Speed changer for coal mine drilling rig hydraulic winch

A technology of hydraulic winches and coal mine drilling rigs, which is applied in the direction of clockwork mechanism and hoisting device, etc. It can solve the problems that cannot meet the requirements of the reducer used in high-performance coal mine drilling rigs, the speed and torque are single, and the work efficiency is low. Maintenance, high safety, reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

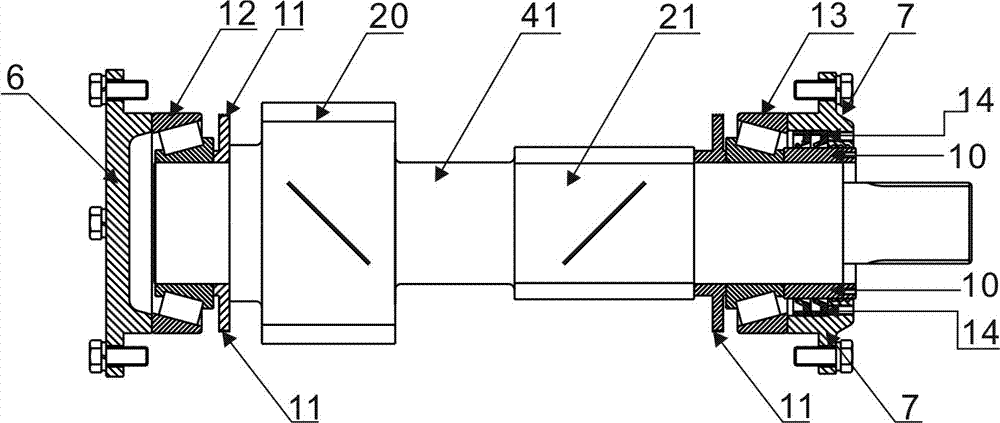

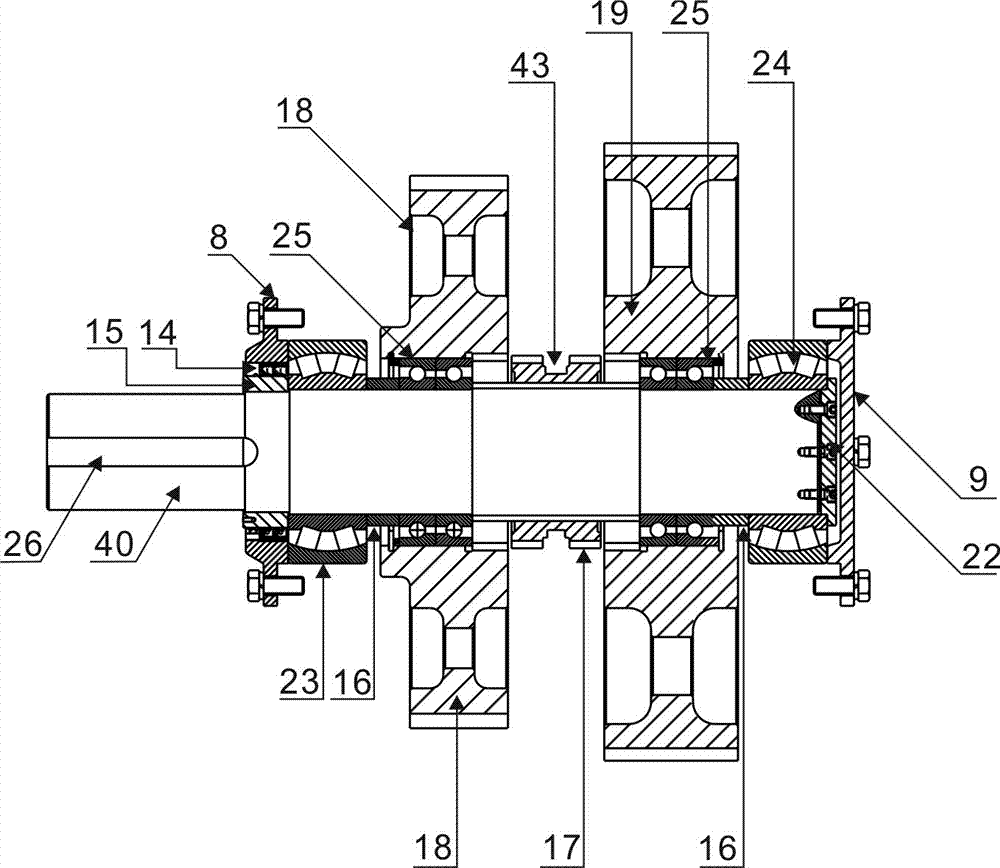

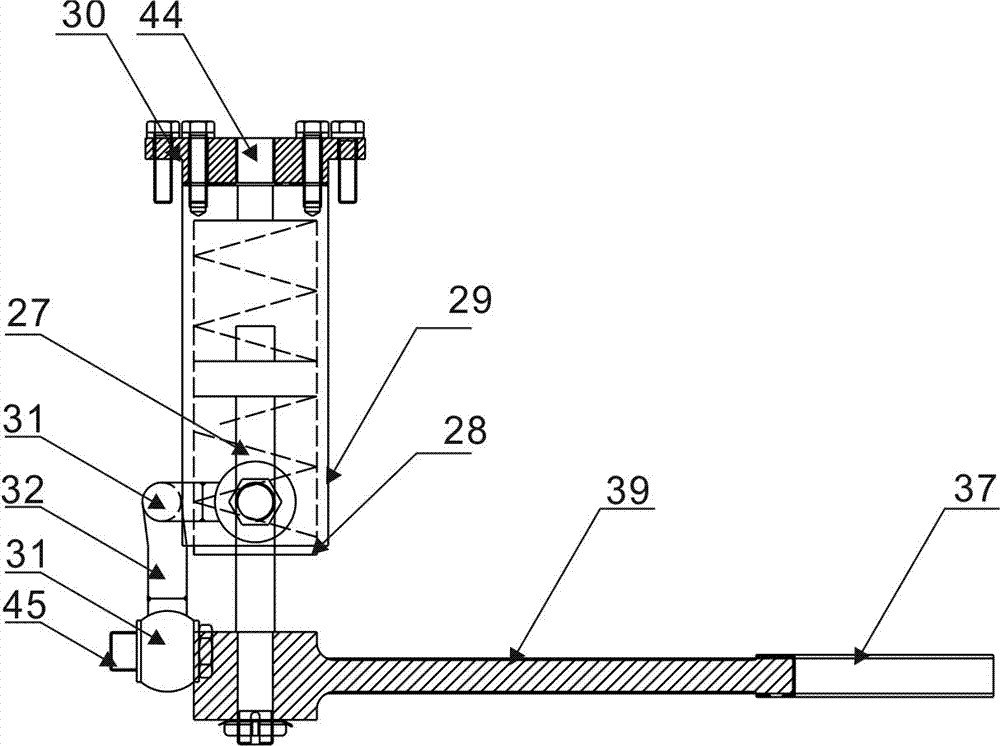

[0036] The coal mine drilling rig hydraulic winch speed changer provided by the present invention comprises a lower box body 2 and an upper box body 1, which are stacked from bottom to top and connected by bolts, spring washers and nuts to form the box body. An input mechanism 41, an output mechanism 40, and a shift actuator 39 are arranged inside the casing, and a shift control mechanism 42 is arranged outside the casing. The input mechanism 41 is used for input power and high-speed rotation speed; the output mechanism 40 is used for output torque and low-speed rotation speed; the shift actuator 39 is used to change the transmission ratio of the input mechanism and the output mechanism, and the shift control mechanism 42 is used for manipulating the shift execution Mechanism 39 realizes automatic gear shifting function.

[0037] A cast s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com