Clutch petal assembly

A clutch pedal and assembly technology, which is applied to control devices, transportation and packaging, vehicle components, etc., can solve the problems of metal pin shaft sleeves coming out, abnormal noise, etc., and achieve the effect of avoiding shifting shock and returning to the original position.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

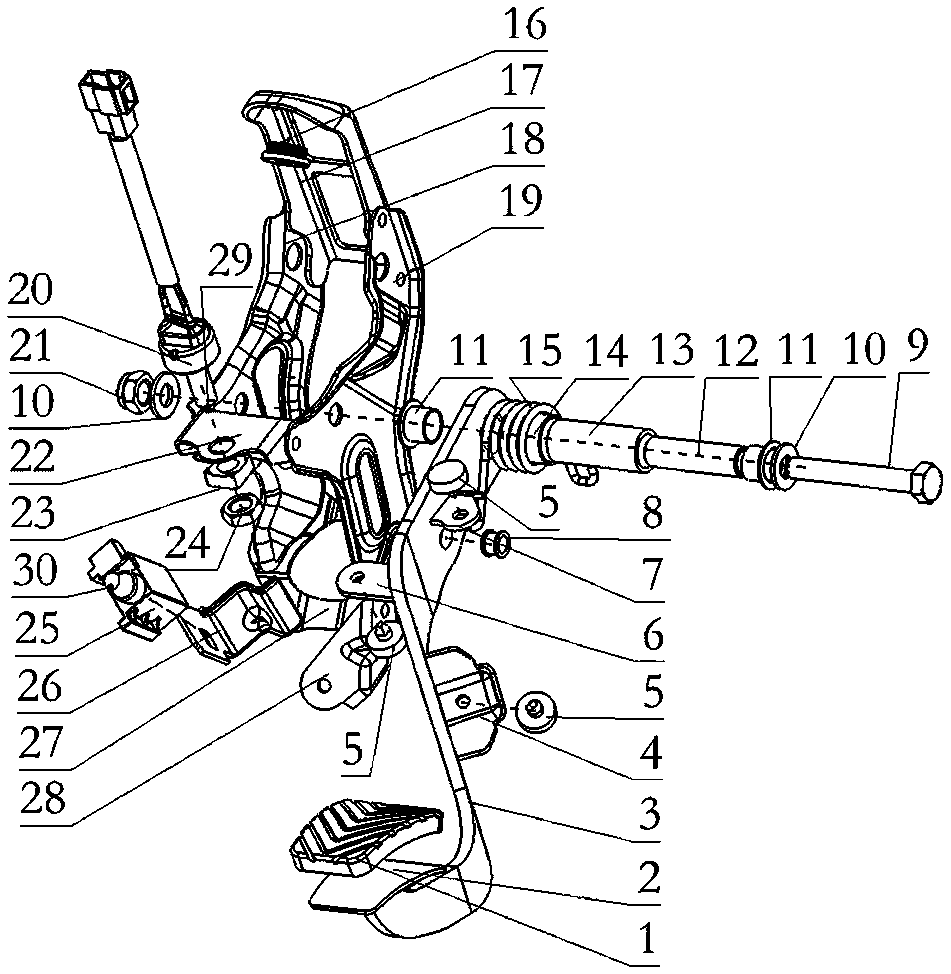

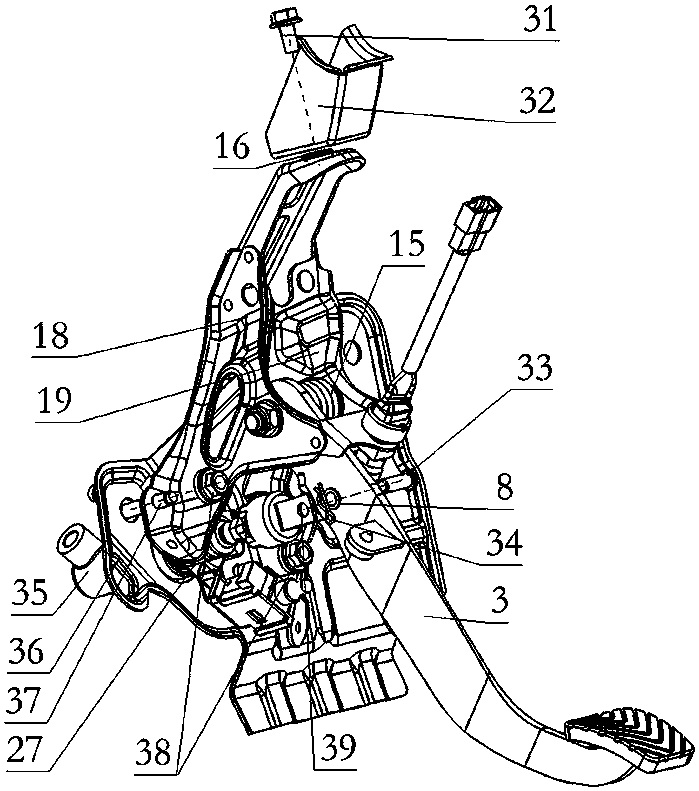

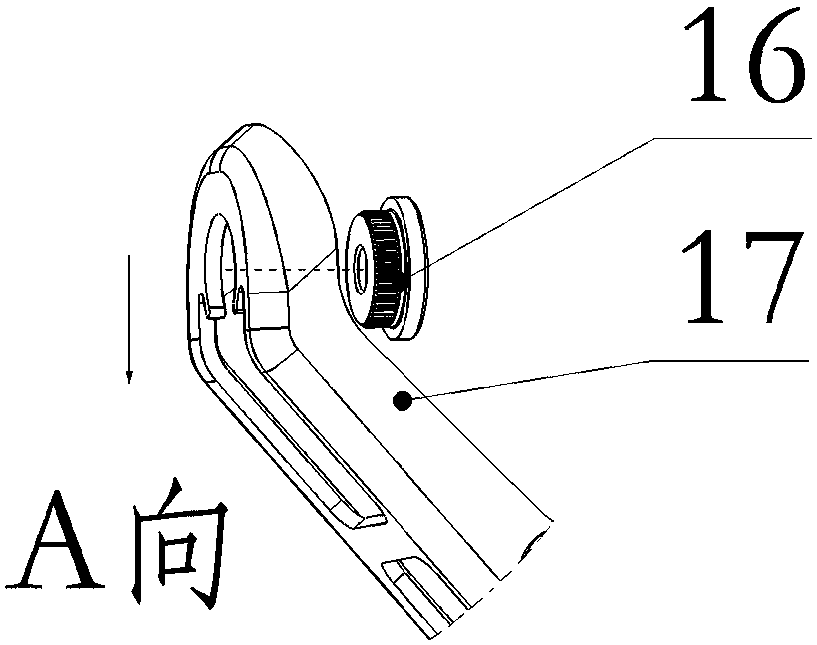

[0025] To make the above-mentioned purposes, features and advantages of the present invention more obvious and understandable, below in conjunction with the attached Figure 1 ~ Figure 3 The present invention will be further described in detail with specific embodiments.

[0026] A clutch pedal assembly, including a clutch bracket body composed of upper bracket 17, left bracket 18, right bracket 19, and lower bracket 27 welded together, and a pedal cover 1 and a pedal pad body 2 connected to the clutch bracket body. Pedal arm 3, axle sleeve 13 first passes through the axle sleeve mounting hole of pedal arm 3, then is fixed between the left support 18 and the right support 19 with the mounting hole on the right support 19 and the mounting hole on the left support 18 successively, and in The inner ring of the shaft sleeve 13 is connected with the shaft tube 12, and one end of the shaft tube 12 is provided with a self-lubricating bearing 11, the inner ring of the shaft sleeve 13 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com