A series-parallel hybrid transmission

A technology of hybrid power and transmission, applied in the field of series-parallel hybrid transmission, which can solve the problems of low driving efficiency, high power motor torque requirements, high cost, etc., and achieve the effects of improving power performance, avoiding shifting impact, and high driving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

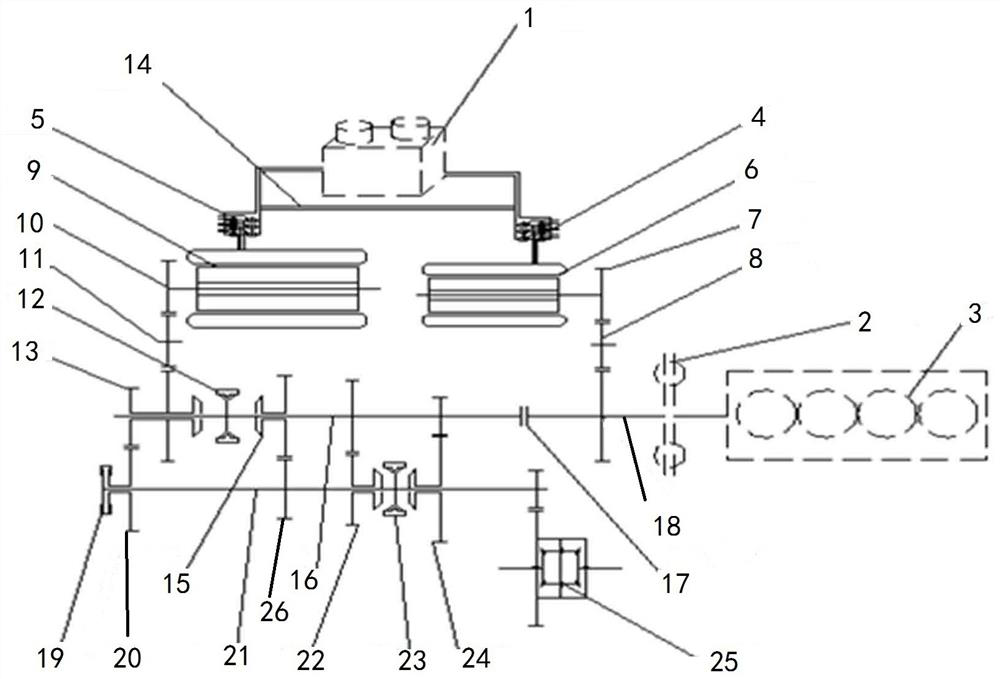

[0030] Such as figure 1 Among them, a series-parallel hybrid transmission includes a transmission device, a wire harness, a shock absorber 2, an internal combustion engine 3, and a controller. The transmission device includes a battery 1 and a battery management system, and the battery 1 and the first inverter 4 It is connected with the second inverter 5, the first inverter 4 is connected with the first motor 6, the output end of the first motor 6 is provided with a first gear 7, and the first gear 7 is connected with the second input through the first idler gear 8. The shaft 18 is connected, the second inverter 5 is connected with the second motor 9, the output end of the second motor 9 is provided with a second gear 10, the second gear 10 is connected with the first input shaft 16 through the second idler gear 11, and the second gear 10 is connected with the first input shaft 16 through the second idler gear 11. An input shaft 16 is provided with a first synchronizer 12 and ...

Embodiment 2

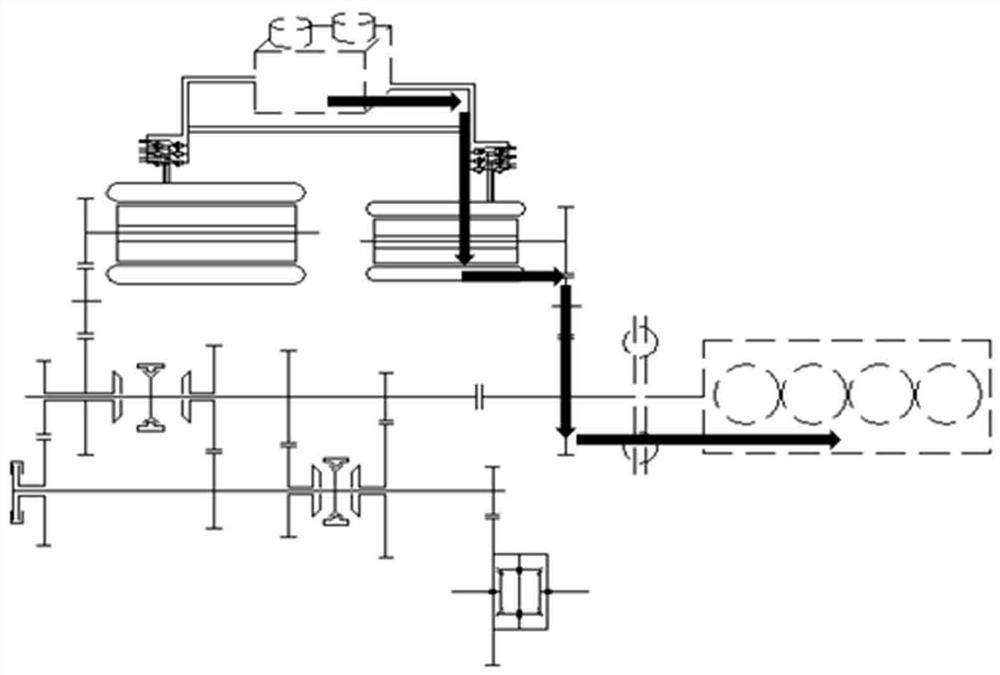

[0038] Such as figure 2 In the transmission path of the cold start internal combustion engine: it is detected that the SOC is less than the specified value, the main clutch 17 and the auxiliary clutch 19 are disconnected, the first synchronizer 12 is in the neutral position, the battery 1 → the first inverter 4 → the first motor 6 → the first Gear 7→first idler gear 8→second input shaft 18→shock absorber 2→internal combustion engine 3.

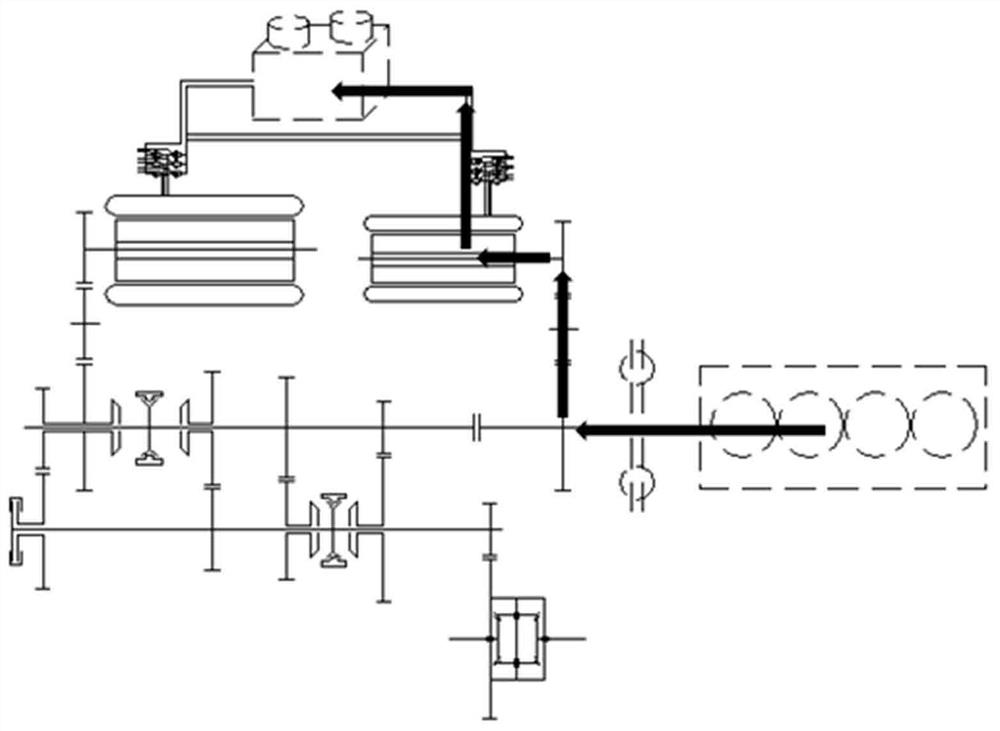

[0039] Such as image 3 , parking charging path: main clutch 17 and auxiliary clutch 19 are disconnected, first synchronizer 12 is in neutral position, internal combustion engine 3→shock absorber 2→second input shaft 18→first idler gear 8→first gear 7→ The first motor 6→the first inverter 4→the battery 1 .

[0040] Such as Figure 4 In the middle, the pure electric first-gear drive power transmission path: the main clutch 17 and the auxiliary clutch 19 are disconnected, the first synchronizer 12 turns to the right position, the second sync...

Embodiment 3

[0059] Such as Figure 1-15 In the description of the working conditions of the dual-motor embodiment, in the table, ON: the internal combustion engine 3 is running; OFF: the internal combustion engine 3 is off; O: the synchronizer is neutral or the clutch is disconnected or the motor is idling; X: the clutch is engaged; Shift to the right; ←: Synchronizer shifts to the left; M: Motor output power; G: Motor accepts power and generates power.

[0060]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com