Film winding device with drainage function on greenhouse

A roll film and greenhouse technology, which is applied in botany equipment and methods, greenhouse cultivation, climate change adaptation, etc., can solve the problems of moldy plants, easy damage of roll film devices and roll film, and affect the value of commodities, so as to improve The effect of wind resistance strength, improvement of drainage effect, and improvement of ventilation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

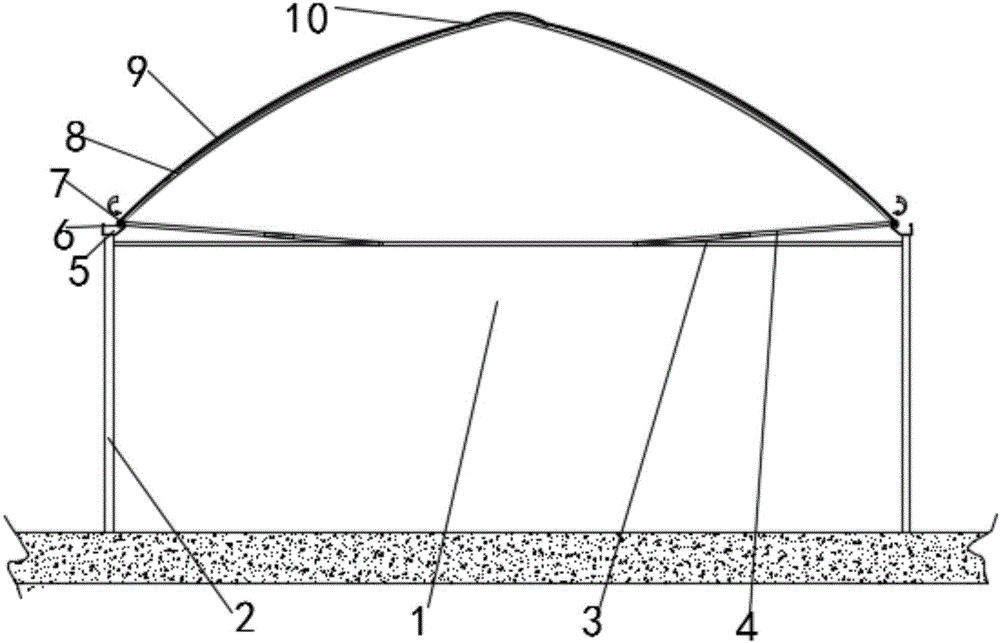

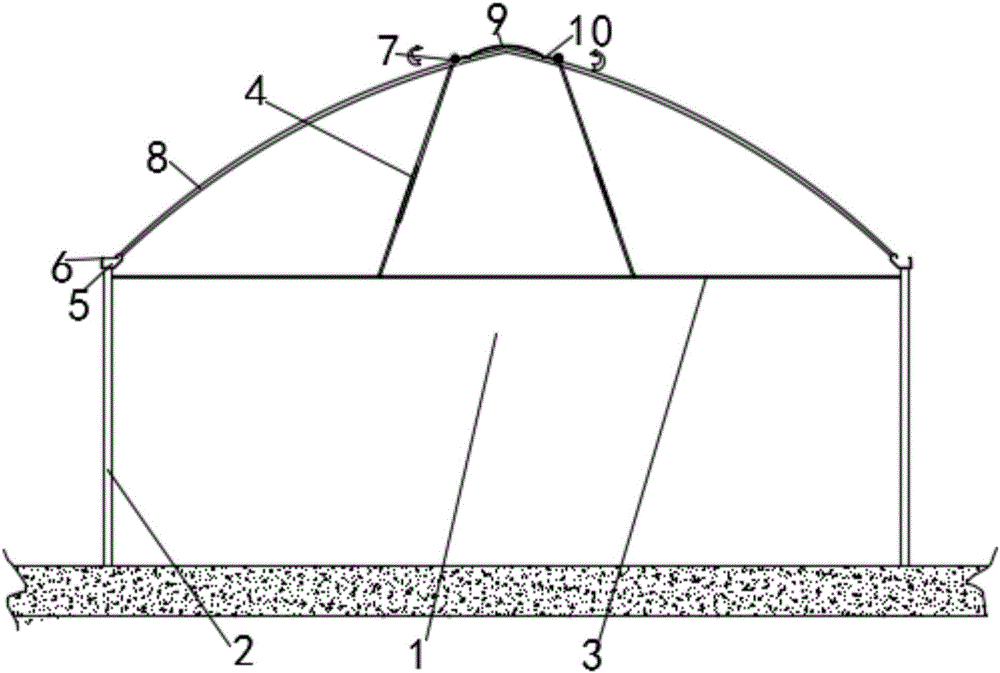

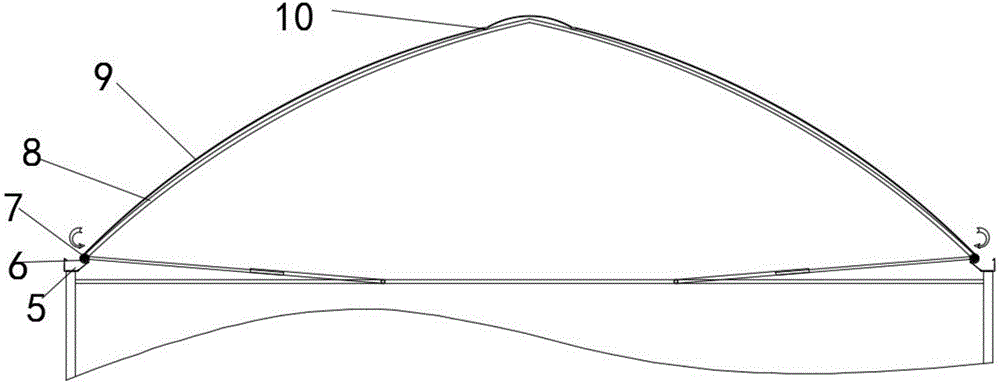

[0029] Such as figure 1 Shown is a schematic view of the unfolded state structure of the roll film device with drainage function provided on the greenhouse by the present invention; as figure 2 Shown is a schematic structural view of the folded state of the film roll device with drainage function provided on the greenhouse in the present invention; as image 3 shown as figure 1 Partial enlarged view; such as Figure 4 shown as image 3 Schematic diagram of the structure of the middle water tank; a film rolling device with drainage function arranged on the greenhouse of the present invention, comprising a film rolling tube 7 arranged on the arch 8 of the greenhouse 1 and a film 9 wound on the film rolling tube 7, On the upper part or side wall of one side of the support 2 of the greenhouse 1, a water tank 5 parallel to the roll film tub...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com