Bulldozer gear shifting control method and device and computer storage medium

A kind of control method, technology of bulldozer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

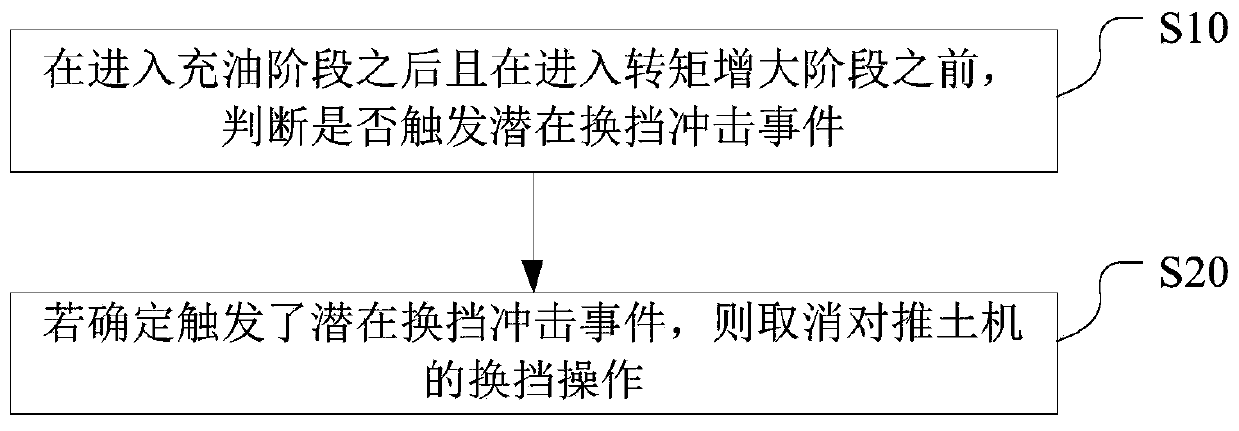

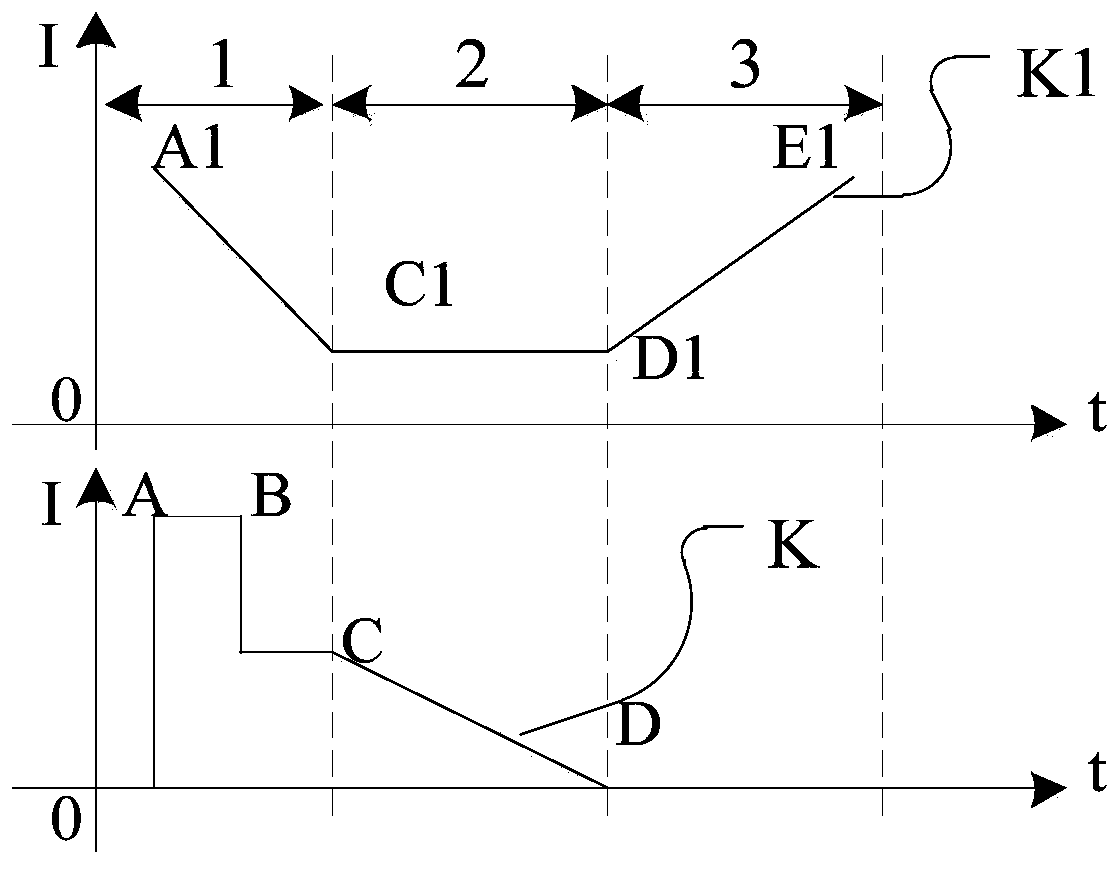

[0041] An embodiment of the present invention provides a bulldozer shift control method, which is suitable for an electronically controlled bulldozer. Bulldozer shift control includes oil filling phase, torque exchange phase and torque increase phase, figure 1 It is a flow chart of a bulldozer shift control method provided in Embodiment 1 of the present invention, refer to figure 1 , the bulldozer shift control method includes:

[0042] S110. After entering the fuel charging phase and before entering the torque increasing phase, determine whether a potential shift shock event is triggered.

[0043] Wherein, a potential shift shock event refers to a shift shock event that has not yet occurred, which is used to indicate that a shift shock is about to occur or there is a risk of a shift shock.

[0044] S120. If it is determined that a potential shift shock event is triggered, cancel the shift operation on the bulldozer.

[0045] Specifically, the shift control of bulldozers in...

Embodiment 2

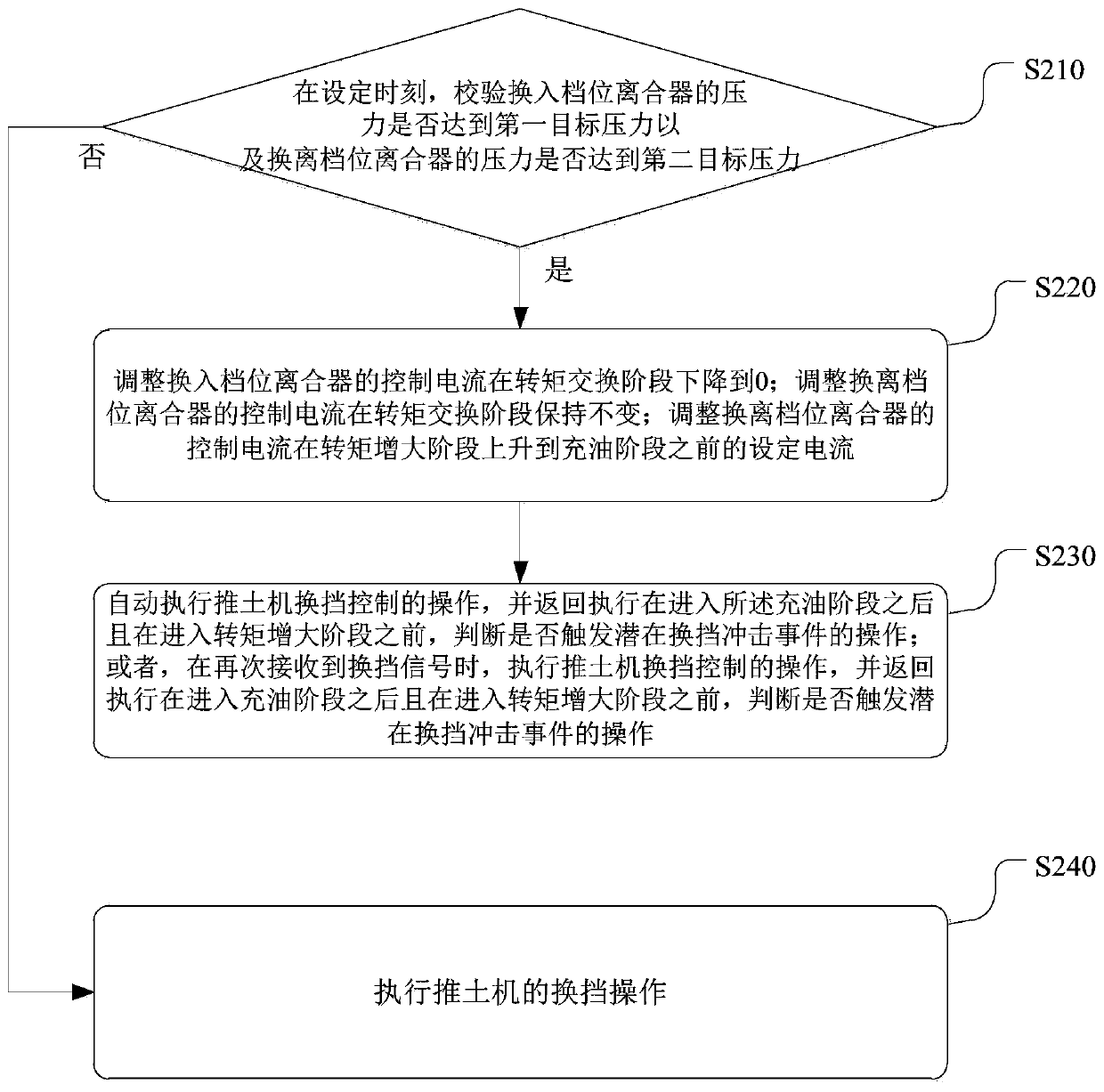

[0048] figure 2 It is a flow chart of a bulldozer shift control method provided by Embodiment 2 of the present invention. Embodiment 2 of the present invention further optimizes the technical solution of Embodiment 1.

[0049] Optionally, after entering the fuel filling phase and before entering the torque increasing phase, it is judged whether to trigger a potential shift shock event, including:

[0050] At the setting time, check whether the pressure of the shift-in gear clutch reaches the first target pressure and whether the pressure of the shift-out gear clutch reaches the second target pressure. the moment after time;

[0051] If the pressure of the shift-in clutch does not reach the first target pressure, and / or the pressure of the shift-out clutch does not reach the second target pressure, it is determined that a potential shift shock event has been triggered; if the pressure of the shift-in clutch When the first target pressure is reached and the off-range clutch ...

Embodiment 3

[0077] Figure 5It is a flow chart of a bulldozer shift control method provided by Embodiment 3 of the present invention. Embodiment 3 of the present invention further optimizes the technical solution of Embodiment 1.

[0078] Optionally, after entering the fuel filling phase and before entering the torque increasing phase, it is judged whether to trigger a potential shift shock event, including:

[0079] After entering the oil filling stage and before entering the torque increase stage, when receiving the engine speed change request signal of the bulldozer, determine according to the engine speed change request signal whether the engine speed requested to change reaches the speed mutation threshold;

[0080] If the engine speed requested to change reaches the speed mutation threshold, it is determined that a potential shift shock event is triggered; if the engine speed requested to change does not reach the speed mutation threshold, it is determined that the potential shift ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com