Transmission electric gear selecting and shifting system and car

A technology for gear selection and transmission, applied in control/regulation systems, instruments, transmission control, etc., can solve problems such as inability to monitor and adjust gear shift force in real time, gear shift impact, and reduce the life of synchronizers, etc., to avoid inability Shift gears in time, avoid gear shift impact, and reduce gear shift noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The specific embodiments described here are only used to explain the present invention, not to limit the present invention. The present invention will now be described in detail with reference to the accompanying drawings.

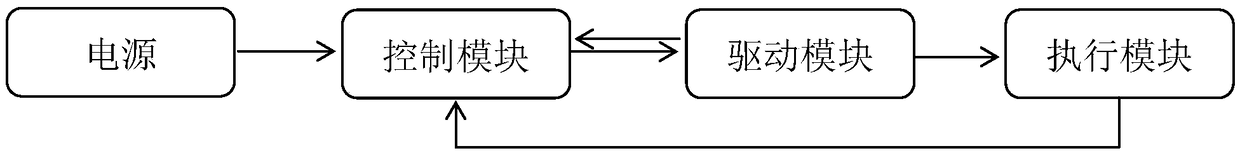

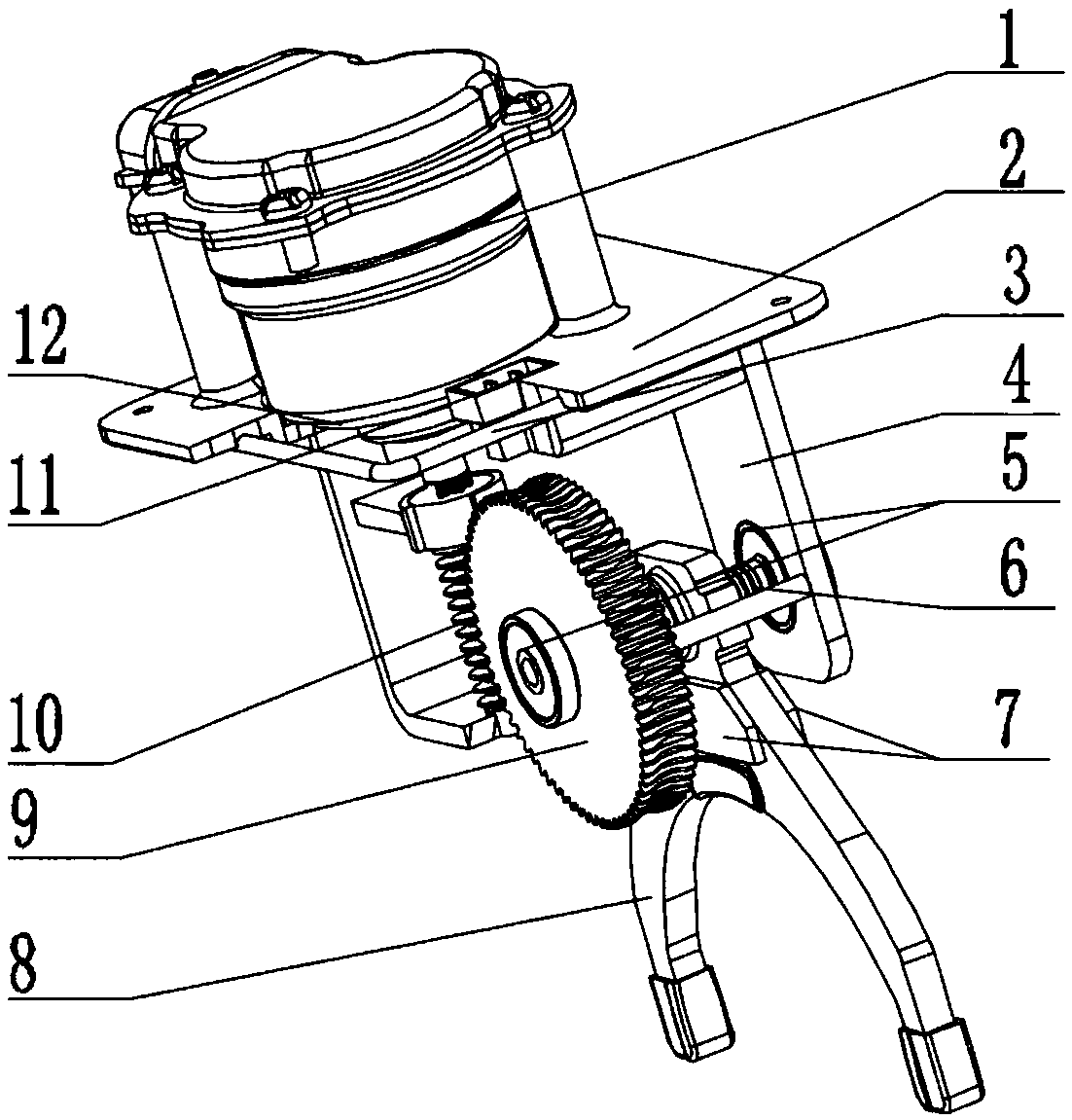

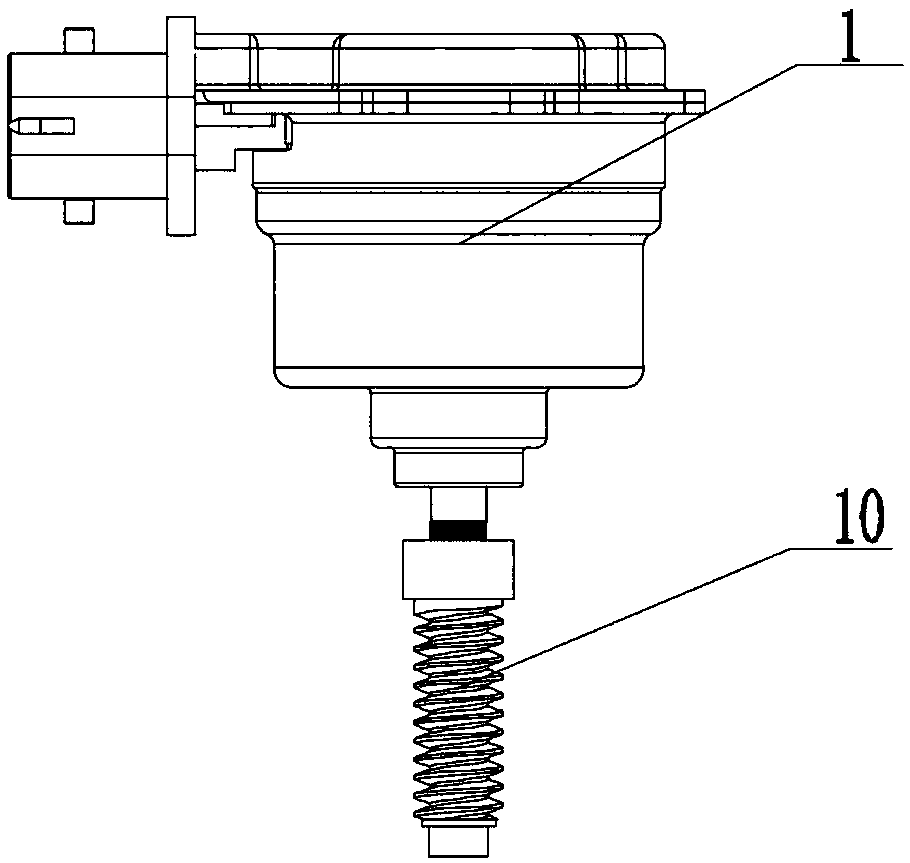

[0026] like figure 1 As shown, in this embodiment, the transmission electric gear selection and shifting system includes a control module, a drive module, and an execution module. The control module is connected to the driving module and the execution module, and is used to monitor the shift force and shift stroke actually output by the execution module, and send an instruction to adjust the shift force to the drive module in real time. The driving module is used to receive instructions from the control module, and drive the execution module to perform gear selection and shifting operations. The execution module includes a gear shift fork, which moves left and right through the gear shift fork, and then pushes the synchronizer to complete the gear...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com