g-C3N4/H-TiO2 based nano tube array as well as manufacturing method thereof and application thereof

A nanotube array, nanotube technology, applied in nanotechnology, nanotechnology, chemical instruments and methods, etc., can solve the problems of nanotube structure damage, decreased light utilization rate, poor effect, etc., to achieve wide application and improve photoelectric conversion. The effect of high efficiency and light conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

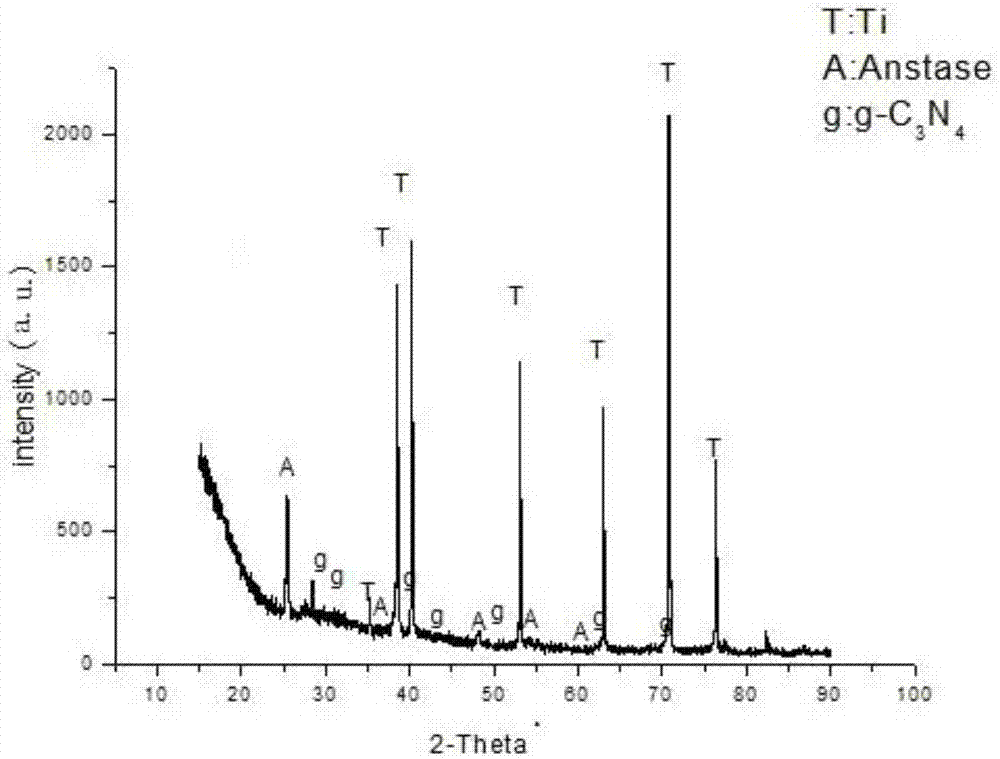

[0041] a g-C 3 N 4 / H-TiO 2 The preparation method of base nanotube array, concrete steps are:

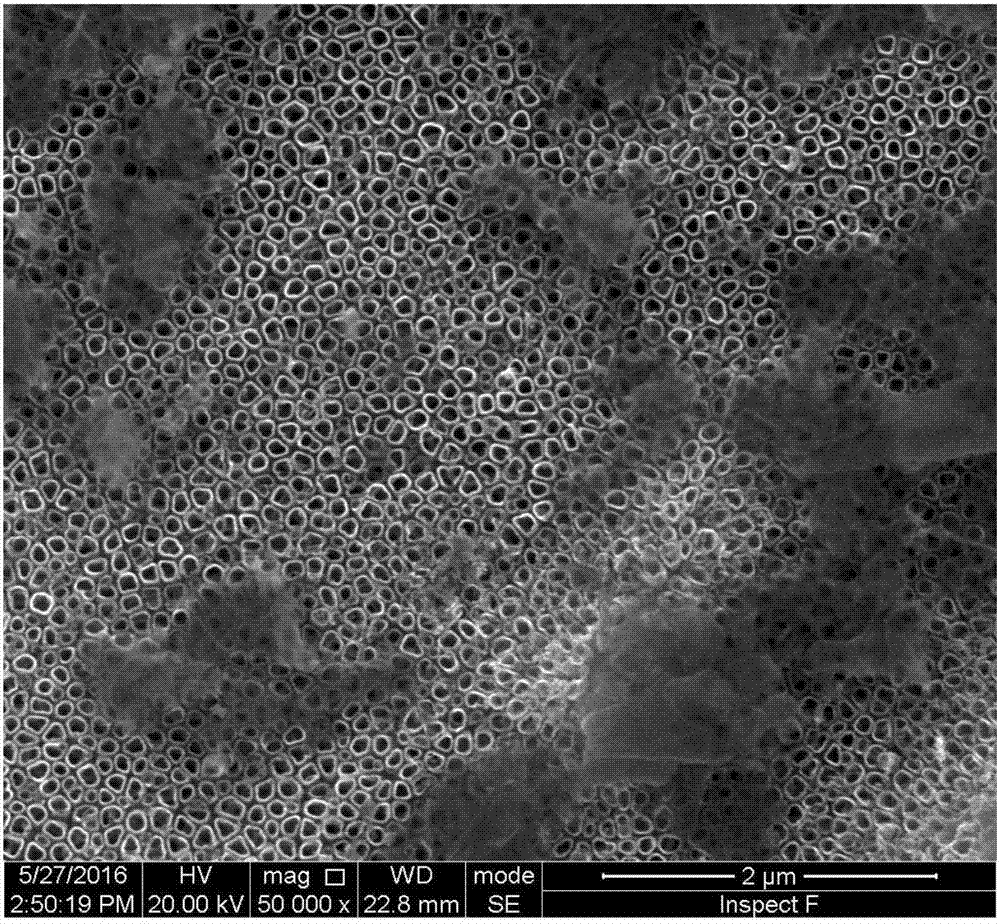

[0042] Electrolyte is selected, specifically 0.5wt% NH 4 F+0.1MH 3 PO 4 An aqueous solution of metal titanium is anodized in the electrolyte system at 20V for 1 hour, and a highly ordered array of nanotubes grows on the surface of metal titanium. The average diameter of nanotubes is about 90nm, the thickness of the tube wall is 15nm, and the tube length 600nm.

[0043] The ordered array of nanotubes was first heat-treated at 500°C for 2h, and then hydrogenated on the surface at 450°C for 5h in a hydrogen atmosphere to obtain H-TiO 2 base nanotube arrays.

[0044] Weigh a certain amount of urea, and heat-treat the urea in a muffle furnace at 500°C for 3 hours to obtain light yellow g-C 3 N 4 Powder; according to the ratio of solid-liquid ratio 1g: 50ml, measure g-C respectively 3 N 4 Powder and absolute ethanol, mixed thoroughly and then ultrasonically peeled off for 2 ho...

Embodiment 2

[0046] a g-C 3 N 4 / H-TiO 2 The preparation method of base nanotube array, concrete steps are:

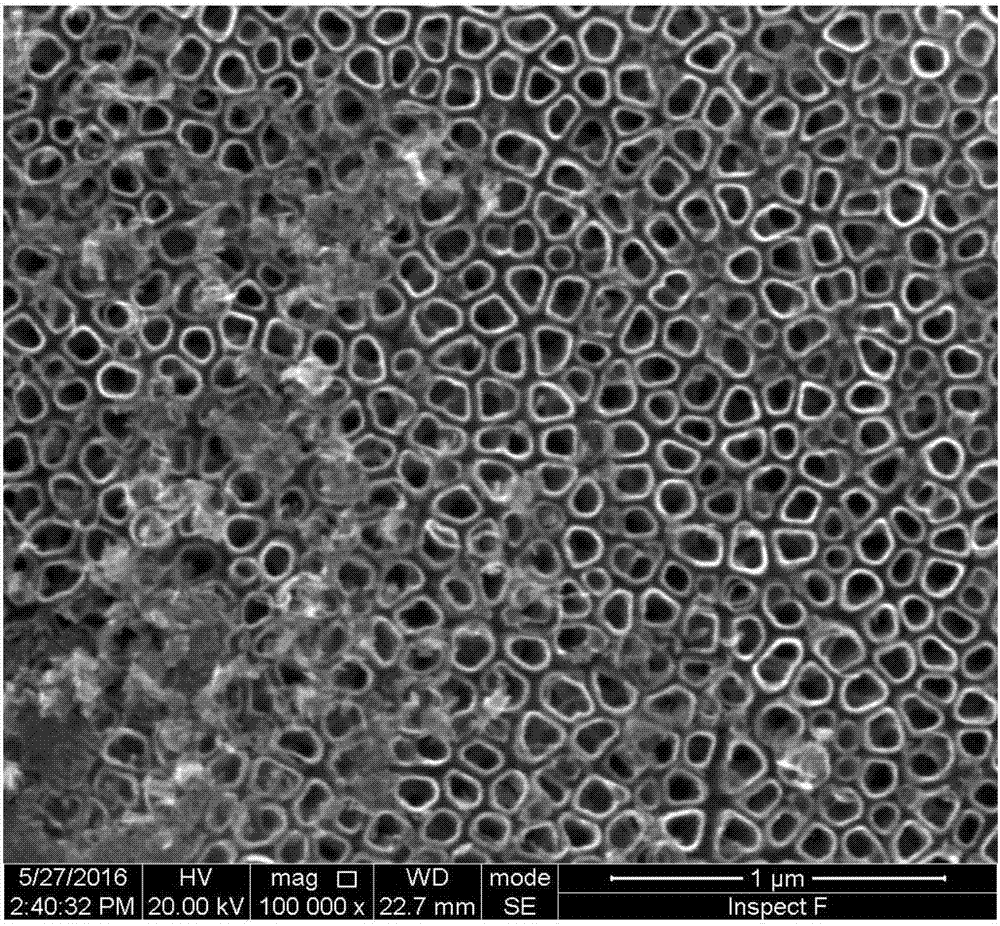

[0047] Prepare electrolyte 0.5wt% NH 4 F+0.1MH 3 PO 4 Aqueous solution, the titanium alloy Ti-0.2Pd (TA9) was anodized in the electrolyte system at 20V for 1h, and a highly ordered ordered array of nanotubes grew on the surface of the titanium alloy TA9. The average diameter of the nanotubes was about 85nm. The tube wall thickness is 20nm and the tube length is 650nm.

[0048] The ordered array of nanotubes was first heat-treated at 500°C for 2h, and then hydrogenated on the surface at 450°C for 5h in a hydrogen atmosphere to obtain H-TiO 2 base nanotube arrays.

[0049] Measure 5g of urea and 30ml of absolute ethanol respectively, and fully dissolve urea in absolute ethanol to obtain an ethanol solution of urea; 2 The base nanotube array was soaked in the urea suspension for 30min, then taken out and heat-treated at 500°C for 3h to obtain g-C 3 N 4 / H-TiO 2 base nanotub...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| verticality | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com