Patents

Literature

230 results about "Sophorolipid" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

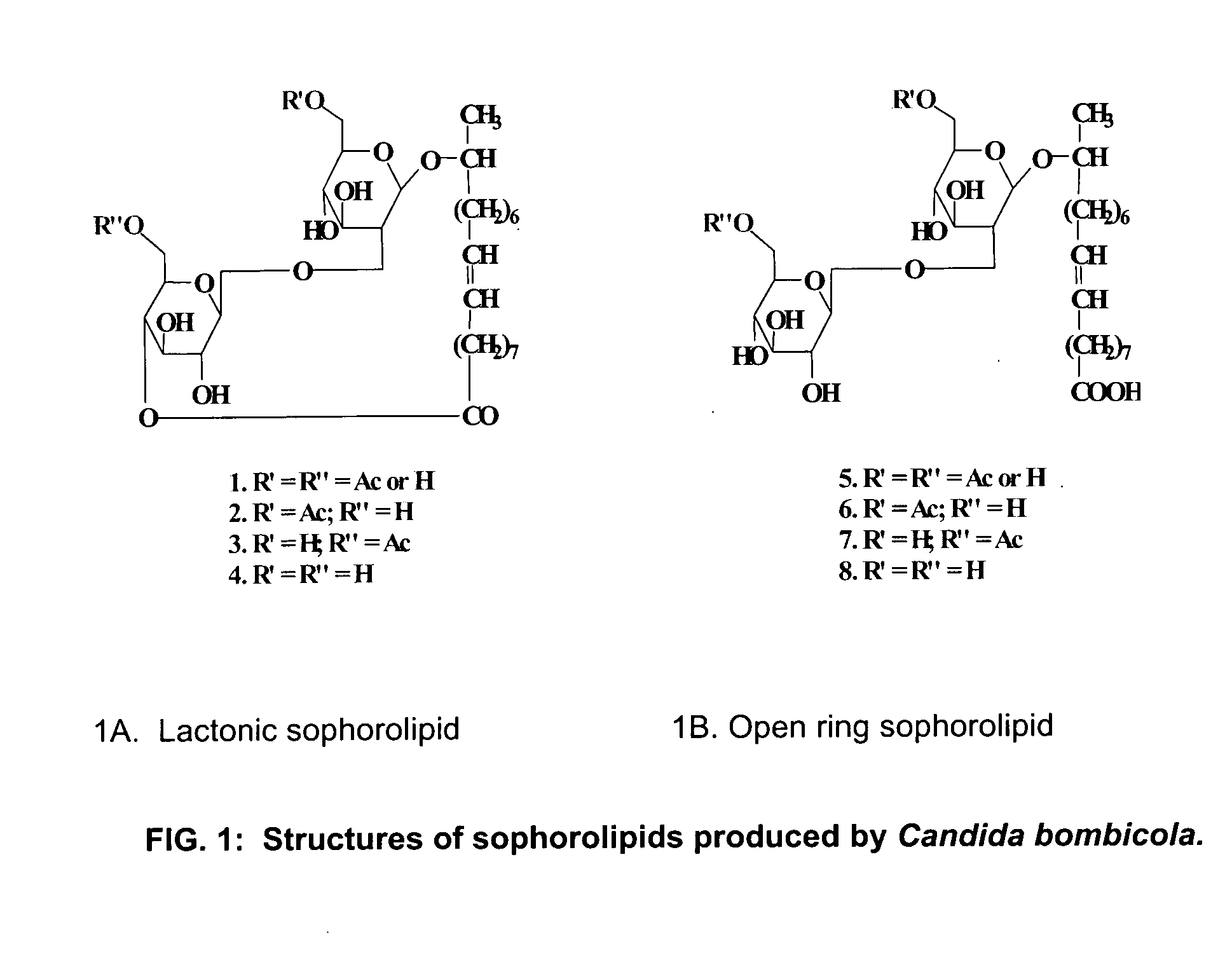

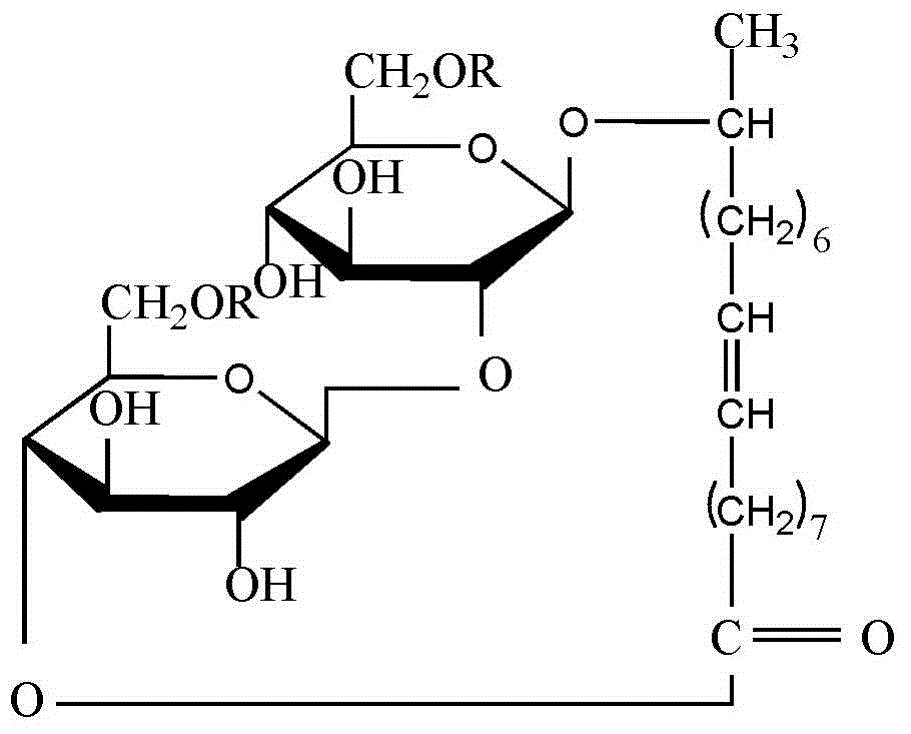

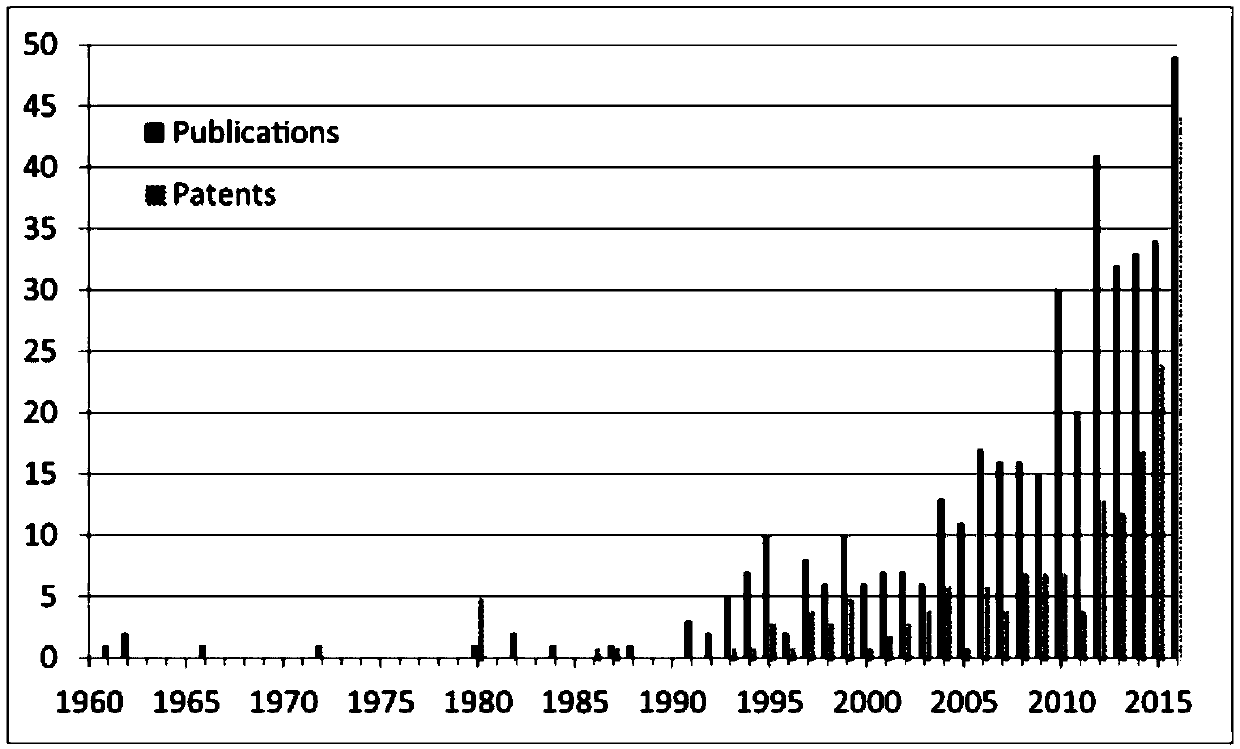

A sophorolipid is a surface-active glycolipid compound that can be synthesized by a selected number of non-pathogenic yeast species. The first report on sophorolipids was published in 1961, but in the last two decades, because of growing environmental awareness, they have gained increased attention as potential bio-surfactants due to their biodegradability and low eco-toxicity. Today sophorolipids are considered promising bio-surfactants.

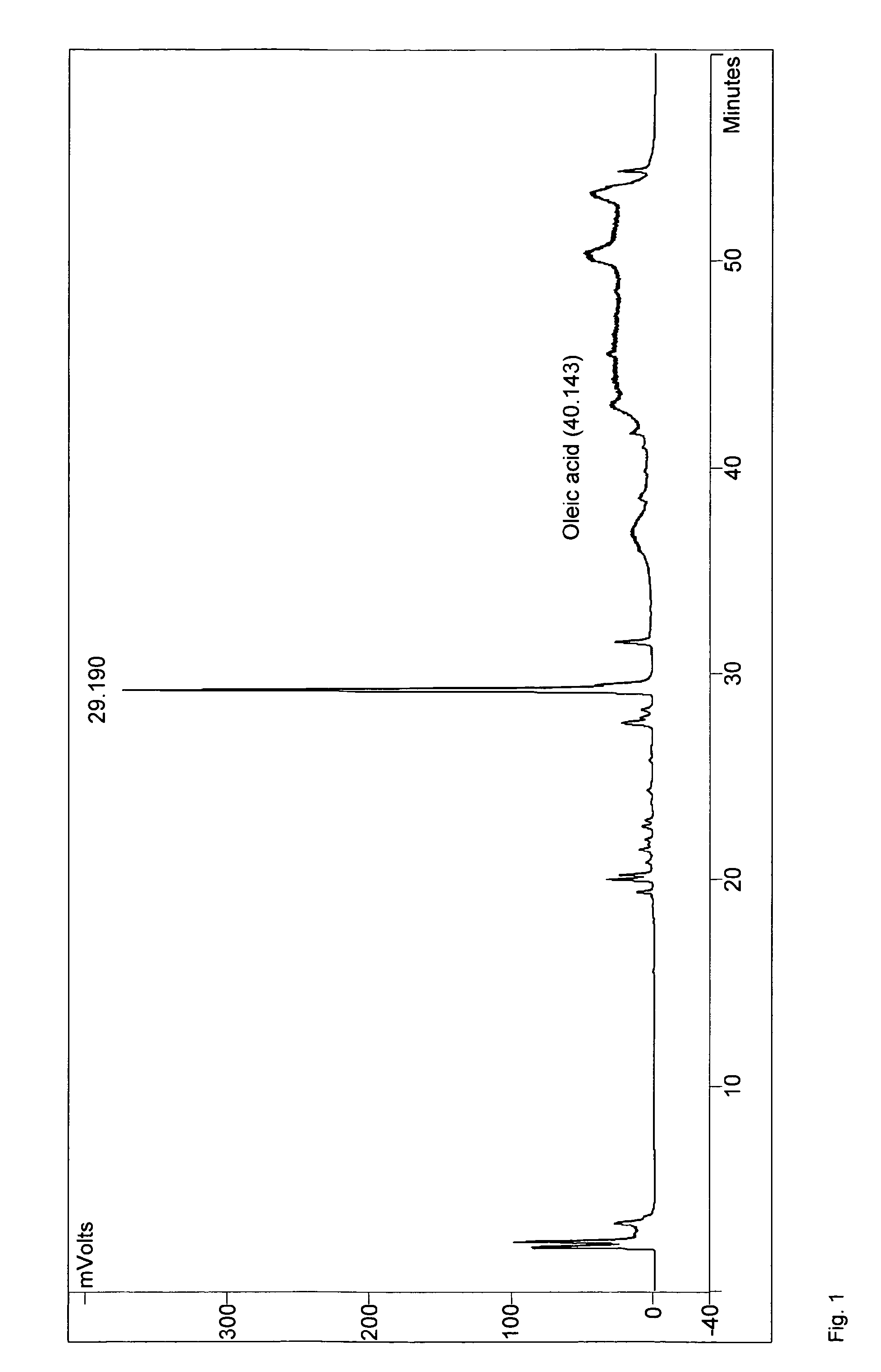

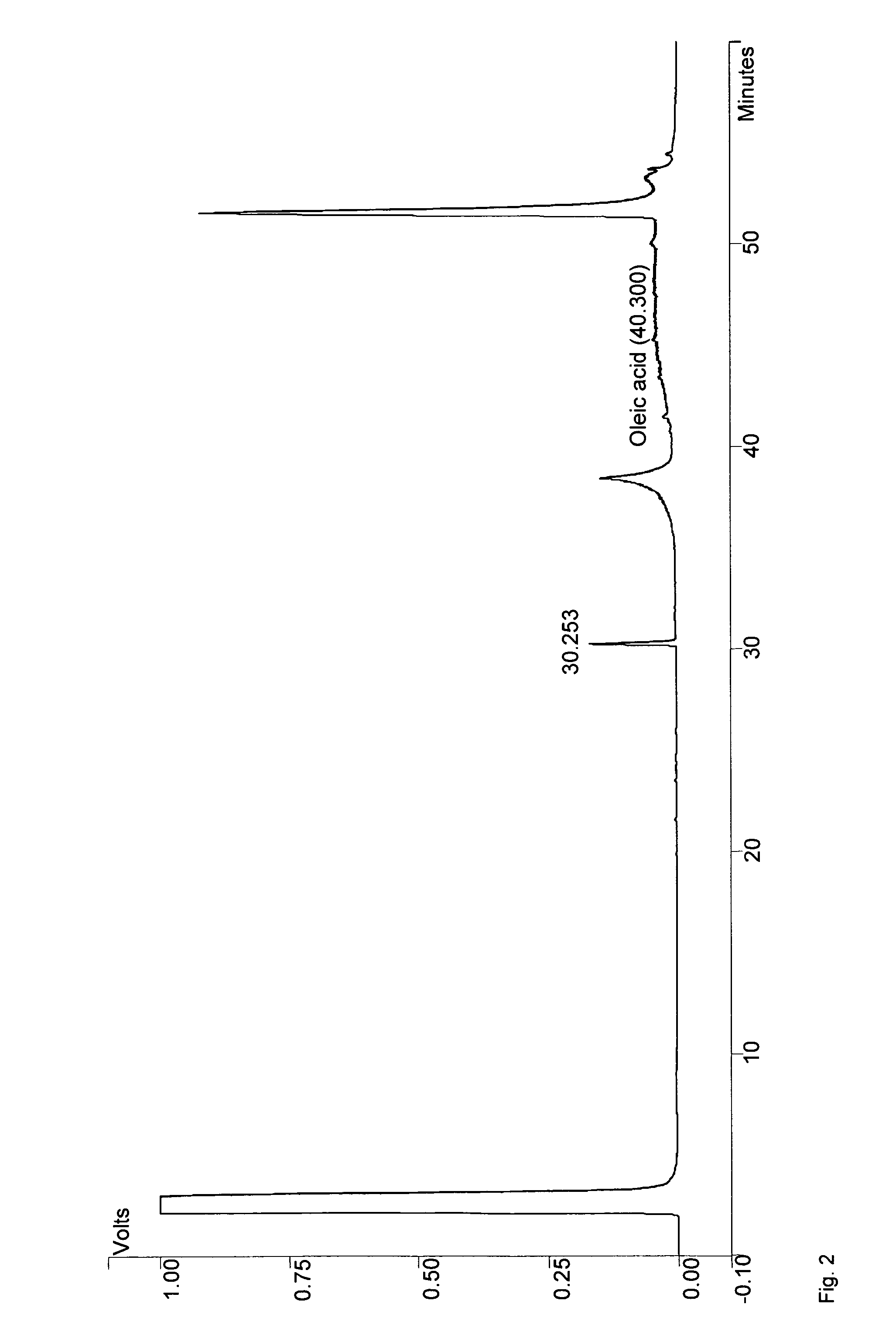

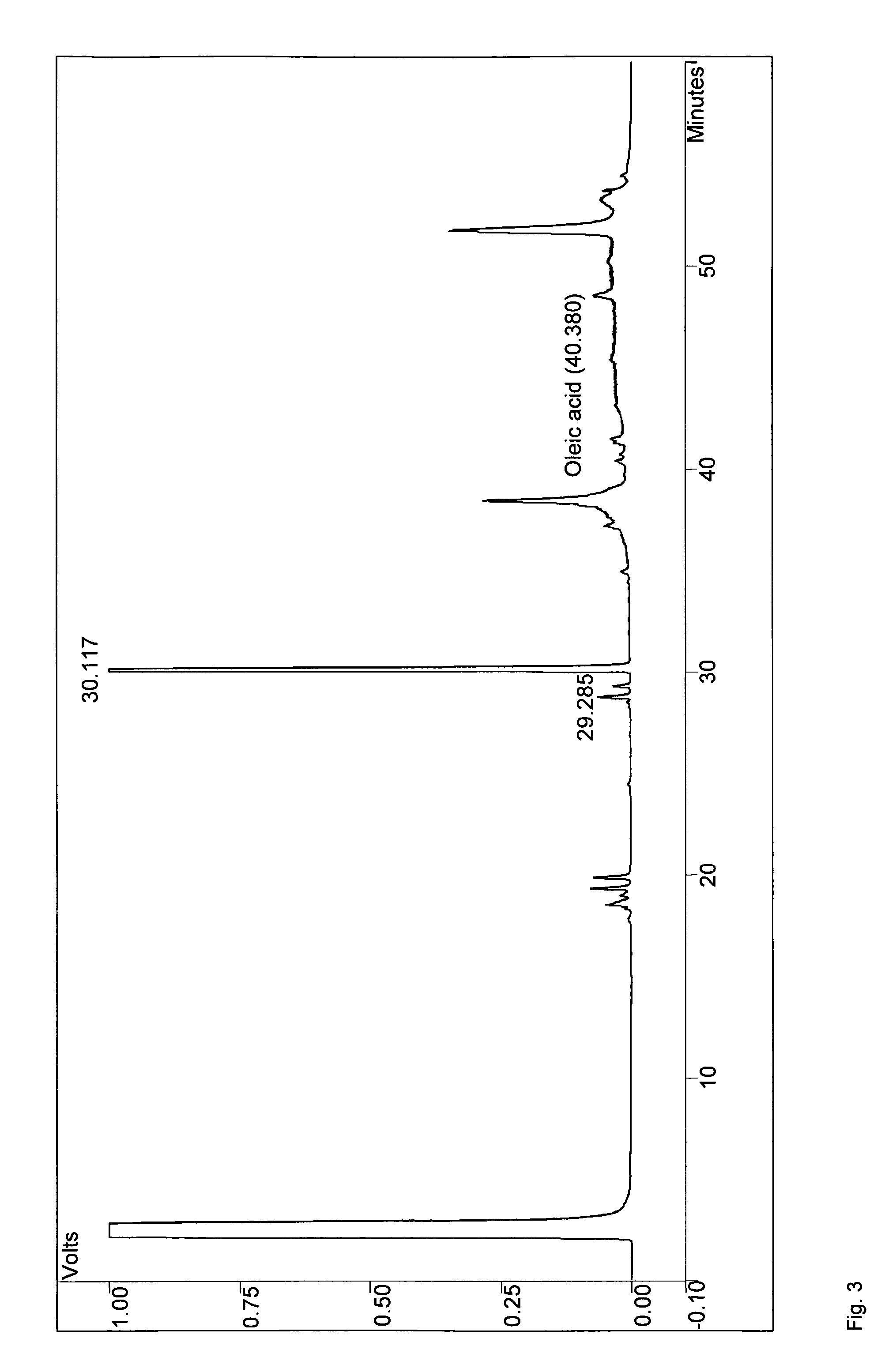

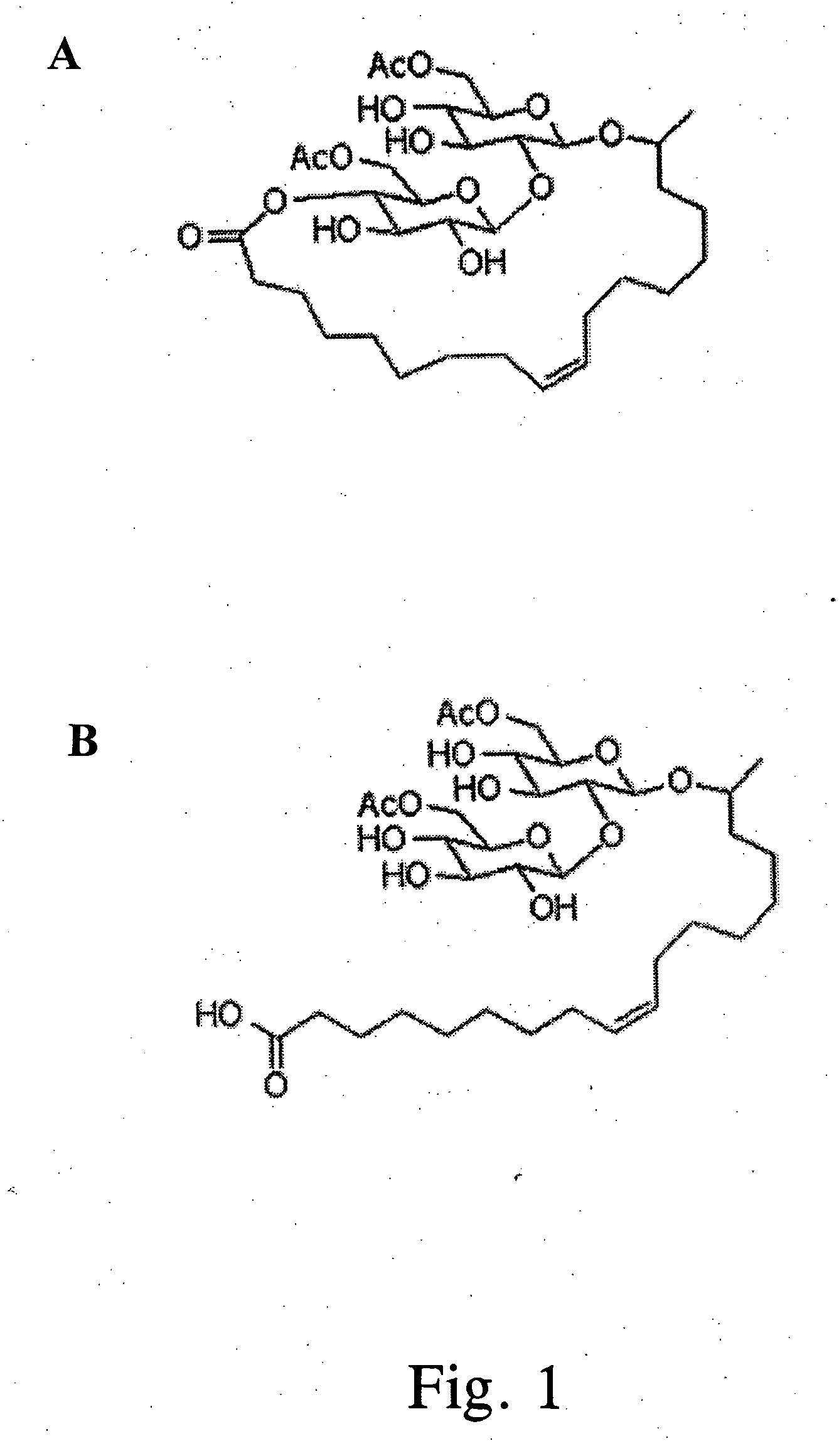

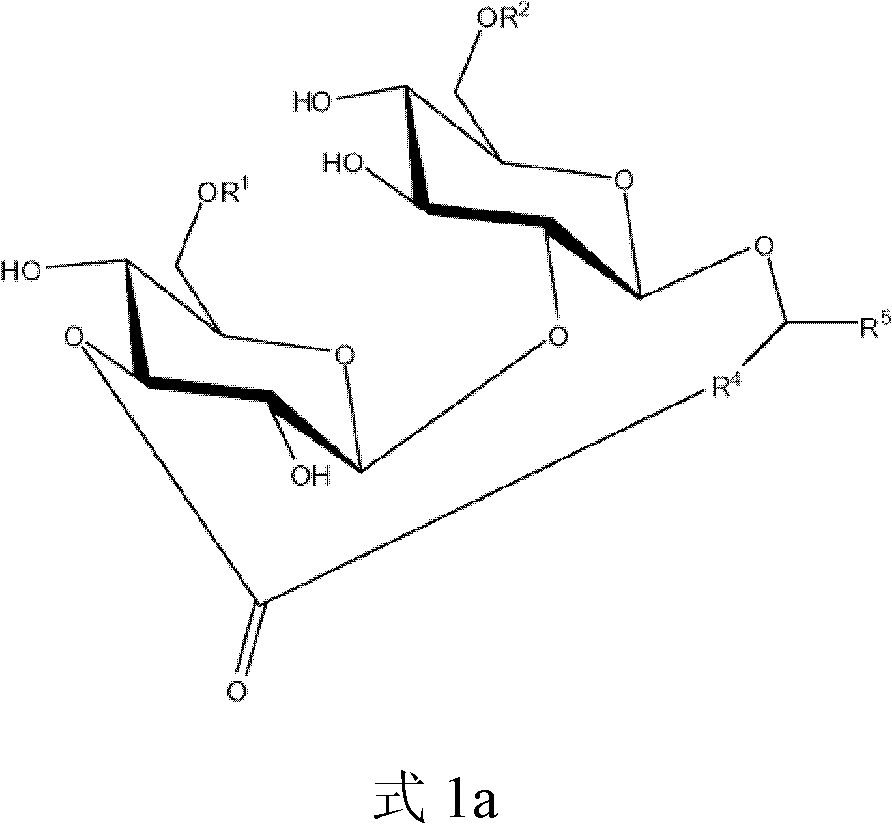

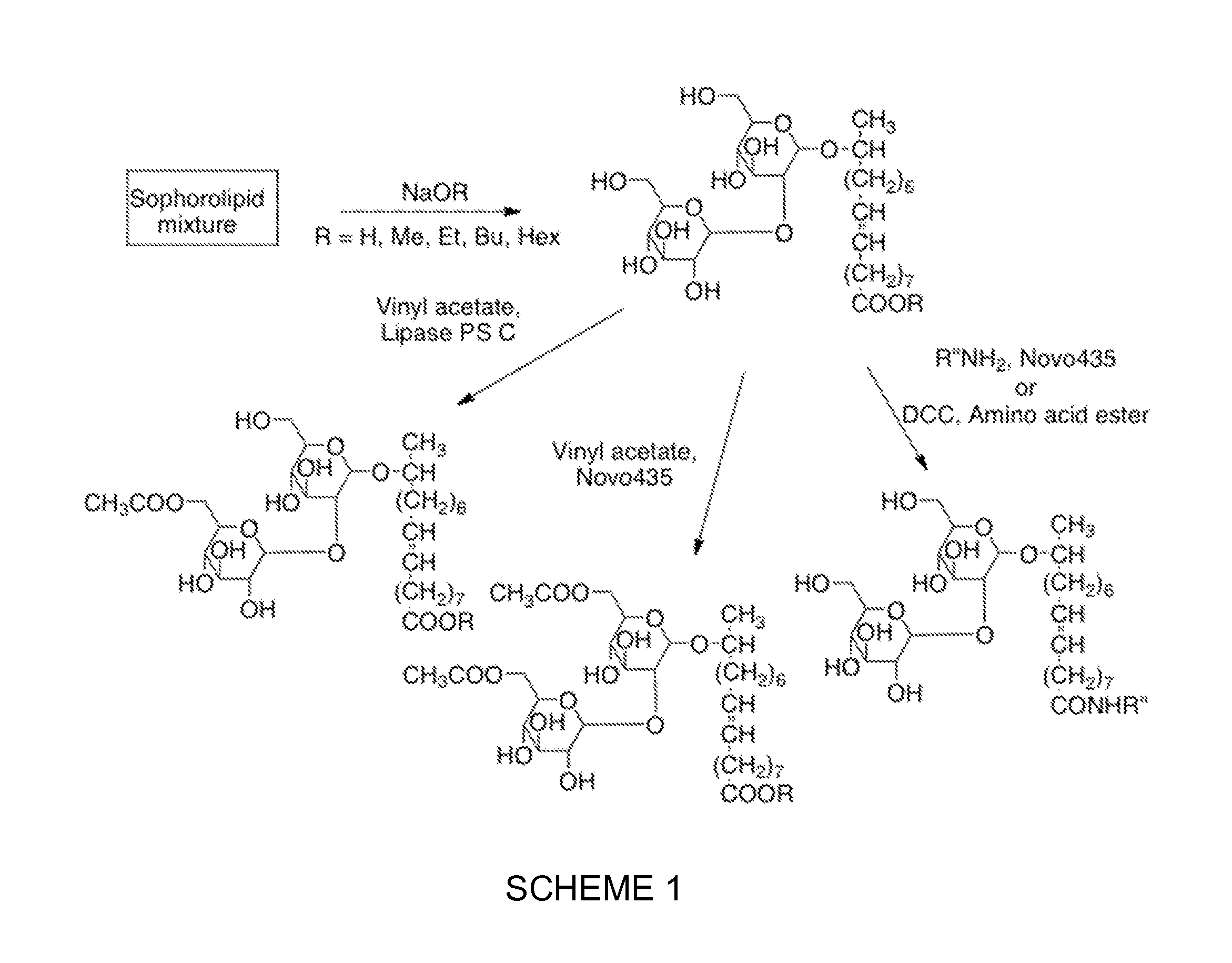

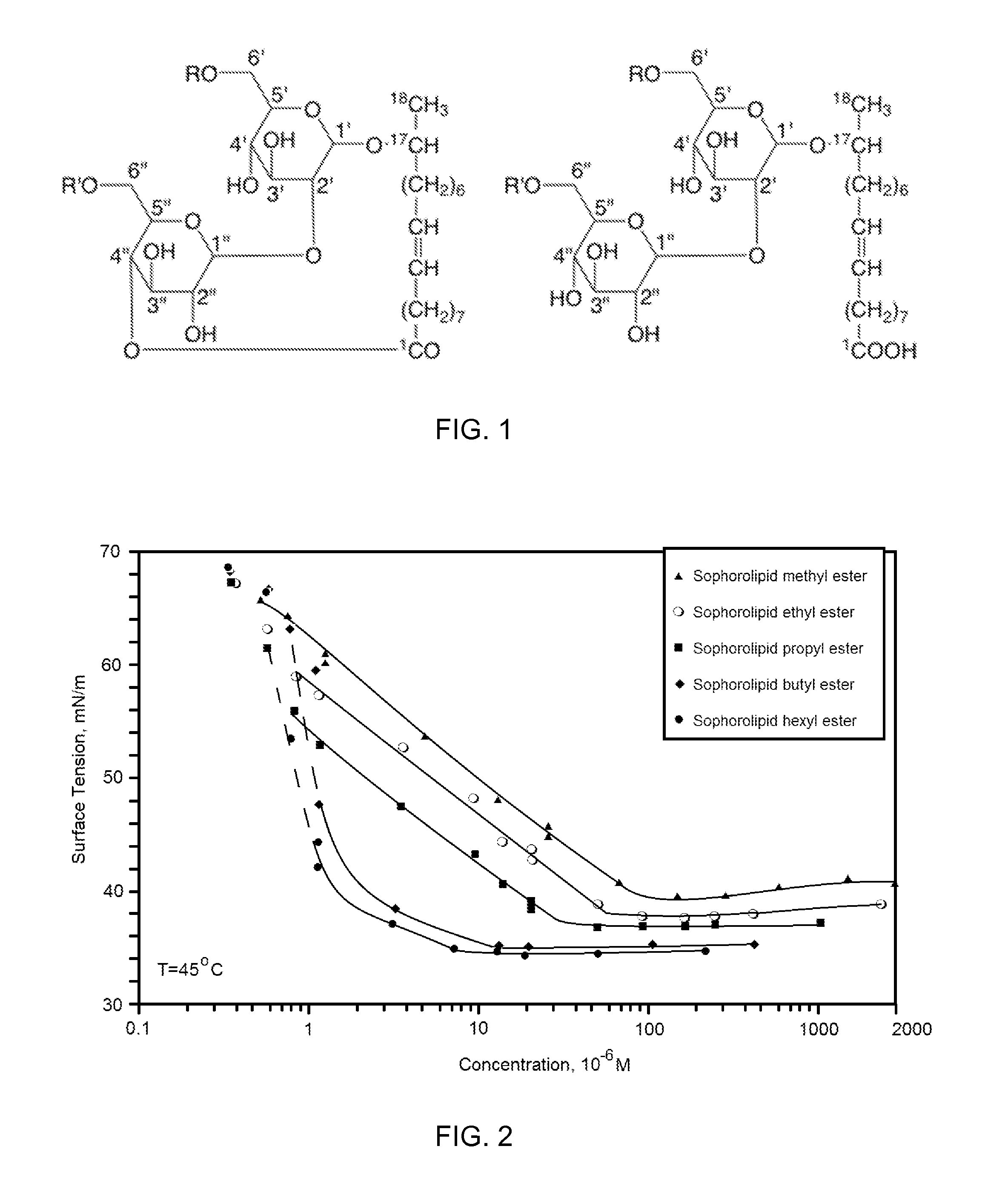

Antifungal properties of various forms of sophorolipids

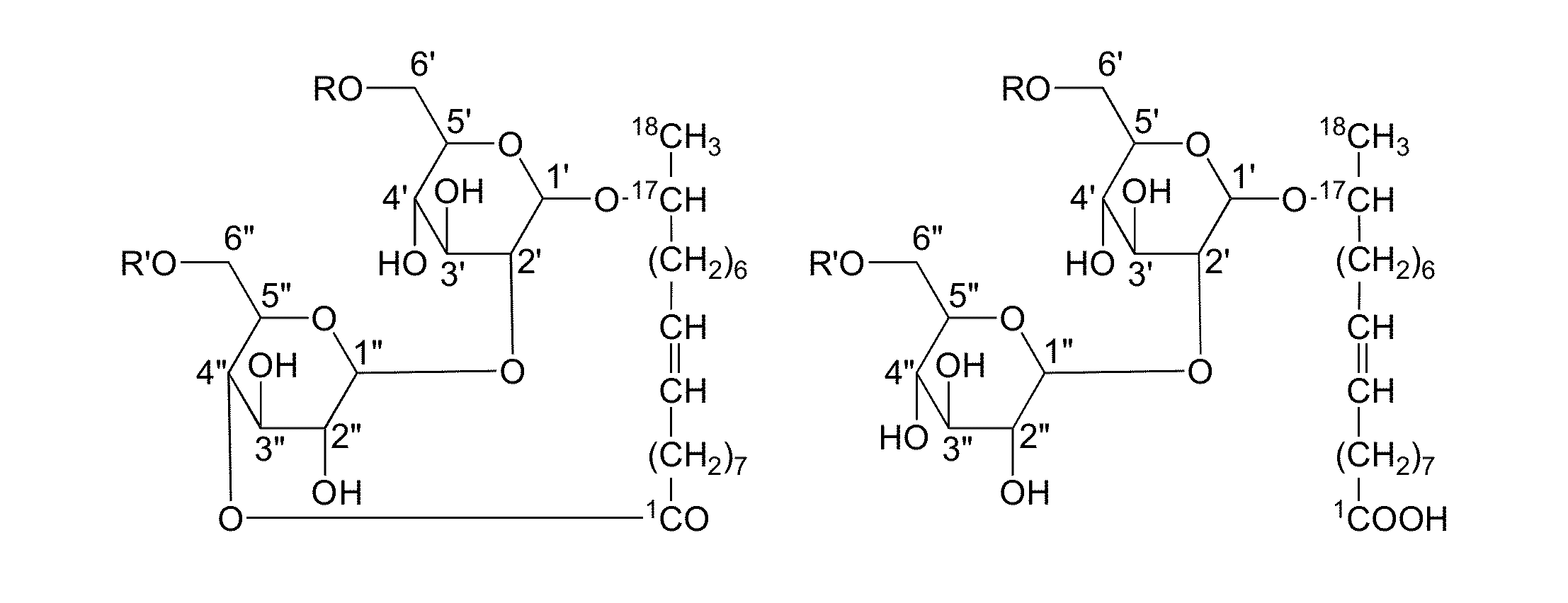

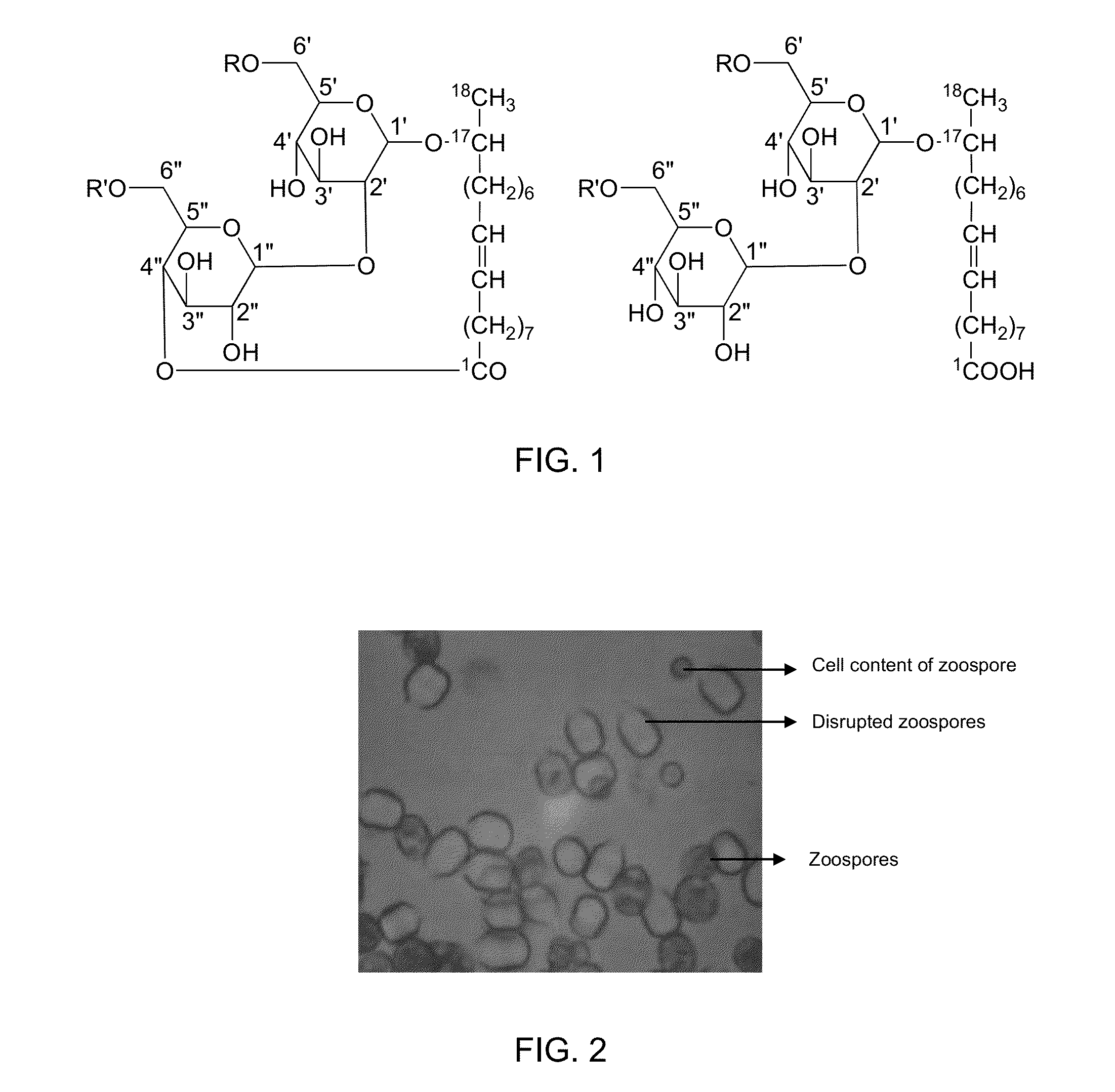

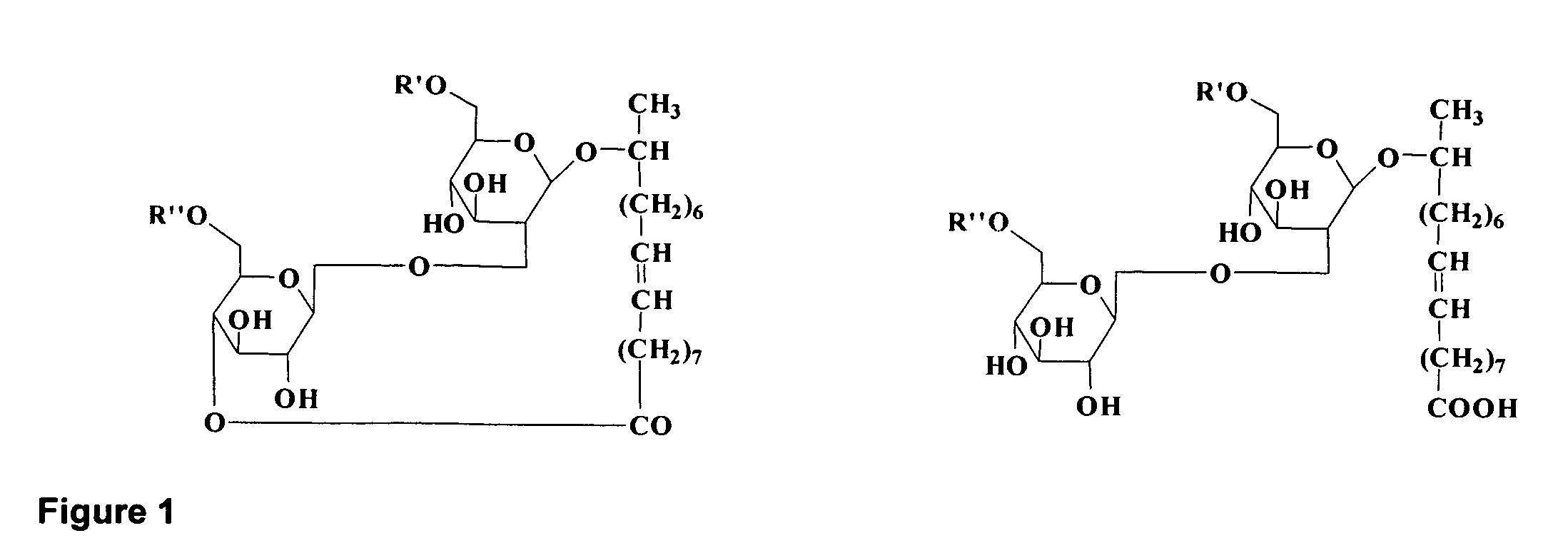

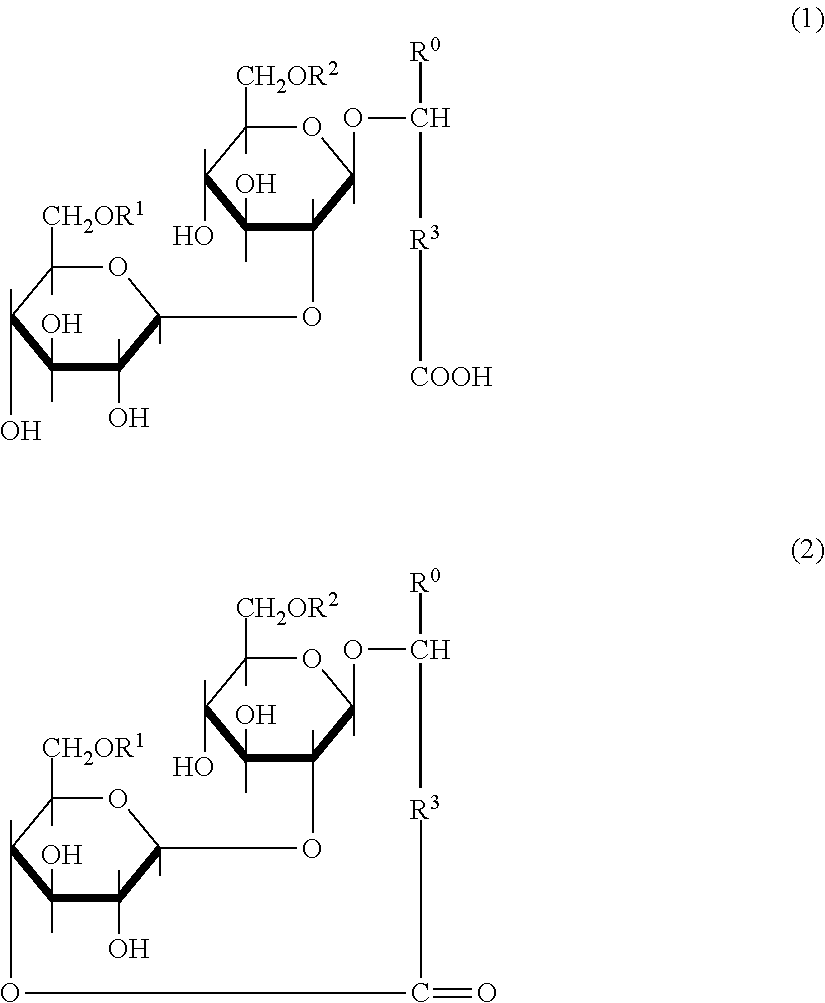

The preparation and use of 17-L-[(2′-O-β-D-glucopyranosyl-β-D-glucopyranosyl)-oxy]-cis-9-octadecenoate, Lactonic and Open ring 17-L-[(2′-O-β-D-glucopyranosyl-β-D-glucopyranosyl)-oxy]-cis-9-octadecenoate, Methyl 17-L-[(2′-O-β-D-glucopyranosyl-β-D-glucopyranosyl)-oxy]-cis-9-octadecenoate, Ethyl 17-L-[(2′-O-β-D-glucopyranosyl-β-D-glucopyranosyl)-oxy]-cis-9-octadecenoate, Hexyl 17-L-[(2′-O-β-D-glucopyranosyl-β-D-glucopyranosyl)-oxy]-cis-9-octadecenoate, Ethyl 17-L-[(2′-O-β-D-glucopyranosyl-β-D-glucopyranosyl)-oxy]-cis-9-octadecenoate-6″-acetate and Ethyl 17-L-[(2′-O-β-D-glucopyranosyl-β-D-glucopyranosyl)-oxy]-cis-9-octadecenoate-6′,6″-diacetate sophorolipids as antifungal agents.

Owner:POLYTECHNIC INST OF NEW YORK +1

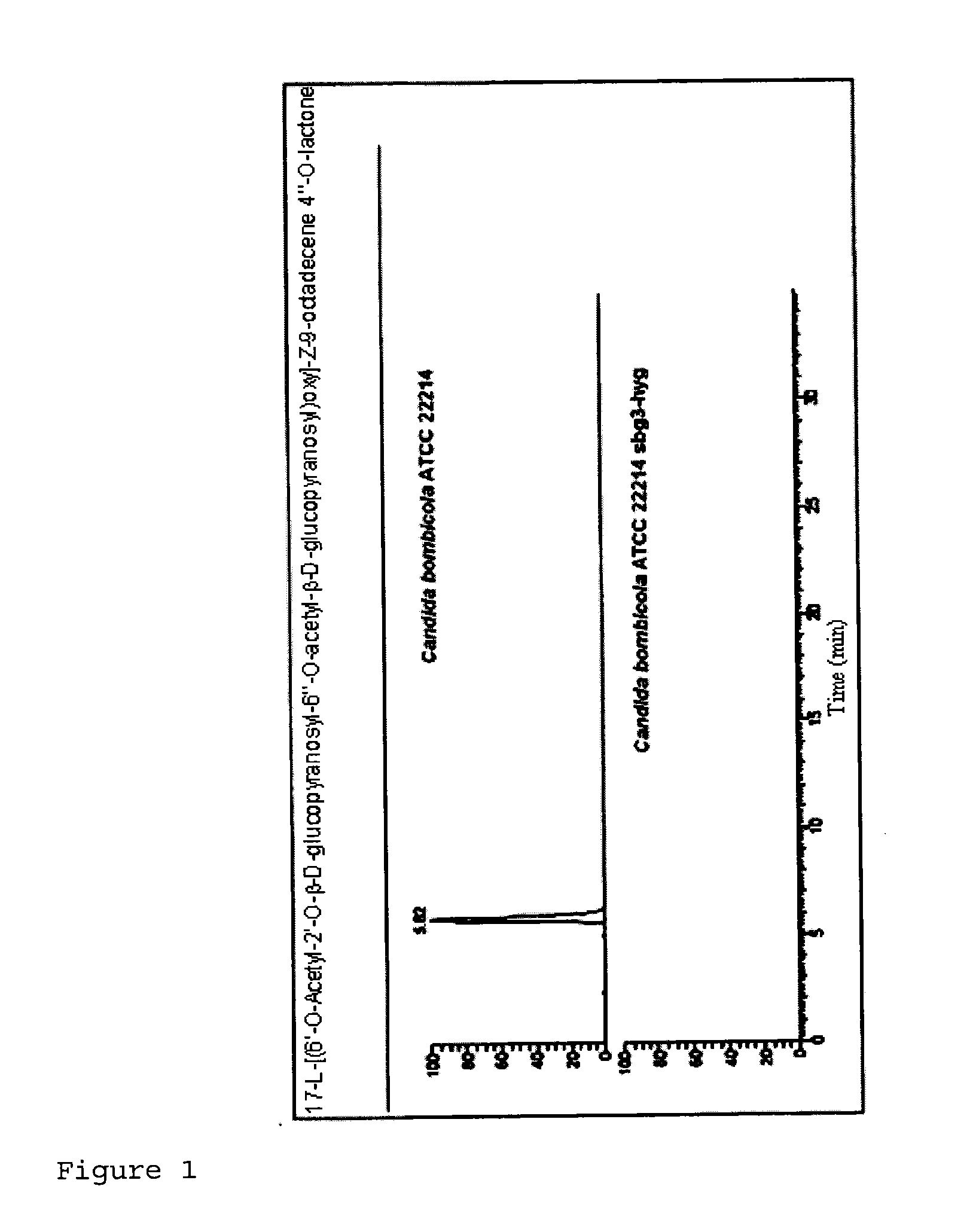

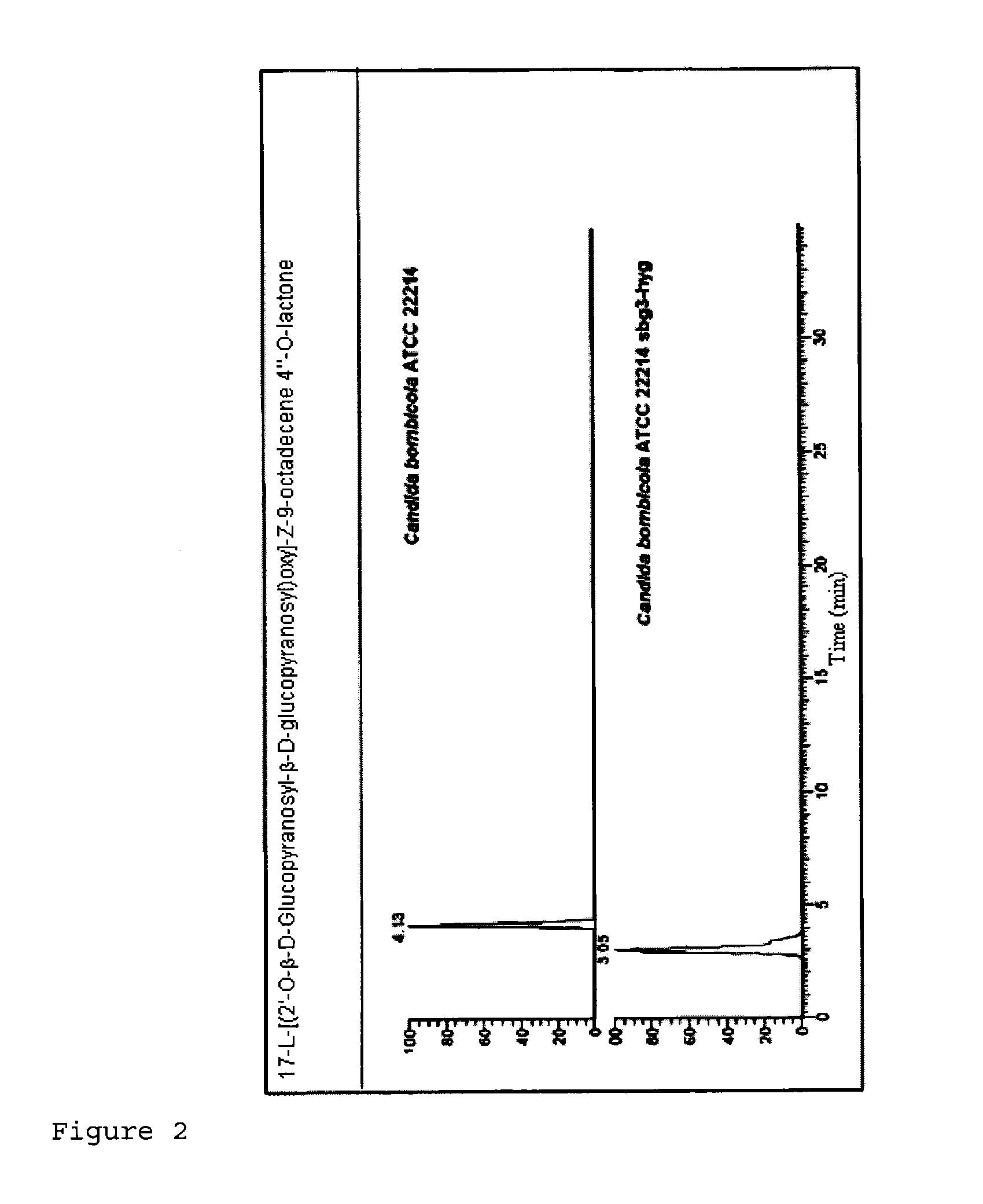

Cells, nucleic acids, enzymes and use thereof, and methods for the production of sophorolipids

InactiveUS20130035403A1Performance parameters of sophorolipid formation, suchHigh yieldOrganic active ingredientsCosmetic preparationsEnzymeNucleic acid

Owner:EVONIK DEGUSSA GMBH

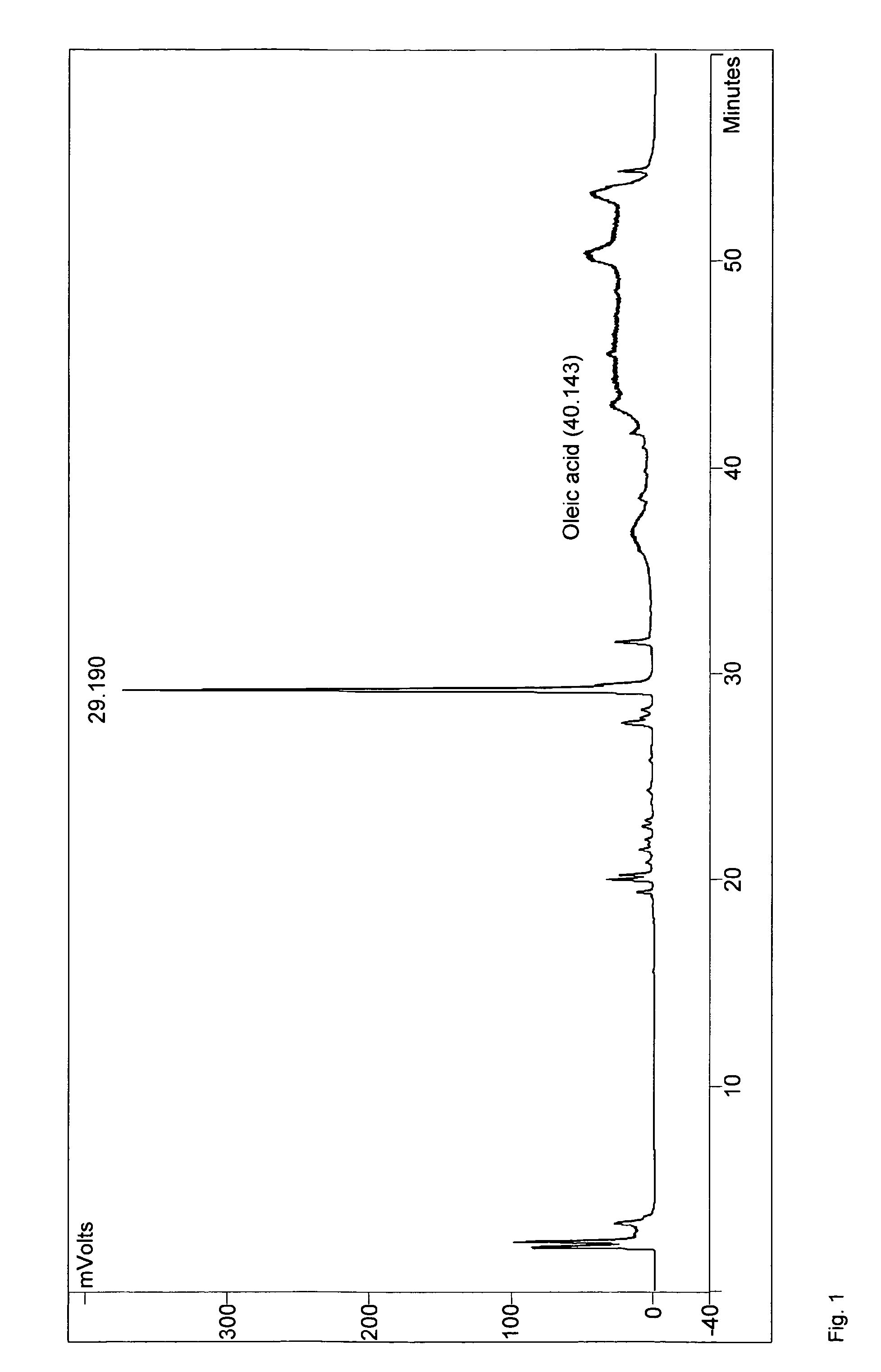

Method for the production of medium-chain sophorolipids

The MFE2 gene of a microorganism capable of producing glycolipids, such as, but not limited to C. bombicola is disrupted with the purpose of blocking the beta-oxidation pathway in the strain. Fermentation of a such strain having such disrupted genes on primary or secondary alcohols or diols, preferably on primary alcohols produces short chained glycolipids in high yield and purity.

Owner:ECOVER CO ORDINATION CENT

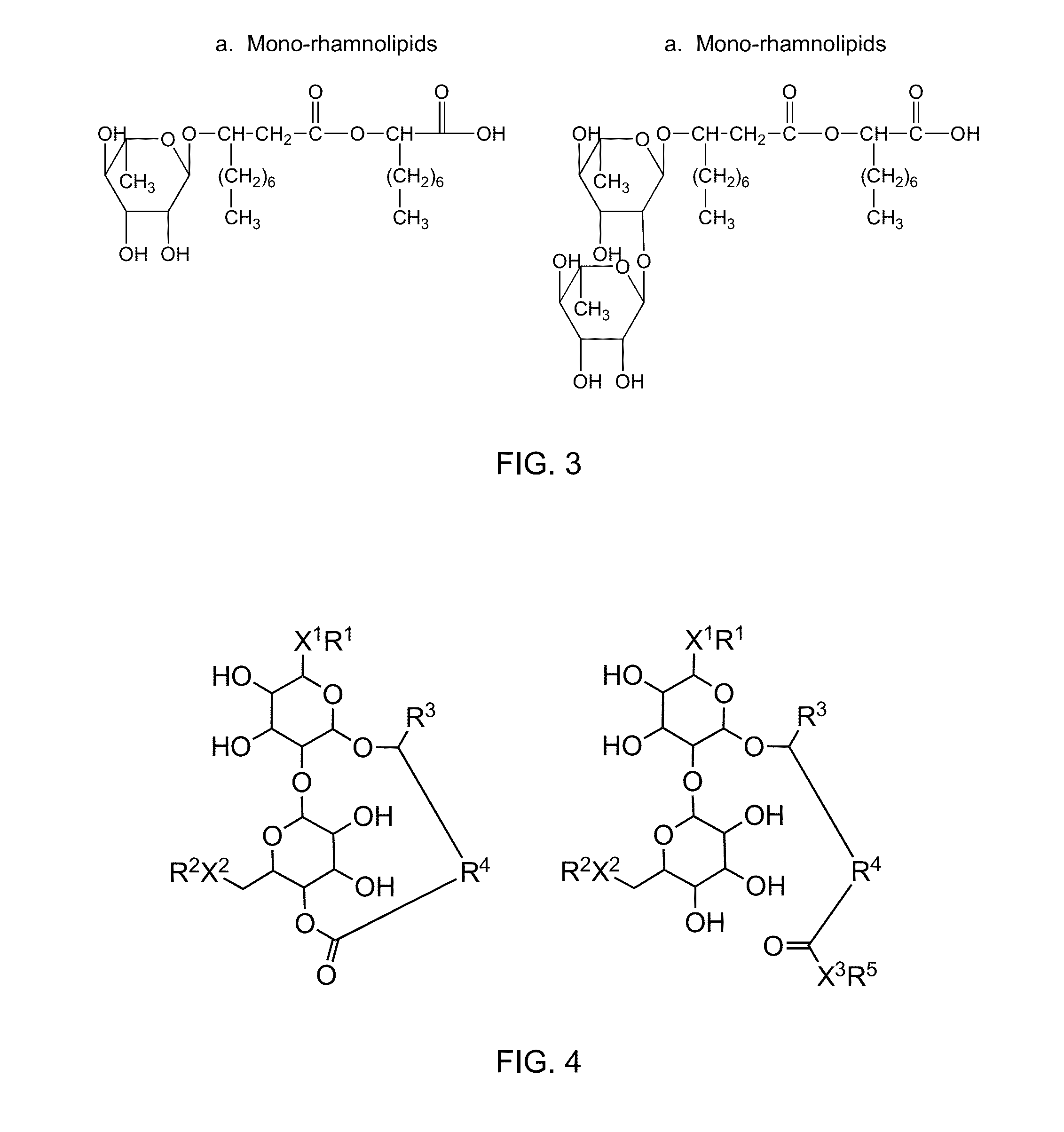

Modified sophorolipids for the inhibition of plant pathogens

A method for controlling pests by modifying derivatives of sophorolipids (SL) and applying the modified sophorolipid derivatives (MSL) to the plant pathogen or to an environment in which the pathogens may occur or are located in an amount such that the pathogens are substantially controlled.

Owner:POLYTECHNIC INSTITUTE OF NEW YORK UNIVERSITY

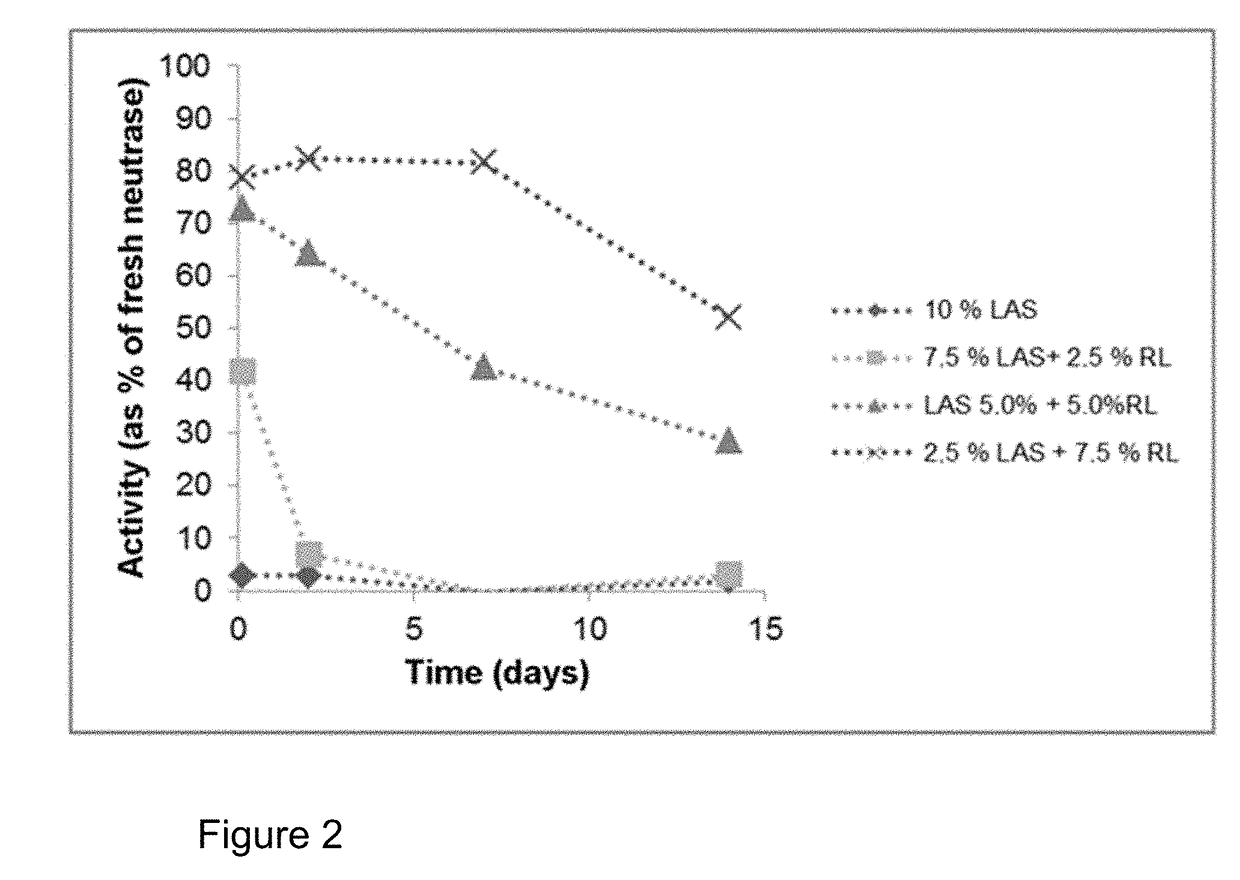

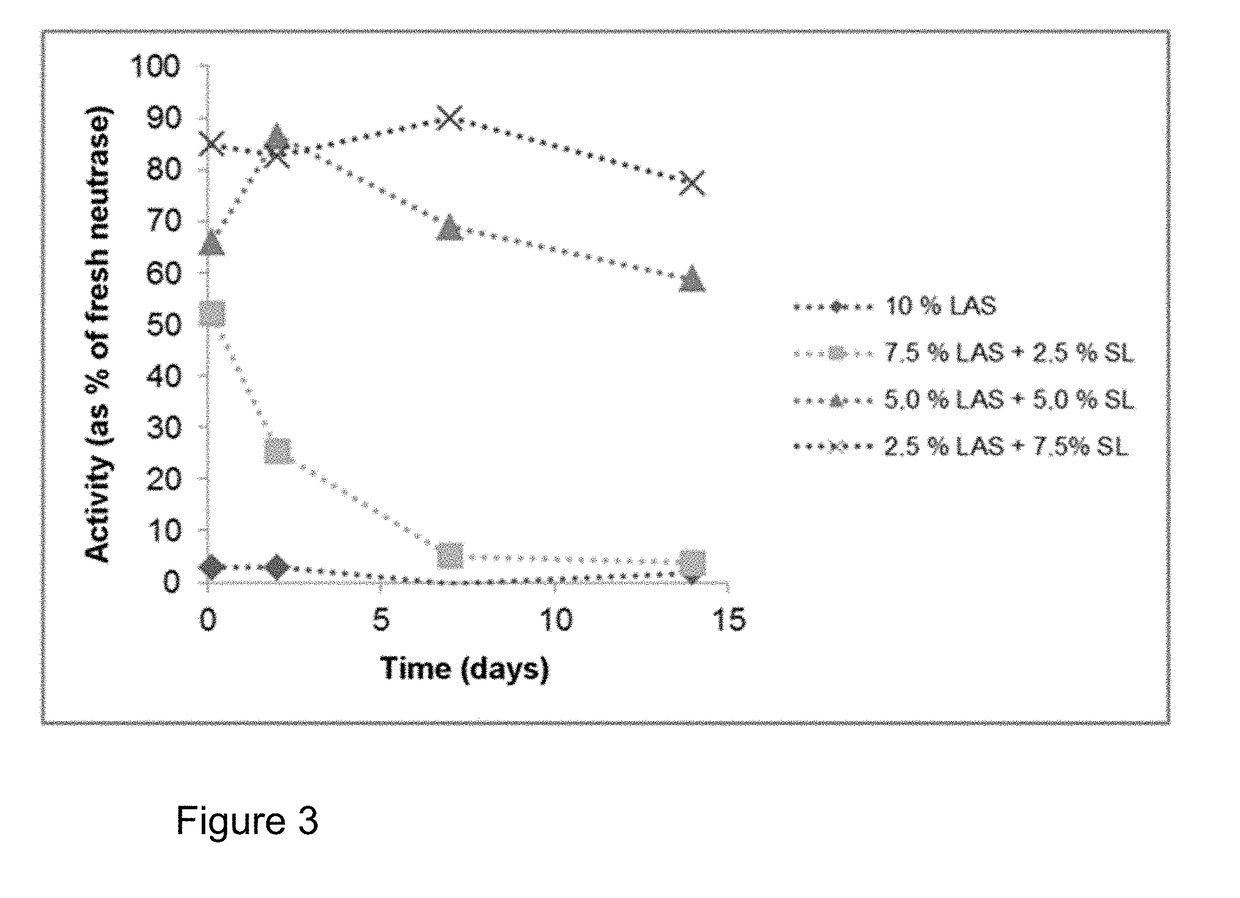

Composition containing peptidase and biosurfactant

ActiveUS20180023040A1Reduce the amount requiredImprove stabilityNon-ionic surface-active compoundsAnionic surface-active compoundsProteinase activityRhamnolipid

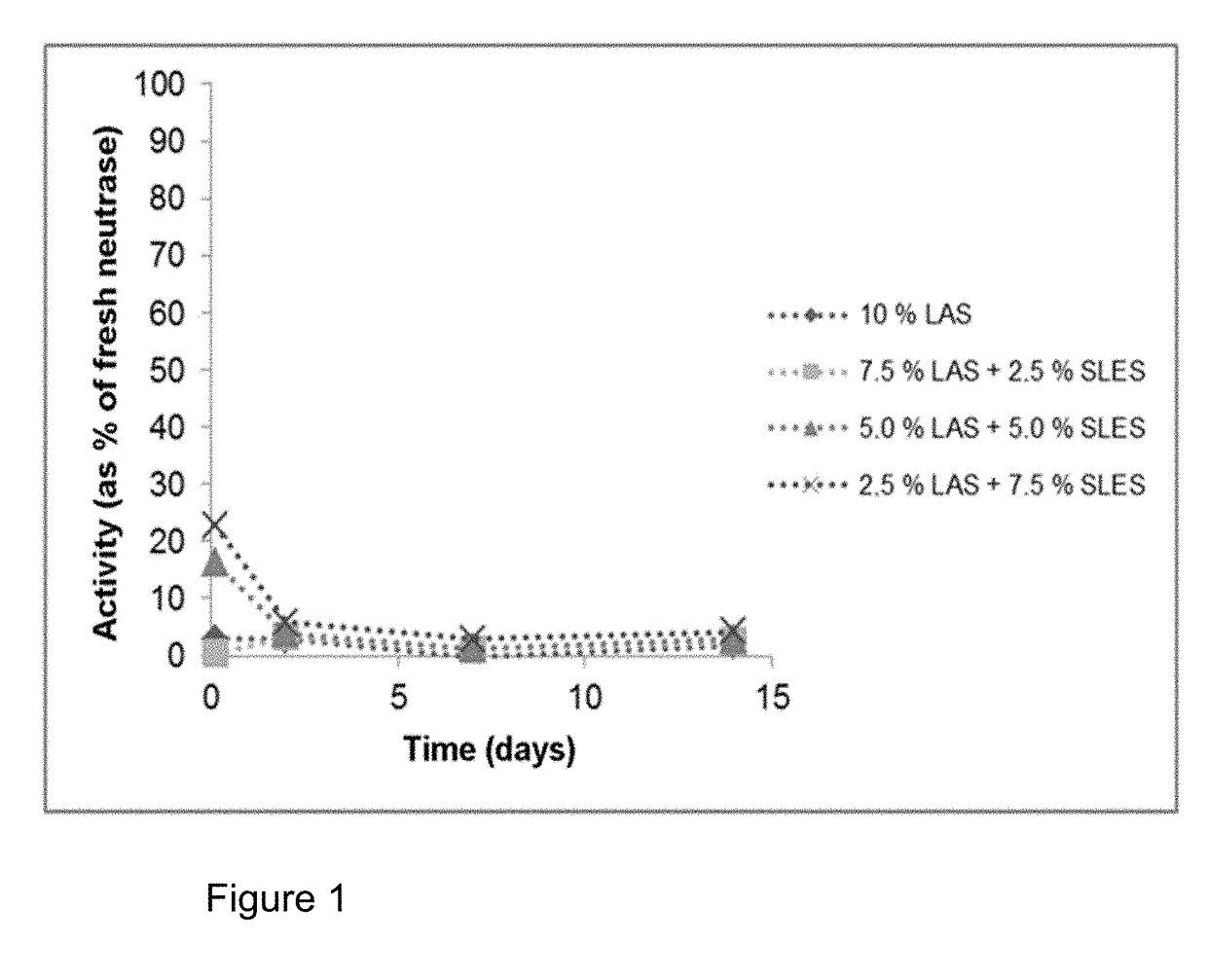

The invention relates to compositions comprising at least one protease and at least one biosurfactant, particularly selected from rhamnolipids and sophorolipids. In particular, the present invention is directed to a composition including A) at least one peptidase, B) at least one biosurfactant, and optionally C) at least one anionic surfactant. The peptidase may be selected from the group of the proteases, particularly from the group of the serine proteases of EC 3.4.21 and the metalloproteases of EC 3.4.24 and the biosurfactant may be selected from the group comprising rhamnolipids and sophorolipids.

Owner:EVONIK OPERATIONS GMBH

Method of using sophorolipids or mannosylerythritol lipids as acid corrosion inhibitors in well treatment operations

Corrosive effects arising during well treatment applications are inhibited and / or prevented by introducing into the well composition containing a corrosion inhibitor of a sophorolipid or a mannosylerythritol lipid or a combination thereof. The composition may also contain a corrosion inhibitor intensifier.

Owner:LUTRON TECH CO LLC

Production of open-chained sophorolipids

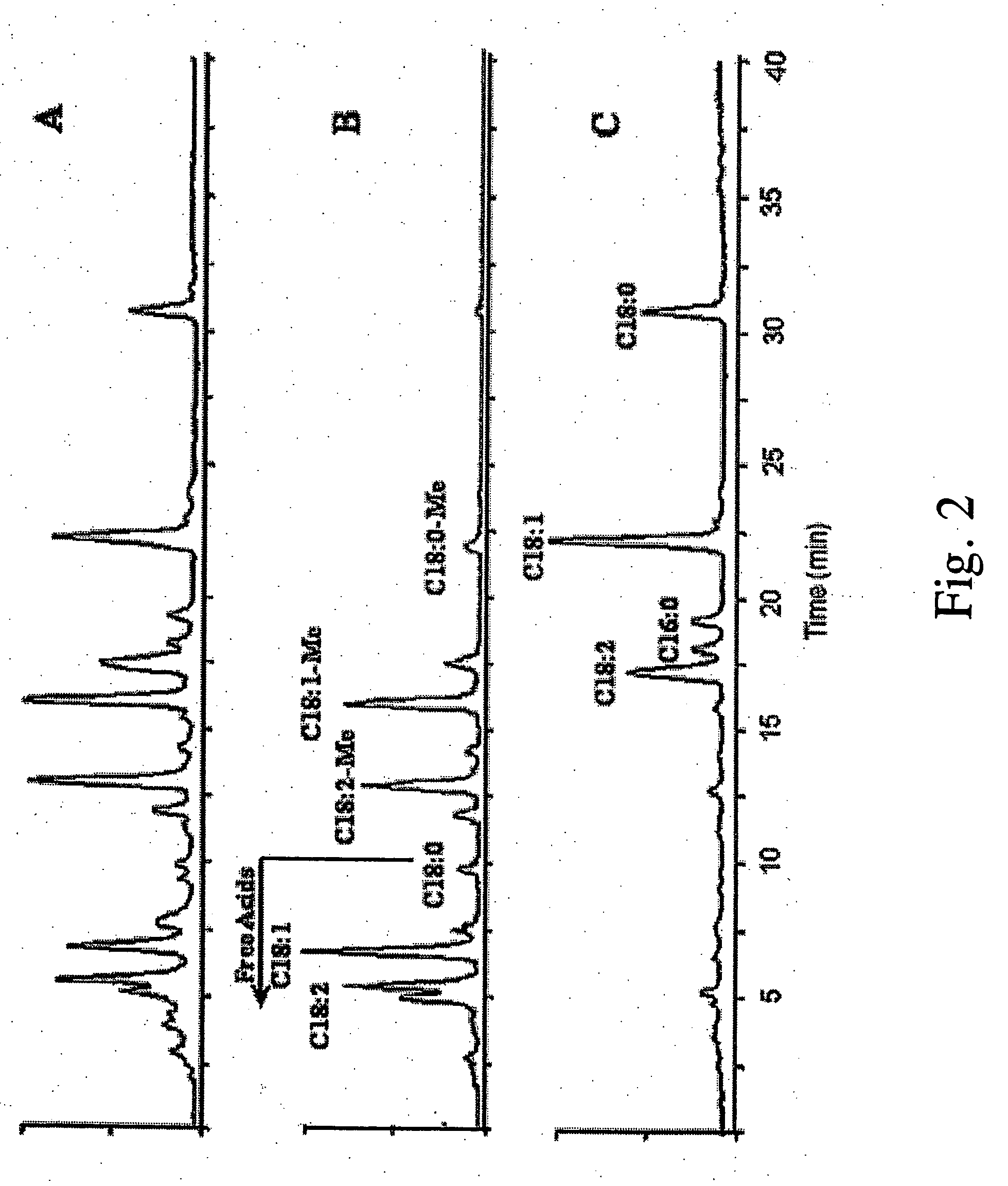

Methods for the production of open-chained sophorolipids, involving cultivating a yeast capable of producing open-chained sophorolipids in a culture medium containing fatty acid alkyl esters, and glycerol or carbohydrates (e.g., glucose) or mixtures thereof; wherein at least about 60% of the sophorolipids produced are open-chained sophorolipids.

Owner:US SEC AGRI

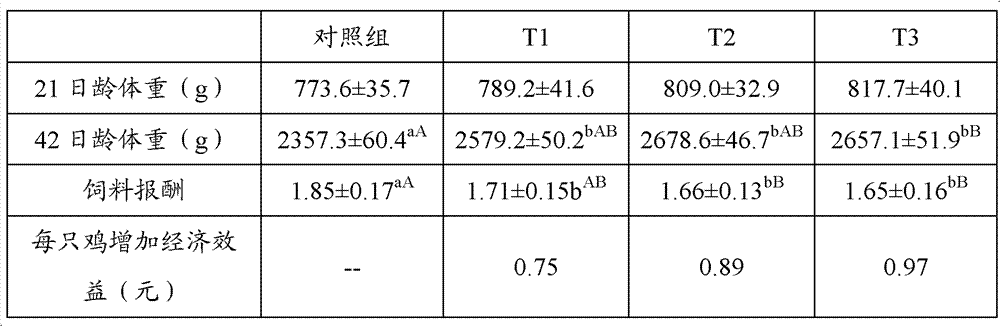

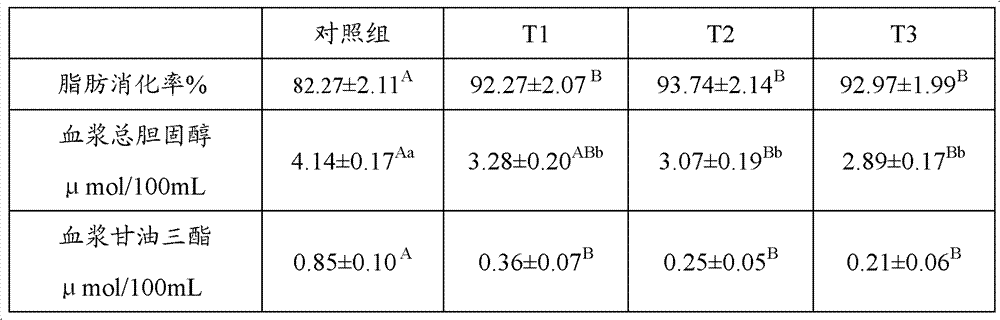

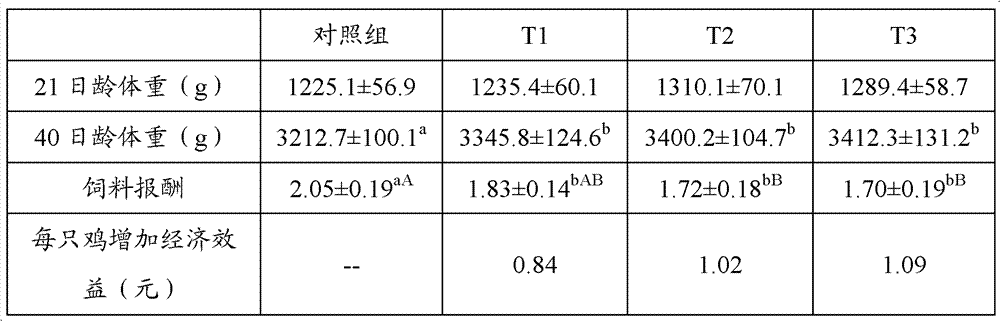

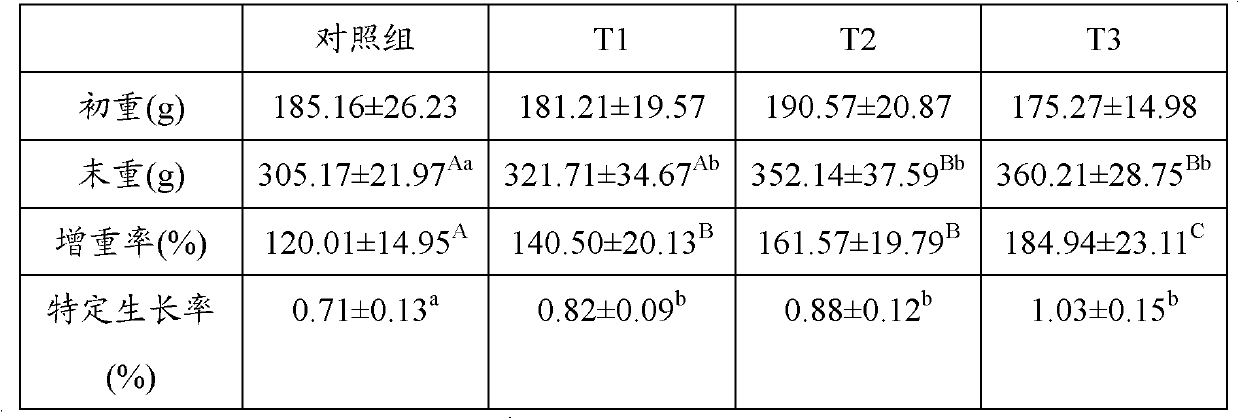

Biologic emulsifier for livestock feed

InactiveCN102696880ADoes not cause residues in the bodyQuality is not affectedAnimal feeding stuffAnimal scienceSecondary metabolite

The invention discloses a biologic emulsifier for livestock feed. The biologic emulsifier is characterized by being prepared by two or more than two of sophorolipid, rhamnolipid and trehalose. The sophorolipid, the rhamnolipid and the trehalose and the like in the emulsifier are all secondary metabolites generated by microbial fermentation, can be naturally metabolized and degraded, do not cause residues in animal bodies, and do not influence quality of animal products. The biologic emulsifier can remarkably improve livestock fat digestion utilizing rate, improves feed reward, reduces livestock blood cholesterol and triglyceride, remarkably improves livestock production performances, improves carcass quality, improves body immune function, reduces morbidity and mortality, and remarkably improves economic returns.

Owner:NINGBO INST OF TECH ZHEJIANG UNIV ZHEJIANG

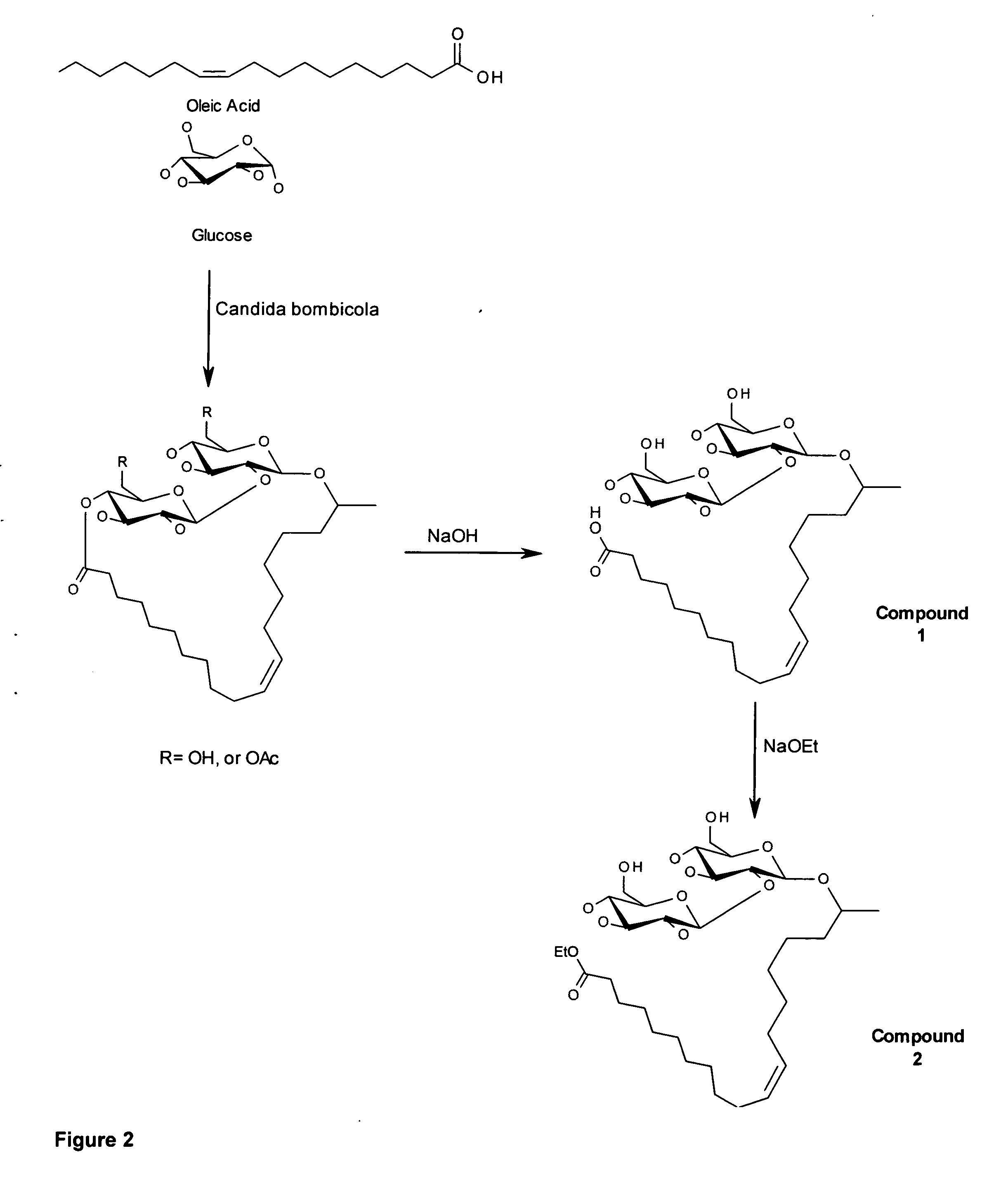

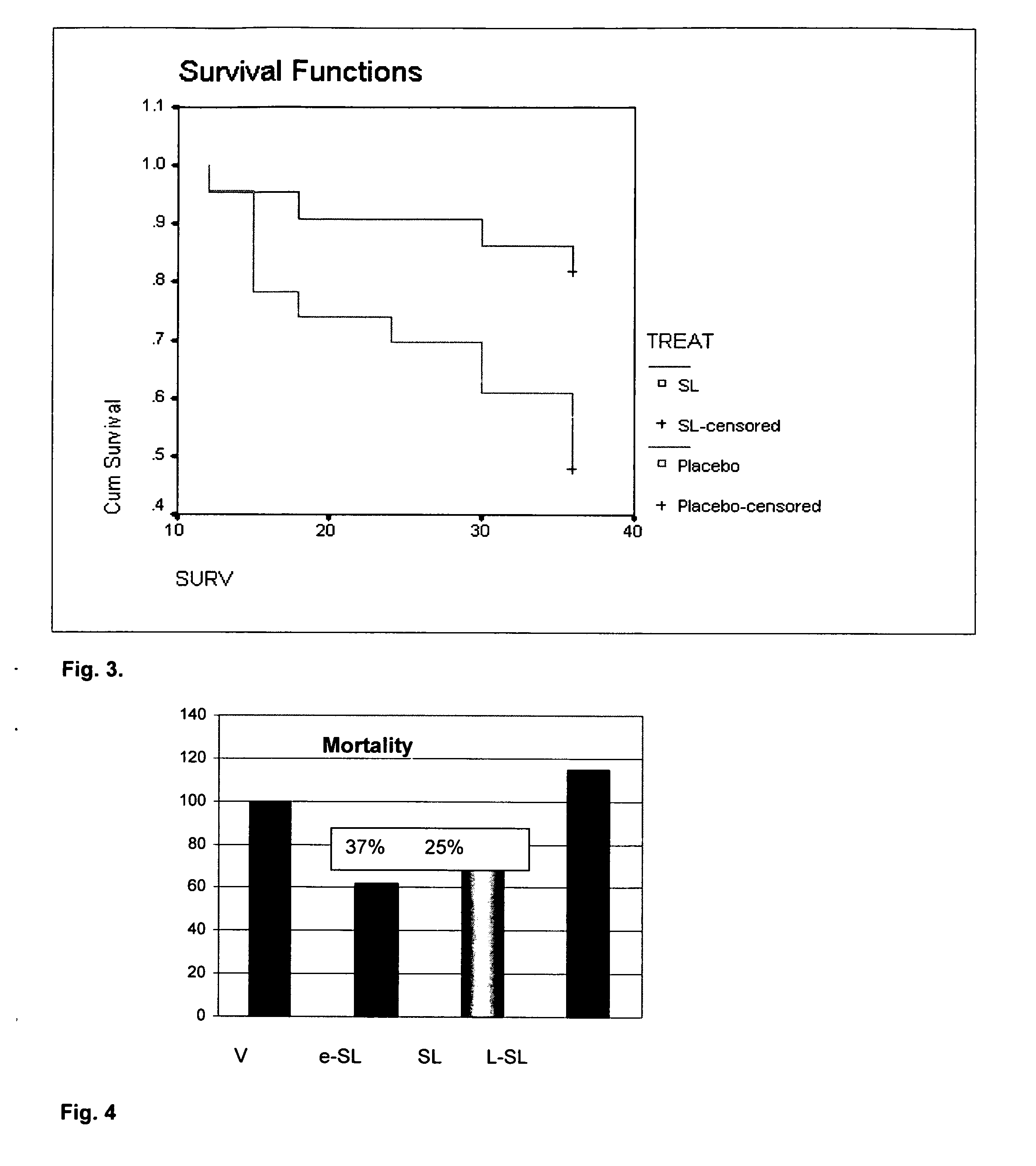

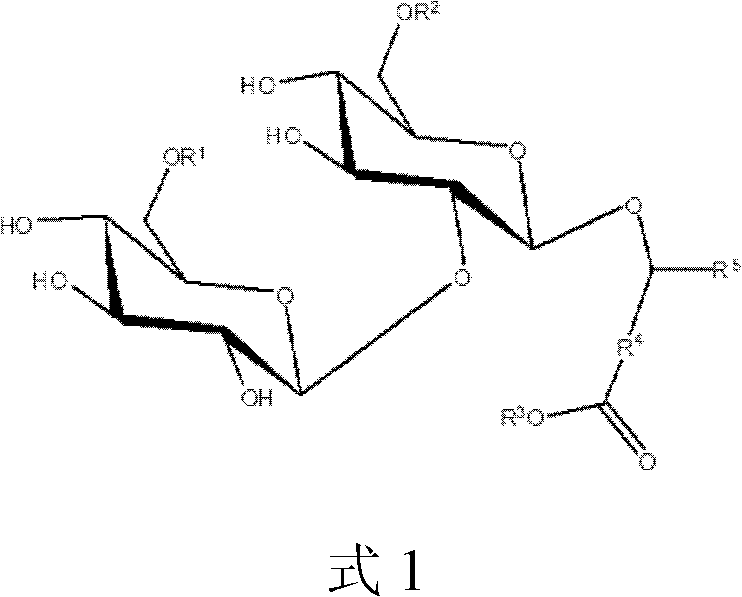

Purified Ethyl Ester Sophorolipid for the Treatment of Sepsis

InactiveUS20120142621A1High purityEfficient productionBiocideCarbohydrate active ingredients[Candida] apicolaChemical transformation

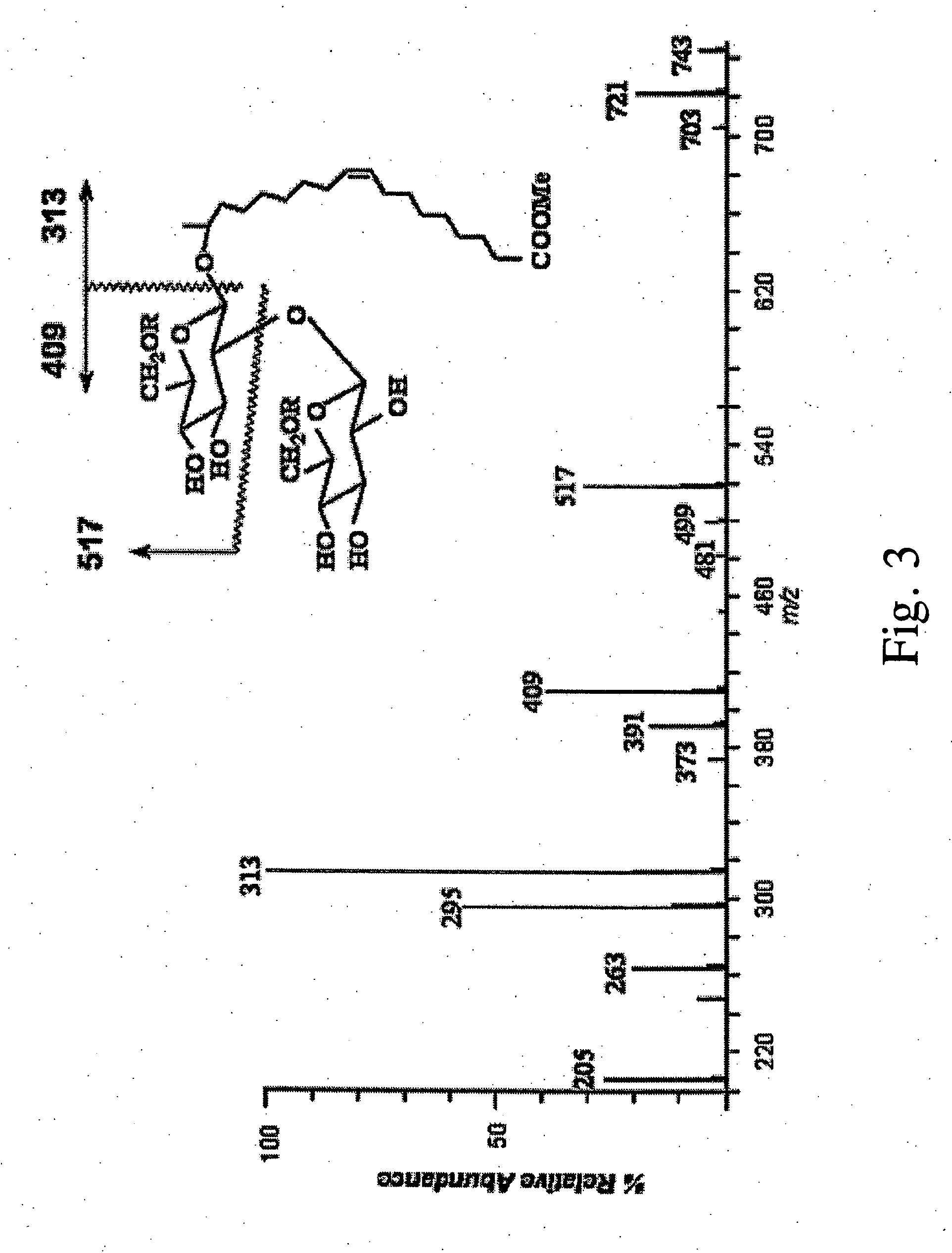

A microbial ethyl esther sophorolipid derivative with no acetylated groups produced by Candida species, for treating and preventing sepsis / septic shock. The method of producing sophorolipids is through microbial resting cells of Candida bombicola. The sophorolipids obtained from resting state cultures are isolated as a complex mixture of compounds and then decanted as a dense oil from the culture broth, subsequently washed to remove free fatty acids. Secondary chemical transformation via base catalyzed hydrolysis is used to reduce the 8 possible structural sophorolipid species to a single moiety, the 17-L-[(2′-O-b-D-glucopyranosyl-b-D-glucopyranosyl)-oxy]-cis-9-octadecenoate de-acetylated free acid. The compound acts primarily through decreasing inflammatory cytokines and eliciting other synergistic anti-inflammatory mechanisms by blocking TLR4-CD14 upstream of the inflammatory signaling cascade. The compound can be administered either intraperitoneally or intravenously at single or multiple doses of 5-30 mg / kg of weight in solvent media or in capped nanoparticles, preferably within 48 hours of sepsis inception.

Owner:STREETCAREC SLOAN

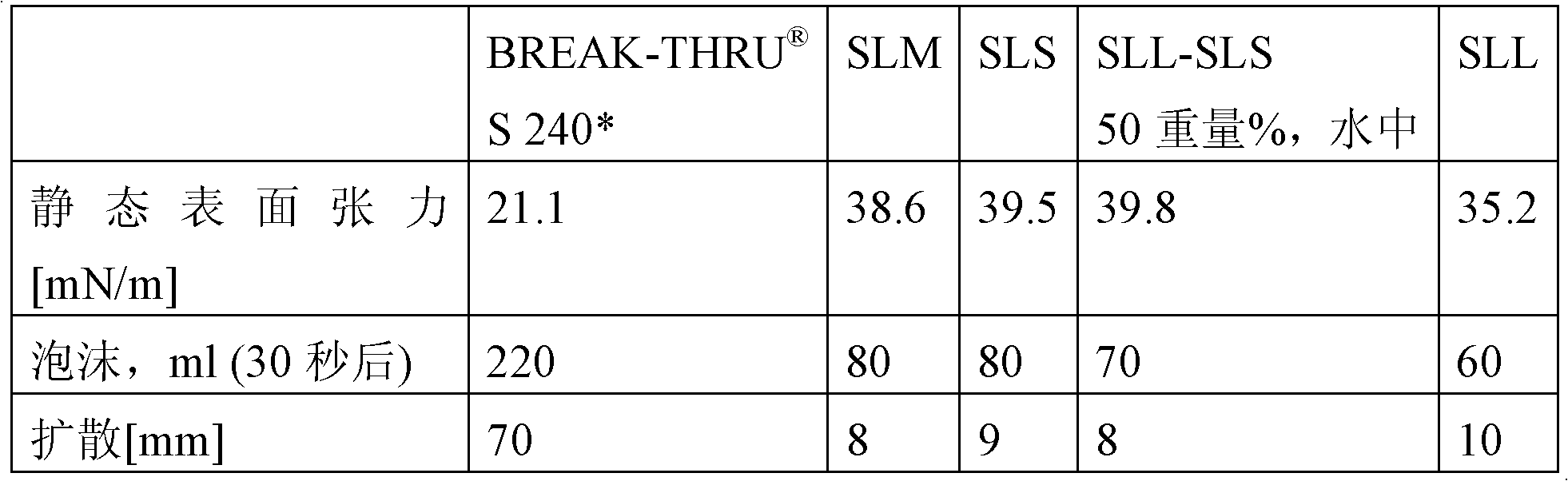

Use of sophorolipids and derivatives thereof in combination with pesticides as adjuvant/additive for plant protection and the industrial non-crop field

Owner:EVONIK OPERATIONS GMBH

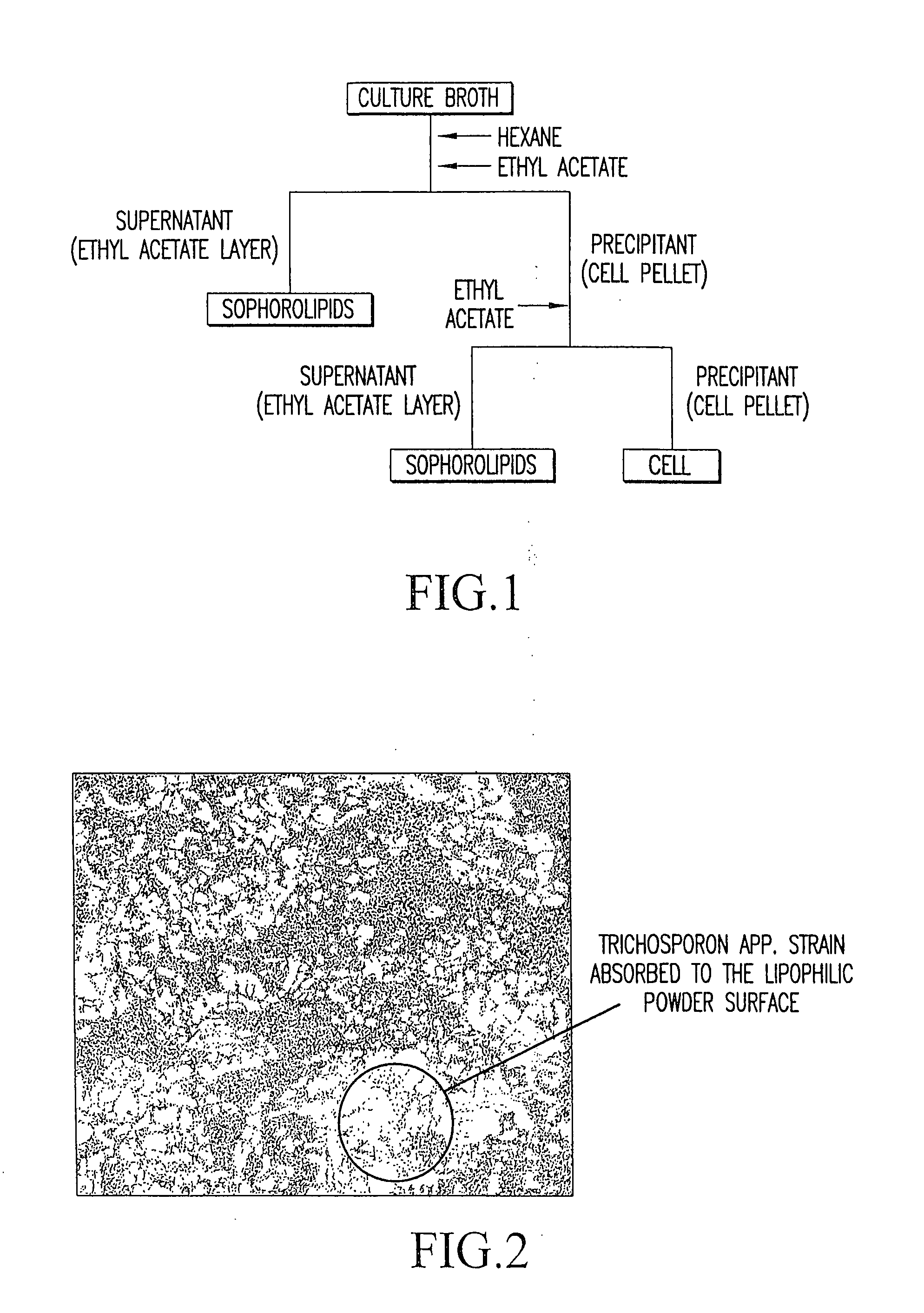

Microbial materials for degradation of oils and toxic chemicals

ActiveUS20080032383A1Efficient degradationEffective treatmentFungiBacteriaFungal microorganismsRapeseed

Provided is microbial materials for degradation of oils and toxic chemicals. The microbial material comprises (a) a microorganism and culture filtrate capable of degrading oil and toxic chemicals being at least one selected from the group consisting of Trichosporon loubieri Y1-A of deposit No. KCTC 10876BP, Trichosporon cutaneum, and white-rot fungi living upon the surface of wood, (b) rapeseed oils for producing more sophorolipid in surface of the said microorganism, (c) lipophilic powder being at least one selected from the group consisting of natural wax, synthetic wax, beeswax and waste candle, and (d) a microbial nutrient. This invention further comprises (e) the Bacillus subtilis of Deposit No. KCCM 10639 and the Bacillus subtilis of Deposit No. KCCM 10640. The microbial material can efficiently, rapidly degrade contaminants that are unreadily degradable, by increasing a contact area with the microorganism capable of degrading the unreadily degradable contaminants.

Owner:KYU JIN YUM

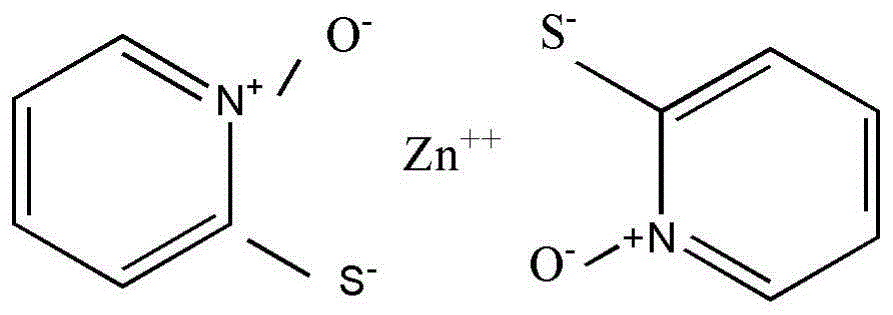

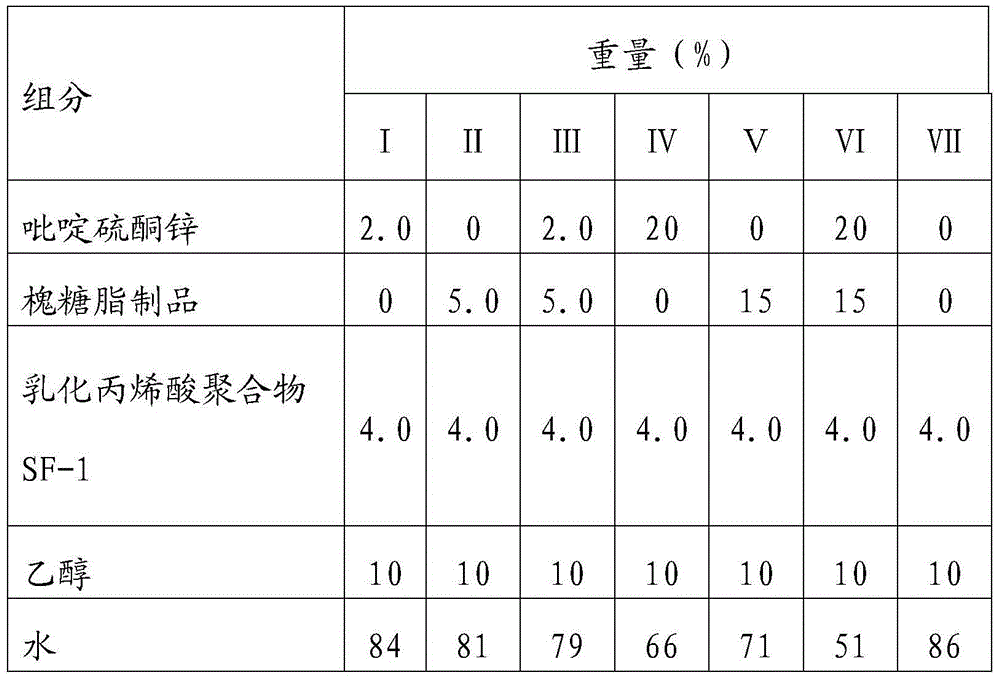

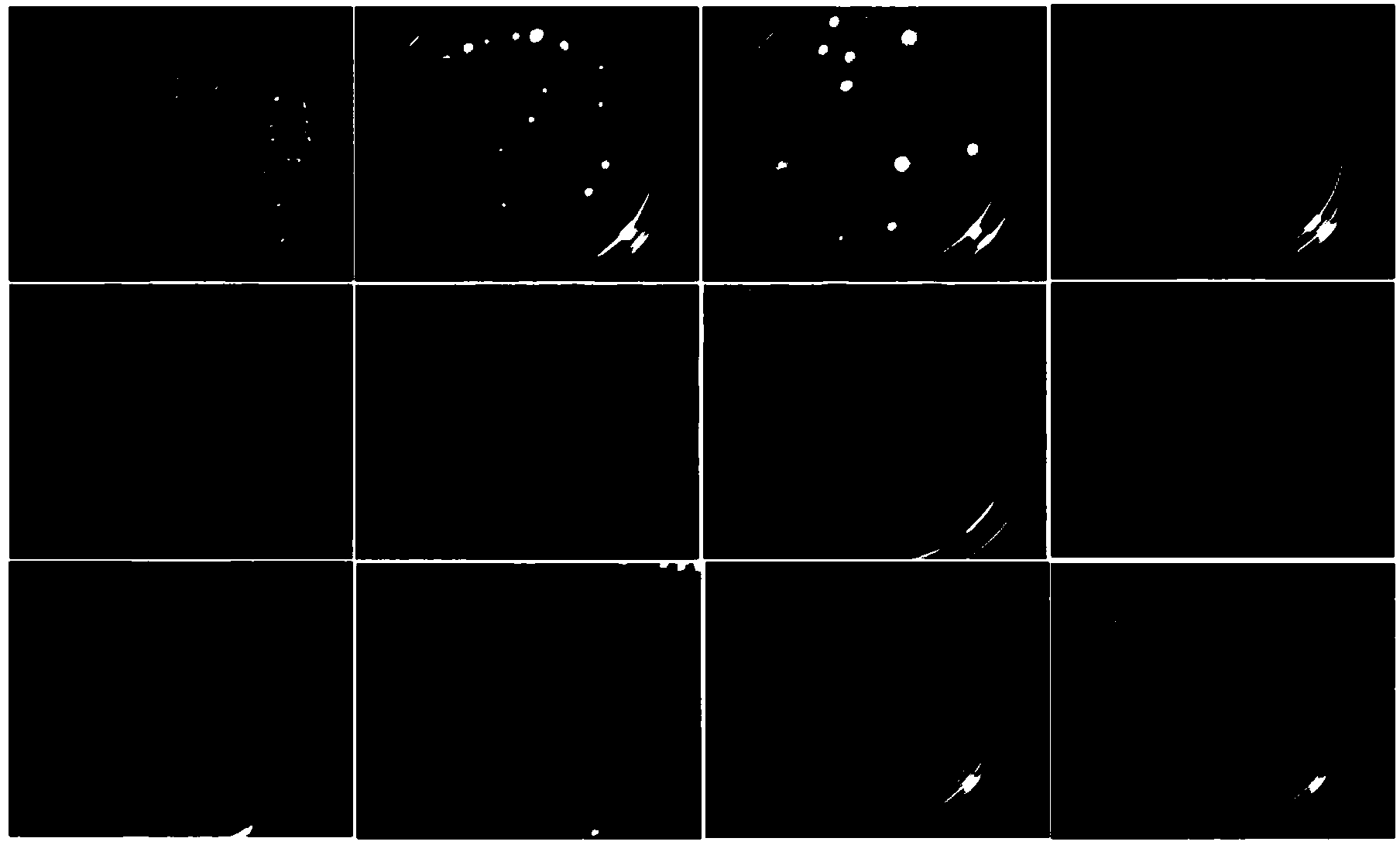

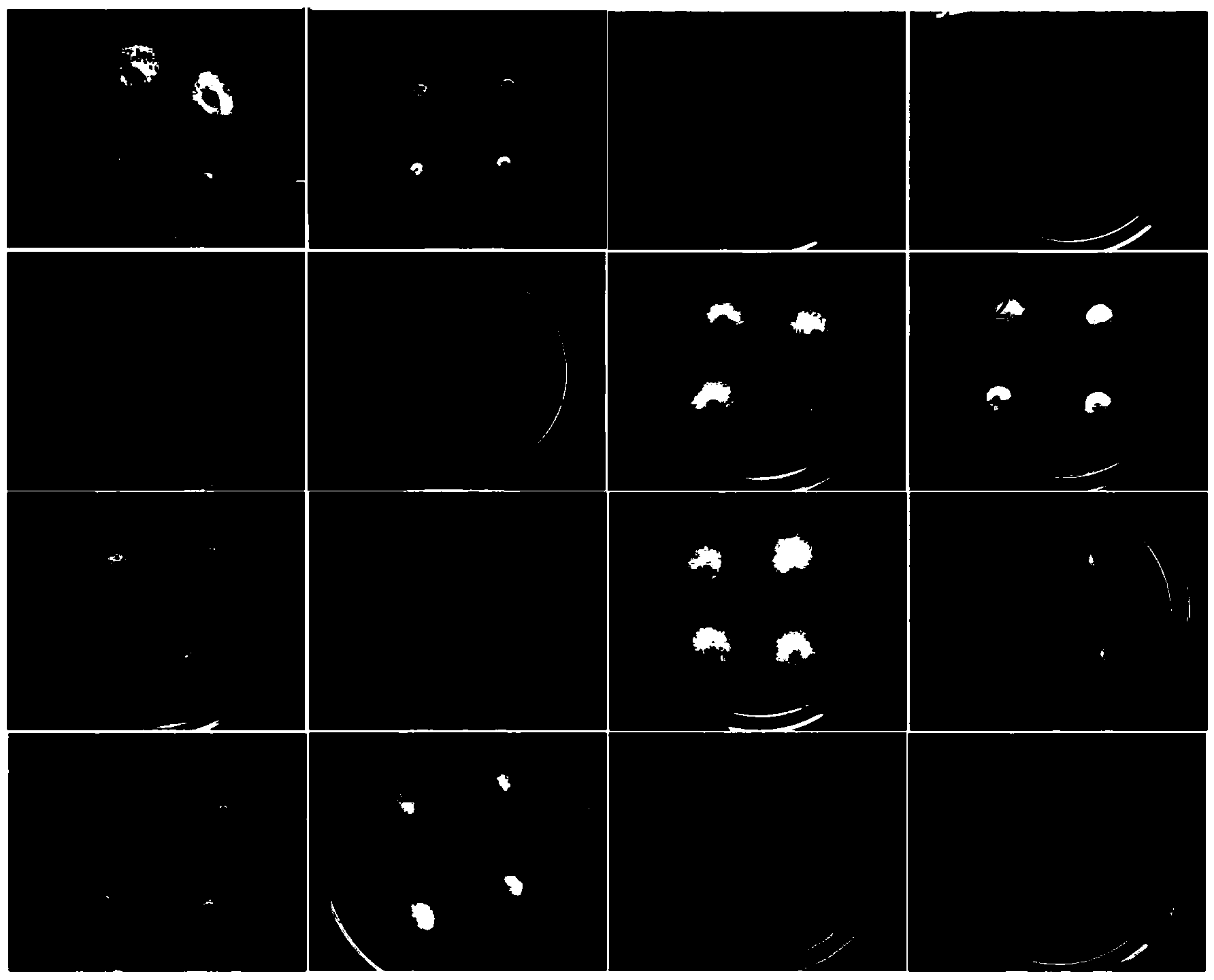

Sophorolipid-enhanced anti-dandruff composition and application thereof

InactiveCN104095766ALittle impact on performanceReduce degreasingCosmetic preparationsHair cosmeticsSodium PyrithioneAlcohol

The invention relates to sophorolipid-enhanced anti-dandruff composition and an application of the anti-dandruff composition in hair shampoo and hair care products. The anti-dandruff composition is water suspension comprising components in percentage by weight as follows: 2.0%-20.0% of pyrithionc zinc, 5.0%-15.0% of a sophorolipid product, 0.3%-2.0% of high-molecular polymer and 63.0%-92.7% of water or / and alcohol, wherein the sophorolipid product has a synergistic effect of inhibition and dandruff removal on zinc pyrithione. The invention further relates to an application of the anti-dandruff composition in hair shampoo and hair conditioner.

Owner:LAFANG CHINA CO LTD

Sophorolipid agricultural antibiotic and application thereof to control of fungal diseases of crops

InactiveCN104178537ASimple dosage formGood control effectBiocideMicroorganism based processesAntibiotic YPlant disease

The invention relates to a sophorolipid agricultural antibiotic and an application thereof to control of fungal diseases of crops. The sophorolipid agricultural antibiotic is prepared by the following steps: obtaining a biosurfactant sophorolipid by virtue of a microbial fermentation technology; and then preparing a sophorolipid solution by using distilled water, wherein the sophorolipid solution is used as the sophorolipid agricultural antibiotic. The sophorolipid agricultural antibiotic is uniformly sprayed to the blade surfaces of crops or surfaces of fruits to achieve the purpose of preventing and controlling fungal diseases of crops. The sophorolipid agricultural antibiotic provided by the invention that the production process is simple, the raw materials are easy and convenient to obtain, in the cost is low, the output is high, and no toxic effect is caused to a human body. The prepared sophorolipid agricultural antibiotic is simple in dosage form, easy to prepare, remarkable in preventing and control effect and convenient to use and has a huge application prospect.

Owner:QILU UNIV OF TECH

Thermo-chemical cleaning agent for polymer-containing oil sludge in oil field as well as preparation method and application thereof

InactiveCN111849651AReduce dosageNo secondary pollutionInorganic/elemental detergent compounding agentsWaste water treatment from quariesOil sludgeChemical cleaning

The invention discloses a thermo-chemical cleaning agent for polymer-containing oil sludge in an oil field as well as a preparation method and application thereof; the cleaning agent comprises a plurality of ionic cleaning agents and an alkaline builder, and a non-ionic cleaning agent is rhamnolipid, sophorolipid, AEO-9, EL100, SP169 or Tween 80; the alkaline builder is one or more of sodium silicate, sodium carbonate and sodium hydroxide. The preparation method of the cleaning agent comprises the steps: firstly, dissolving one or more alkaline builders in water to prepare a solution; and adding several non-ionic cleaning agents, and uniformly stirring to obtain the thermo-chemical cleaning agent for the polymer-containing oil sludge in the oil field. The interfacial tension of the oil sludge is greatly reduced, the surface wettability of a solid phase is changed, and residual oil can be helped to be removed from the solid phase; the alkaline builder plays a better dispersing role; thecomponents interact with one another, so that the use amount of the cleaning agent is reduced, and the recovery rate of crude oil is increased. The method for treating the polymer-containing oil sludge is simple to operate, low in cost and high in crude oil recovery rate, the oil content in the oil sludge can be reduced to 1%, and the national emission standard is achieved.

Owner:OCEAN UNIV OF CHINA

Application of sophorolipid

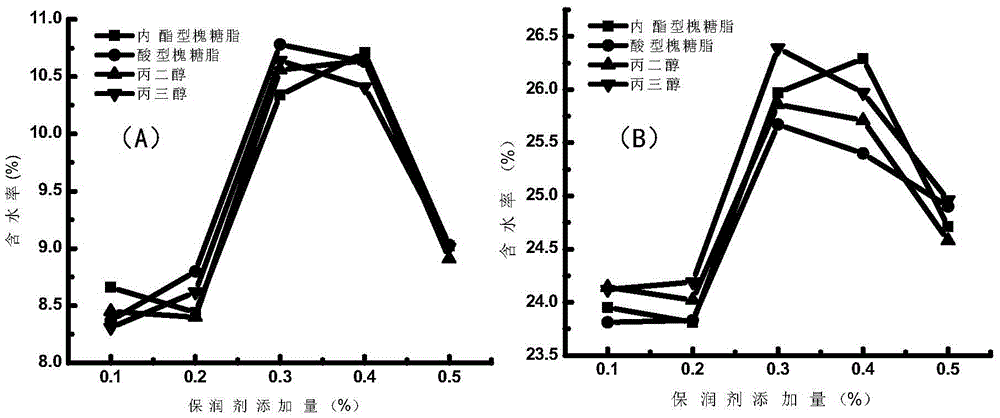

The invention discloses application of sophorolipid. Serving as a microbial source bi-directional humectant having a physical moisture retention damp-proof function and an aroma enhancement function, the humectant is natural, non-toxic and harmless. Sophorolipid comprises any one of lactone type sophorolipid and acid type sophorolipid or mixture of lactone type sophorolipid and acid type sophorolipid. The humectant can be applied to cigarettes, tobacco shreds, tobacco sheets and other tobacco products. The humectant is evenly sprayed on the tobacco shreds, the spraying proportion is 0.05%-2.0% of the weight of the tobacco shreds, and the humectant has effects of obviously retaining tobacco shred moisture under low humidity conditions and obviously controlling moisture increase under high humidity conditions; the moisture retention and dampproof effect is more excellent than that of propylene glycol and glycerin, and the humectant is an excellent natural bi-directional humectant.

Owner:CHINA TOBACCO ANHUI IND CO LTD +1

Biologic emulsifier for aquatic animal feed

InactiveCN102696895AImprove digestion utilizationIncrease production capacityAnimal feeding stuffAquatic animalSecondary metabolite

The invention discloses a biologic emulsifier for aquatic animal feed. The biologic emulsifier is characterized by being prepared by two or more than two of sophorolipid, rhamnolipid and trehalose. The sophorolipid, the rhamnolipid and the trehalose and the like in the emulsifier are all secondary metabolites generated by microbial fermentation, can be naturally metabolized and degraded, do not cause residues in aquatic products, and do not influence water quality. The biologic emulsifier can remarkably improve feed fat digestion utilizing rate of fishes, shrimps and crabs and the like, reduces bait coefficient, remarkably improves production performances of aquatic animals, improves body immune function, reduces morbidity and mortality of the animals, and remarkably improves economic returns.

Owner:NINGBO INST OF TECH ZHEJIANG UNIV ZHEJIANG

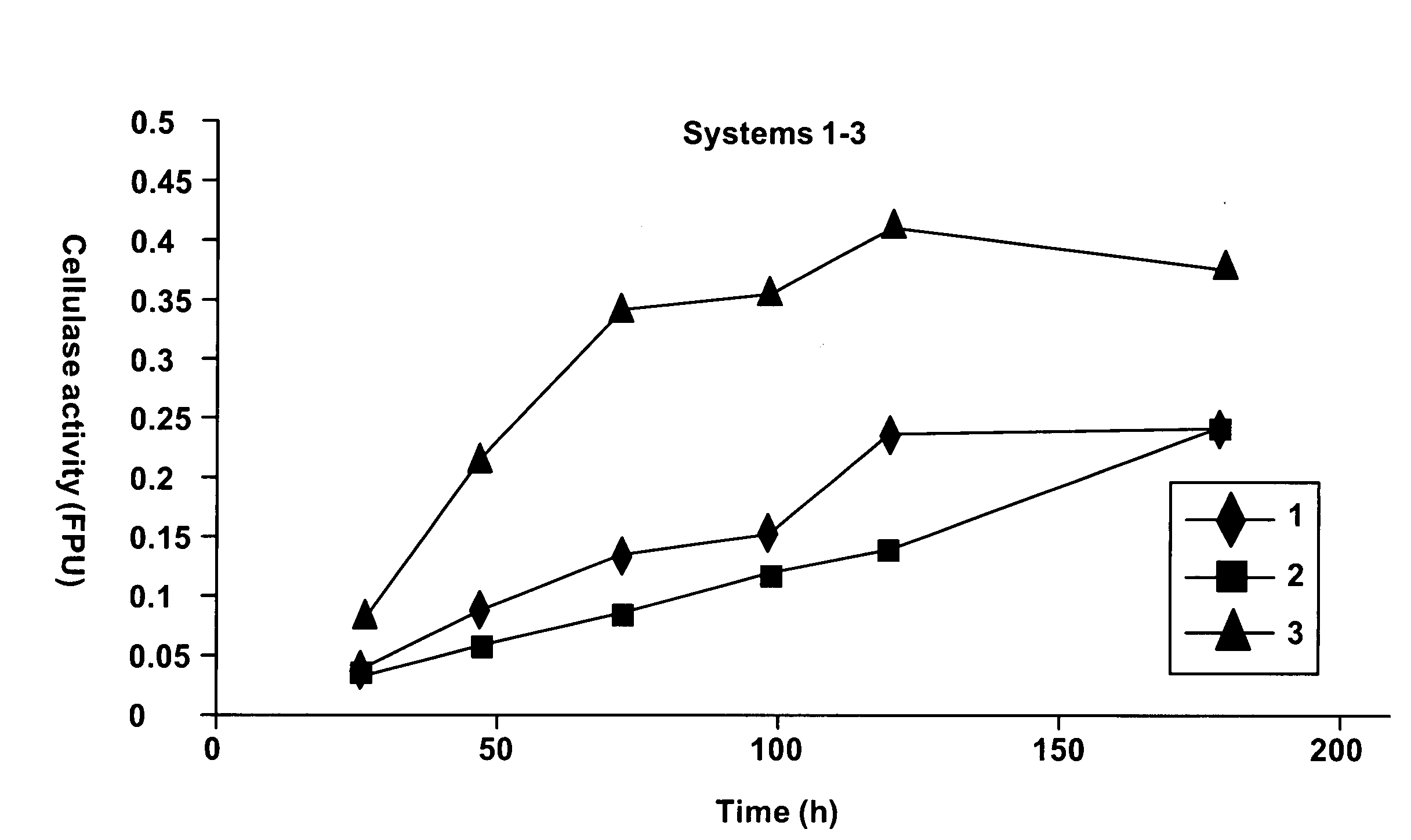

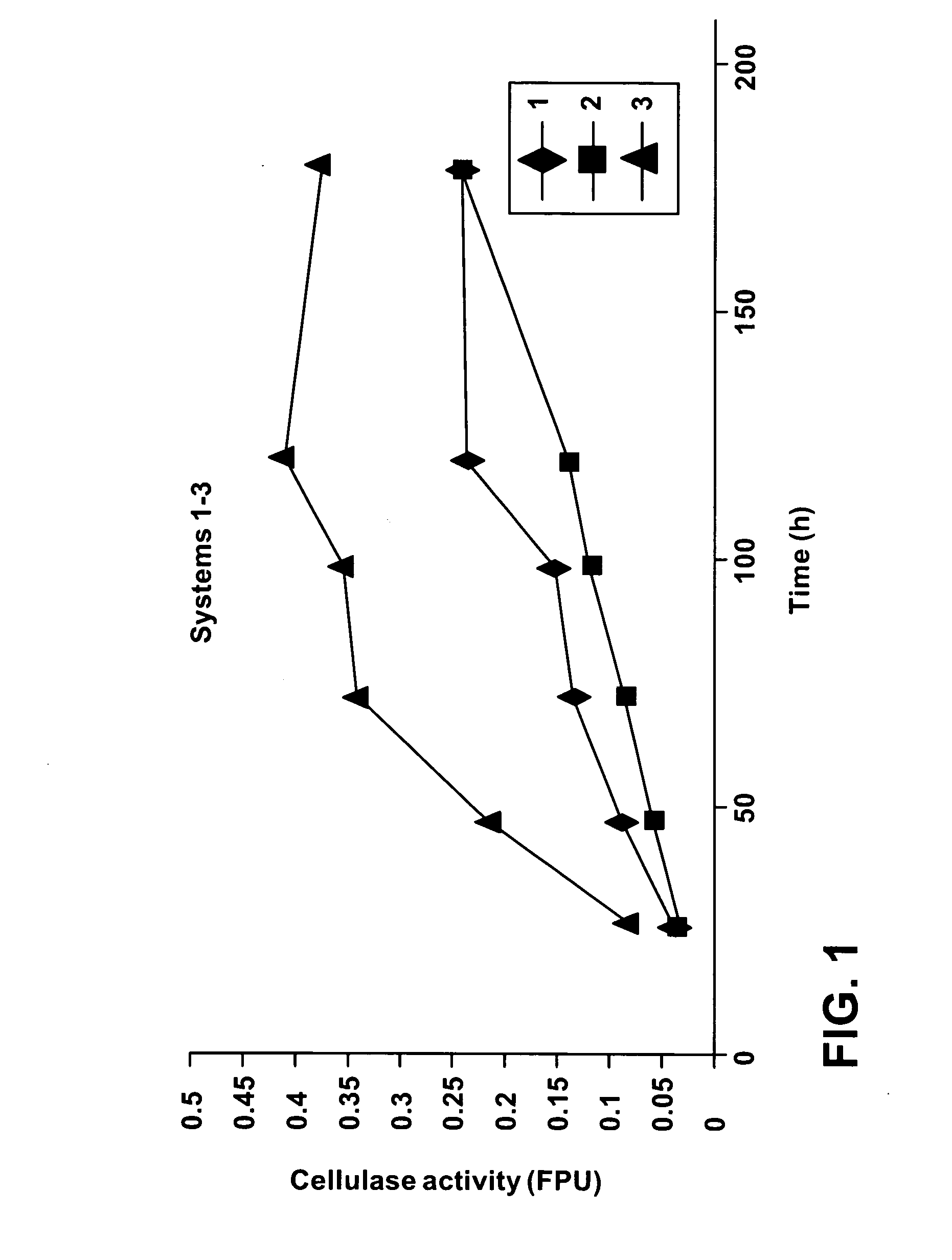

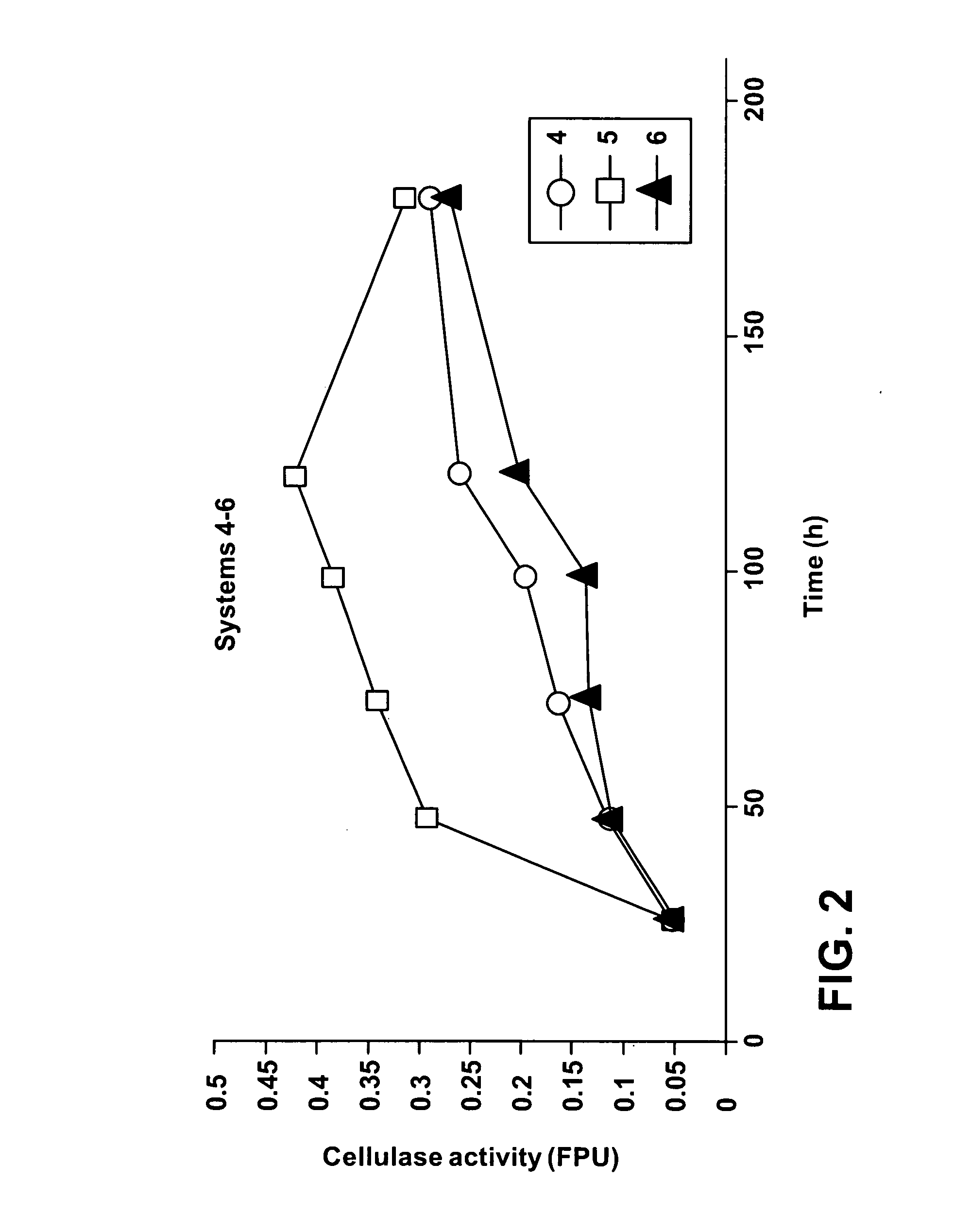

Process for producing cellulase

Various methods for the production of cellulase are disclosed. In one embodiment the method for producing cellulase includes contacting a culture comprising a sophorolipid producer and a cellulase producer with a substrate that is consumed by the sophorolipid producer. In addition, a microorganism culture made from a sophorolipid producer and a cellulase producer is disclosed.

Owner:THE UNIVERSITY OF AKRON +1

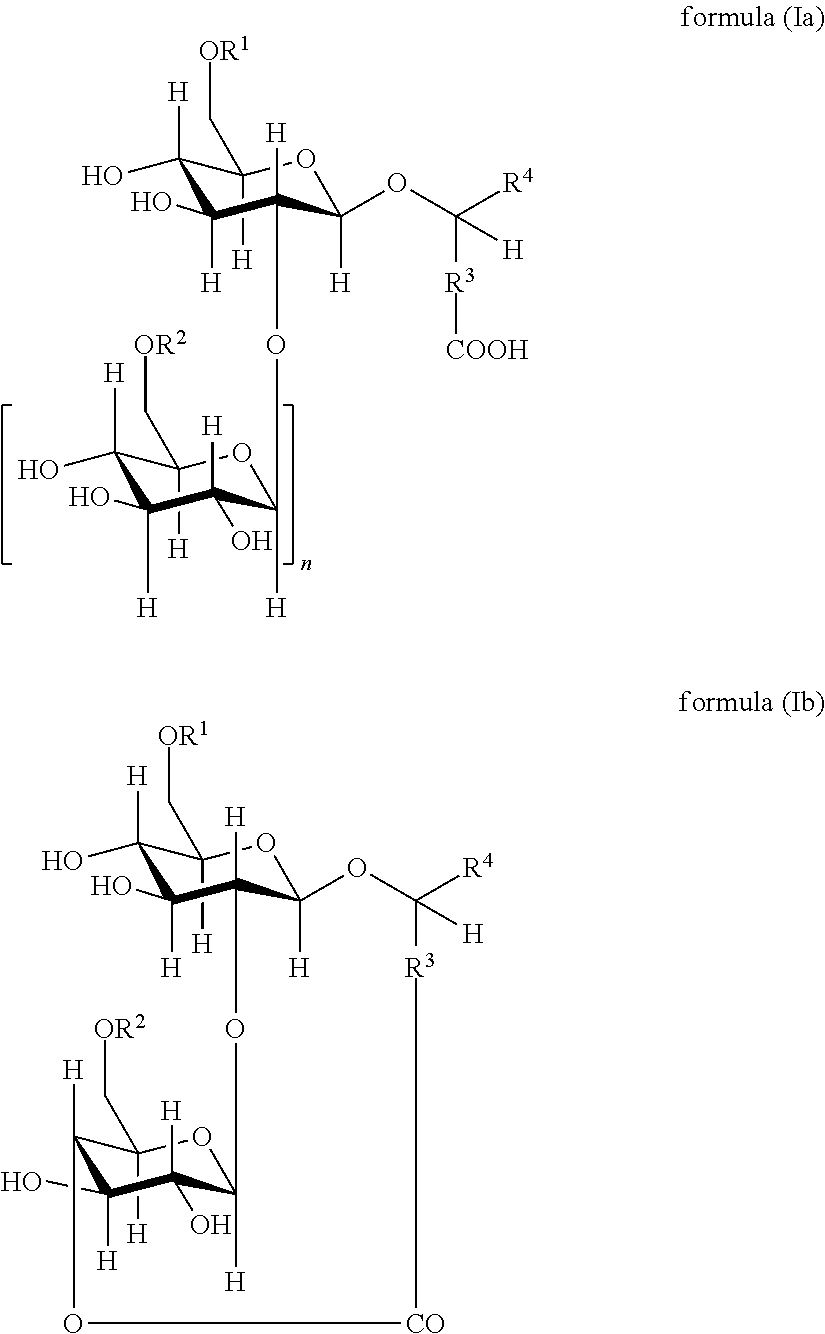

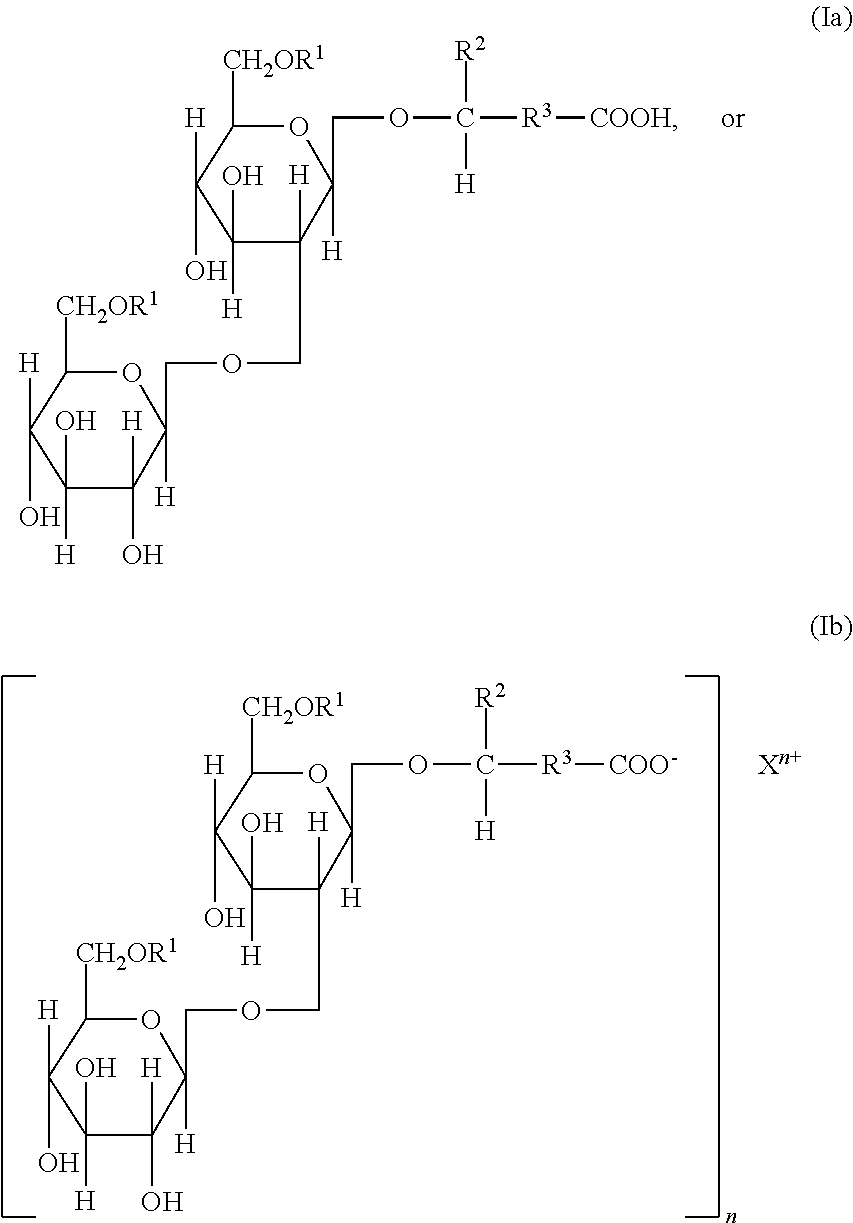

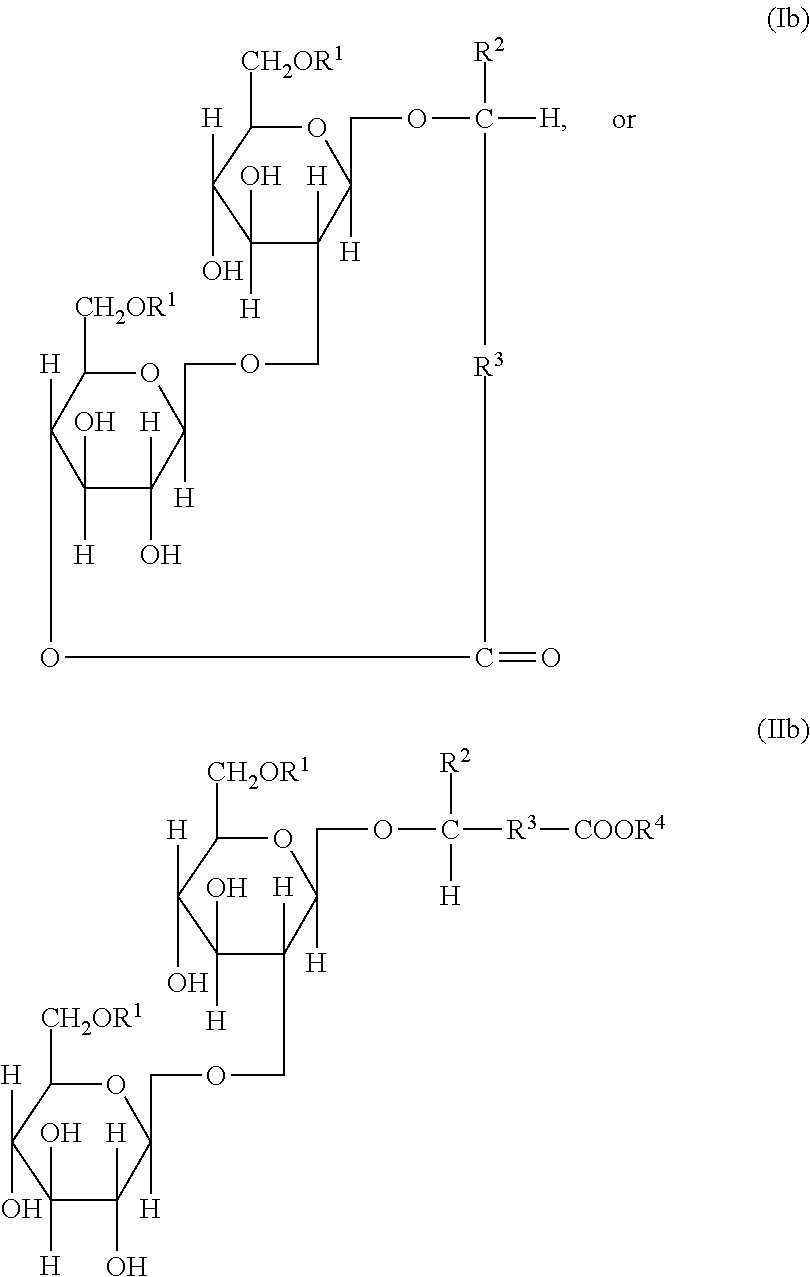

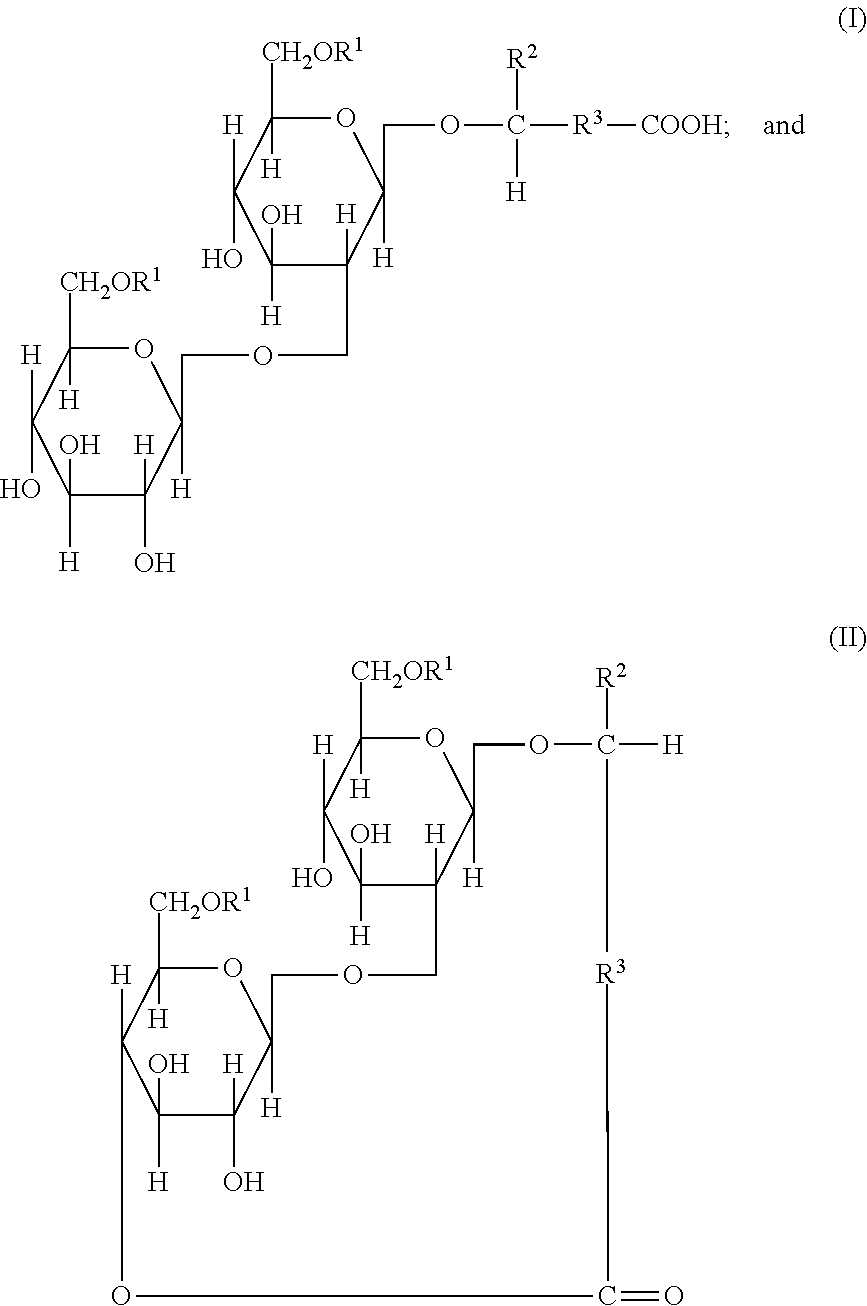

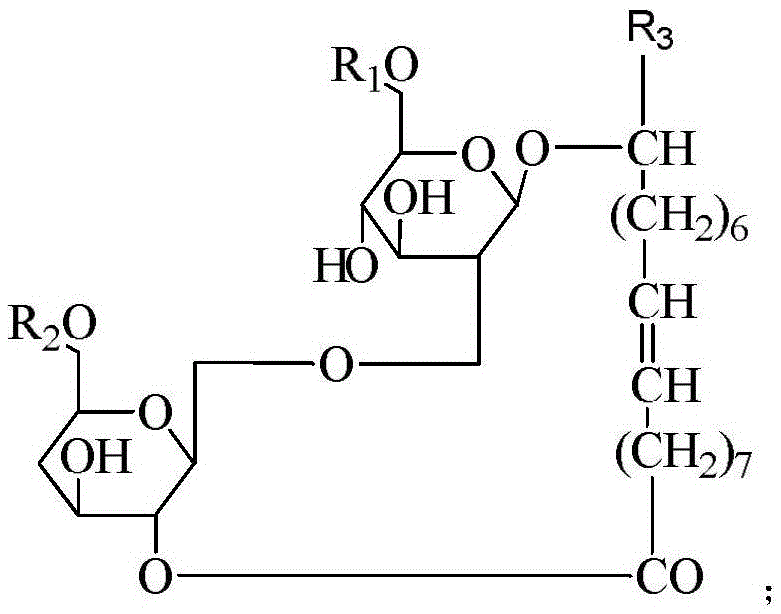

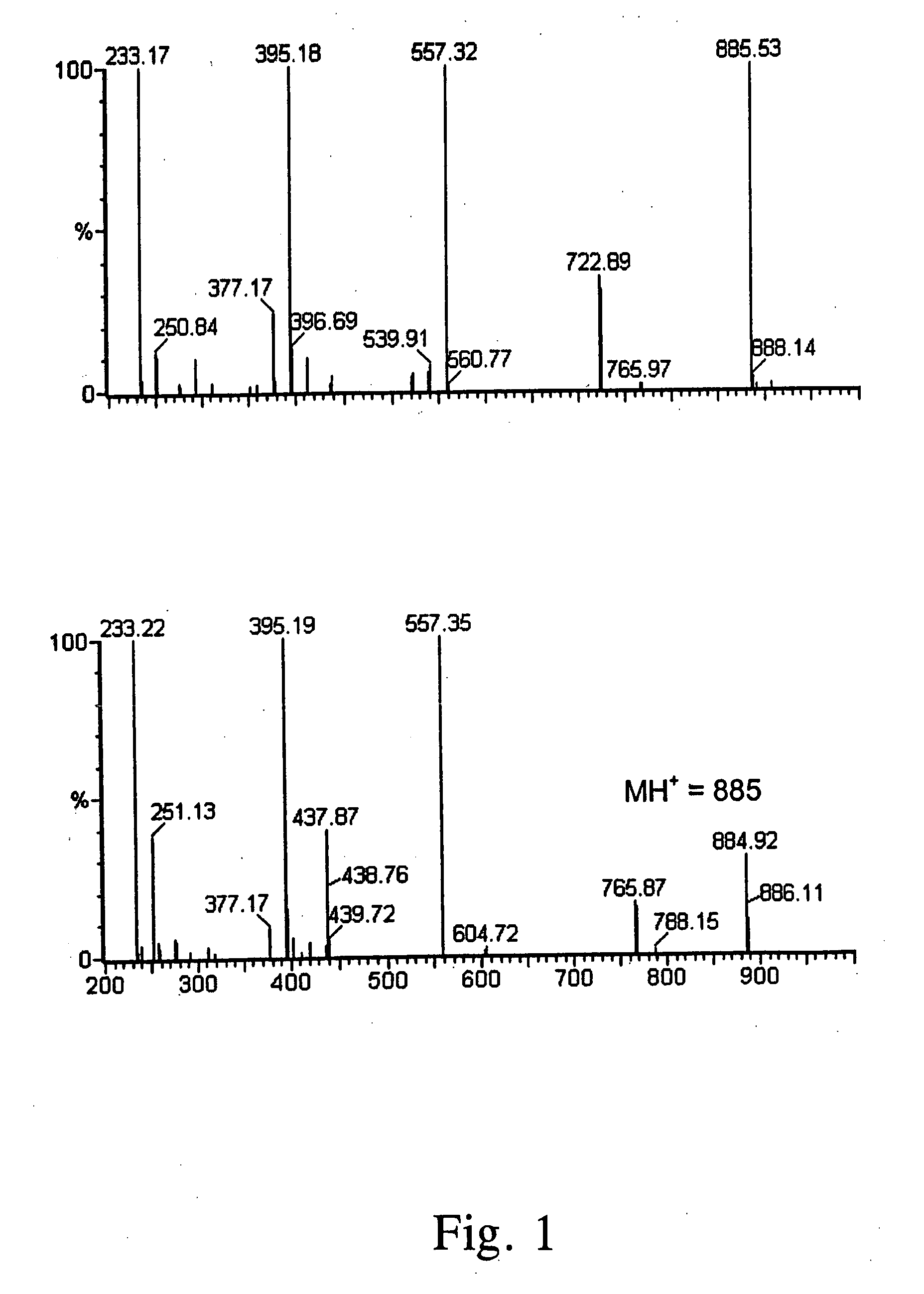

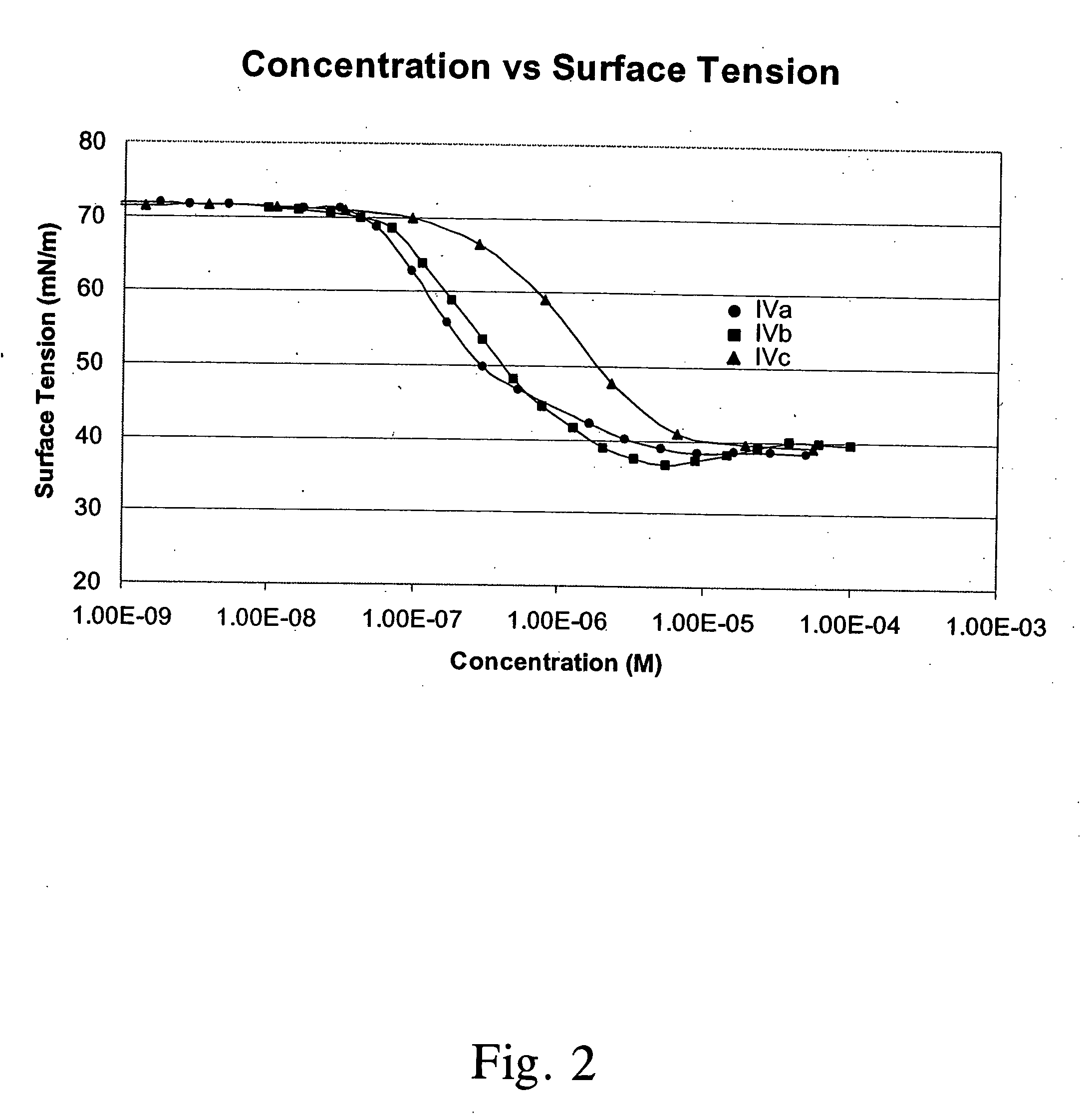

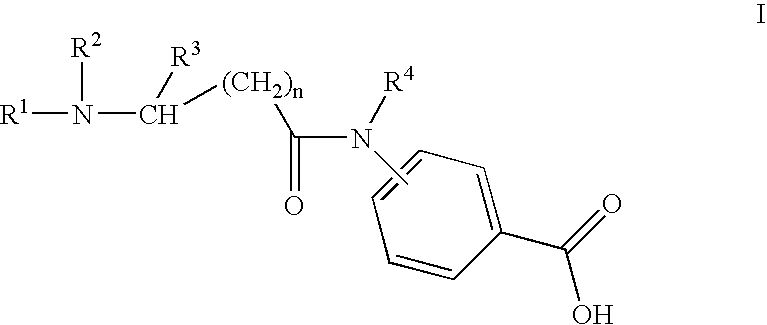

Charged sophorolipids and sophorolipid containing compounds

A sophorolid produced by a method involving reacting a compound of formula I with a compound of formula II wherein R1 and R2 are H, C1-C18 alkyl, C3-C18 alkenyl, C3-C10 cycloalkyl, phenyl, or C1 through C18 acyl or alkoxycarbonyl, R1 and R2 are not both acyl, R3 is H, CH3, CH2-phenyl, CH2—C6H4—OH, CH2CO2H, CH2CH2CO2H, CH(CH3)2, CH2CH(CH3)2, CH(CH3)CH2CH3, CH2OH, CH(CH3)OH, CH2CH2CH2CH2NH2, CH2CH2CONH2, CH2CONH2, CH2—C3N2H3(histidine), CH2CH2CH2NHC(NH)NH2, CH2CH2SCH3, R2 and R3 may be joined in a ring, R4 is H, C1-C18 alkyl, C3-C18 alkenyl, C3-C10 cycloalkyl, or phenyl, n is 0-6, R5 and R6 are H, C1-C18 alkyl, C3-C18 alkenyl, C3-C10 cycloalkyl, or phenyl, and X is C1-C18 alkyl or C1-C18 alkenyl; optionally followed by acidolytic (treating with an acid) or hydrogenolytic deprotection (treating with a hydrogenolysis catalyst) which removes one of the groups R1 or R2 and replaces it with hydrogen. Also a sophorolipid containing composition containing a carrier and at least one sophorolipid described above.

Owner:US SEC AGRI

Multifunctional organic/inorganic compound fertilizer and preparation method thereof

Owner:山东华粮生物工程集团股份有限公司

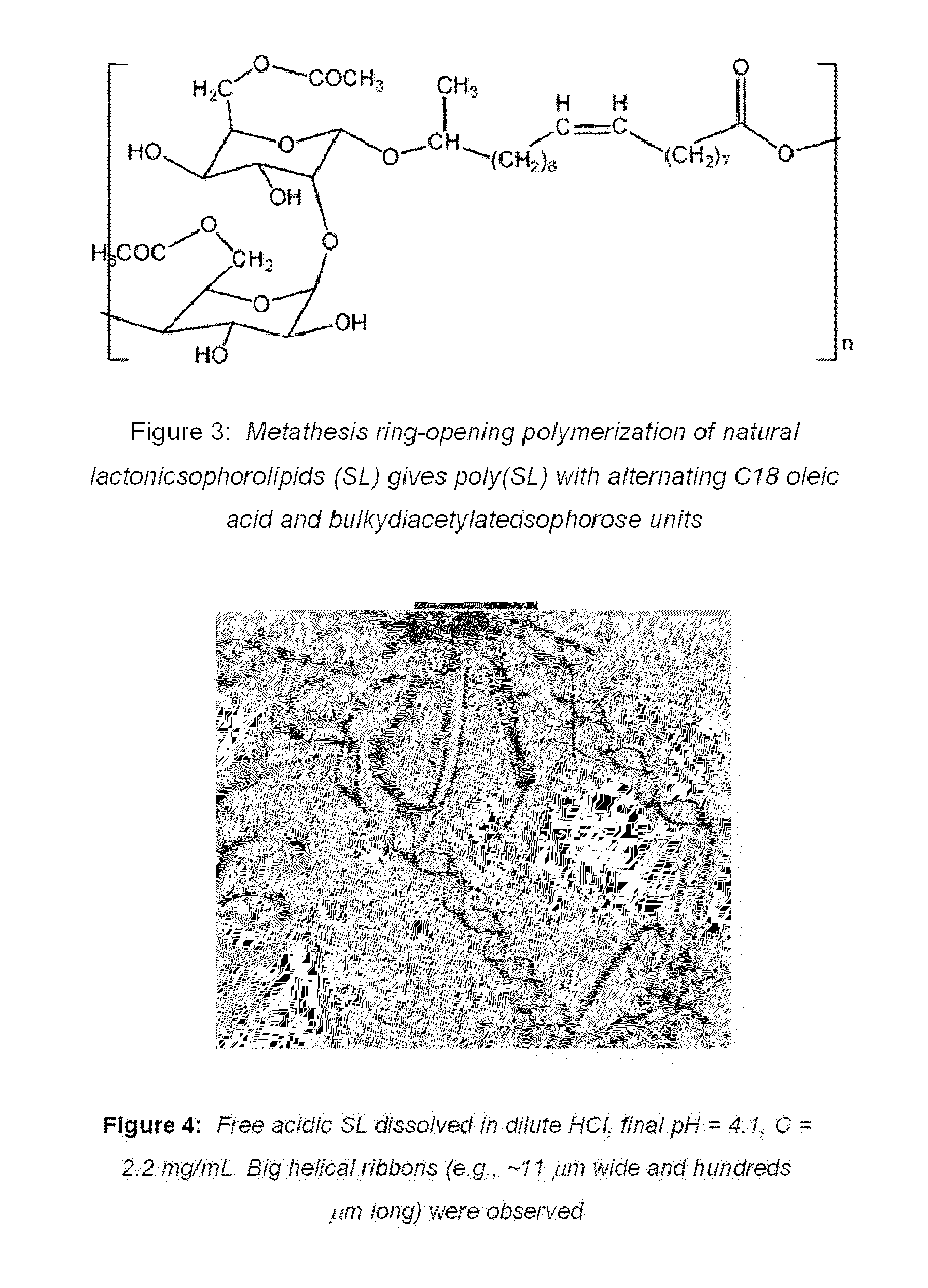

Sophorolipid Analog Compositions

A composition of matter comprising sophorolipids as antimicrobial agents, antifungal agents, biopesticides, for uses as drugs to treat HIV, septic shock, cancer, asthma, dermatological conditions, as spermicidal agents, as anti-inflammatory drugs, as ingredients in cosmetics and building blocks for monomers and polymers and self-assembled templates for further chemical elaboration.

Owner:SYNTHEZYME

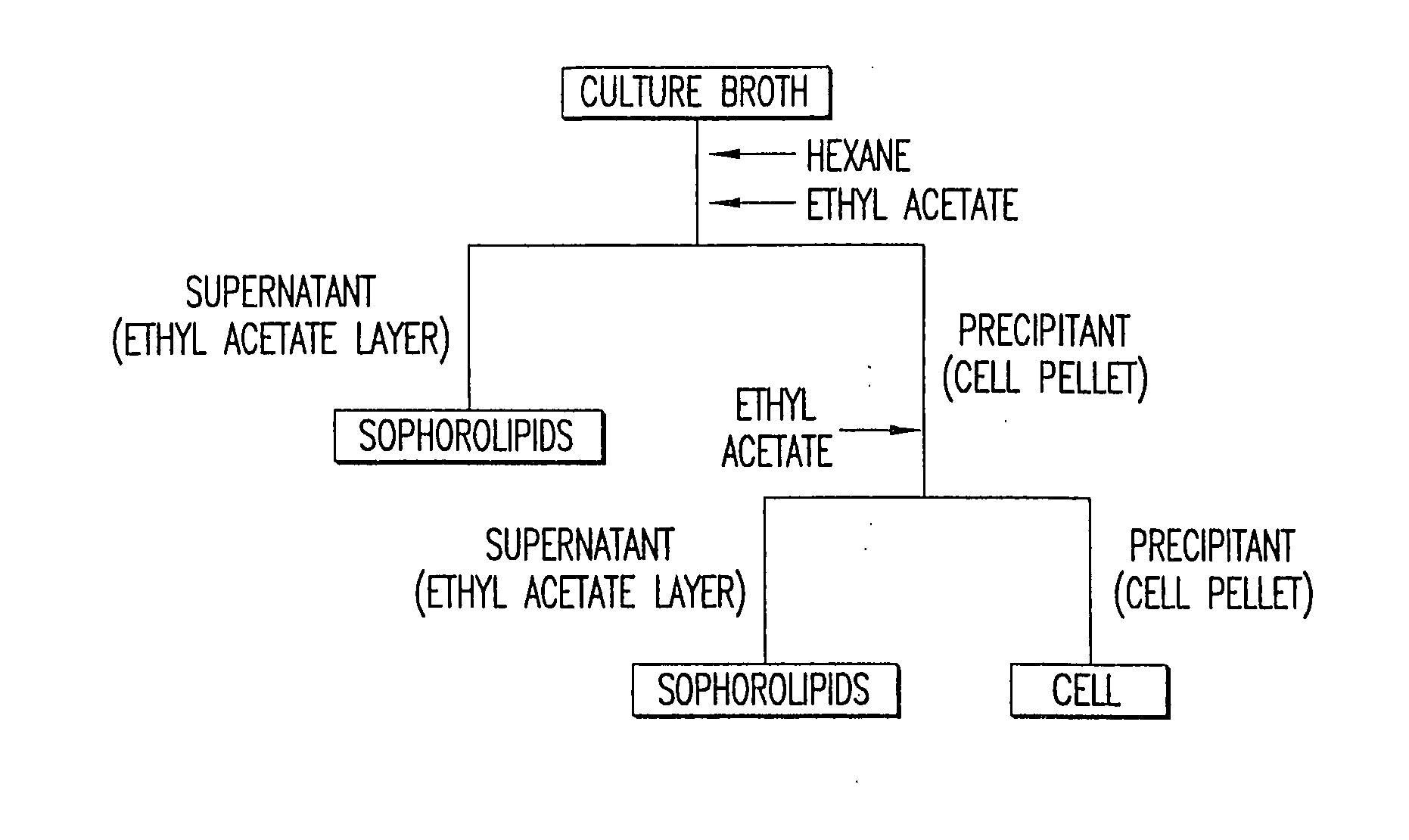

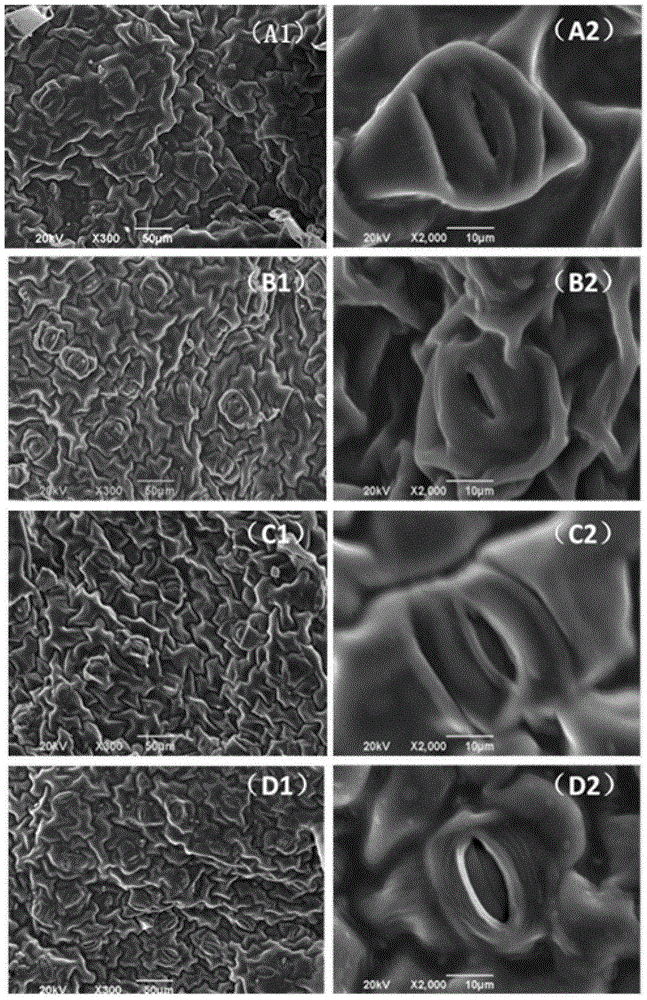

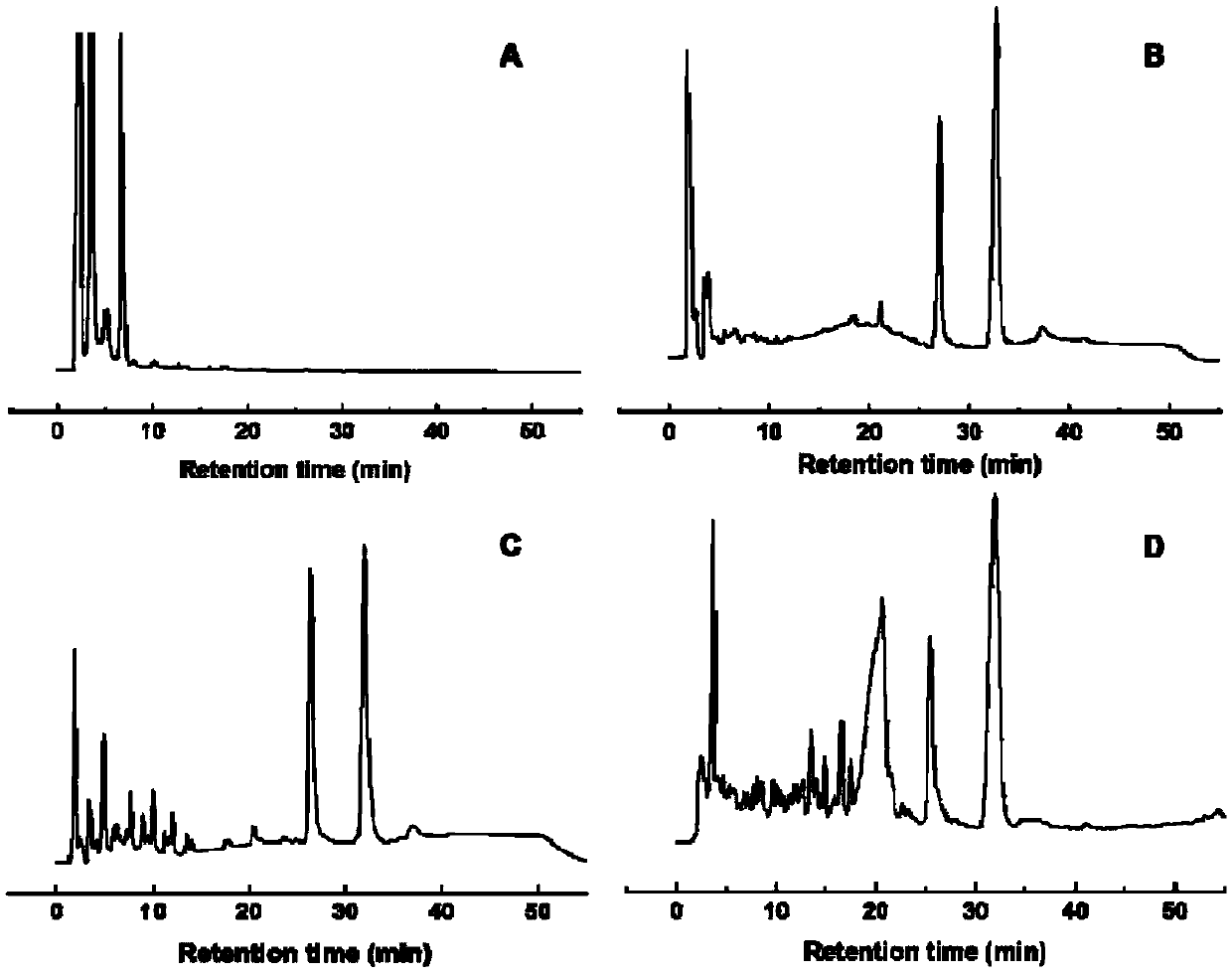

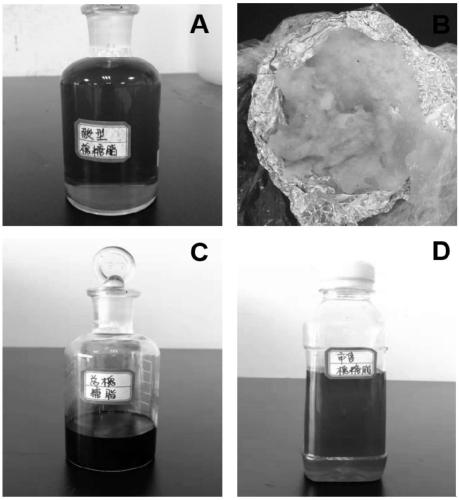

Method for pre-treating sophorolipid fermentation solution and separating and purifying sophorolipid with different structures

ActiveCN109678914AEase of industrial productionImprove product qualitySugar derivativesSugar derivatives preparationFiltrationUltrafiltration

The invention discloses a method for pre-treating a sophorolipid fermentation solution and separating and purifying sophorolipid with different structures. The method comprises the following steps of:pre-treating the sophorolipid fermentation solution; collecting and treating lower-layer lactone type sophorolipid; removing thalli through plate and frame filtering; carrying out resin adsorption and ultra-filtration for impurity removal; carrying out nanofiltration concentration on acidic type sophorolipid; drying. According to the method disclosed by the invention, lactone type, acidic type and mixed type sophorolipid liquid and solid products are obtained respectively by selectively adopting the steps. A traditional ethyl acetate extraction method is replaced with a natural sedimentationmethod and a traditional laboratory centrifuging method is replaced with a common plate and frame filtering method in industrial production to remove mycelia; a common organic solvent extraction method and an alcohol sedimentation method in a laboratory and a production process are replaced with the resin adsorption and ultra-filtration method to remove impurities, and the sophorolipid with quality standards better than those of related commercial products is successfully obtained. According to the method disclosed by the invention, the dosage of organic reagents is greatly reduced and the safety and environmental friendliness of the production of the sophorolipid are improved.

Owner:HEFEI UNIV OF TECH

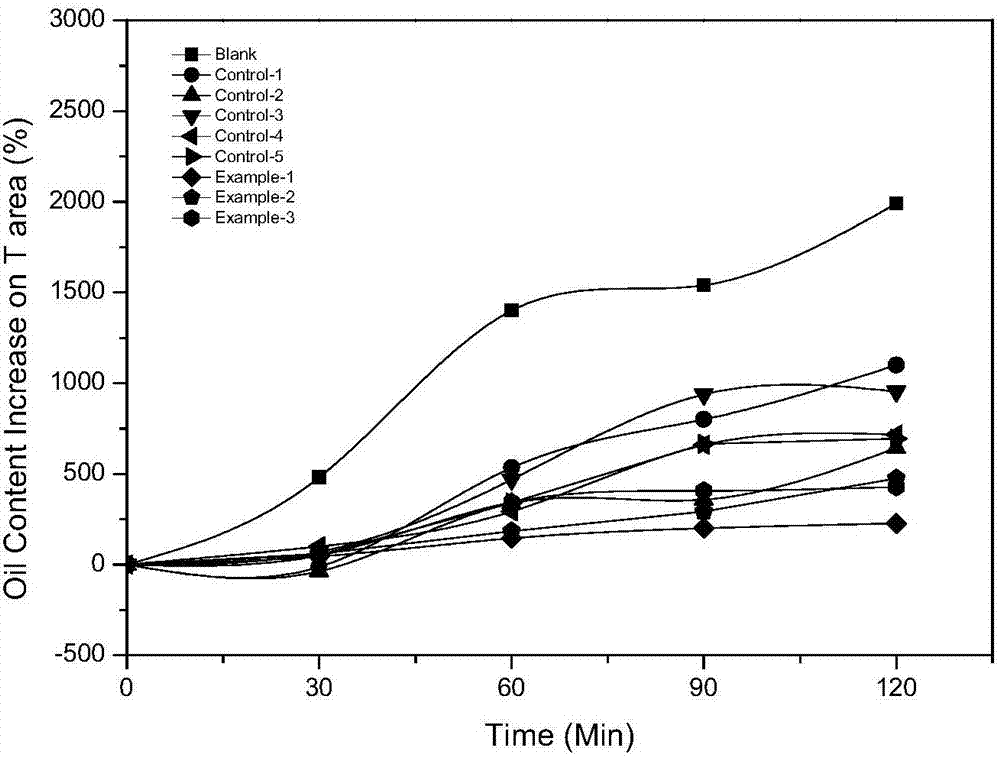

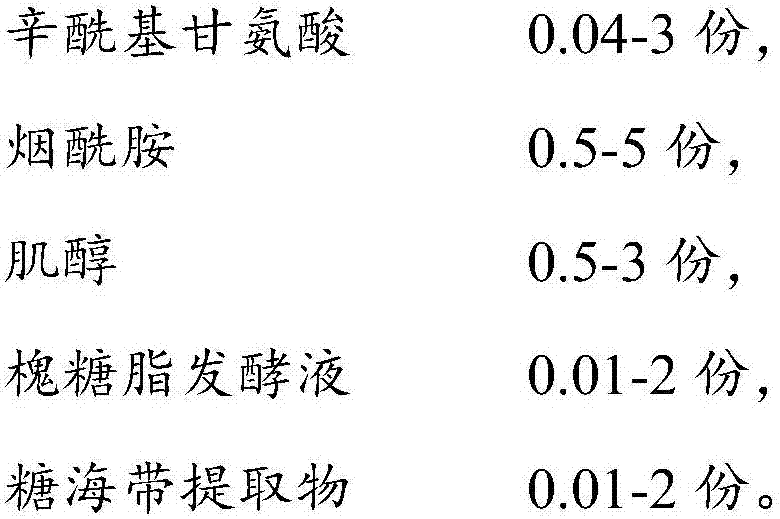

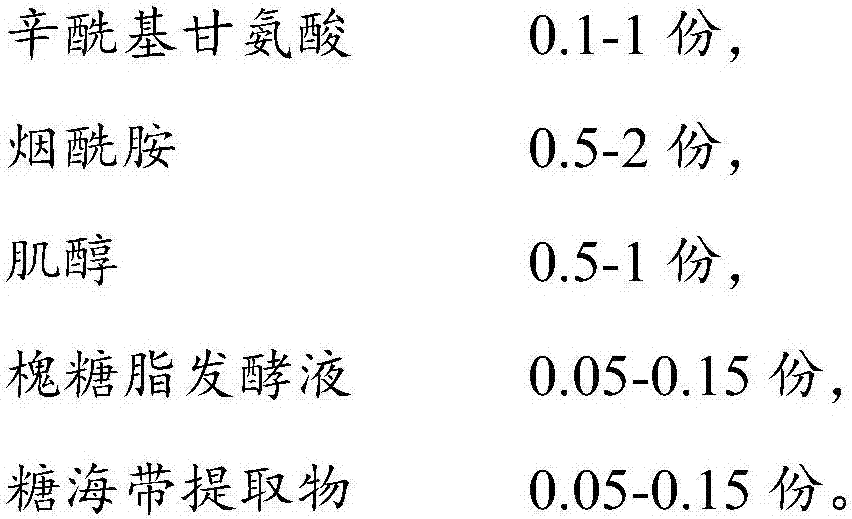

Oil control composition and application thereof

ActiveCN107019655ATo promote metabolismRegulate secretionCosmetic preparationsToilet preparationsSophorolipidSecretion

The invention relates to an oil control composition, which is prepared from octanoyl glycine, nicotinamide, inositol, sophorolipid fermentation liquor and a laminaria saccharina extract. The oil control composition prepared from the nicotinamide, the inositol, the octanoyl glycine, the laminaria saccharina extract and the sophorolipid fermentation liquor adjusts oil secretion on the basis of moisture retention, and establishes a three-dimensional balance oil control technology aiming at inhibition for the activity of three target points, i.e., lipase, 5 alpha-reductase and sebum flow regulation.

Owner:HUNAN YUJIA COSMETICS MFG CO LTD

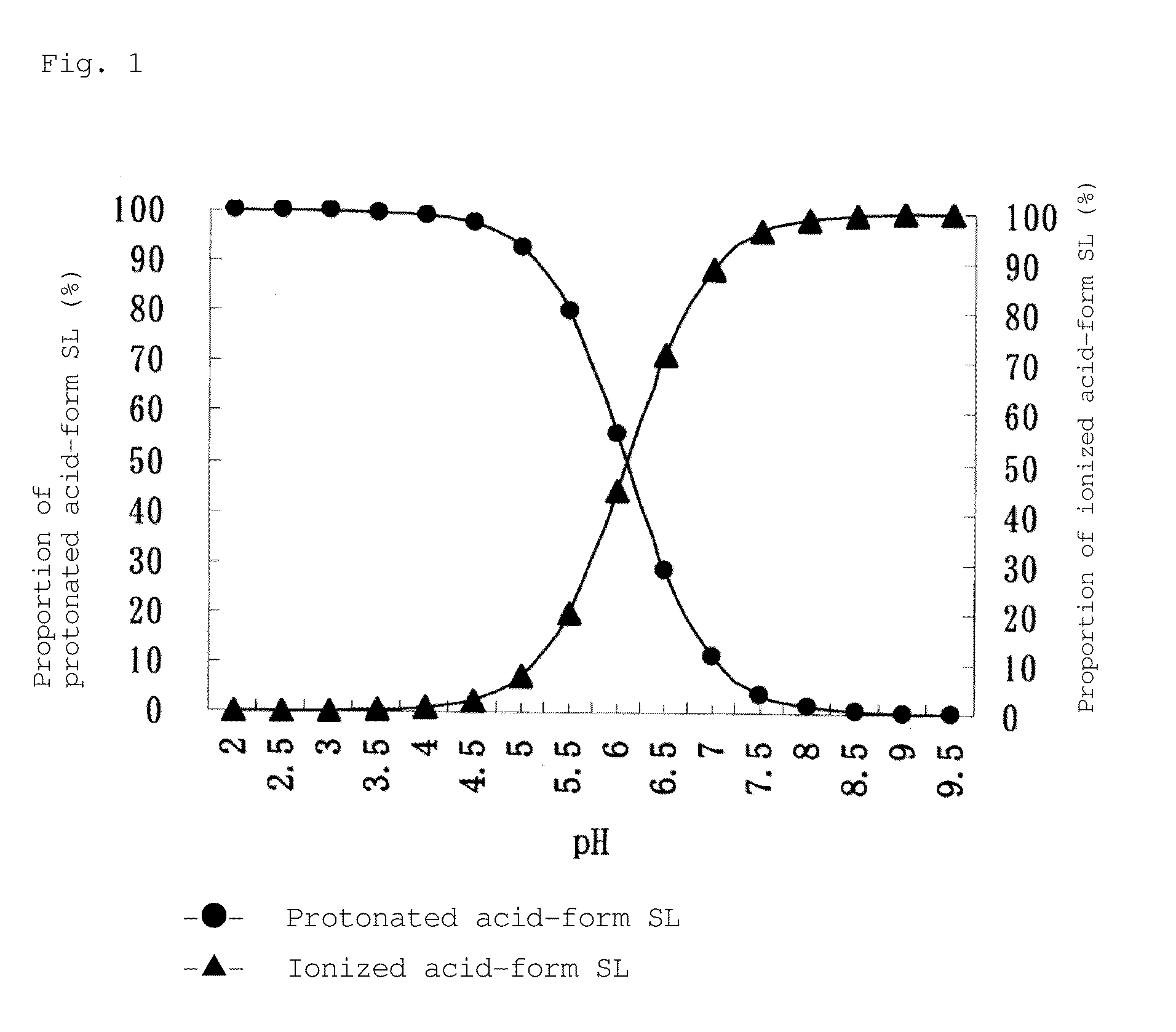

High-purity acid-form sophorolipid (SL) containing composition and process for preparing same

ActiveUS20150112049A1Less energyPurified safelyCosmetic preparationsSugar derivativesAcetic acidSophorolipid

The present invention provides a high-purity acid-form sophorolipid (SL)-containing composition characterized by substantially not containing acetic acid. The high-purity acid-form SL-containing composition can be produced, for example, by the following method:(i) adjusting the pH of a partially purified acid-form SL-containing composition to an acidic range; and(ii-a) subjecting an acidified partially purified acid-form SL-containing composition obtained in step (i) to chromatography to acquire a fraction containing an acid-form SL, or(ii-b) leaving the acidified partially purified acid-form SL-containing composition obtained in step (i) to stand under a low-temperature condition to acquire a resulting gelled object.

Owner:SARAYA CO LTD

Method for producing sophorose ester through fermenting waste molasses and waste glycerin

InactiveCN102329833ASolve the problem of difficult storage and large emission pollutionReduce manufacturing costFungiMicroorganism based processesBiotechnologySporeling

The invention relates to a method for producing sophorose ester through fermenting waste molasses and waste glycerin, which comprises the following implementation steps that: (1) spore suspension preparation: torulopsis utilis TJZKBA 10326 is inoculated on the inclined surface of a culture medium and is cultured for 2 to 4 days at the constant temperature being 30 DEG C, and normal saline with the mass concentration being 0.75 percent is added for washing mycelia, and the bacterial suspension is obtained; (2) the bacterial suspension is used for being inoculated into the sterilized liquid seed culture medium, the spore suspension is inoculated into the cooled liquid seed culture medium according to the inoculation quantity with the volume percentage being 2 to 5, and liquid seeds are obtained; (3) the liquid seed culture medium is used for being inoculated into a sterilized 5L fermentation tank, then, the liquid culture medium is inoculated into the cooled fermentation tank culture medium according to the inoculation quantity with the volume percentage being 2 to 5, the fermentation temperature is 30 to 34 DEG C, the dissolved oxygen is controlled to be 30 to 40 percent, and the fermentation time is 48 to 72h; and (4) after the fermentation is completed, the mixed organic solvent of organic solvent ethyl acetate / isopropanol with the same volume as the fermentation liquid is used for extracting the sophorose ester. The method has the advantages that the process is simple, the cost is low, and the effect is obvious.

Owner:天津实发中科百奥工业生物技术有限公司

Production method for sophorolipid with hair growing effect

InactiveCN106282264AHigh antibacterial activityStrong growth inhibitory effectFermentationGlycosylasesSophorolipidHair growth

The invention discloses a production method for sophorolipid with a hair growing effect. According to the production method, reprocessed oils extracted from animals or plants serve as raw materials, and a hydrolysis method of the raw material oils, a fermentation method of sophorolipid and an extraction and separation method are included. The sophorolipid has better hair growing and hair losing resisting effects when applied to cosmetic production, and is natural and nontoxic, capable of promoting cell proliferation and enhancing cell metabolism and beneficial to hair growth.

Owner:BIOLAND BIOCHEM HAIMEN CO LTD

Method for producing sophorolipid by double carbon source fermentation of waste molasses and illegal cooking oil

ActiveCN103589759AReduce manufacturing costRealize resource utilizationMicroorganism based processesFermentationBiotechnologyEthyl acetate

The invention discloses a method for producing sophorolipid by double carbon source fermentation of waste molasses and illegal cooking oil. The method is characterized by comprising the following steps: (1) inoculating torulopsis utilis to a YPD (yeast peptone dextrose) slant culture medium to prepare a bacterial suspension; (2) preparing a seed solution; (3) inoculating the seed solution to a fermentation medium taking the waste molasses and the illegal cooking oil as substrates for fermenting; (4) extracting the sophorolipid by ethyl acetate. According to the method, wastes are recycled, the production cost of the sophorolipid is greatly reduced, the problems of high emission pollution and large harm in the field of foods for the illegal cooking oil are solved, illegal cooking oil resources are reasonably utilized, complex equipment is not required, a fermentation process is simple and easy to implement, and the development, application and popularization of the sophorolipid are facilitated.

Owner:QINGDAO UNIV OF SCI & TECH

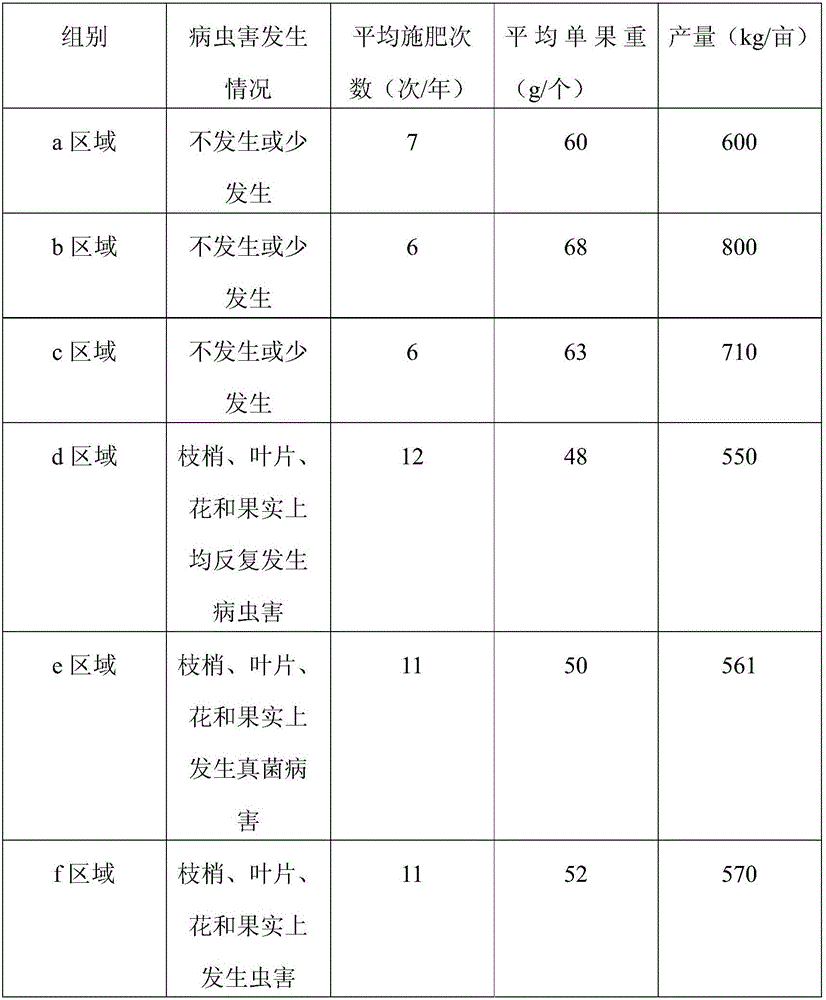

Special organic fertilizer for hawthorn trees, and preparation method thereof

InactiveCN106588417AGrowth inhibitionInhibition of germinationBio-organic fraction processingExcrement fertilisersPlant diseaseBiology

The invention discloses a special organic fertilizer for hawthorn trees, and a preparation method thereof, and relates to the technical field of organic fertilizers. The special organic fertilizer for hawthorn trees comprises cow dung, domestic fungus residues, crop straws, sugar residues, soybean meal, sophorolipid, Bacillus subtilis, Streptomyces badius, Pseudomonas aeruginosa, Amur Corktree Bark, fructus cnidii, garlic, Artemisia sieversiana, pyrethrum, tobacco, hairypetal millettia root stem and leaf, and castor-oil plants. The special organic fertilizer for hawthorn trees effectively controls soil borne diseases of the hawthorn trees, and improves the output and the quality of hawthorn fruits.

Owner:罗永志

Grinding aid as well as production process and application thereof

The invention relates to a grinding aid as well as a production process and application thereof, and belongs to the technical field of cement additives. The grinding aid is prepared from the followingraw materials, by weight: 3-7 parts of triethanolamine, 1-9 parts of acetic acid, 1-5 parts of butyltriphenylphosphonium bromide, 85-105 parts of water, 2-8 parts of sodium dodecyl benzene sulfonate,3-7 parts of p-aminophenol, 3-9 parts of acid sophorolipid, 7-13 parts of sodium alginate, 1-7 parts of aminophenol, 6-14 parts of biosurfactant and 10-14 parts of hyperdispersant. The mixing amountof the grinding aid in the cement clinker grinding process is 0.03%-0.05%, and the grinding aid has the effect of improving the cement clinker grinding efficiency so as to reduce the energy consumption in the cement clinker grinding process.

Owner:北京金隅水泥节能科技有限公司 +3

Method for the production of medium-chain sophorolipids

The MFE2 gene of a microorganism capable of producing glycolipids, such as, but not limited to C. bombicola is disrupted with the purpose of blocking the beta-oxidation pathway in the strain. Fermentation of a such strain having such disrupted genes on primary or secondary alcohols or diols, preferably on primary alcohols produces short chained glycolipids in high yield and purity.

Owner:ECOVER CO ORDINATION CENT

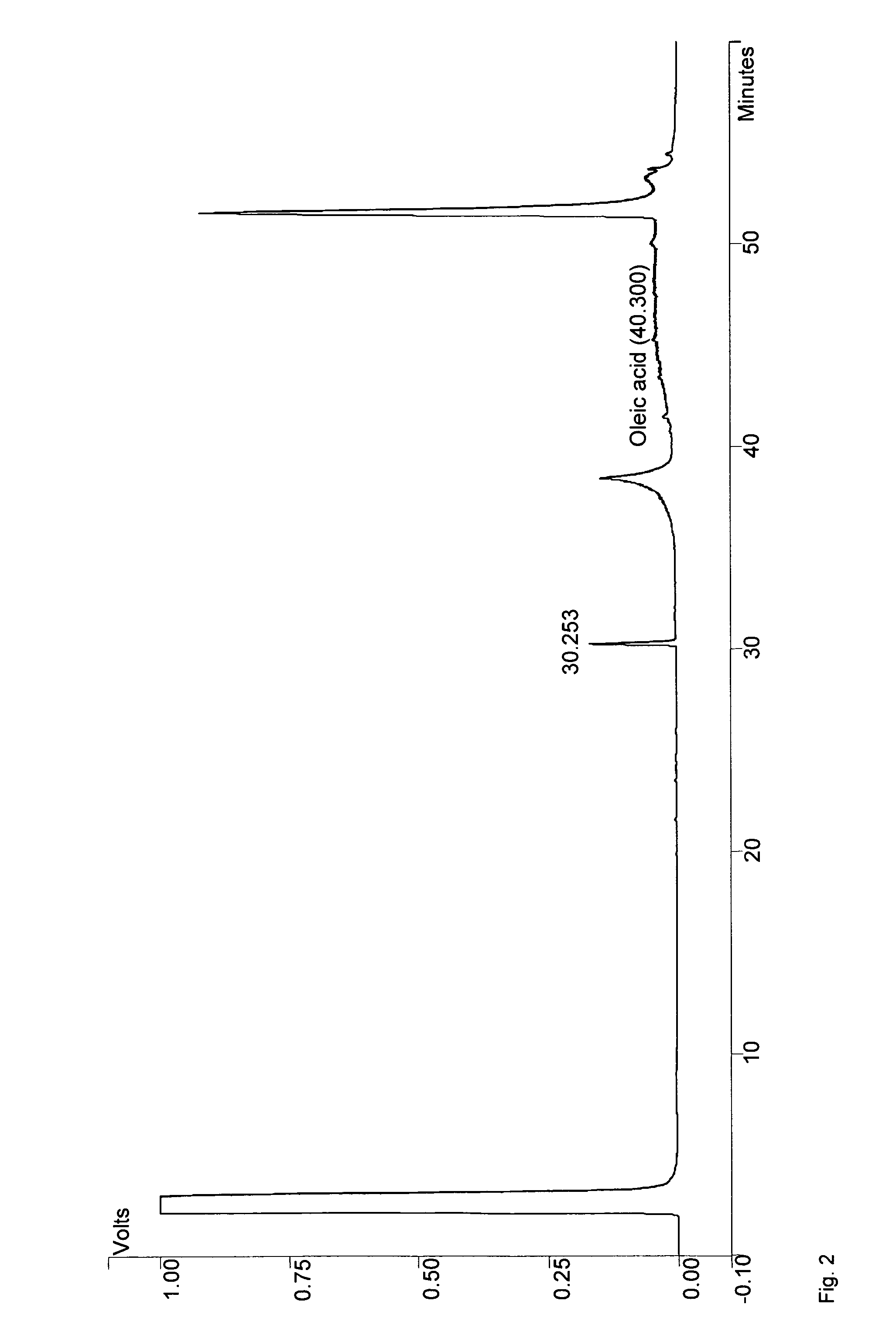

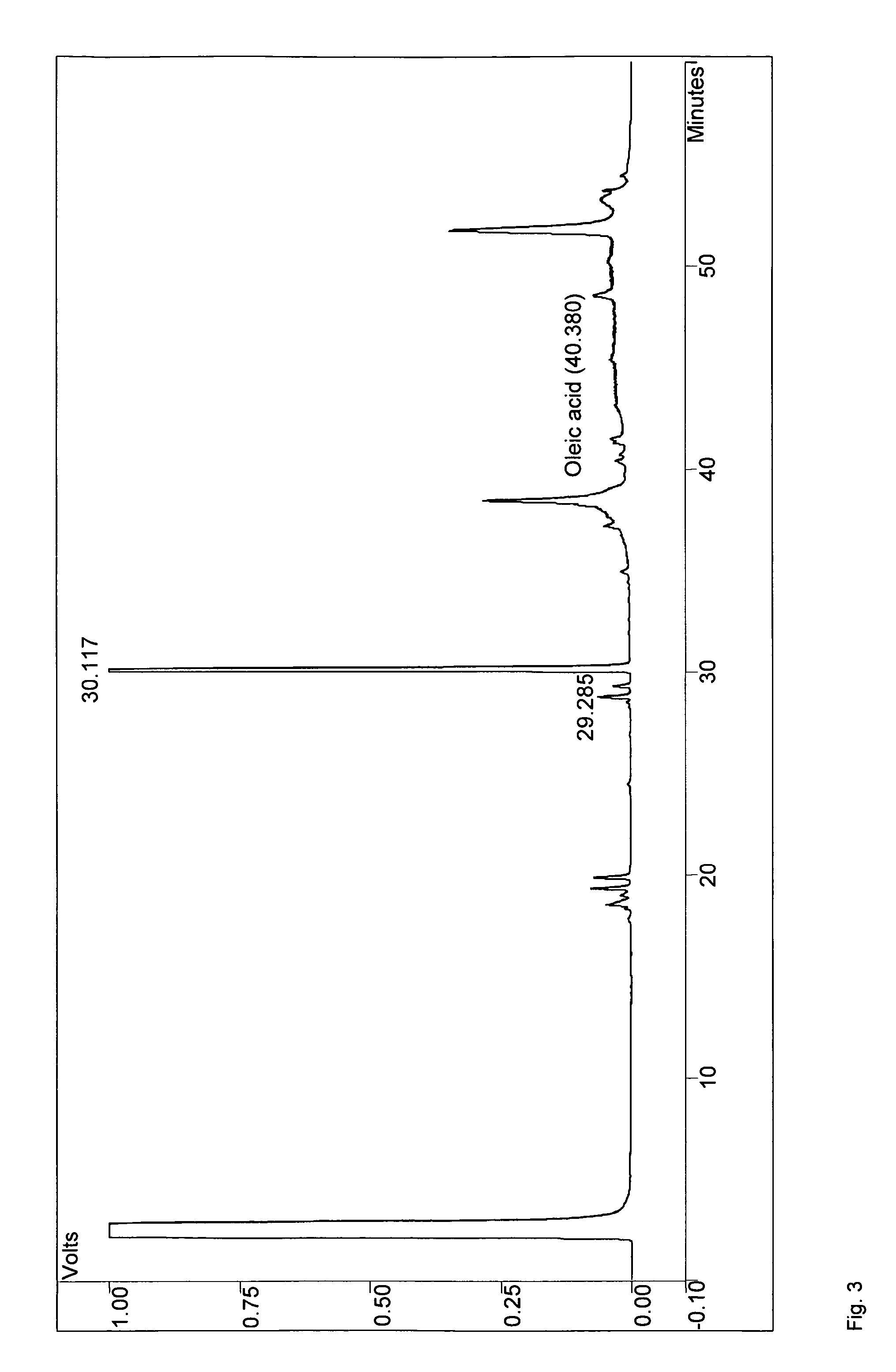

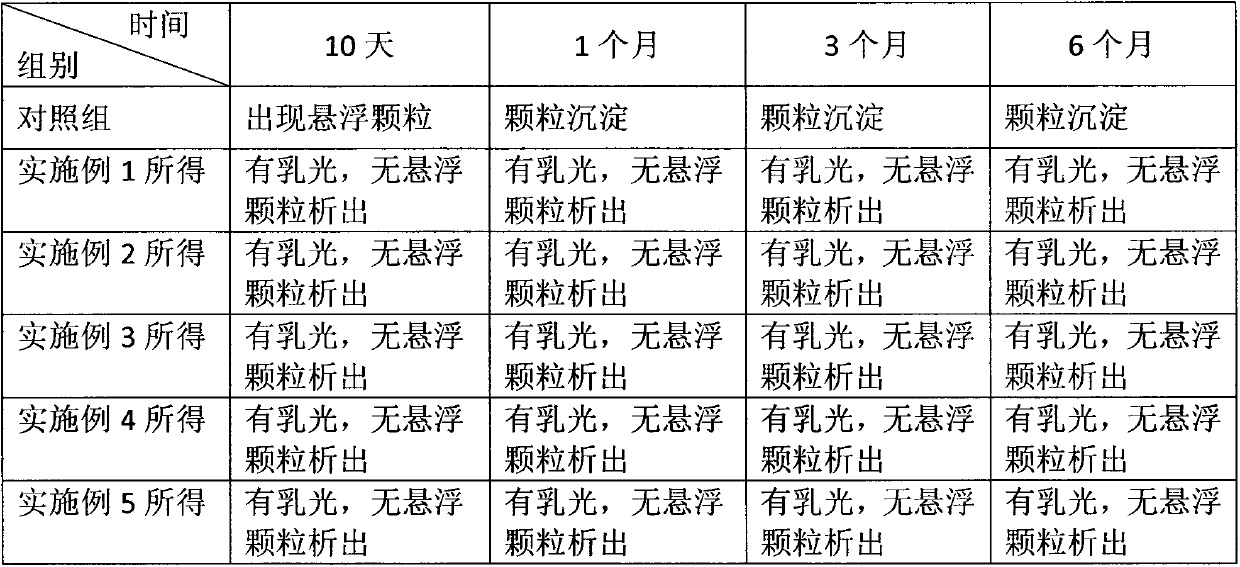

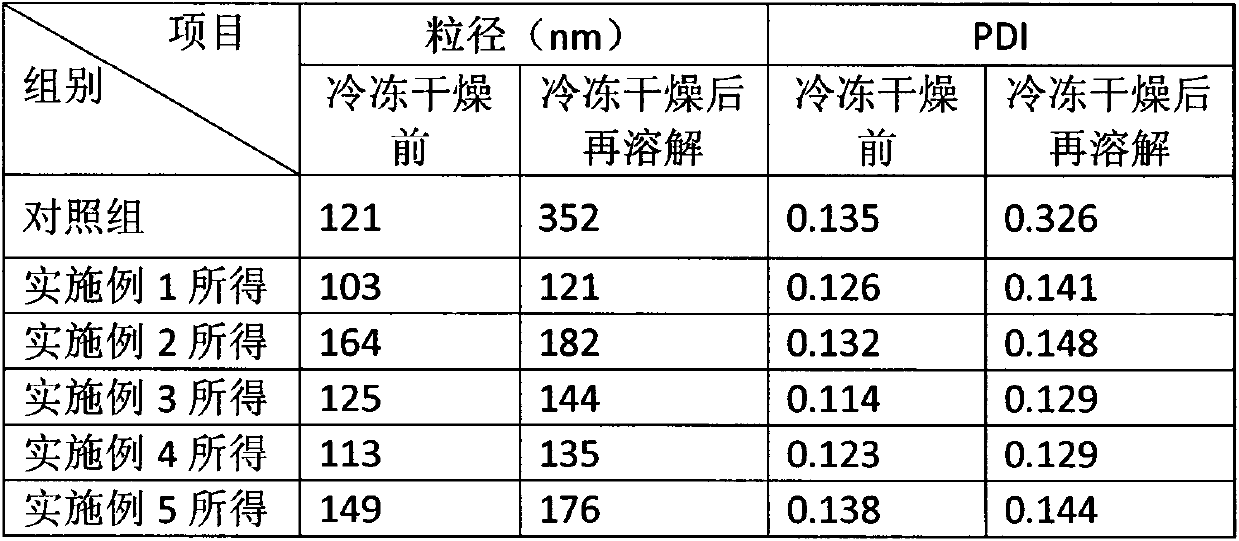

Polyethylene glycol vitamin E succinate and calprotectin modified nanoparticle and preparation method thereof

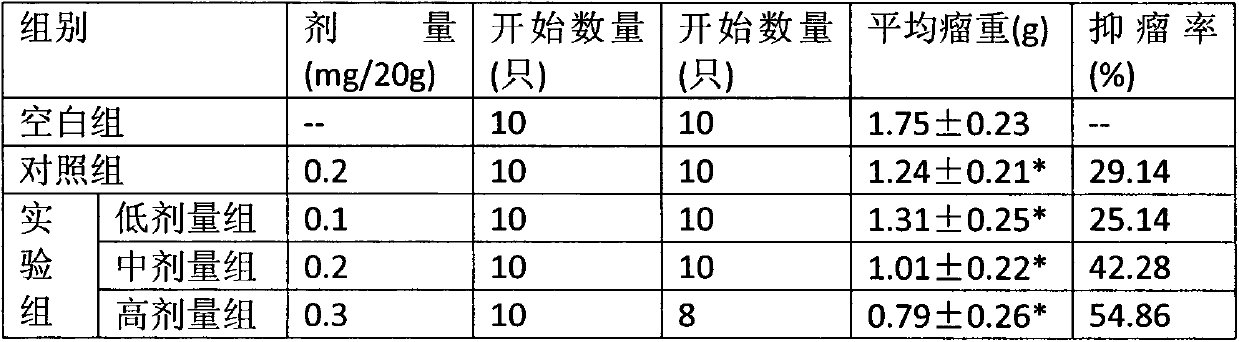

InactiveCN103735514AAverage tumor weight reductionImprove tumor inhibition rateOrganic active ingredientsPowder deliveryFreeze-dryingPolyethylene glycol

The invention discloses polyethylene glycol vitamin E succinate and calprotectin modified nanoparticle and a preparation method thereof. The polyethylene glycol vitamin E succinate and calprotectin modified nanoparticle is prepared from the following raw materials in parts by weight: 1 part of active medicine, 20 to 40 parts of phospholipid, 2 to 4 parts of sophorolipid, 1 to 2 parts of calprotectin, and 5 to 10 parts of polyethylene glycol vitamin E succinate. Compared with the prior art, the nanoparticle modified by olyethylene glycol vitamin E succinate, sophorolipid and calprotectin has the advantages that (1) the preparation process is simple and controllable; (2) the stability of the nanoparticle is greatly improved, and the nanoparticle can be stabilized in a solution for up to 6 months; (3) a freeze-drying protective additive is not needed for freezing and drying; the obtained freeze-dried powder dissolved again shows small change on particle size and polydispersity index compared with freeze-dried powder without being dissolved; (4) the targeting for tumor cells is enhanced.

Owner:CHINA PHARM UNIV

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com