Method for pre-treating sophorolipid fermentation solution and separating and purifying sophorolipid with different structures

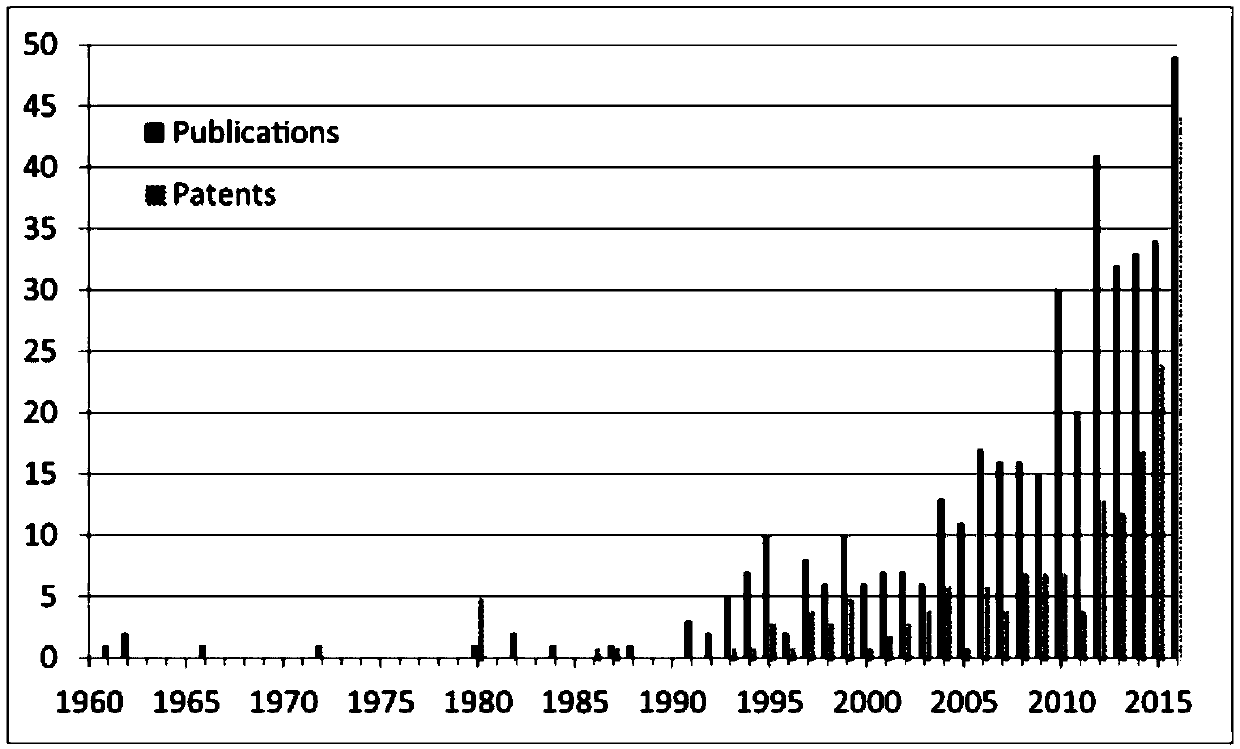

A technology for separation and purification of sophorolipids, which is applied in the field of preparation and purification of biosurfactant sophorolipids, can solve the problem of low organic solvent usage, achieve reduced usage, huge economic value, and improve safety and environmental protection sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Preparation of sophorolipid fermentation broth and determination of sophorolipid yield:

[0046] Fermentation of sophorolipids: carried out in a ventilated stirring fermenter with a volume of 50 L. The liquid volume of the medium is 80% (40L), and the initial dissolved oxygen is 60% (V 氧气 / V 空气 ), the stirring speed is 200rpm, the air flow rate is 0.3m 3 / h. The formula of the fermentation medium is as follows: 6.0% of glucose, 0.3% of yeast powder, 0.1% of potassium dihydrogen phosphate, 0.1% of disodium hydrogen phosphate dodecahydrate, 0.05% of magnesium sulfate heptahydrate, and 6.0% of rapeseed oil. Silicone oil defoamer 1ml. Natural pH fermentation was carried out for 7 days, and samples were taken every 8 hours to measure indicators such as biomass, residual sugar, and sophorolipid production.

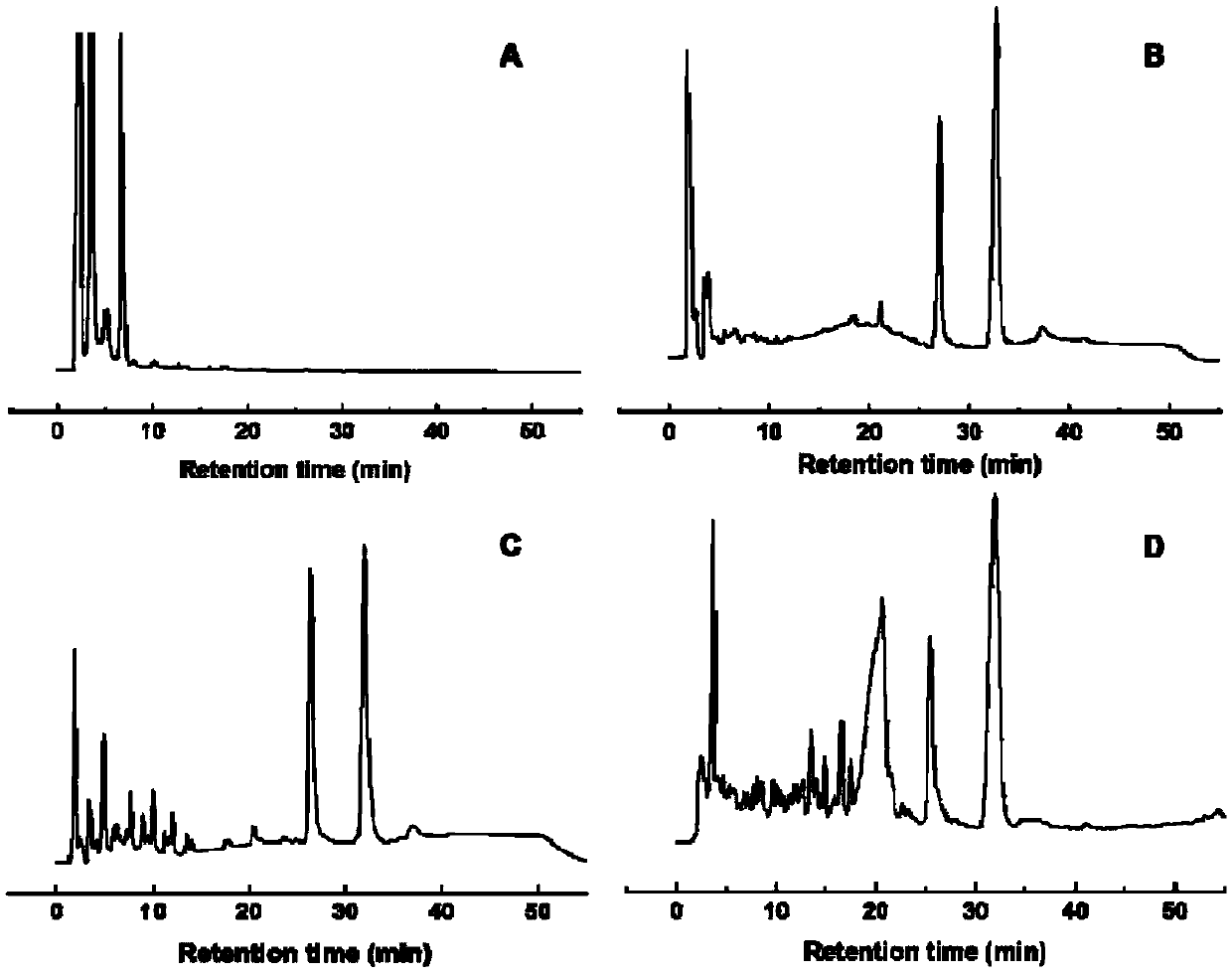

[0047] Determination of sophorolipid yield:

[0048] DNS method was used to determine the residual amount of glucose in the fermentation broth, and anthrone-sulfuri...

Embodiment 2

[0050] A method for pretreatment of sophorolipid fermentation broth and separation and purification of sophorolipids with different structures, comprising the following steps:

[0051] (1) Pretreatment of fermentation broth

[0052] After the fermentation, the fermented broth with a total sophorolipid content of 117.25g / L, a lactone-type sophorolipid content of 48.88g / L, and an acid-type sophorolipid content of 68.37g / L was first raised to 50°C Sterilize for 40 minutes, cool down naturally for 1.5 hours, and at the same time turn off the stirring and reduce the air flow;

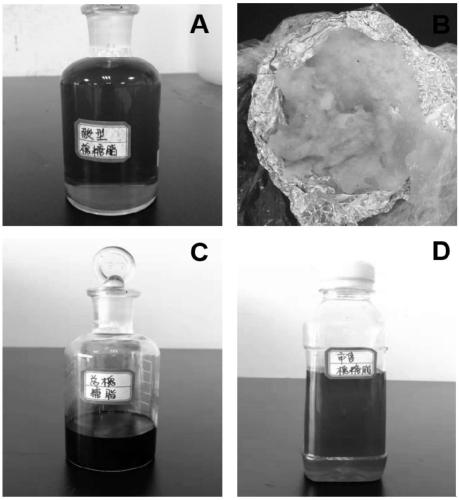

[0053] (2) Collection and processing of lower lactone-type sophorolipids

[0054] Collect the fermented liquid into a cylindrical container, connect it with a chromatographic column with a height of 30 cm and a diameter of 2.5 cm, and collect the viscous lactone-type sophorolipid in the lower layer after standing for 20 minutes; the fermented liquid in the upper layer is set aside;

[0055] (3) Plate and f...

Embodiment 3

[0070] A method for pretreatment of sophorolipid fermentation broth and separation and purification of sophorolipids with different structures, comprising the following steps:

[0071] (1) Pretreatment of fermentation broth

[0072] After the fermentation, the fermentation liquid with a total sophorolipid content of 62.95g / L, a lactone-type sophorolipid content of 36.52g / L, and an acid-type sophorolipid content of 26.43g / L was first raised to 50°C Sterilize for 40 minutes, cool down naturally for 1.5 hours, and at the same time turn off the stirring and reduce the air flow;

[0073] (2) Collection and processing of lower lactone-type sophorolipids

[0074] Collect the fermented liquid into a cylindrical container, connect it with a chromatographic column with a height of 30 cm and a diameter of 2.5 cm, and collect the viscous lactone-type sophorolipid in the lower layer after standing for 20 minutes; the fermented liquid in the upper layer is set aside;

[0075] (3) Plate an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| recovery rate | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com