Pressure regulating system and method for working machine

A technology for pressure regulation and working machinery, which is applied in the direction of mechanical equipment, fluid pressure actuation devices, transmission devices, etc. It can solve the problems of complicated operation and increased cost, and achieve the effects of quick disengagement, simplified structure, and avoiding shifting shocks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

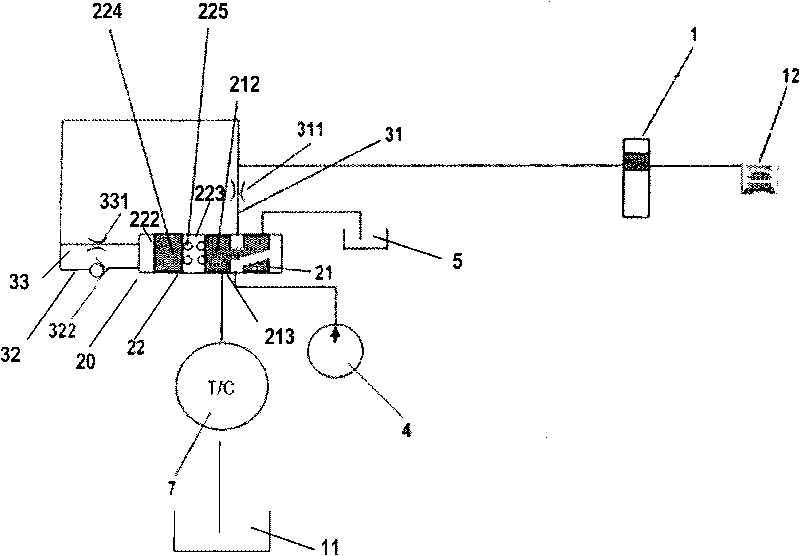

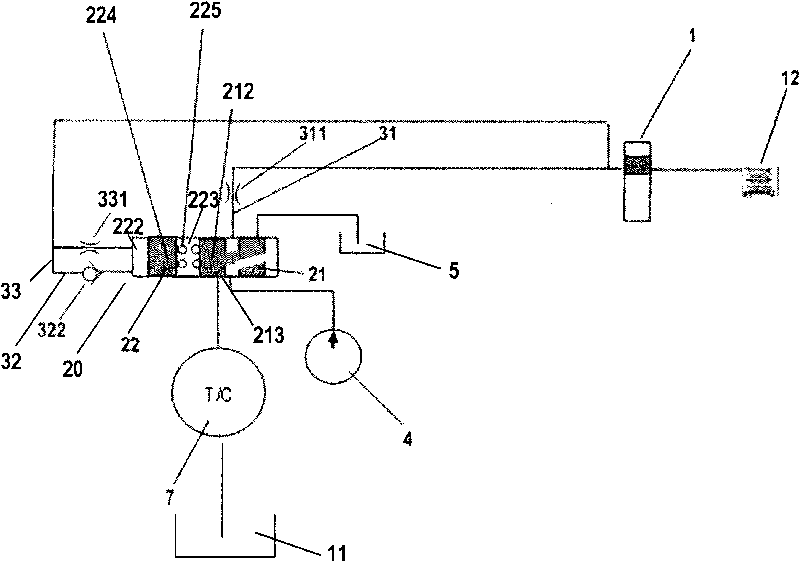

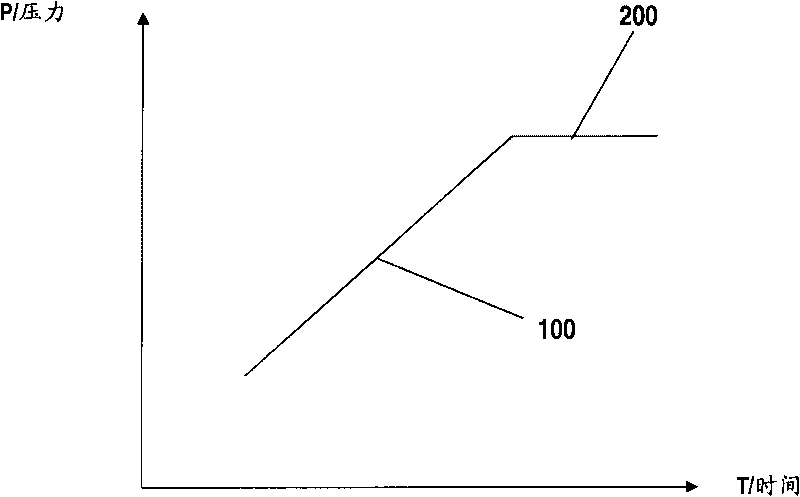

[0022] The pressure regulating system and method of the present invention can be applied to various hydraulically controlled working machines. For the purpose of illustration, in this embodiment, a transmission mechanism of a loader is used for description. Those skilled in the art can understand that the working machine can be any kind of working machine, such as a loader, an excavator or other machines in the construction industry or other machines in other industries such as agriculture and forestry. The transmission mechanism may include clutches of different gears and shift valve groups such as neutral gear, reverse gear and forward gear, such as shift distribution valve groups, which are selectively engaged with the clutches to control the output speed and direction of the transmission. For example, the shift valve group can include a directional shift valve connecting forward gear and reverse gear, a high-low gear shift valve and a brake valve. Those skilled in the art ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com