Seawater culture net cage of improved structure

A seawater farming and improved structure technology, applied in the field of farming equipment, can solve problems such as low work efficiency, lack of oxygen for fish, and difficulty in catching fish, and achieve the effects of improving quality, reducing fluidity, and reducing farming costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

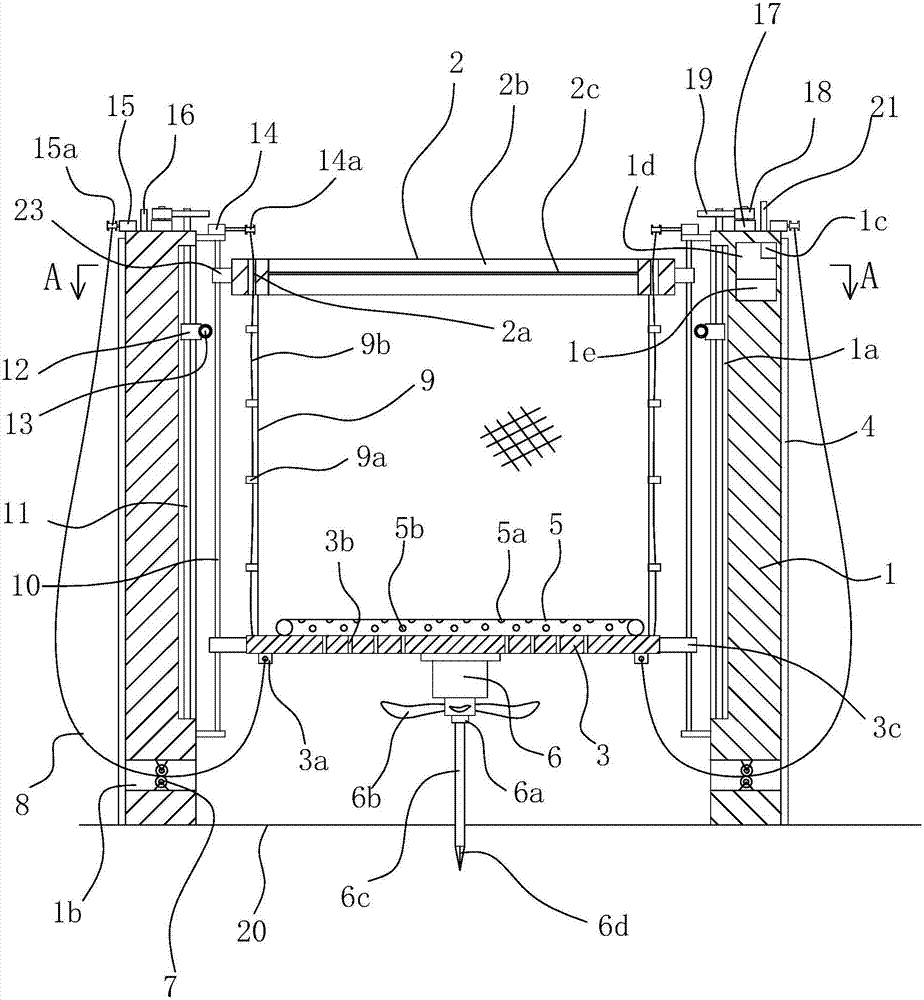

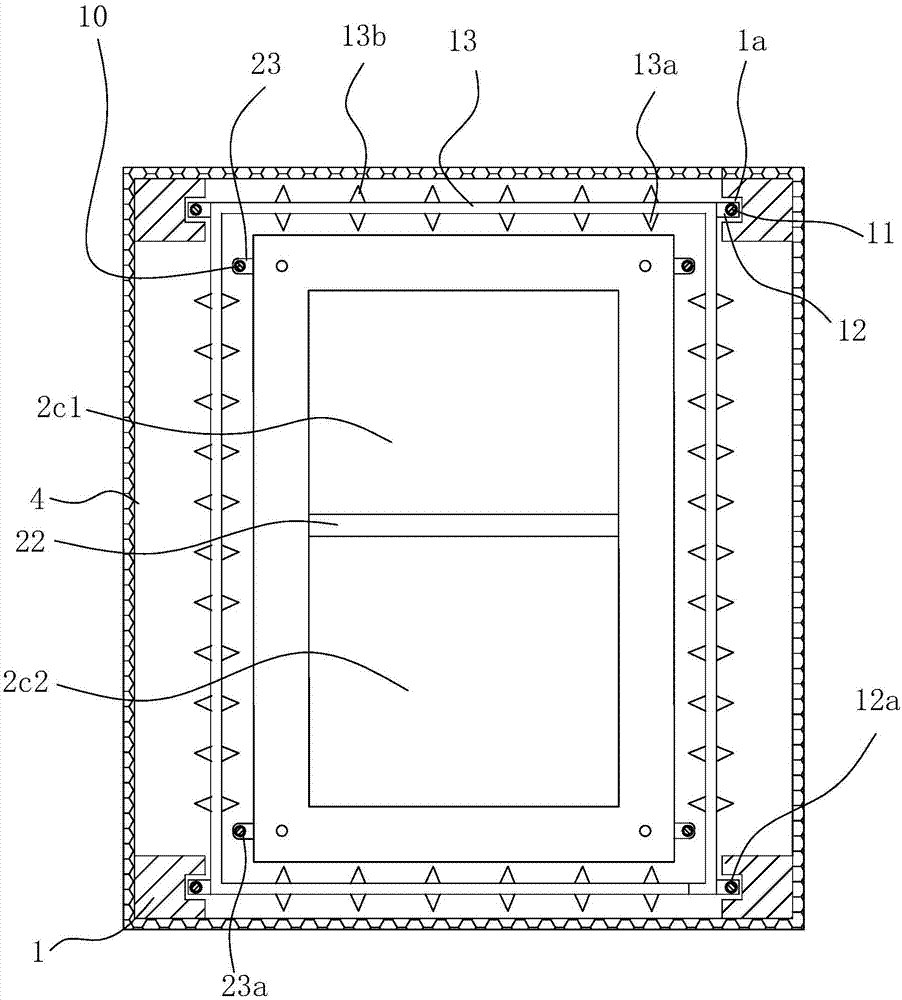

[0030] Such as Figure 1 to Figure 4 Shown, a kind of mariculture net cage of improved structure is characterized in that, comprises rectangular upper floating body 2, bottom plate 3, column 1, cleaning pipe 13 and water pump 21, offers net cage opening 2b on the described upper floating body 2 , the cage opening 2b is detachably connected with a cage cover 2c, and a net 9 is arranged between the upper floating body 2 and the bottom plate 3, and the floating body 2, the bottom plate 3 and the net 9 surround the seawater of the improved structure The breeding area for breeding cages;

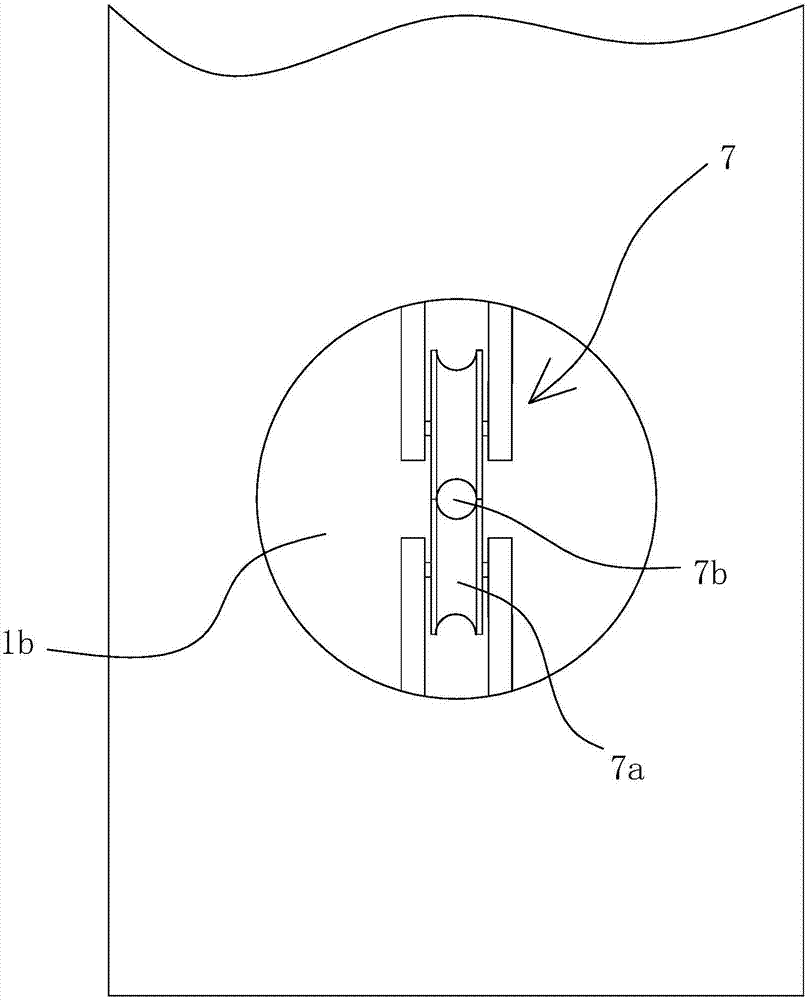

[0031] There are four uprights 1 and they are located at four corners outside the floating body 2 respectively. The four uprights 1 are all v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com