Combined sensor applied to measurement of water ratio in oil well

A water content and sensor technology, applied in the field of sensor devices, to achieve the effects of making up for poor resolution, increasing response range, and increasing effective area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with accompanying drawing:

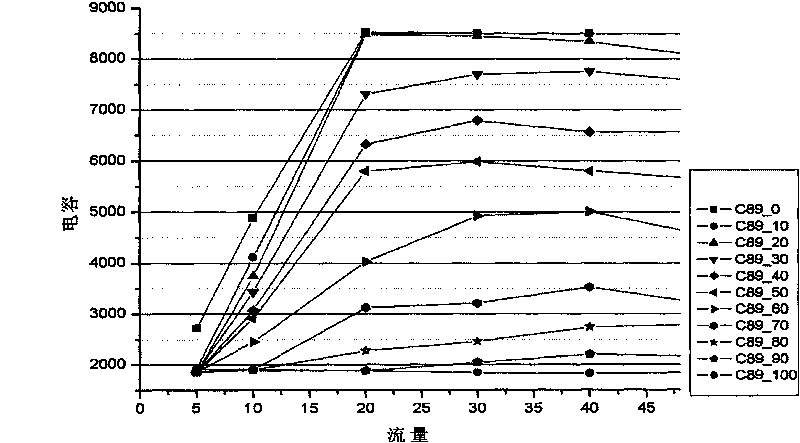

[0022] Firstly, the reason why the resolution of the existing coaxial capacitance water cut measurement sensor decreases in the case of low flow oil-water layer is analyzed below.

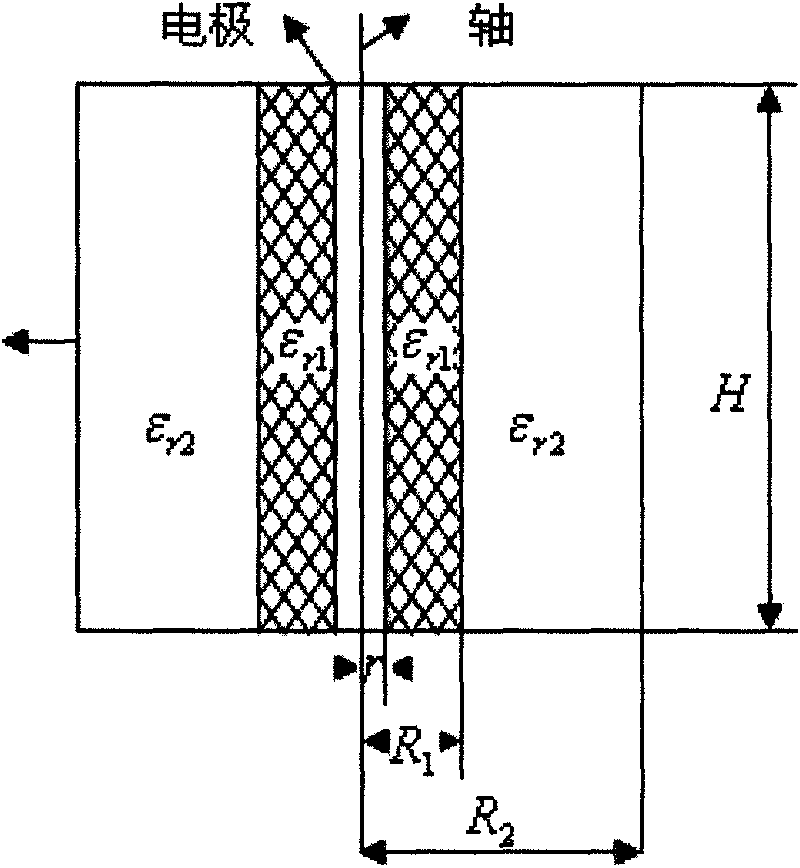

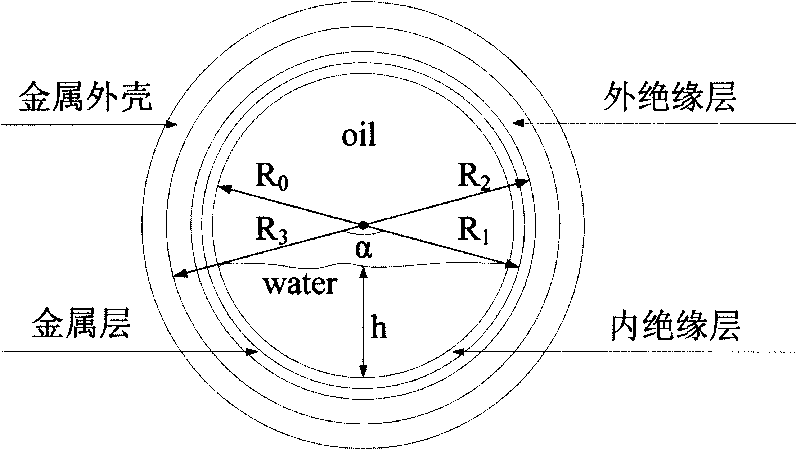

[0023] The structure of the coaxial capacitive moisture content measurement sensor is as follows: figure 1 As shown, the sensitive element of the coaxial capacitance water content measurement sensor is actually a coaxial cylindrical capacitor, and oil, water or oil-water mixture is its dielectric. When the mixing ratio of oil and water is different, the capacitance changes accordingly, so The moisture content can be obtained by measuring the capacitance value and interpreting it. Set the radius of the central electrode of the capacitor at this time as r, and the radius of the insulating layer surrounding the electrode as R 1 , the relative permittivity of the insulating material is ε r1 , the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com