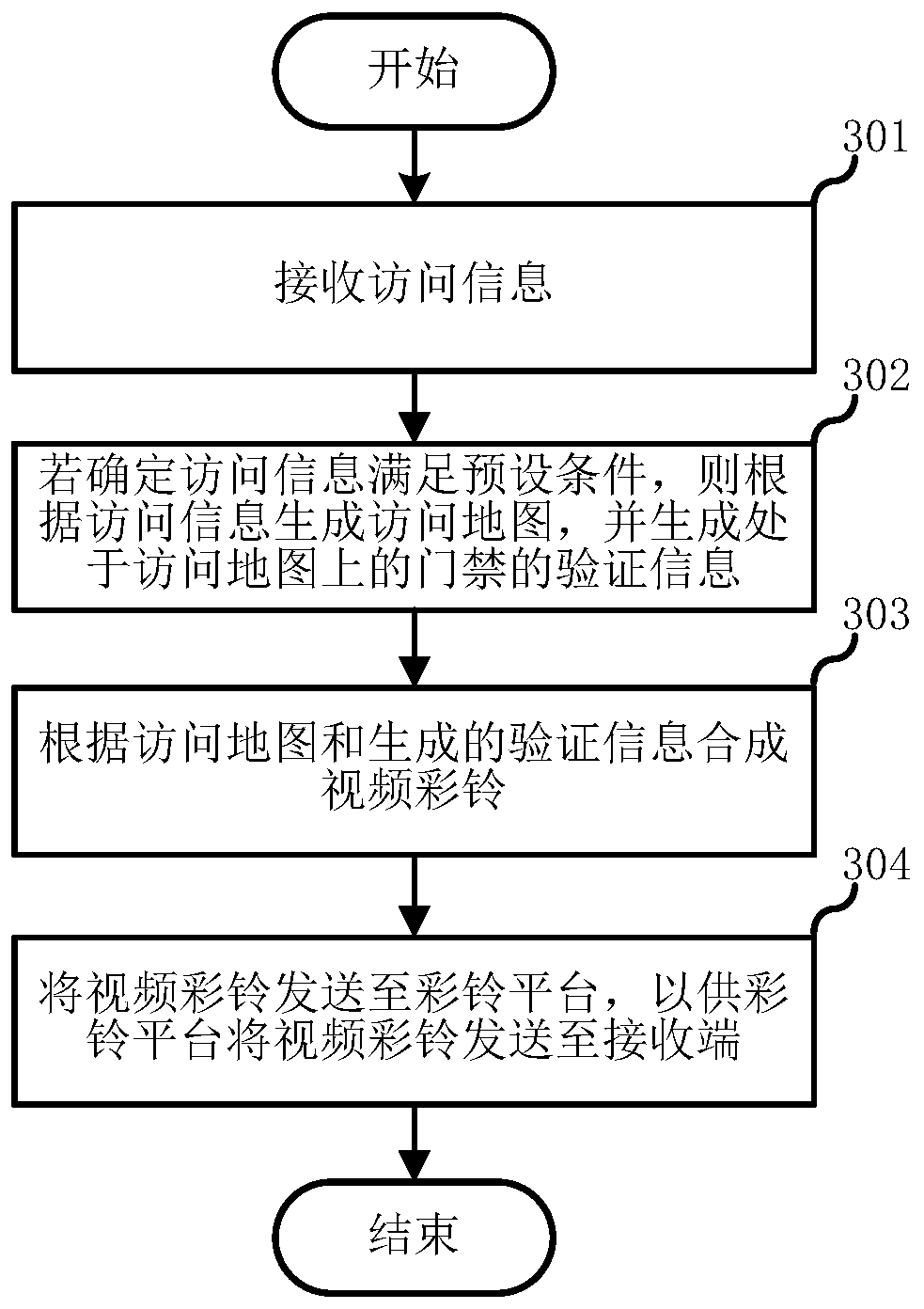

InactiveCN110992556AEasy accessImprove securityIndividual entry/exit registersTelecommunicationsReal-time computing

The embodiment of the invention relates to the technical field of intelligent access control, and discloses an access control opening method and system, a control center, a visited end and a readablestorage medium. The access control opening method comprises the following steps: receiving access information, wherein the access information comprises current position information of a visited objectand current position information of a visited object; if it is determined that the access information meets a preset condition, generating an access map according to the access information, and generating verification information of an access control located on the access map; and sending the access map and the generated verification information to a receiving end. The access convenience is improved while the access control opening safety of the access object is improved.

Owner:MIGU MUSIC CO LTD +2

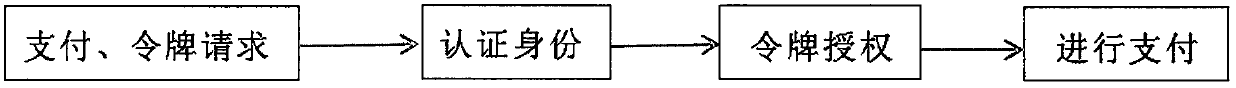

Secure payment system and method for a mobile terminal

PendingCN110084586ASecurityAvoid loss of fundsPoint-of-sale network systemsProtocol authorisationComputer securityPayment system

The invention discloses a secure payment system for a mobile terminal. The secure payment system comprises a mobile terminal device, a terminal binding program, an authentication server, a special server for the payment system, tokens, a token server and a card issuing bank, wherein the tokens are bound with a bank account, the tokens are bound with unique identification information of users in anauthentication server, and the tokens are stored in mobile terminal device or a special server for a payment system. According to the secure payment system and method for the mobile terminal, tokensare adopted among merchants, acquirers and transaction transfer servers to identify cards in the whole payment process, and for the card number with the most important account information. The card number is only transmitted among the transaction transfer servers, the token servers and the card issuing bank. The safety of the card number is ensured by limiting the activity range of the card number, and the probability of leakage is reduced.

Owner:上海方付通科技服务股份有限公司

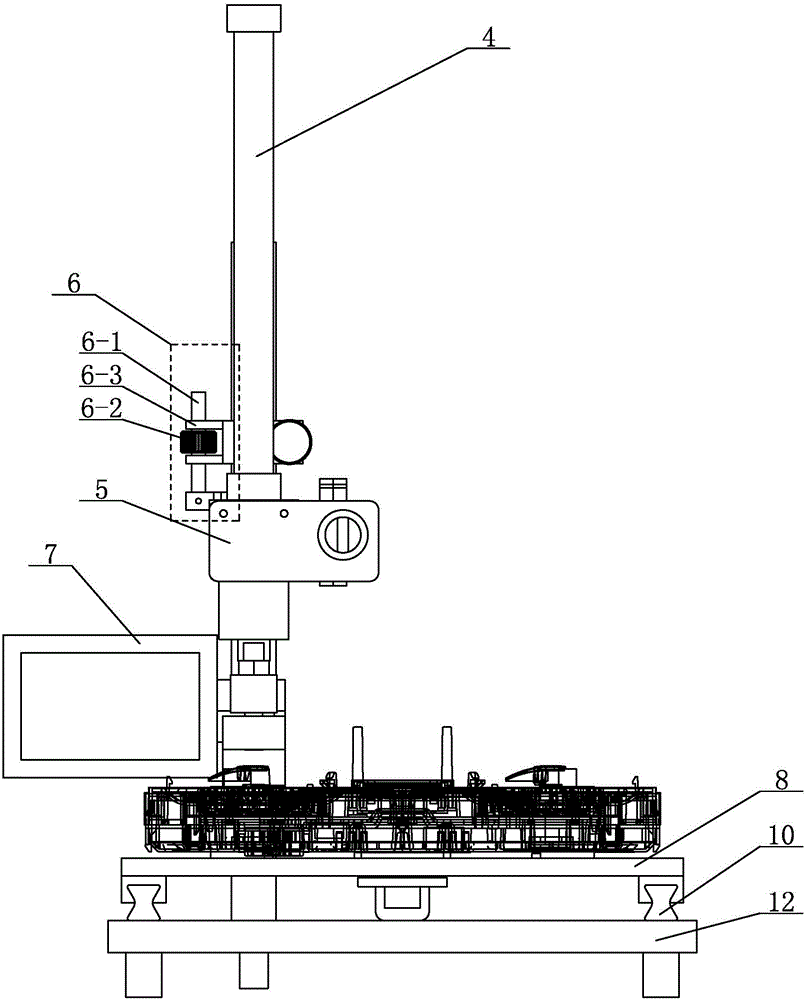

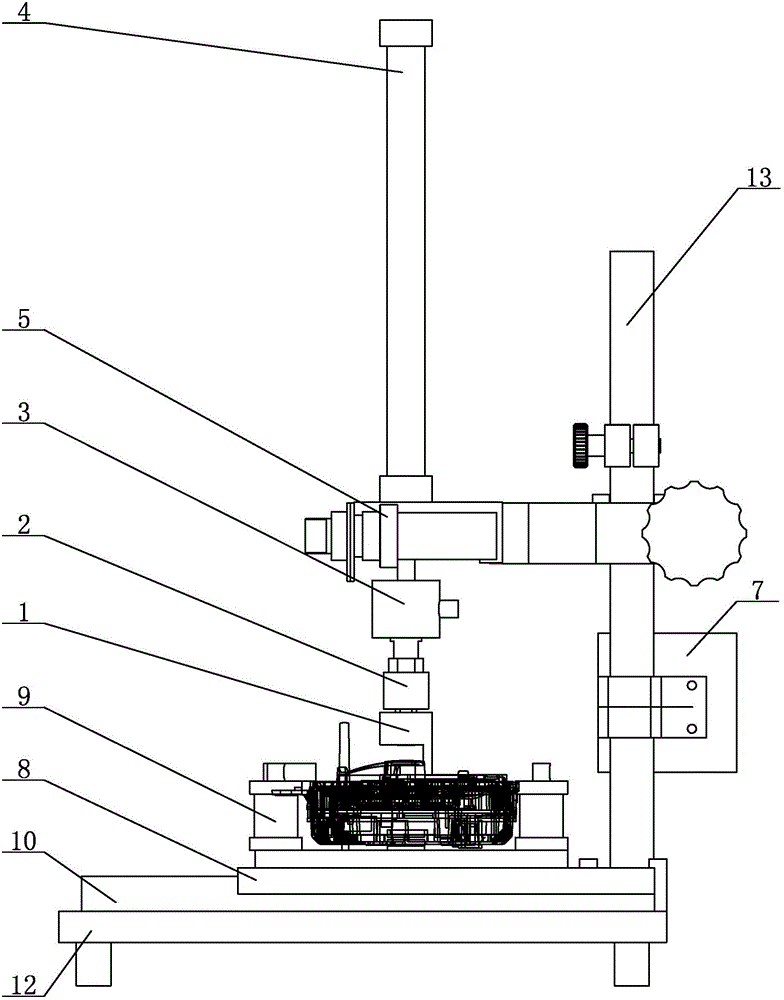

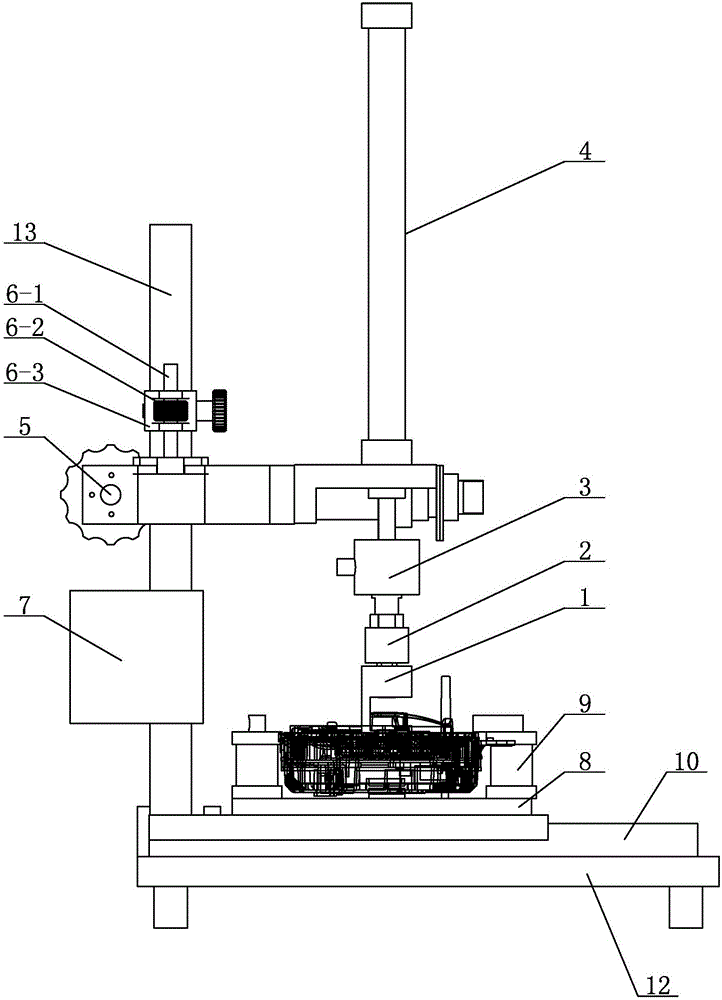

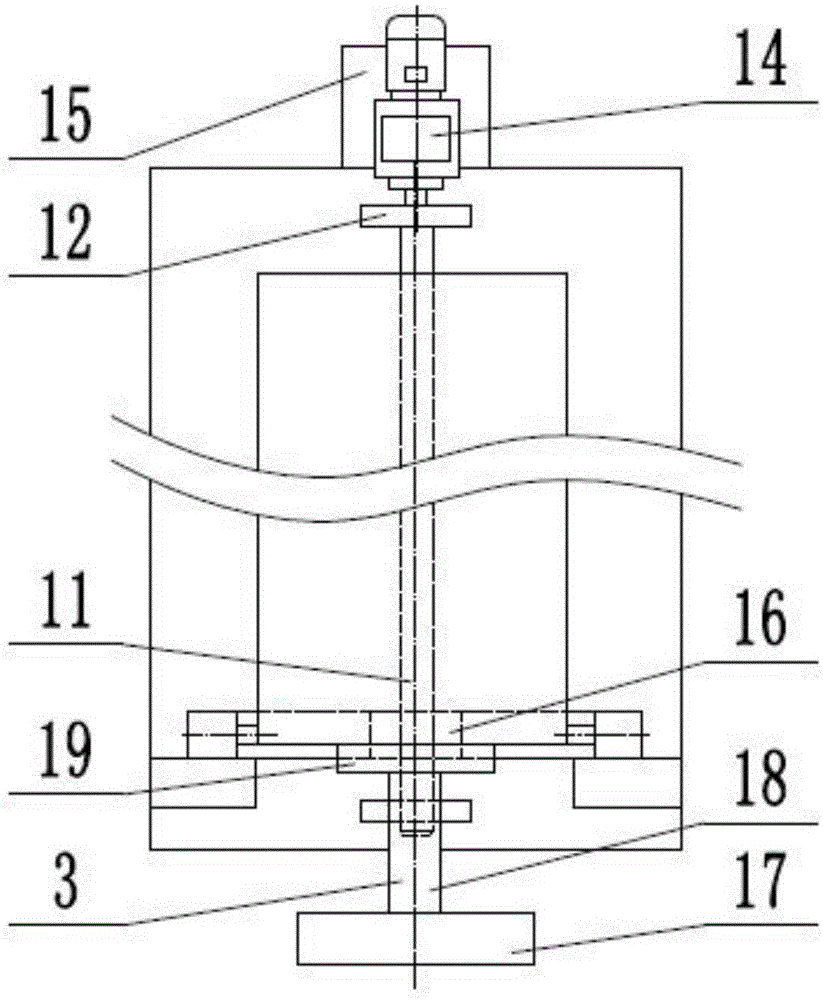

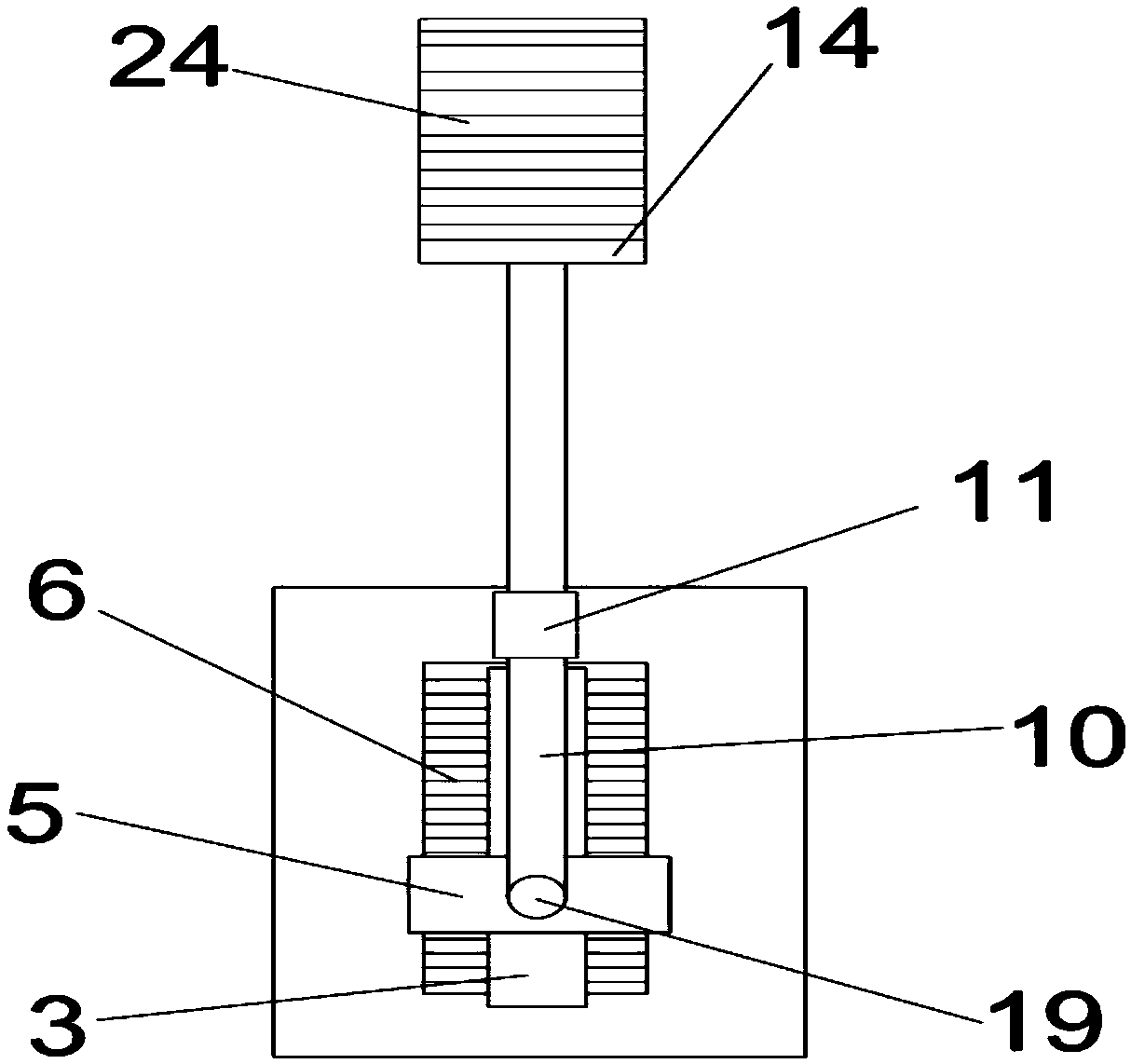

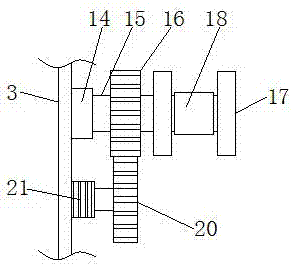

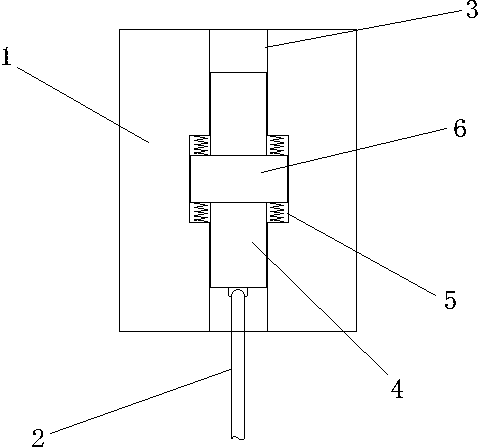

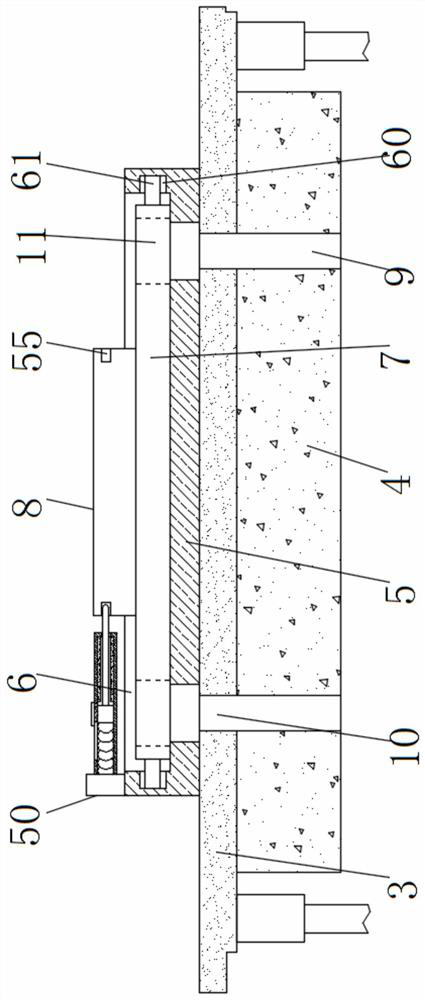

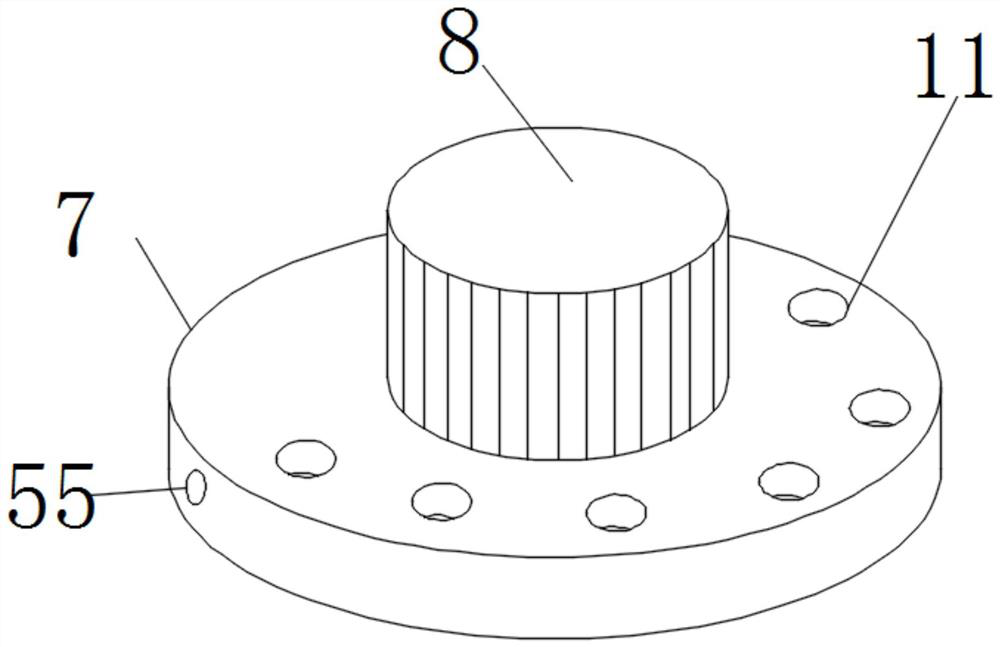

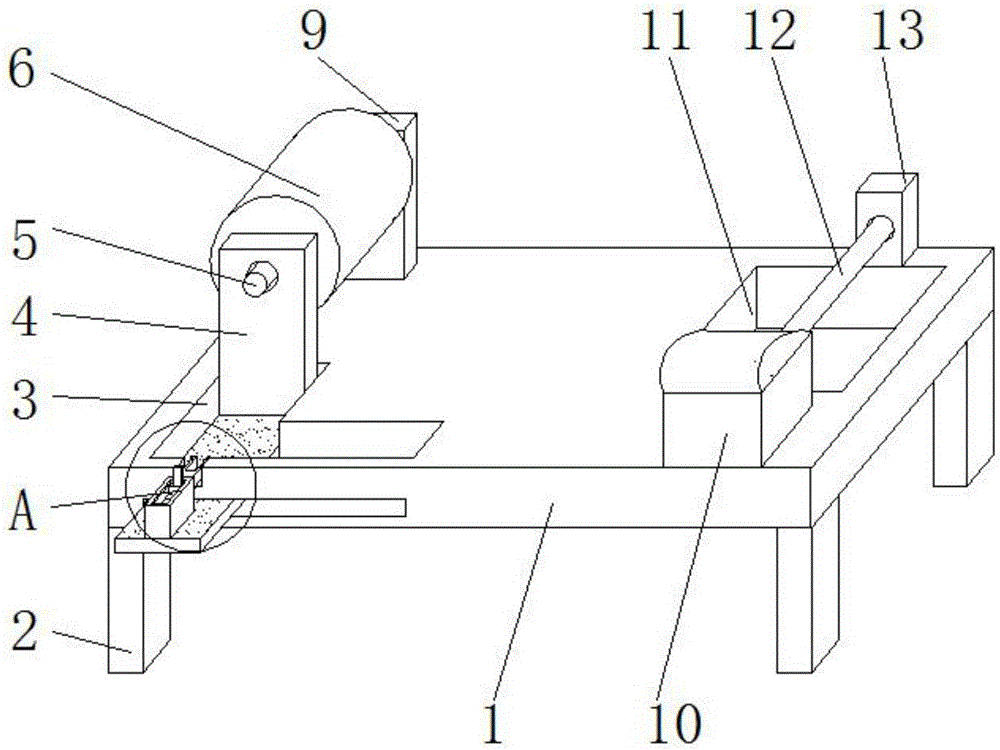

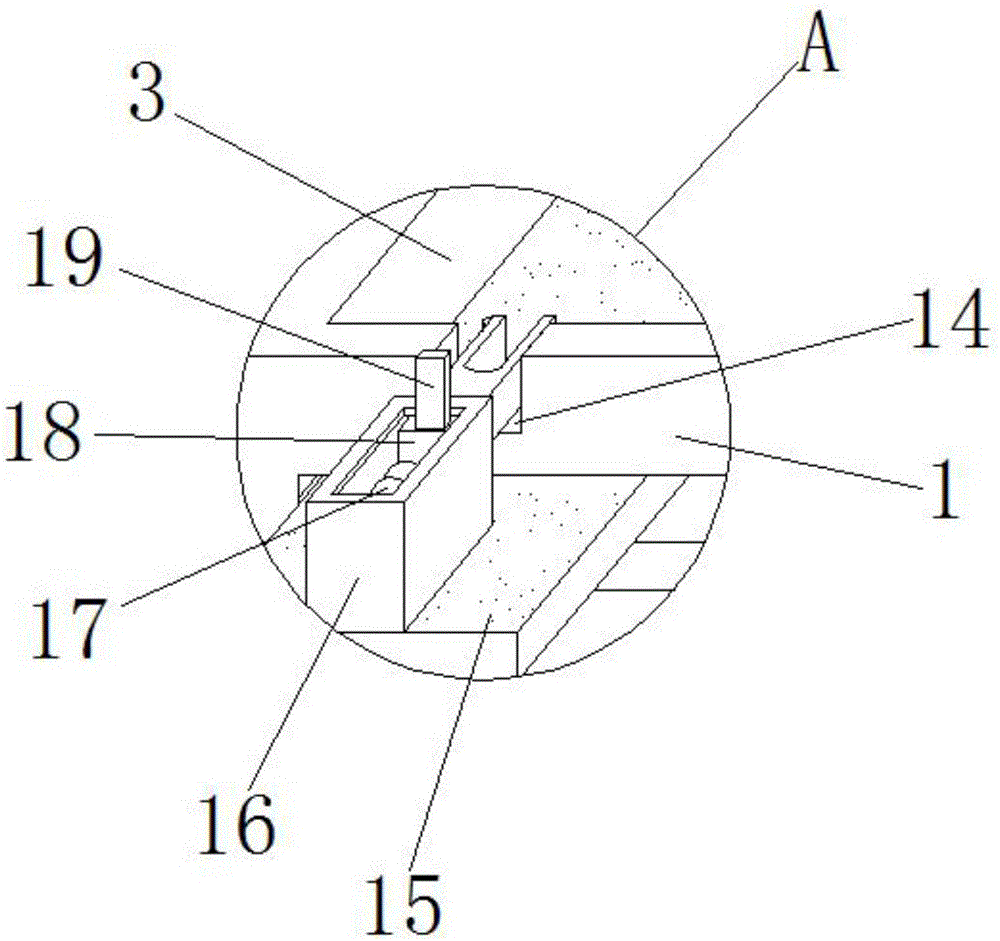

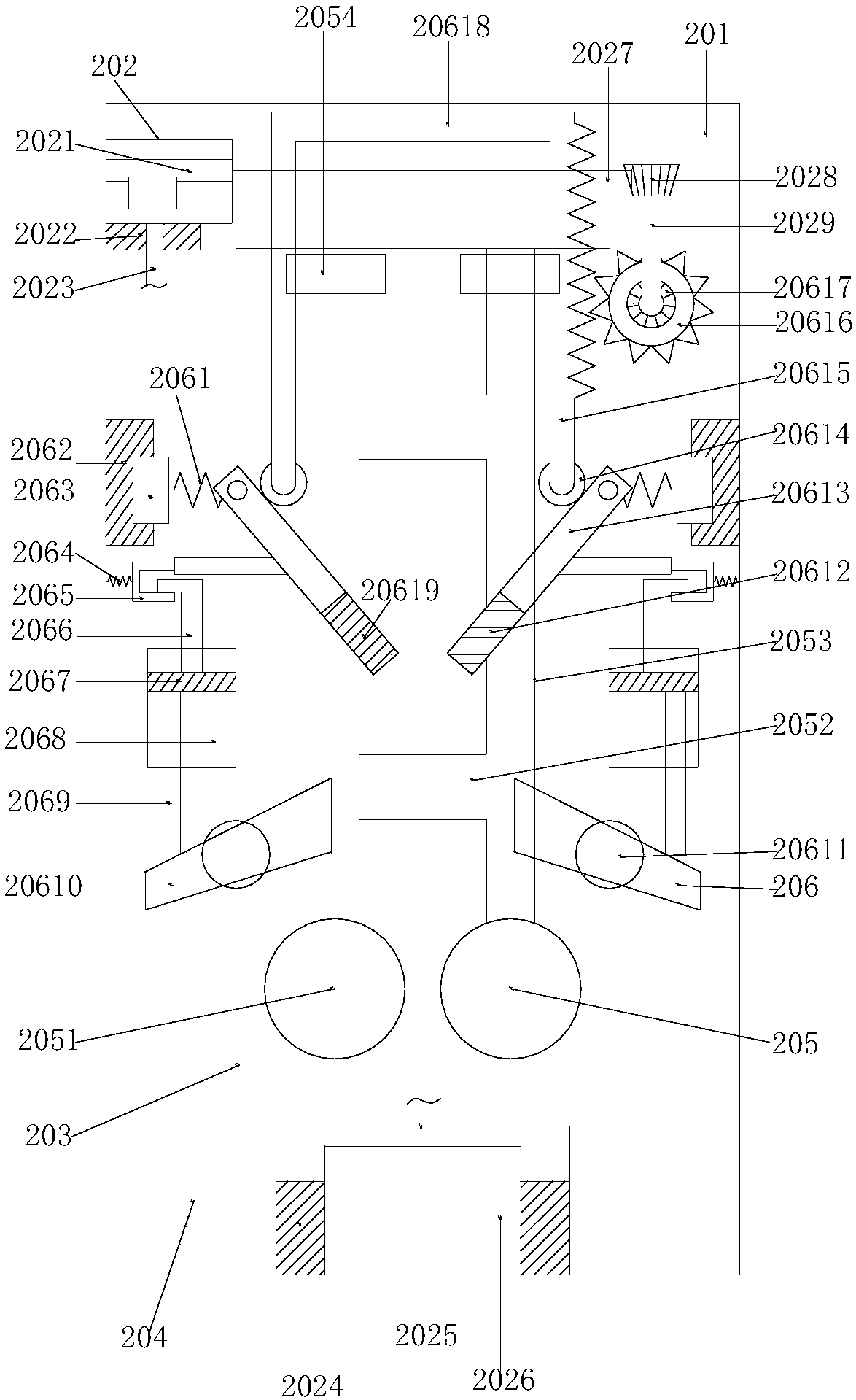

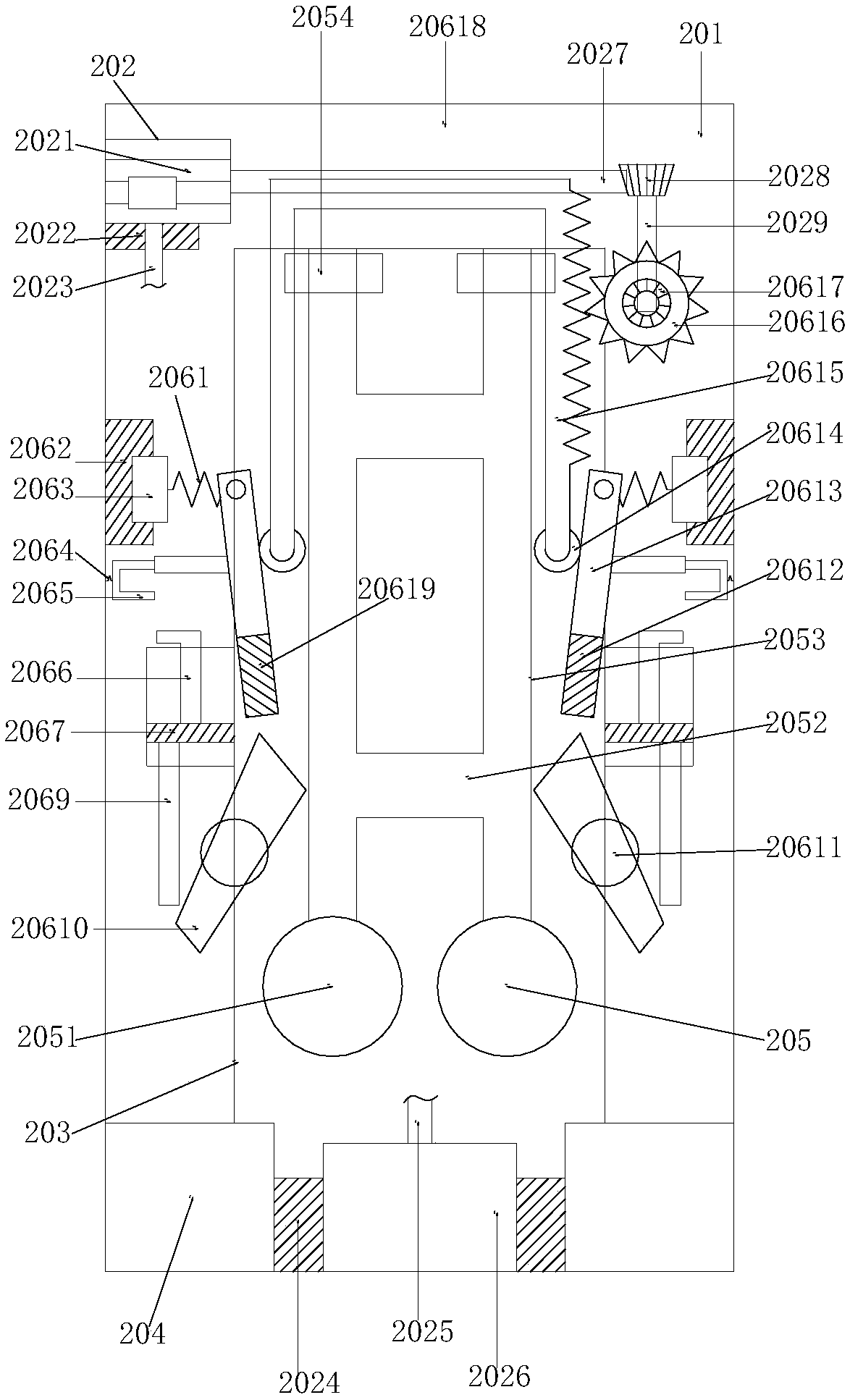

Instrument pointer pulling force detection device

The invention relates to a detection device and specifically relates to an instrument pointer pulling force detection device. The invention solves problems that a conventional pointer pulling force detection device is low in detection efficiency and is low in automation degree and the qualified rate of products is affected by the high operation difficulty. A pedestal is arranged horizontally, and two sliding rails are arranged in parallel on the upper surface of the pedestal. A fixed instrument pedestal is disposed on the two sliding rails. A Y-axis push cylinder is disposed on the upper surface of the pedestal, and a push rod of the Y-axis push cylinder is connected with the fixed instrument pedestal. A vertical column is vertically disposed on the upper surface of the pedestal. The cylinder is connected with the vertical column through a lifting clamping mechanism. A pointer handle head is connected with a centering mechanism, and the centering mechanism is connected with the push rod at the lower end of the cylinder. A plurality of rotating cylinders are uniformly distributed on the upper surface of the fixed instrument pedestal. The invention belongs to the field of instrument detection.

Owner:AEROSPACE HI TECH HLDG GROUP

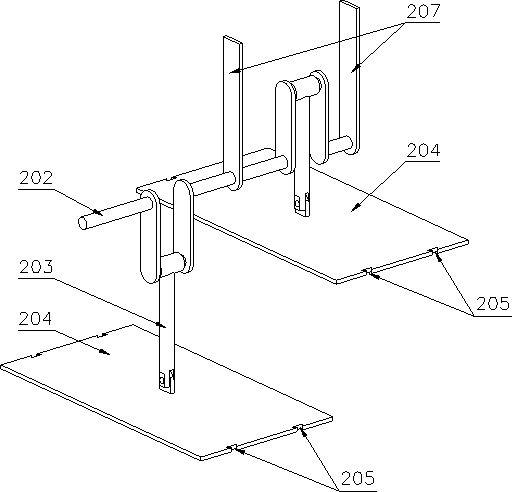

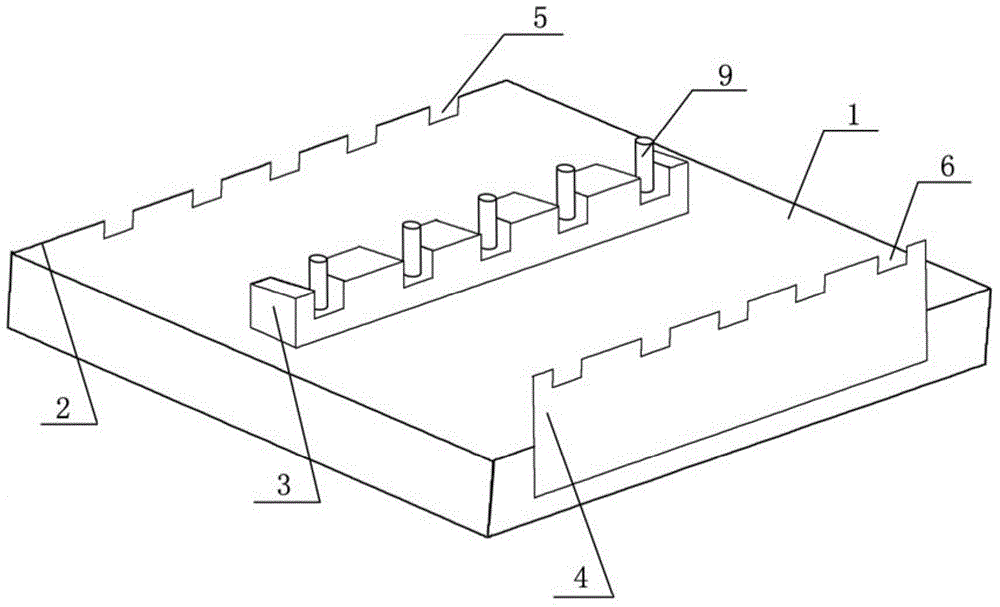

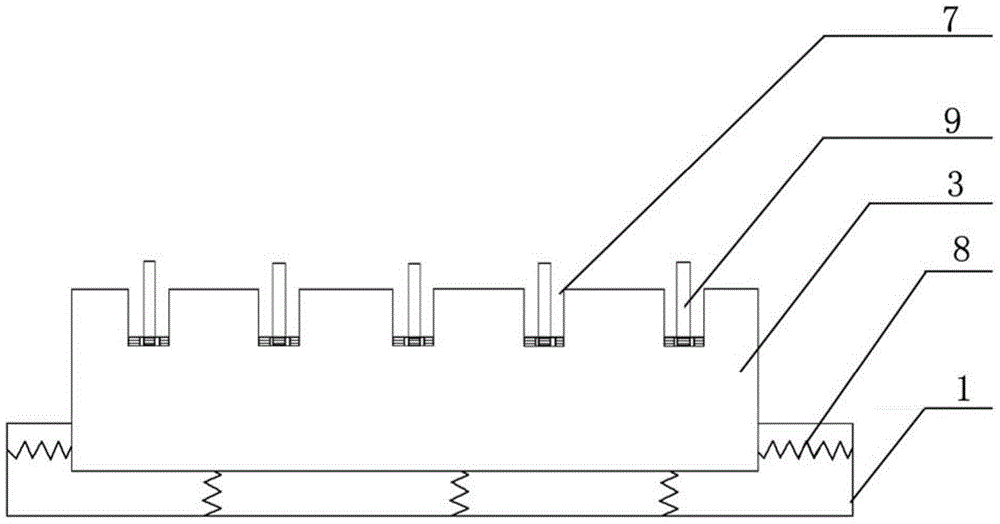

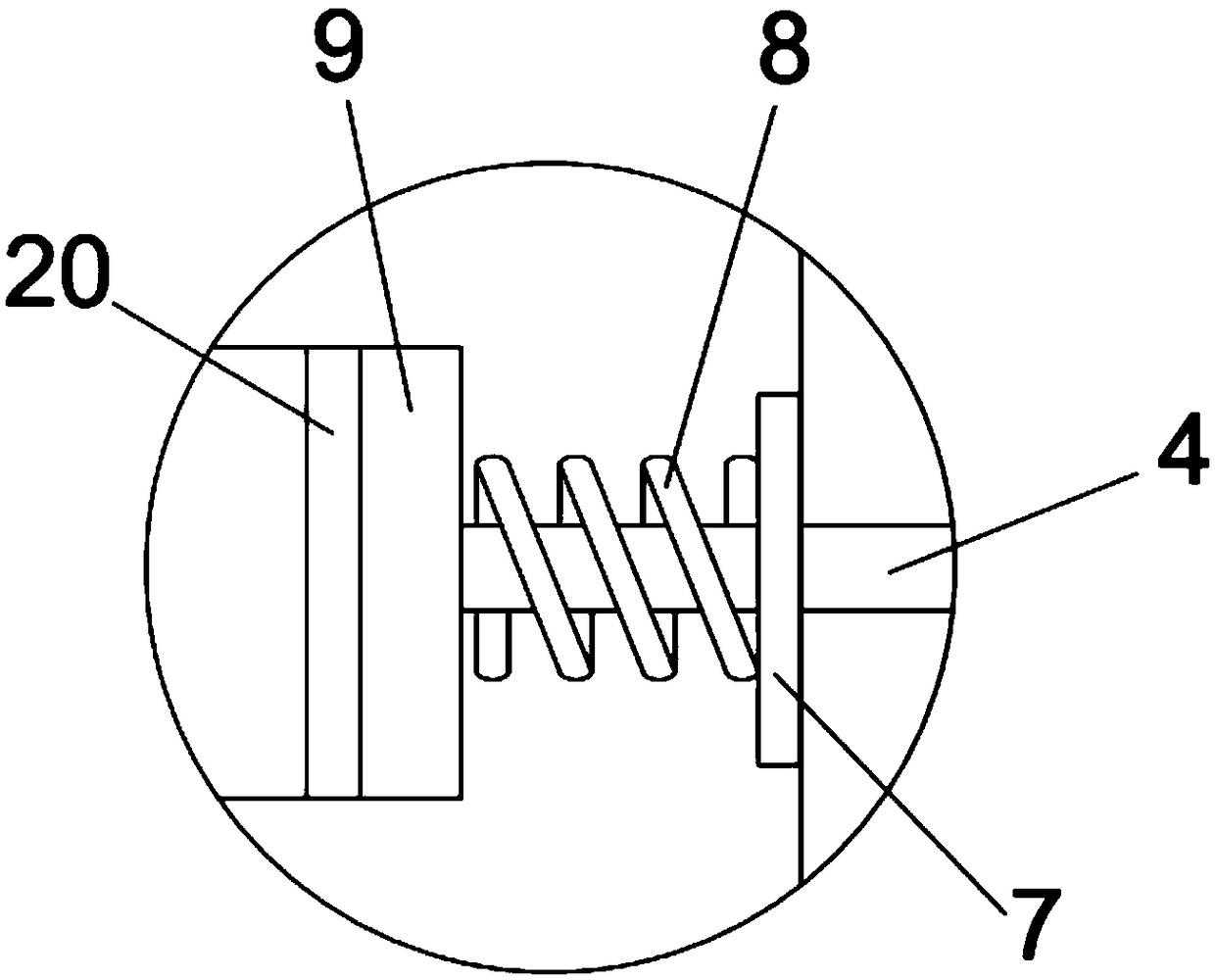

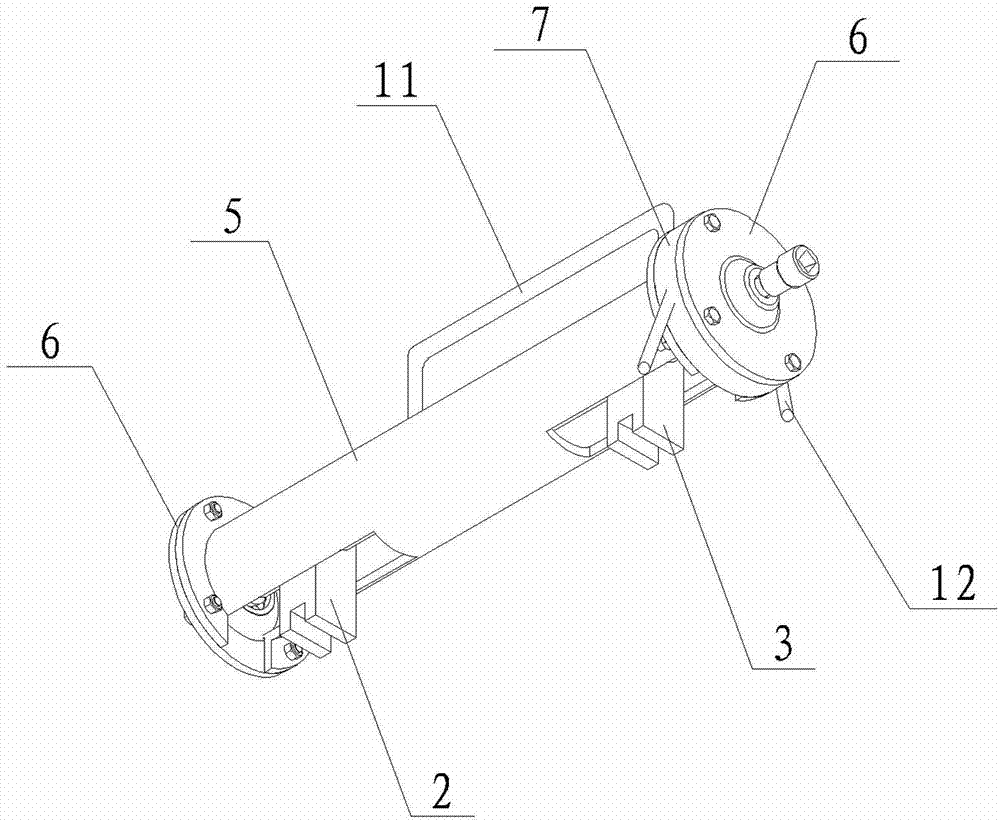

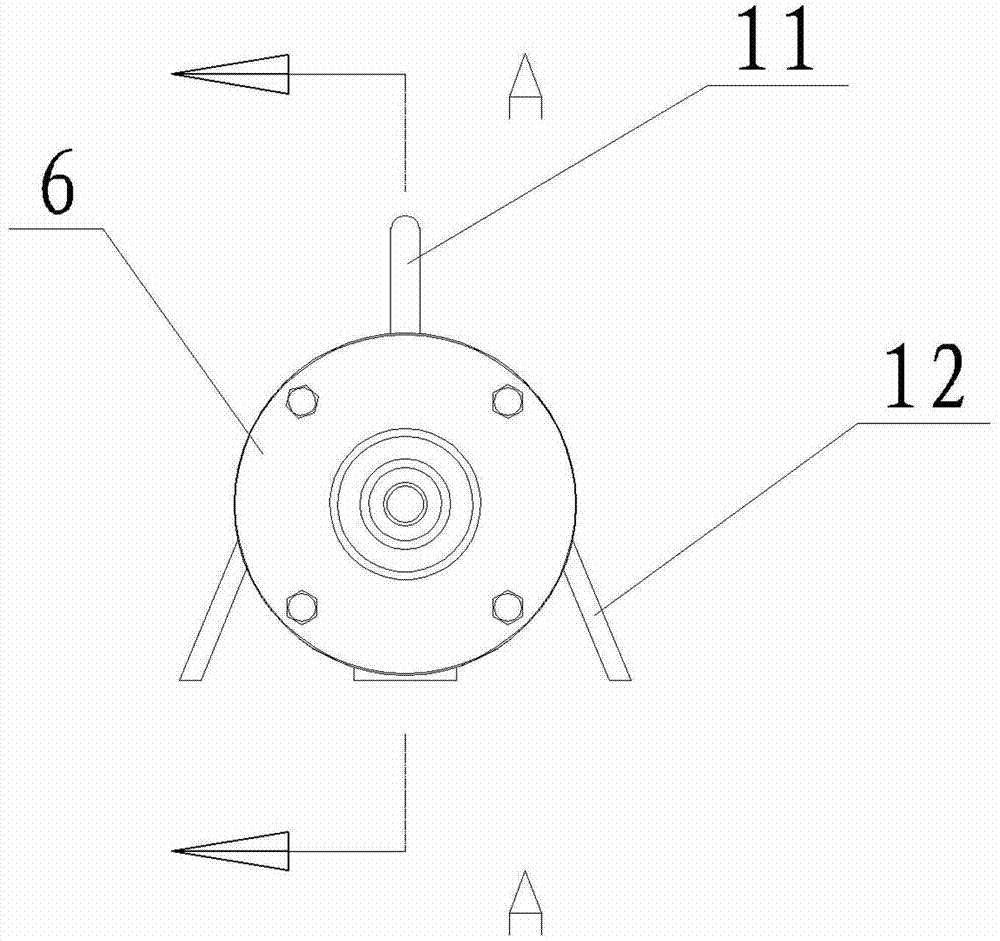

Spinning yarn positioning jig

The invention relates to the technical field of spinning equipment, in particular to a spinning yarn positioning jig. The spinning yarn positioning jig comprises a guiding platform. The guiding platform is provided with a yarn inlet end, a yarn guiding device and a yarn outlet plate. A plurality of notches are formed in the yarn inlet end. A plurality of slots are formed in the yarn outlet plate. The yarn guiding device is provided with a plurality of breaking openings. Spinning yarn passes through the breaking openings of the yarn guiding device through the notches and then is led out of the slots, and accurate guiding on the spinning yarn is achieved. The notches, the breaking openings and the slots are correspondingly arranged in pairs, and the bottom faces of the notches, the breaking openings and the slots pass the same plane, wherein a certain upward inclination angle is formed between the plane and the horizontal plane. The spinning yarn walks in the manner of being closely attached to the bottom faces of the notches, the breaking openings and the slots in the walking process, and the moving range of the spinning yarn is limited through friction. Meanwhile, positioning columns are in threaded connection with the bottom faces of the breaking openings, the possible moving tendency of various kinds of spinning yarn in the left and right direction can be further limited through the positioning columns, and the swinging amplitude of the various kinds of spinning yarn in the walking process is better reduced. An elastic body is arranged at the lower portion of the yarn guiding device, and the walking process of the spinning yarn is more smooth and gentler.

Owner:WUXI XUEJIANG ENVIRONMENT ENG EQUIP

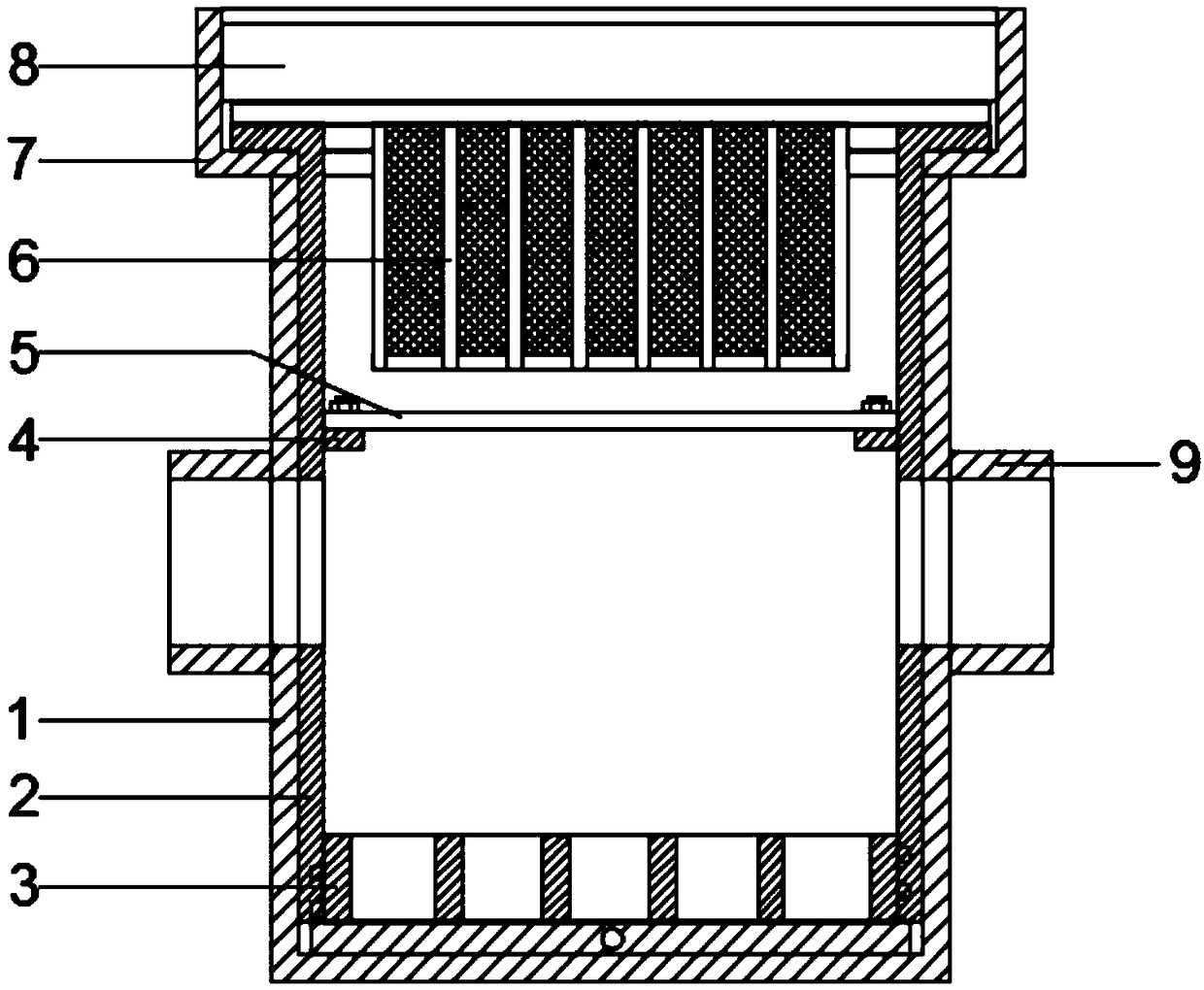

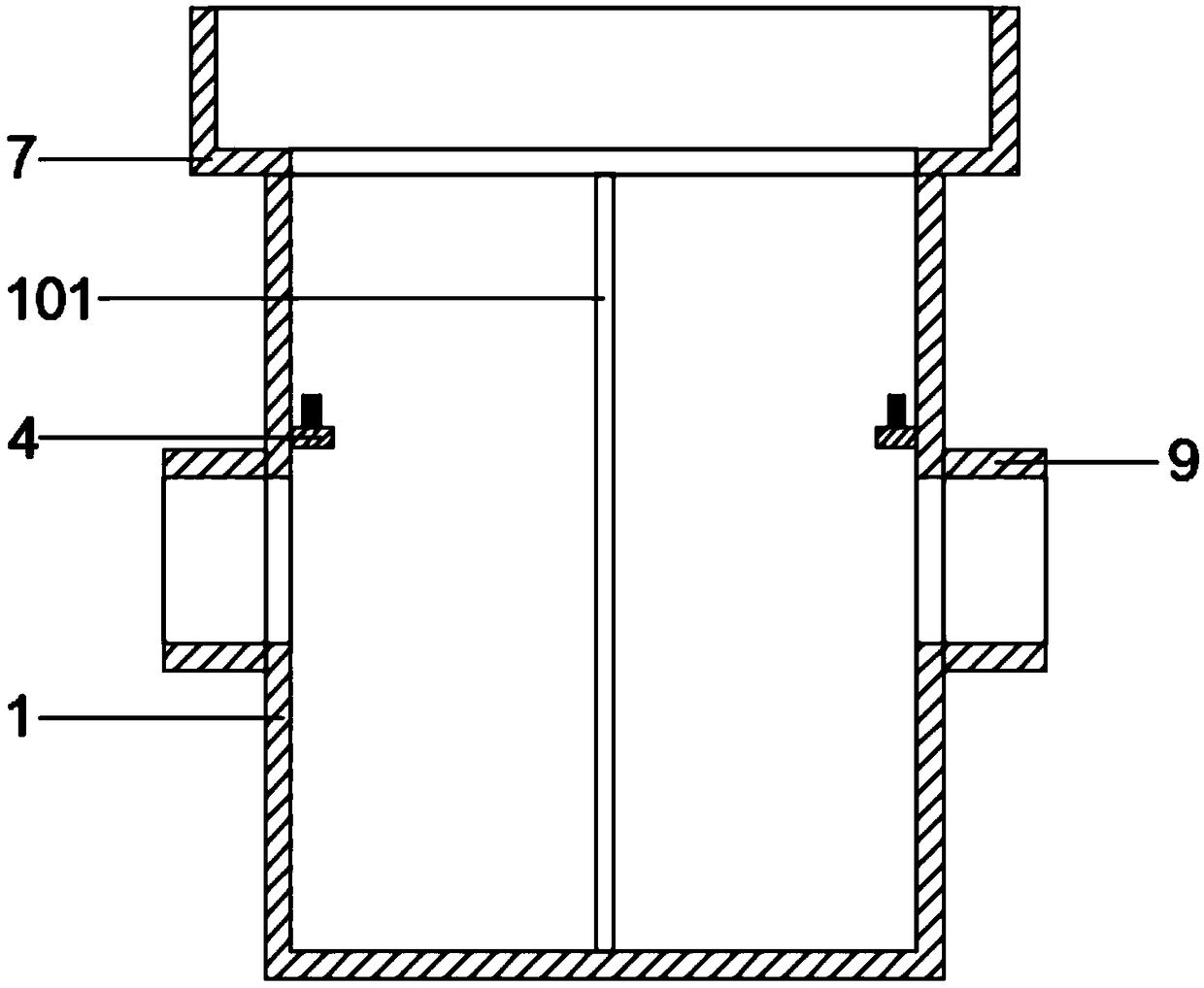

Detachable and easy-to-clean rainwater collection well device

InactiveCN109183903AAvoid cloggingImprove filtering effectFatty/oily/floating substances removal devicesSewerage structuresRainwater harvestingEngineering

The invention provides a detachable and easy-to-clean rainwater collection well device, comprising a first cylindrical cylinder, a water inlet hole and a water outlet pipe; The top of the first cylindrical cylinder is welded with the stopper ring; A lid plate is arrange at that position above the filter screen in the stop re. The second cylindrical cylinder can be directly slid out of the first cylindrical cylinder when the sediment in the device is cleaned after use, and then the sediment in the device is memorized and cleaned, so that the cleaning is more convenient; Through the arrangementof the sediment collecting cover, on the one hand, the sediment collecting cover is provided with threads and is threadably connected with the inner wall of the second cylindrical cylinder, Therefore,when cleaning, the sand collecting cover can be directly rotated and removed for cleaning, so as to improve the convenience of cleaning; on the other hand, because the sand collecting cover is weldedwith four baffles in a rectangular array, the movement range of the sand particles can be limited to prevent the sand particles from moving with the rain water.

Owner:张耿强

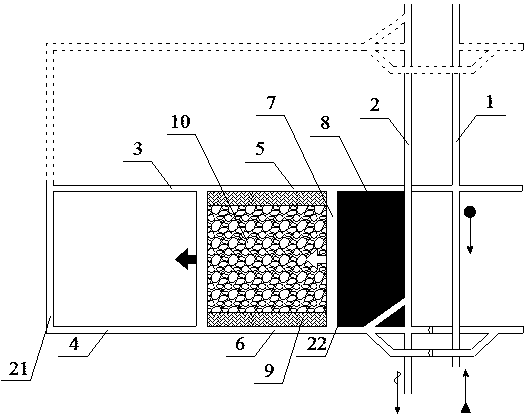

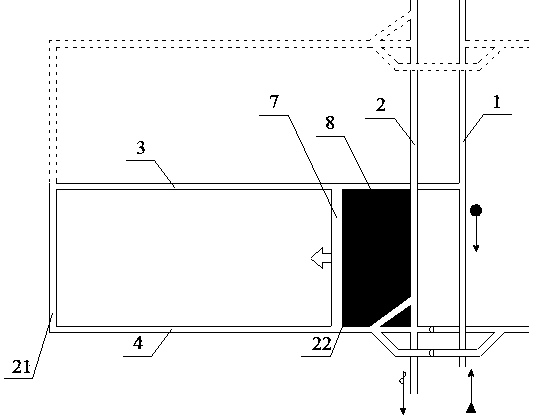

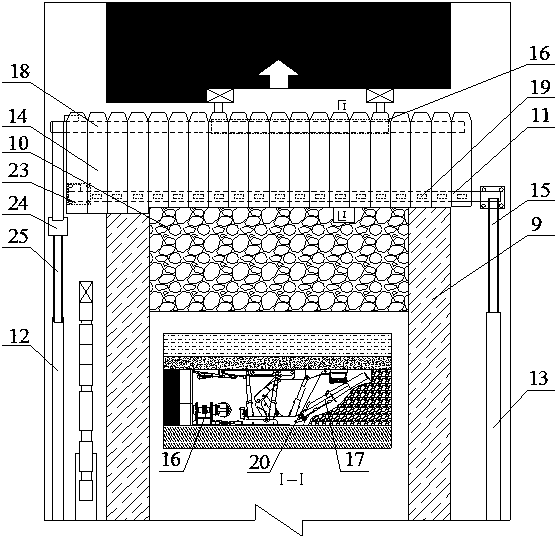

A kind of pre-excavation two-way forward solid filling coal mining method

ActiveCN102996131BSolve the technical problems that cannot guarantee the filling effectEasy to useUnderground miningSurface miningSolid massFilling materials

Owner:CHINA UNIV OF MINING & TECH

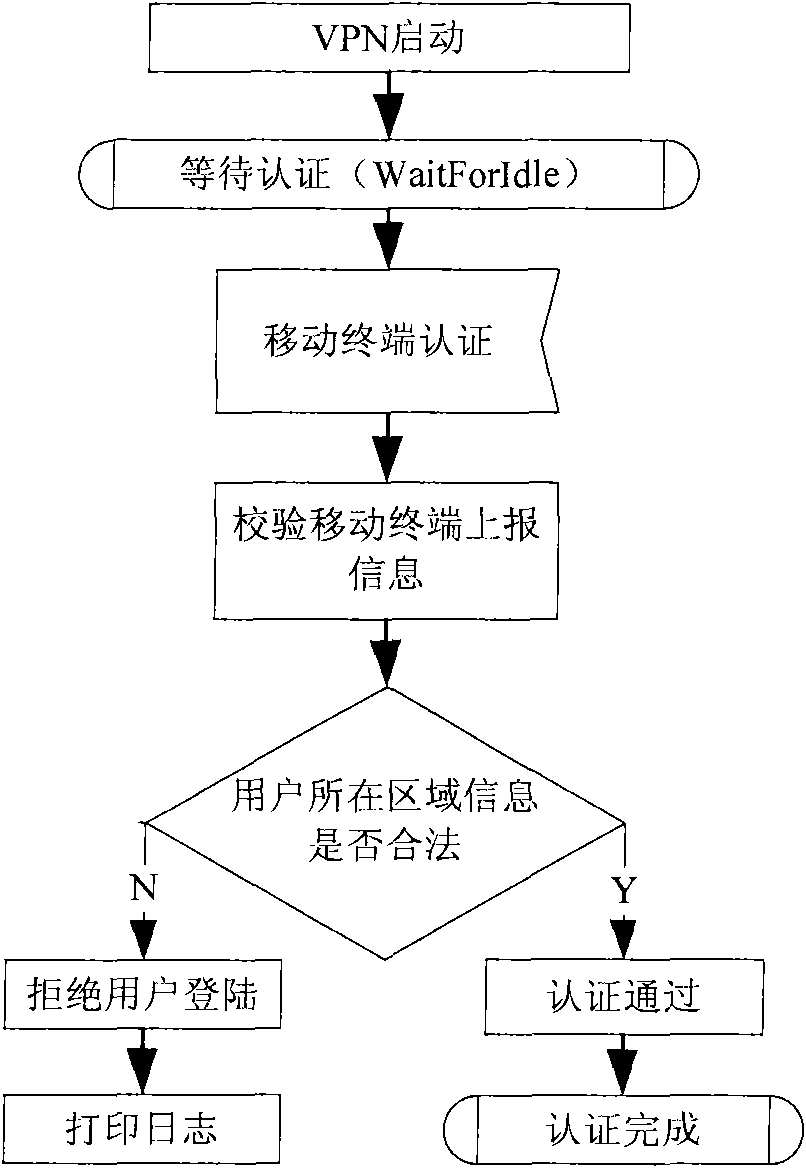

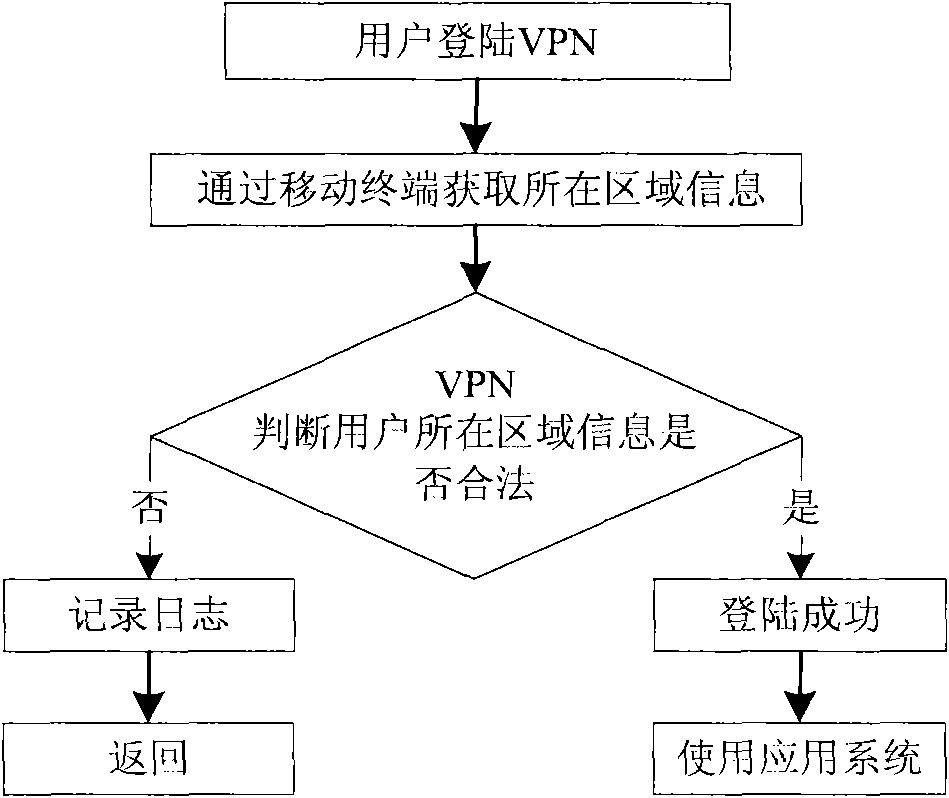

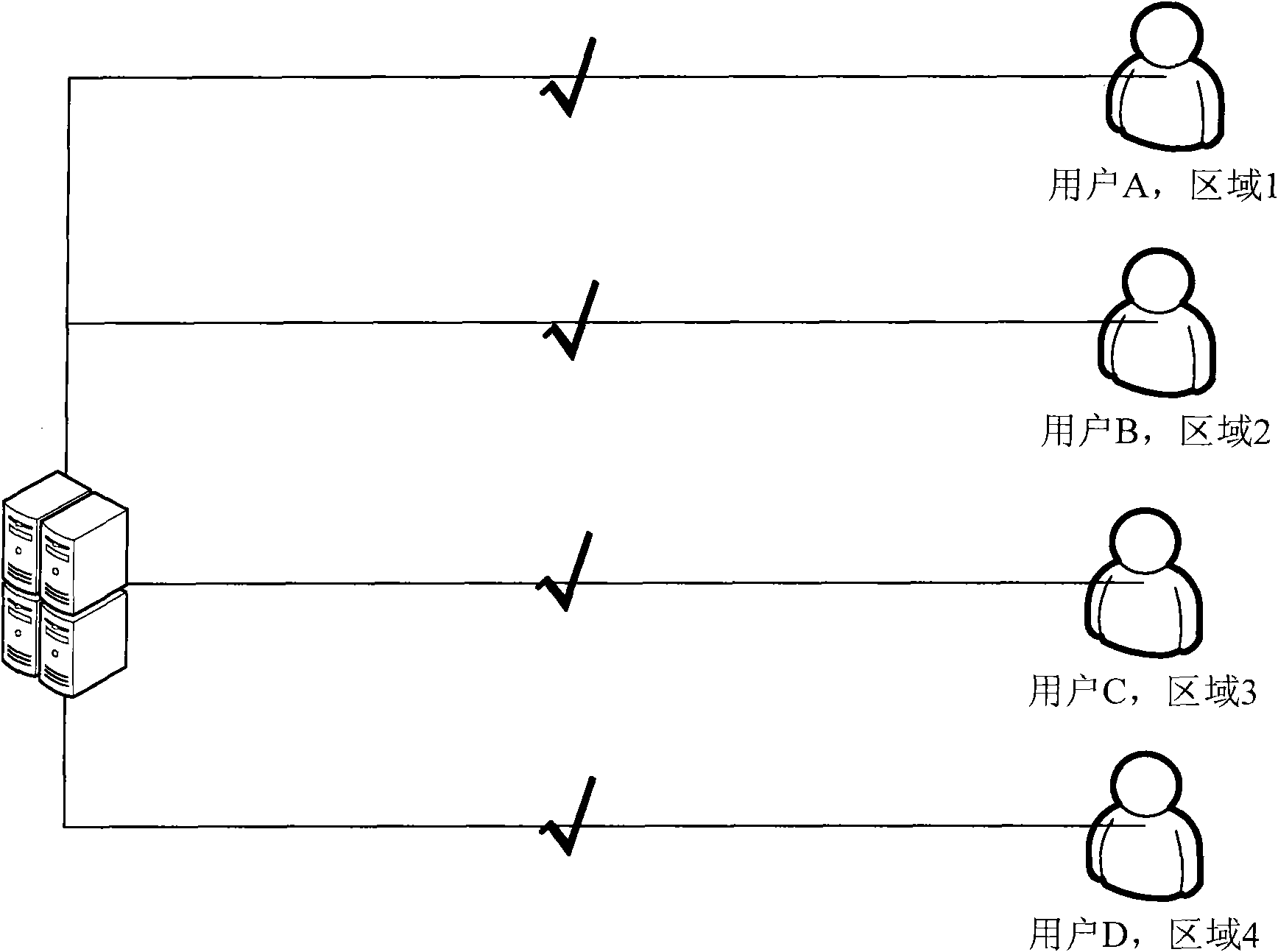

VPN authentication method

InactiveCN101610512ALimit the range of activitiesSidestepping limitationsUser identity/authority verificationSecurity arrangementEnd userAuthentication

The invention relates to a VPN authentication method which comprises the following steps: acquiring area information reported by a mobile terminal user; rejecting the mobile terminal user in an illegal area to access a VPN; and allowing the mobile terminal user passing authentication in a legal area to access the VPN. The VPN authentication method helps improve safety of authentication by limiting areas, can limit a movement range of the user for reasons of service and the like, and can further reduce probability of misappropriation of a user account (an appropriator must be in the same area as the user).

Owner:SANGFOR TECH INC

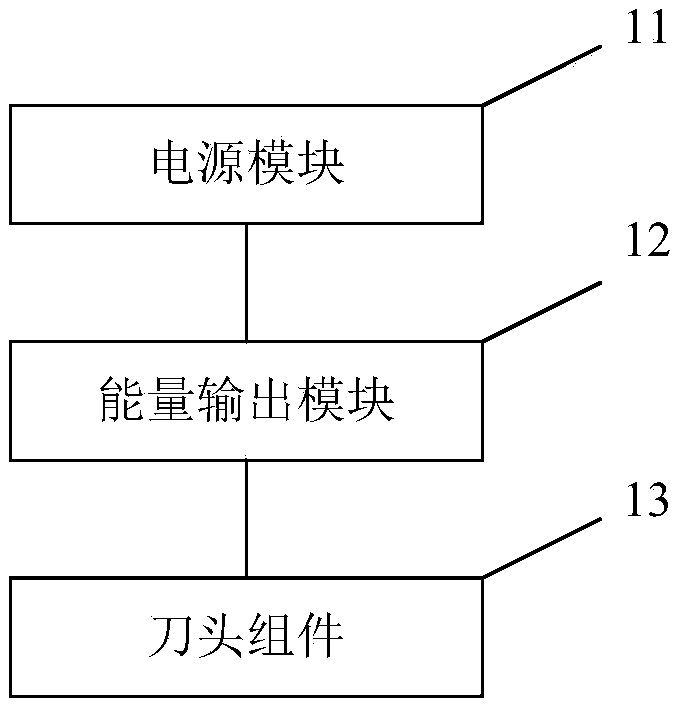

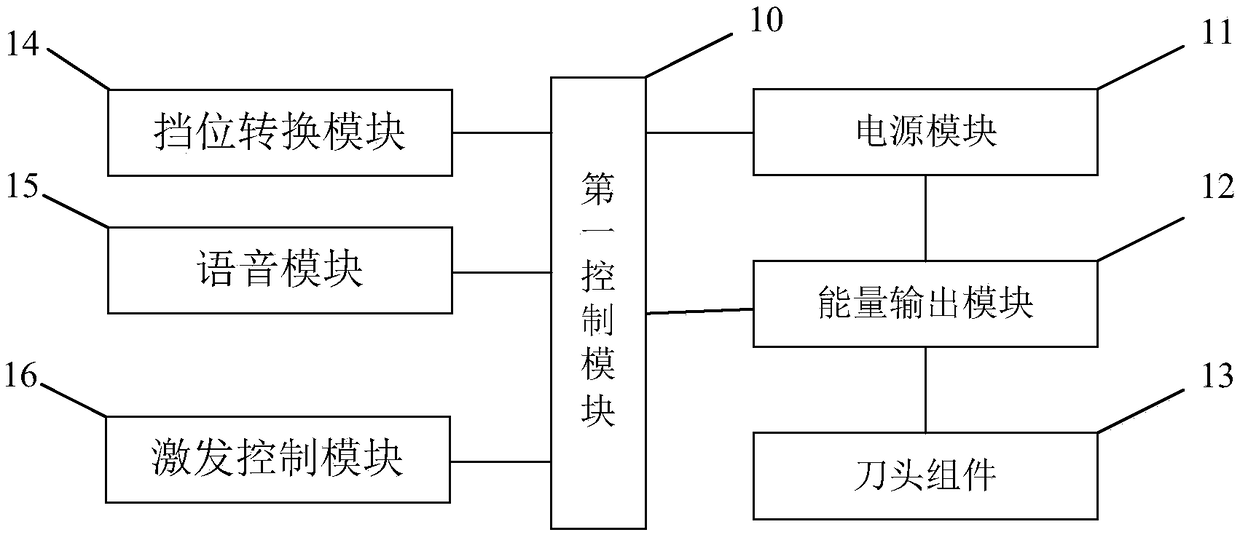

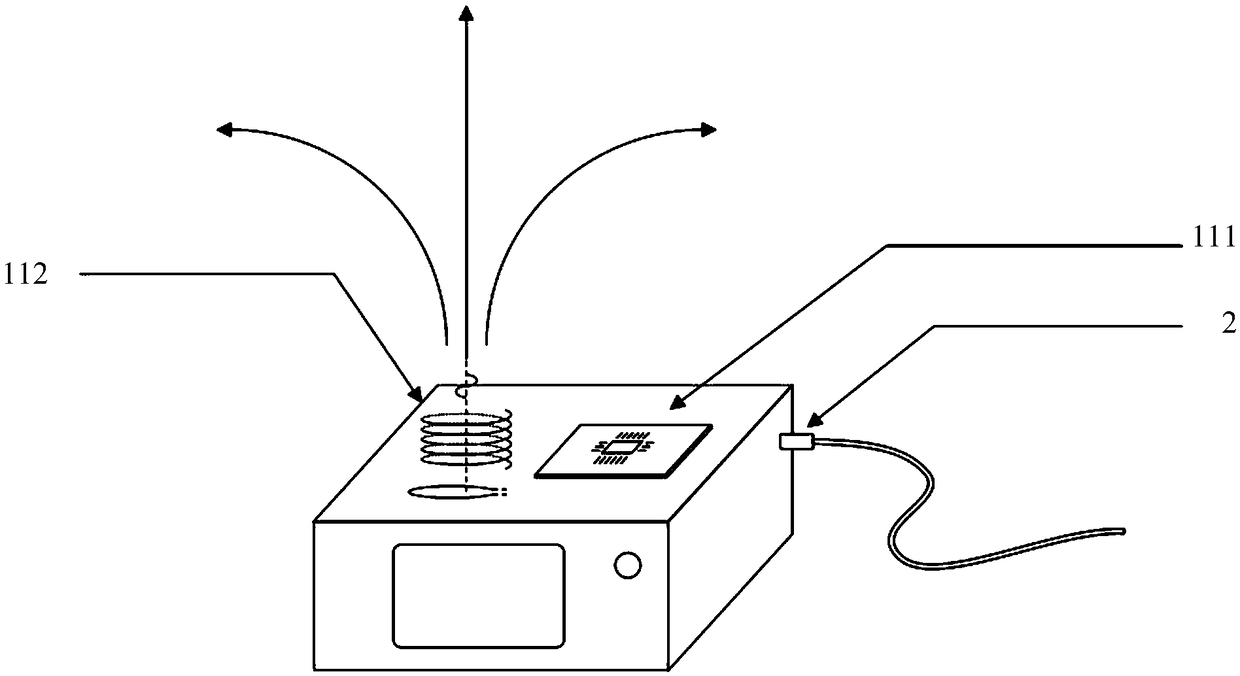

Electrosurgical scalpel and control method thereof

PendingCN108888336ALimit the range of activitiesExpand the scope of activitiesFluid jet surgical cuttersSurgical instruments for heatingPower flowElectrosurgery

The embodiment of the invention discloses an electrosurgical scalpel and a control method thereof. The electrosurgical scalpel comprises a power module, which is used for outputting electric energy ofa preset voltage or a preset current in a wireless power supply manner. An energy output module, connected with the power supply module, for generating preset energy based on the preset voltage or the preset current; A knife head assembly is coupled to the energy output module for outputting the preset energy to a target tissue. So as to solve the technical problem that the portability of the electrosurgical scalpel of the prior art is limited due to the energy problem, and the technical effect of improving the portability of the electrosurgical scalpel is achieved.

Owner:SURGSCI SHENZHEN MEDICAL TECH CO LTD

Floor grooving equipment

InactiveCN105108854AReduce noise and dust pollutionRun smoothlyWood mortising machinesWood slotting machinesWoolAgricultural engineering

The invention provides floor grooving equipment, and belongs to the technical field of floor processing. The floor grooving equipment comprises a bearing mechanism, a grooving mechanism and a denoising mechanism, a translation support of the grooving mechanism is arranged between a male groove cutter support and a female groove cutter support, a translation lead screw is rotatably arranged on a bearing support, the translation lead screw is connected with a lead screw nut of the translation support in a threaded mode, the rear end of the bearing support of the bearing mechanism is fixed on a fixed bearing support, the front end of the bearing support of the bearing mechanism is provided with a bearing plate, the lower end face of the bearing plate is flush with a cutting platform, maintenance platforms of the denoising mechanism are fixed on the two sides of the lower portion of a rack respectively, the upper ends of denoising doors are hinged to the upper end of the rack, one end of each gas spring is hinged to the rack, the other end of each gas spring is hinged to the corresponding denoising door, acoustic wool is arranged on the inner side of each denoising door, and mobile maintenance windows are arranged on the two sides of the rack respectively. According to the floor grooving equipment, the noise and dust which pollute the workshop environment are effectively reduced, and repair and maintenance of the equipment are very convenient.

Owner:TIANJIN CHAOMAI TECH DEV CO LTD

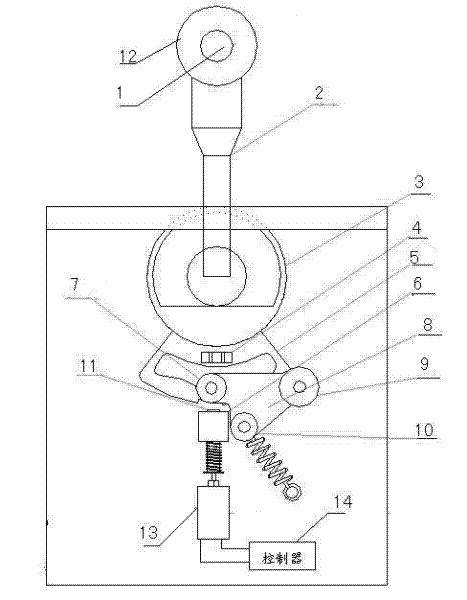

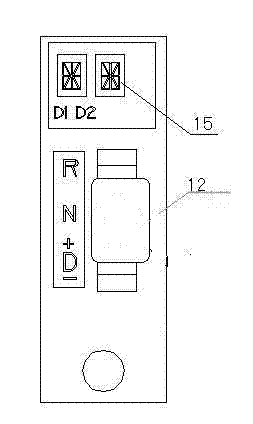

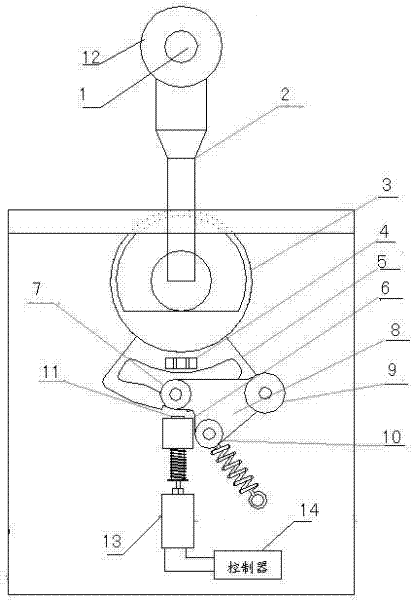

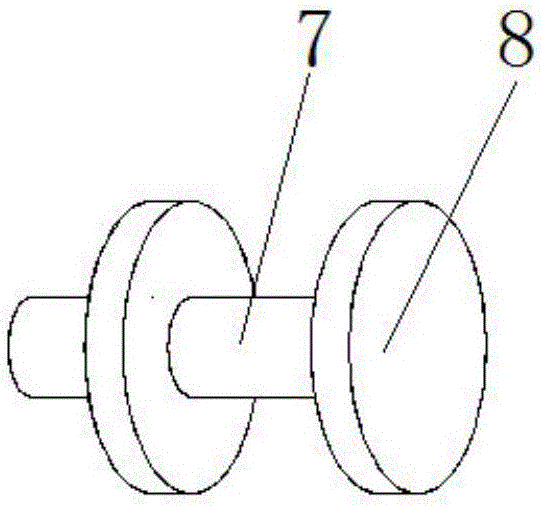

Gear shifting handle

ActiveCN102345729ASimple mechanical structureReasonable designGearing controlAutomatic transmissionAgricultural engineering

The invention belongs to the technical field of a vehicle automatic transmission gearshift, and in particular relates to a gear shifting handle. The gear shifting handle comprises a controller and an operating machine unit, wherein a fixed pulley, a spring tension wheel, and an embeded wheel are arranged at three ends of a gear limiting move spring block in the operating machine unit; the upper end of an operating arm is provided with an operating arm grab handle, an unlock button is arranged on the operating arm grab handle, one side of the lower end of the operating arm is connected with a circle handle block, and a gear limiting block is connected with the circle handle block; the gear limiting block is provided with three grooves, a magnet block is fixed on the gear limiting block, and the gear limiting move spring block is arranged on the lower end of the gear limiting block; the embedded wheel is embedded in the gear limiting block, and the fixed pulley is used for fixing one end of the gear limiting block; and an iron prop is arranged below the gear limiting move spring block, and the lower end of the iron prop is connected with an electromagnet. The gear shifting handle provided by the invention has the advantages of simple mechanism unit structure, reasonable design, and practical function.

Owner:SPECIAL VEHICLE TECH CENT OF HUBEI AEROSPACE TECH RES INST

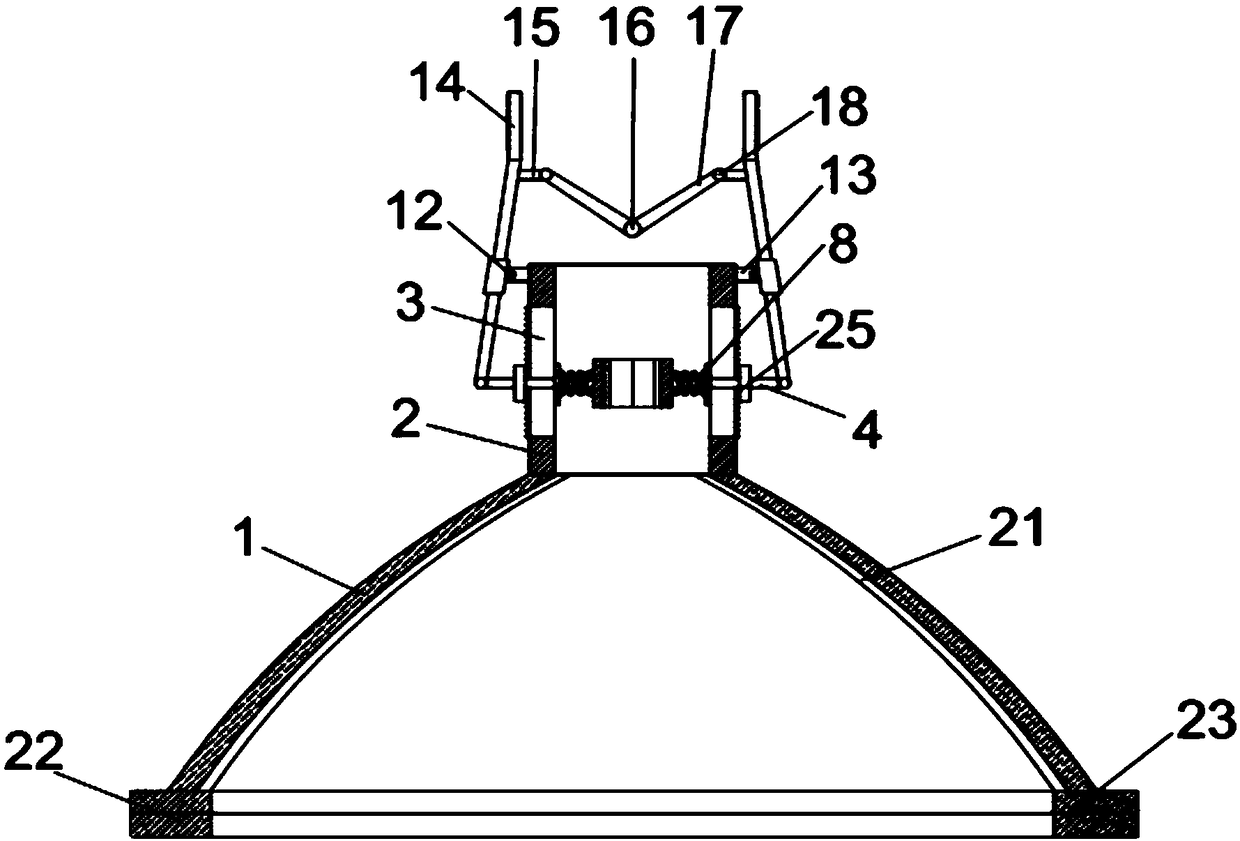

Suspension fixator for nipple inversion surgery

InactiveCN108904109AUniform and fixed forceIncrease painNon-surgical orthopedic devicesEngineeringNipple part

The invention discloses a suspension fixator for a nipple inversion surgery. The suspension fixator comprises a sleeve and sliding grooves. The sliding grooves are formed in the centers of the outer walls of the left and right sides of the sleeve correspondingly. The inner side of a fixing block is fixedly connected with a spring. The tail end of the inner side of a first connecting rod is fixedlyconnected with a clamping plate. The spring is fixedly connected with the clamping plate. The tail end of the outer side of the first connecting rod is fixedly connected with a third rotating shaft.The bottom end of a fourth connecting rod is fixedly connected with a first rotating shaft. According to the suspension fixator for the nipple inversion surgery, the nipple parts of a patient are bearforce evenly and fixed by mounting the clamping plate, and thus the situation that the pain of the nipple parts of the patient is increased due to shaking generated when the patient moves slightly isavoided; and by forming the sliding grooves, outer clamping teeth, a fixing plate and inner clamping teeth, the height of the clamping plate can be adjusted, and the clamping plate can be fixed afterthe height of the clamping plate is adjusted, thus the pain caused by secondary damage to the patient after the surgery is reduced, a user can complete operation only by pinching a handle during using, using is convenient, the clamping plate bears the force evenly, and the pain of the patient is reduced.

Owner:XIANGYA HOSPITAL CENT SOUTH UNIV

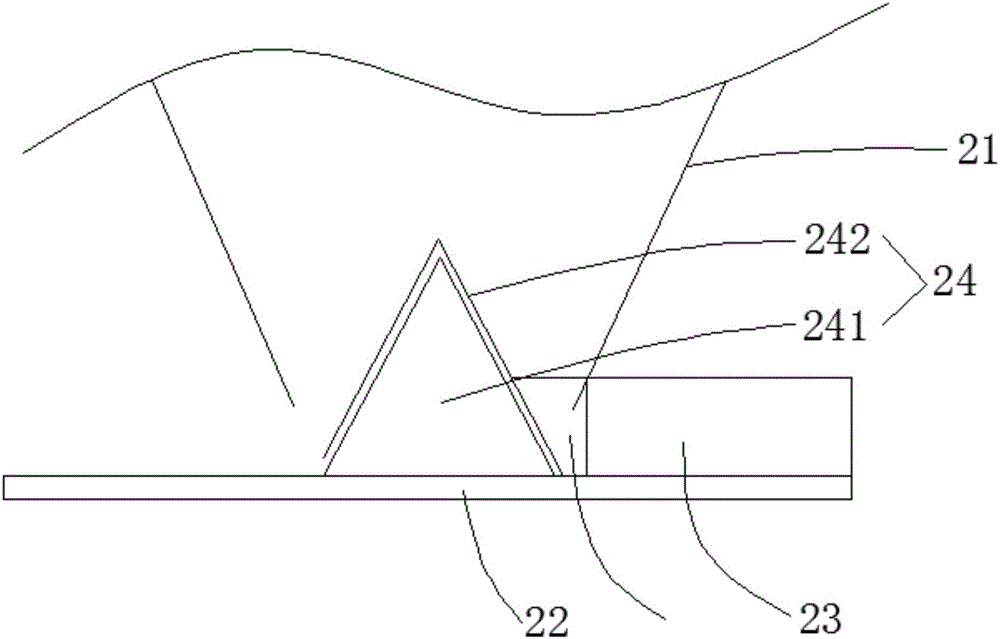

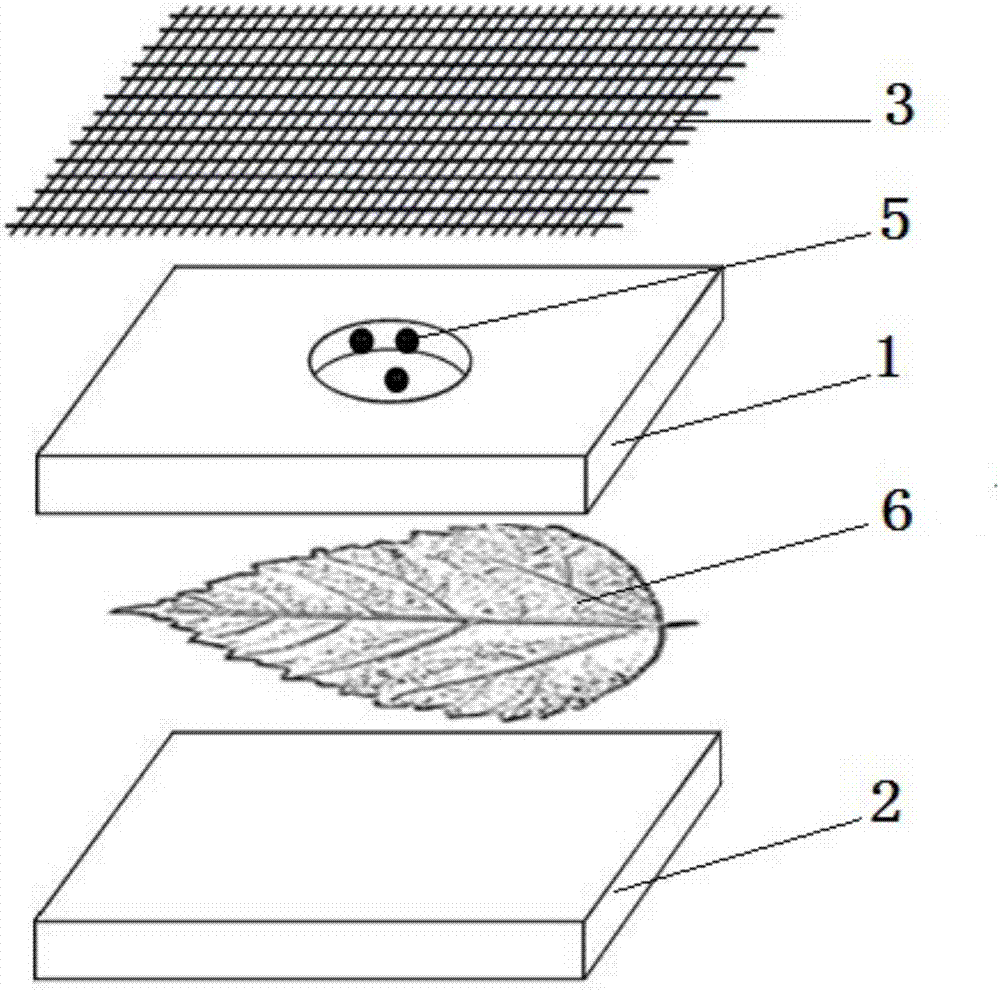

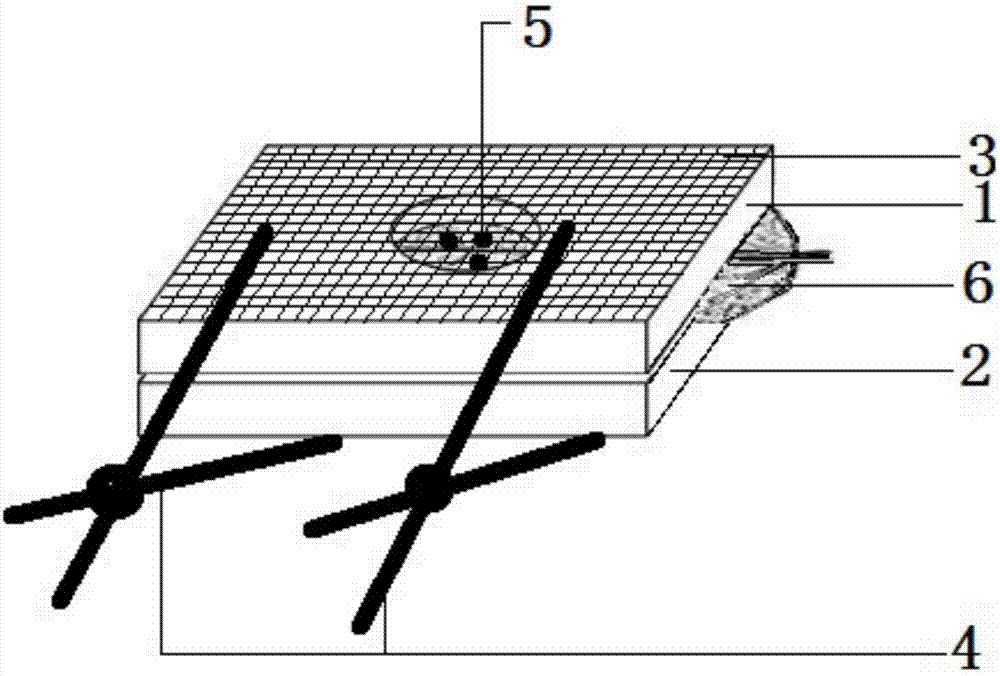

Device for limiting aphid activity range and method for fixed-point aphid breeding and reproduction

InactiveCN107306897ALimit the range of activitiesSimplification of fixed-point breeding stepsAnimal husbandryApidaeEngineering

The invention discloses a device for limiting an aphid activity range. The device comprises a range limit foam sheet, a culturing support foam sheet, an insect-proof screen and a clamp, a circular hole is formed in the center of the range limit foam sheet, the range limit foam sheet and the culturing support foam sheet are oppositely placed on two sides of the same blade, the insect-proof screen covers the range limit foam sheet, and the range limit foam sheet, the culturing support foam sheet, the insect-proof screen and the blade are fixed by the clamp. The invention further provides a method for fixed-point aphid breeding by the aid of the device. According to the device and the method, fixed-point breeding of the aphids can be achieved, the device has the advantages that materials are conveniently taken, the device is simple to manufacture, the aphids are remarkably limited, the device meets requirements of aphid breeding at specific positions, the breeding efficiency of the aphids at the specific positions of plants is improved, and the device can be simply reconstructed, so that the device is applicable to other small insects.

Owner:SHANGHAI JIAO TONG UNIV

Teaching board for computer education

InactiveCN107344465AAchieve the effect of rotationEasy to useWriting boardsFurniture partsEngineering

Owner:苏州艾虎数码科技有限公司

Tower minimum space operating method based on insulated isolation umbrella

InactiveCN104051986ALimit the range of activitiesProtected from high voltage threatsApparatus for overhead lines/cablesIsolation layerEngineering

The invention provides a tower minimum space operating method based on an insulated isolation umbrella. The movement range of operating personnel is limited through a constraint limiting rod and an isolation layer of the constraint limiting insulated isolation umbrella, the distance between the operating personnel and an electrified body meets the safety requirement all the time when the operating personnel enter the range and reaches the operating position to work, and the method is applicable to various tower operations along a tower cross arm, wherein the various tower operations include detection of zero resistance insulators, replacement of a whole string of linear insulators on a tower, replacement of a whole string of tension insulators on the tower, and replacement of the whole string of tension insulators on the tower in cooperation with equipotential. In the operating process of the method, shutting down is not required, the operating personnel are prevented from entering the electrified space according to limiting prompt of the insulated isolation umbrella and can work at ease, operating efficiency is improved, operation is easy and convenient, and safety of the operating personnel is effectively guaranteed.

Owner:PINGDINGSHAN POWER SUPPLY ELECTRIC POWER OF HENAN

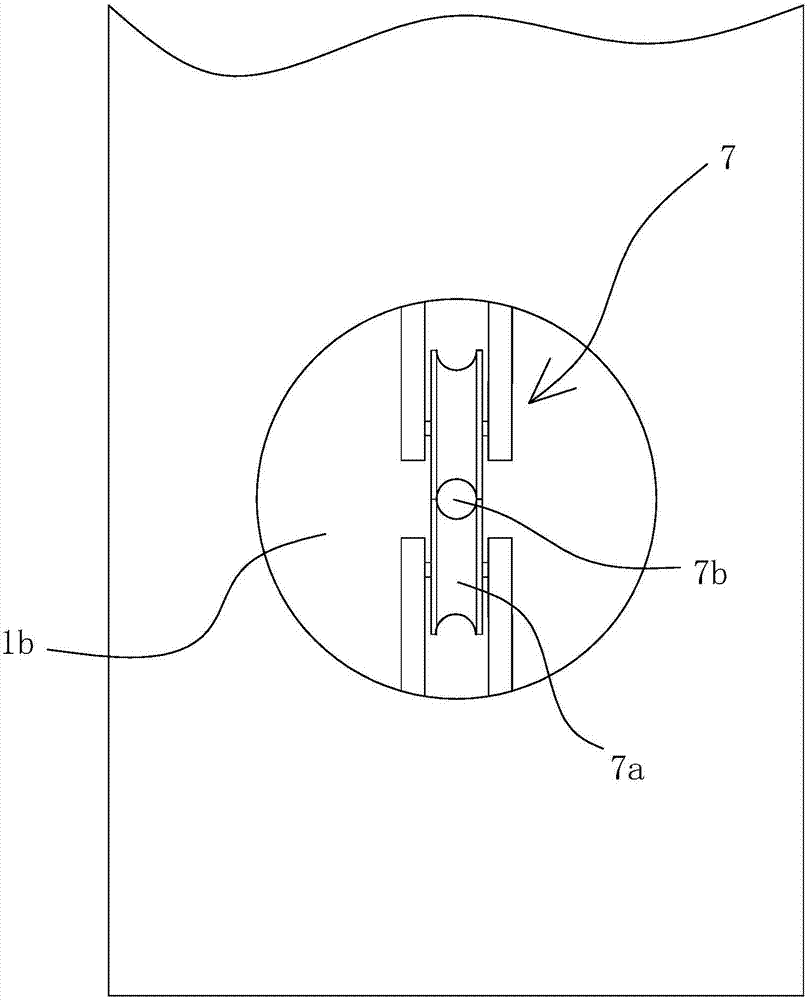

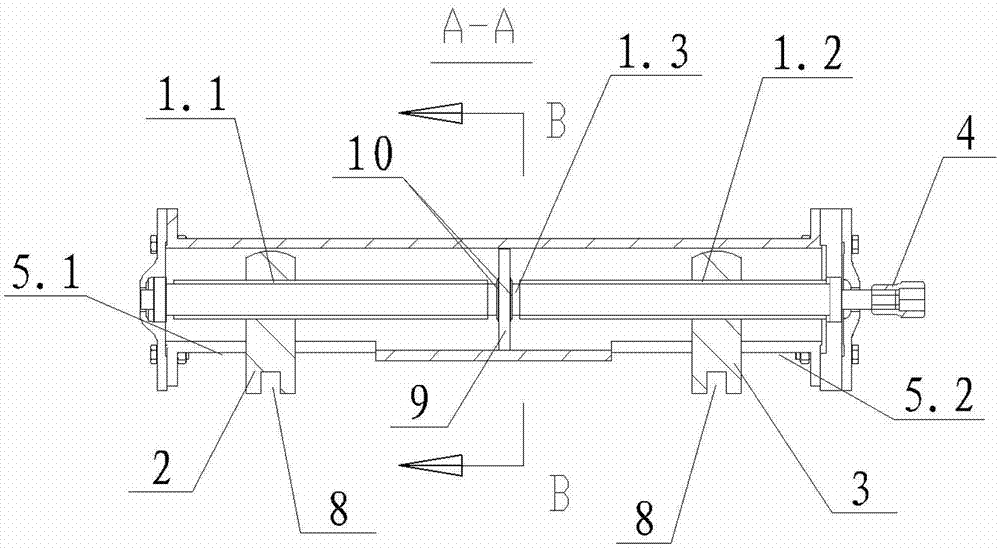

Tensioning device for end beam of crane

The invention discloses a tensioning device for an end beam of a crane. The tensioning device comprises a support frame, a bidirectional screw rod, a left clamp block and a right clamp block, wherein the bidirectional screw rod is provided with a left threaded section and a right threaded section, and the thread direction of the left threaded section is opposite to that of the right threaded section; two ends of the bidirectional screw rod are respectively supported on the support frame; the left clamp block and the right clamp block are respectively screwed on the left threaded section and right threaded section of the bidirectional screw rod; the left clamp block and the right clamp block are circumferentially limited by the support frame; the left clamp block and the right clamp block move close to or away from each other when being driven by the clockwise rotation or anticlockwise rotation of the bidirectional screw rod; clamping parts for being clamped on side plates of the end beam of the crane are arranged on the left clamp block and the right clamp block; a connecting head for connecting the driving device is arranged at one end of the bidirectional screw rod. By utilizing the tensioning device, the interval between the two side plates of the end beam of the crane can be accurately regulated, the time and the labor are saved, and no noise is generated.

Owner:宁波市凹凸重工有限公司

Buffer piston structure of compressor

ActiveCN103775308ASimple structureWide applicabilityPositive displacement pump componentsPositive-displacement liquid enginesExhaust gasCheck valve

The invention discloses a buffer piston structure of a compressor. The buffer piston structure of the compressor comprises a piston body, and a crankshaft connecting rod connected with the piston body, wherein a buffer through hole is formed inside the piston body; a piston barrel is arranged inside the buffer through hole; the crankshaft connecting rod is hinged at one end of the piston barrel. Compared with the prior art, the buffer piston structure of the compressor has the advantages as follows: a built-in piston is arranged inside an ordinary piston, the built-in piston is hinged with a crankshaft, and the crankshaft drives the built-in piston first and then drags the external piston to move through a traction buffer device connected with the external piston, so that when a check valve of the compressor intakes and exhausts gas, a buffer effect is achieved, thereby avoiding an instantaneous relatively-high pressure and reducing wear and tear of mechanical equipment.

Owner:南通市红星空压机配件制造有限公司

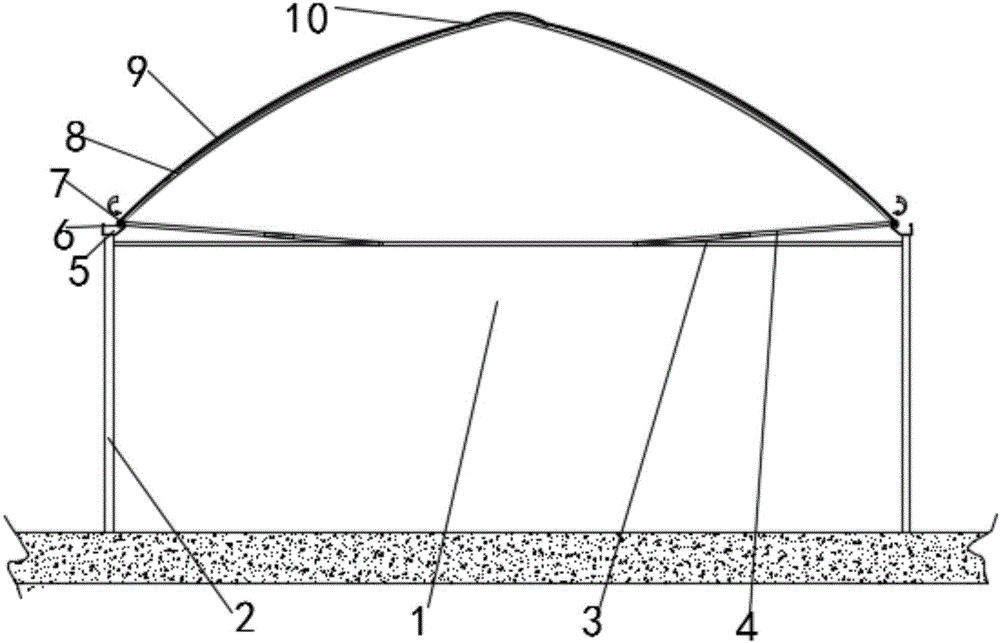

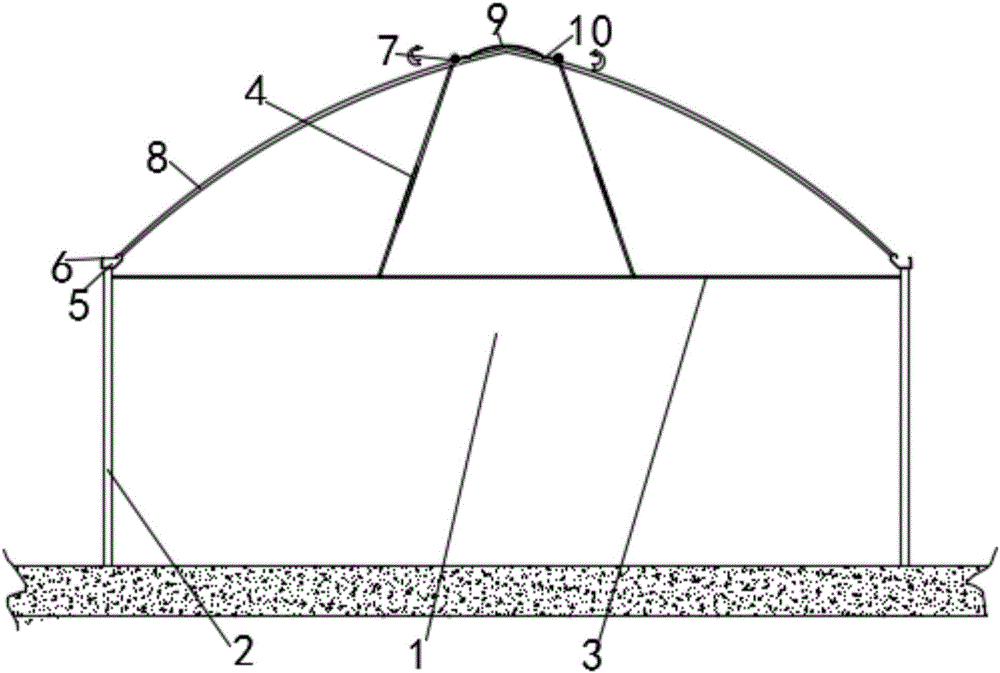

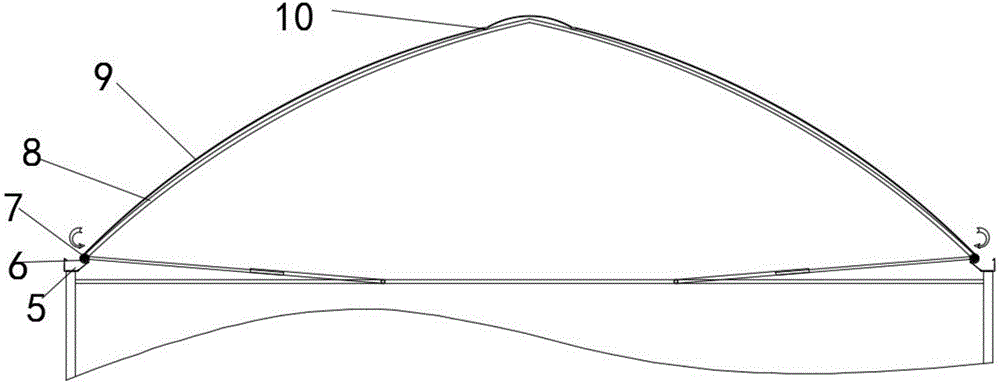

Film winding device with drainage function on greenhouse

InactiveCN106718317AImprove wind strengthImprove drainage effectRoof coveringClimate change adaptationAgricultural engineeringHigh humidity

The invention discloses a film winding device with a drainage function on a greenhouse. The film winding device comprises film winding pipes and a film, wherein the film winding pipes are arranged on a greenhouse arch frame, and the film is wound on the film winding pipes. A water channel parallel to the film winding pipes is formed in the upper portion or the sidewall on one side of the greenhouse arch frame, the inner wall of the water channel is provided with clamping grooves for clamping the film winding pipes, and the film on the film winding pipes can bypass the sidewall of the water channel to lay on the greenhouse arch frame. The film winding device with the drainage function on the greenhouse has the advantages that the water channel is arranged on the upper portion or the sidewall of the greenhouse, and the clamping grooves for fixing the film winding pipes are formed in the water channel, so that fixation of the film winding pipes and the film is facilitated, wind resistance of the film winding pipes and the film is enhanced, rainwater can be drained through outlets at two ends of the water channel in rainy days, greenhouse drainage effects are improved, forming a high-humidity environment in the greenhouse is avoided, and greenhouse planting efficiency is improved.

Owner:江西欣林农机制造有限公司

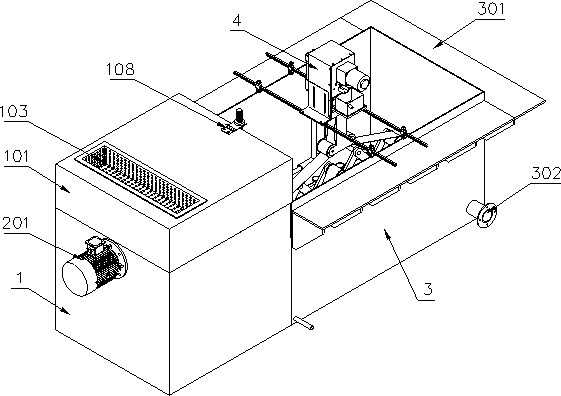

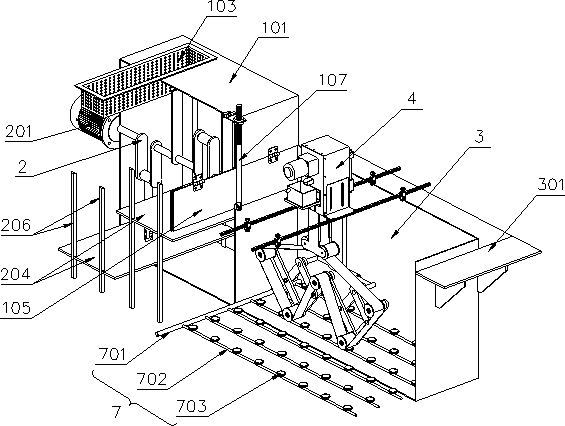

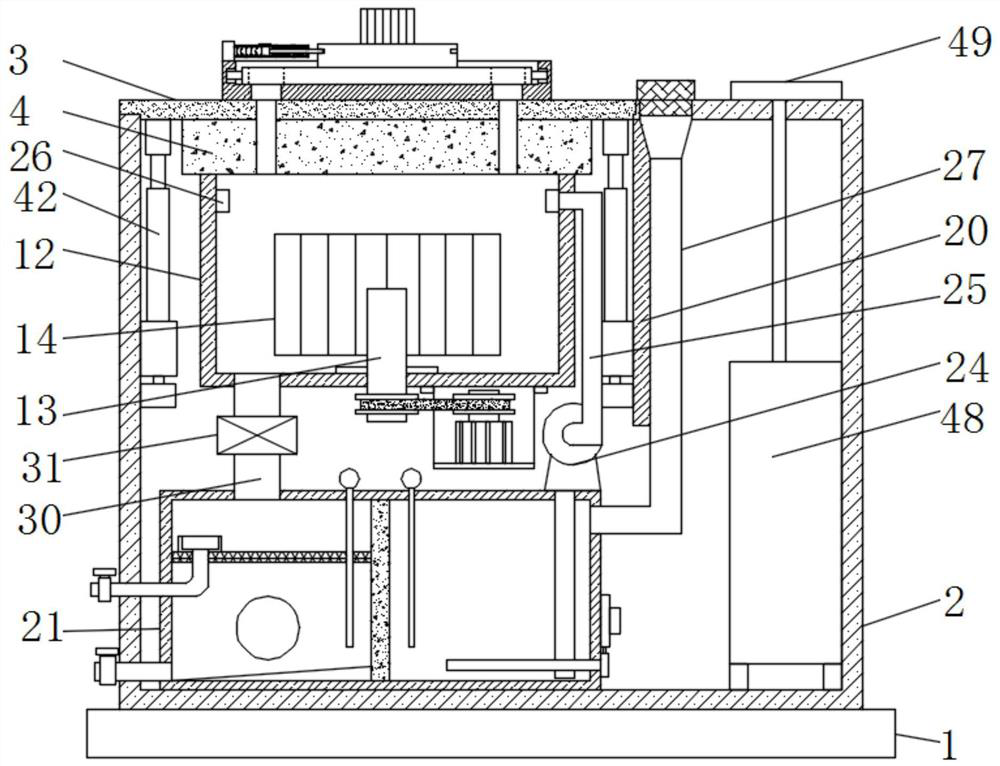

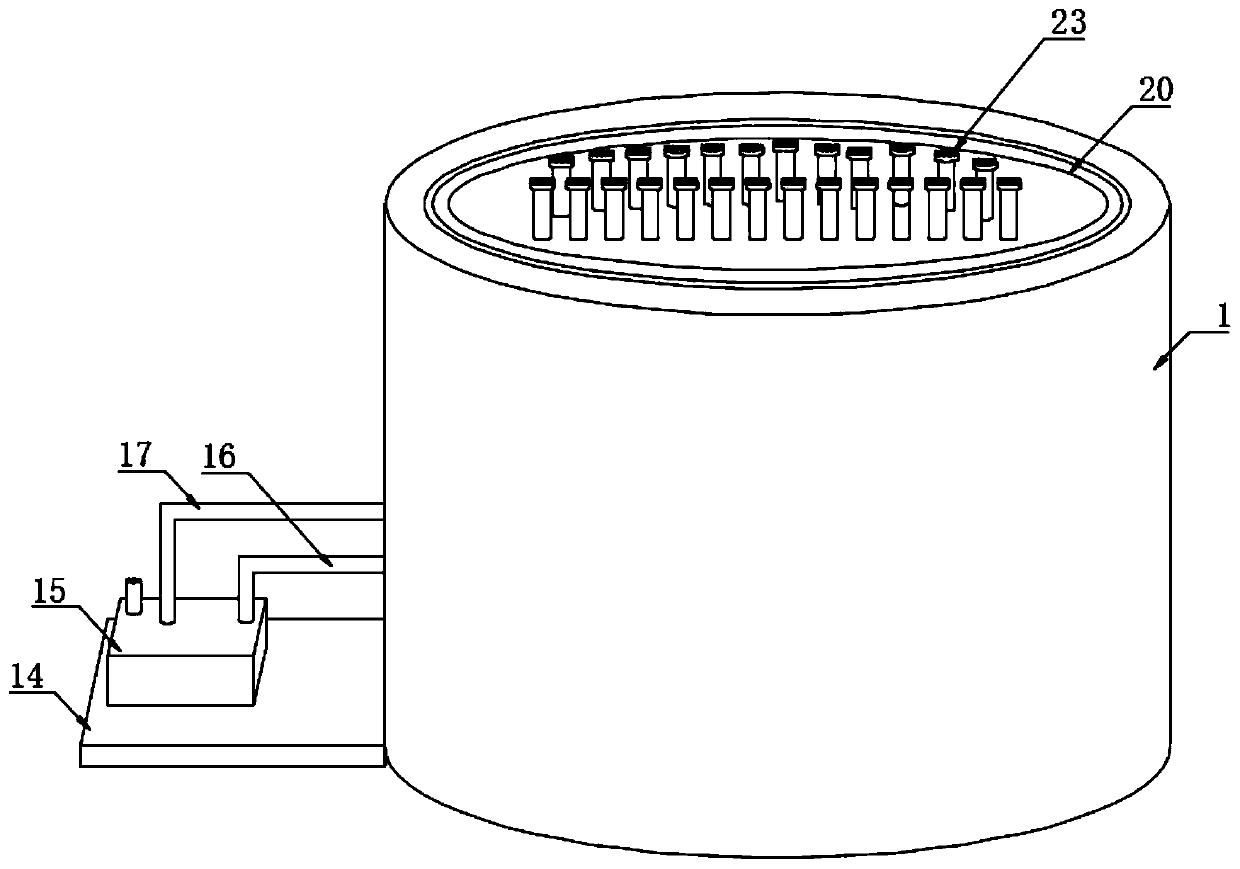

Automatic cover opening and closing type liquid multifunctional cleaning machine

ActiveCN112058833AAvoid blockingImprove securityHollow article cleaningStationary filtering element filtersStructural engineeringManufacturing engineering

The invention discloses an automatic cover opening and closing type liquid multifunctional cleaning machine which comprises a bottom plate, a box body is fixedly connected to the top of the bottom plate, and a cover plate is hinged to the top of the box body. A sealing plate is fixedly connected to the bottom of the cover plate, a fixed plate is fixedly connected to the top of the cover plate, anda groove is formed in the top of the fixed plate. A shielding plate is arranged in the groove, a rotating block is fixedly connected to the top of the shielding plate, a plurality of first round holes are formed in one side of the sealing plate, second round holes are formed in the positions, close to the first round holes, of the surface of the cover plate, and third round holes matched with thesecond round holes are formed in the surface of the shielding plate. A cleaning cylinder is fixedly connected to the interior of the box body, a water tank is fixedly connected to the position, located at the bottom end of the box body, below the cleaning cylinder, and a cleaning cavity and a waste liquid cavity are formed in the water tank. The automatic cover opening and closing type liquid multifunctional cleaning machine has the beneficial effects that the blockage of a circulating pump due to sludge can be avoided, and the influence of water vapor on an operator is reduced, so that the cover opening safety is improved.

Owner:菏泽鼎新仪器有限公司

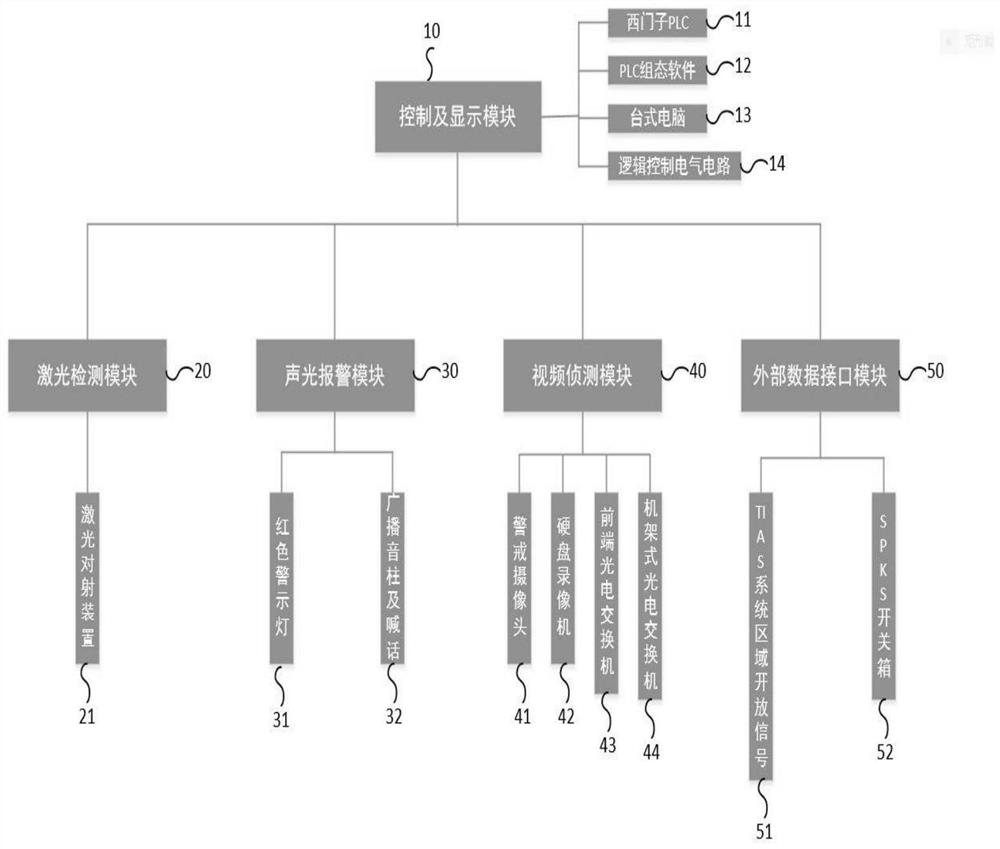

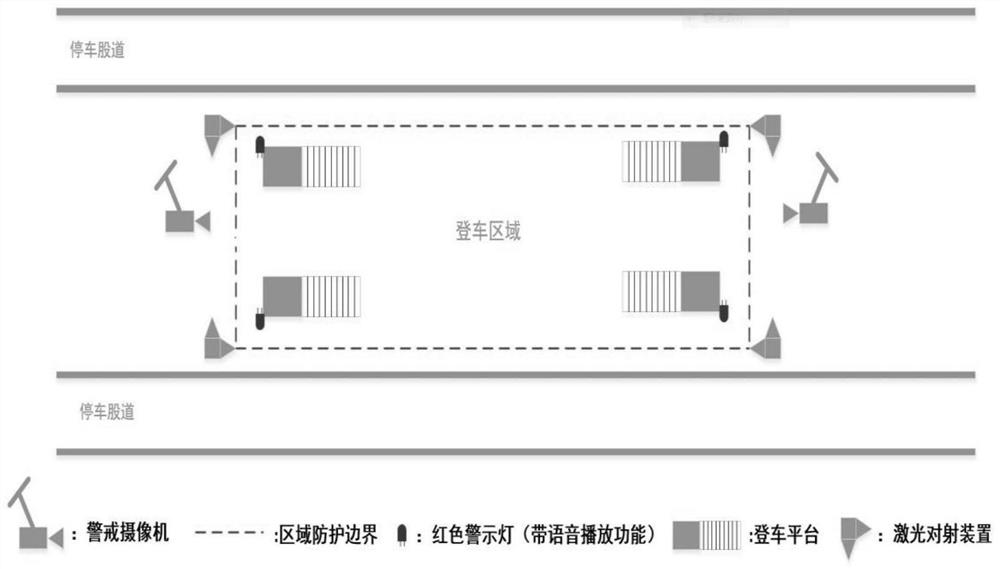

Protection system for driver boarding area in full-automatic driving maintenance area of subway train

InactiveCN112188168ALimit the range of activitiesPrevent random walk throughTelevision system detailsColor television detailsAutomatic controlSwitching signal

The invention relates to a protection system for a driver boarding area in a full-automatic driving maintenance area of a subway train. In the system, a control and display module is used for controlling and monitoring field equipment in real time and displaying the field equipment; a video detection module is used for carrying out boundary crossing detection on the boarding area, capturing crossing behaviors and returning the crossing behaviors to the control and display module; a laser detection module is used for physically detecting the boundary of the boarding area; a sound-light alarm module is used for driving a field alarm lamp to flicker and playing voice to urge border-crossing personnel to leave a dangerous area; and an external interface module accesses an area opening signal and a personnel protection switch signal of a full-automatic driving maintenance area TIAS system as protection control conditions of the system. The personnel protection function of the full-automaticdriving maintenance area of subway train is achieved, a traditional manual protection mode is replaced, automatic control is achieved, manual intervention is not needed, operation efficiency, operation advancement and protection reliability are improved, and warning effect is obvious.

Owner:CHINA RAILWAY FIRST SURVEY & DESIGN INST GRP

Steel strip winding machine with muff-coupling limiting function

The invention discloses a steel strip winding machine with a muff-coupling limiting function. The steel strip winding machine comprises a base. An L-shaped movable groove is formed in the left front end of the upper surface of the base. A movable plate is arranged in an inner cavity of the L-shaped movable groove. The rear end of the upper surface of the movable plate is fixedly connected with the bottom of a fixed plate. One end of a first supporting shaft penetrates through the top of the front side of the fixed plate. The other end of the first supporting shaft is fixedly connected with the axis of the front side of a sleeve. The left rear end of the upper surface of the base is fixedly connected with the bottom of a fixing device. According to the steel strip winding machine with the muff-coupling limiting function, the movable plate is pulled and moved to the other end in the inner cavity of the L-shaped movable groove; the sleeve is sleeved with a steel strip; the movable plate is moved to the original position, so that the first supporting shaft is sleeved with a through hole in the fixed plate, the movement range of the steel strip can be limited in the process of winding and pulling the steel strip after the steel strip is arranged on the sleeve in a sleeved mode, and the situation that the steel strip breaks away from the sleeve due to strong tensile force of a reel to the steel strip in the winding process when the steel strip is pulled through the reel cannot occur.

Owner:江苏中康金属材料有限公司

Lifting fountain device

PendingCN110465440ALimit the range of activitiesAvoid damageLiquid spraying apparatusEngineeringMotion range

The invention discloses a lifting fountain device and particularly relates to the technical field of fountain equipment. The lifting fountain device comprises a performance pool. A fountain mechanismis arranged in the performance pool. A lifting mechanism is arranged on the bottom of the fountain mechanism. A pipeline folding mechanism is arranged on the bottom of the lifting mechanism. A power mechanism is arranged on one side of the performance pool. According to the lifting fountain device, the pipeline folding mechanism is arranged, the ascending track of a third connecting plate and a second connecting plate can be limited, thus the motion range of hoses can be limited, damage to other equipment by the hoses is effectively prevented, a pipeline needing to be bent is partitioned intothe first hose and the second hose, and the bending difficulty of the bent pipeline is reduced; and by arranging a bearing rod and a bearing plate, the distance between the adjacent connecting platesis effectively controlled, the situation that the hoses are pressed by the connecting plates and damaged is effectively prevented, compared with the prior art, the motion range in the hose bending process is narrowed, and the service life of the device is prolonged.

Owner:合肥仁泰科技发展有限公司

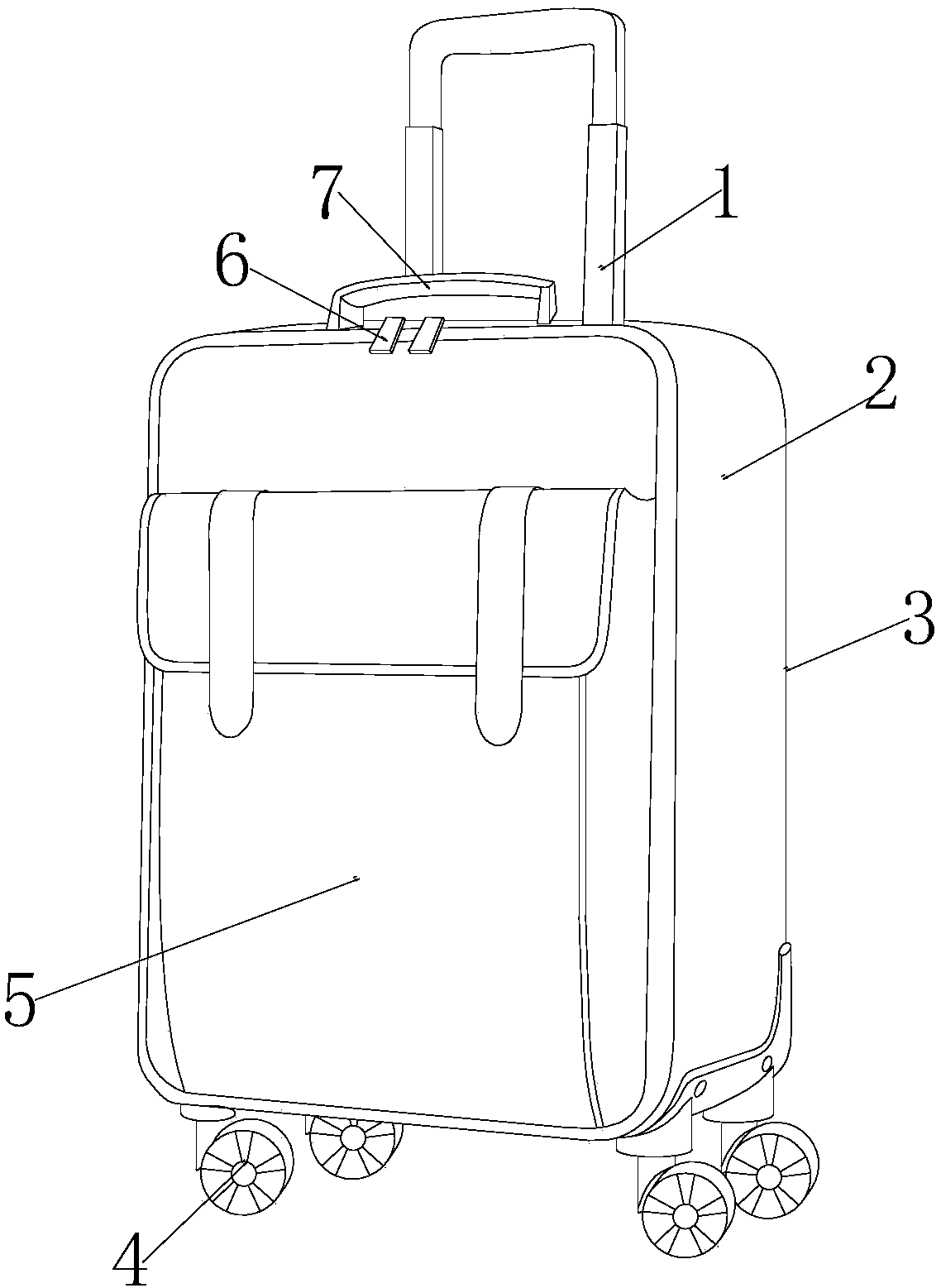

Lightening case

InactiveCN108497659ALimit the range of activitiesAvoid affecting useLuggageOther accessoriesEngineeringPower apparatus

The invention discloses a lightening case. The structure of the weight reducing case comprises a pull bar, a lightening device, a shell, casters, a small storage chamber, a zipper and a handle, the pull bar is arranged at the top of the shell, the pull bar goes through the shell and is in sliding fit with the shell, the quantity of the casters is four, the four casters are respectively mounted atthe bottoms of four corners of the shell, the lightening device is mounted in the shell, the small storage chamber is arranged on the front panel of the shell, the small storage chamber and the shellare arranged to for an integral structure, the zipper encircles around the shell, the zipper is in chain connection with the shell, the handle is arranged at the top of the shell, and the handle is fixedly mounted on the top panel of the shell. The coaction of a power device, the movable lightening device and a lightening device folding and unfolding mechanism makes the lightening of the case in the use process realized; and the lightening device is simple to fold and unfold, so the lightening case is convenient to use.

Owner:孙伟鹏

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com