Thermo-chemical cleaning agent for polymer-containing oil sludge in oil field as well as preparation method and application thereof

A cleaning agent and oil-sludge technology, applied in chemical instruments and methods, detergent compositions, polymer surface active compounds, etc., can solve the problems of increasing the complexity of steps, complex reagents, and difficult handling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Dissolve sodium silicate: SP169: rhamnolipid in water at a mass ratio of 10:1:0.5, mix well to obtain a cleaning solution for later use; take 20g of poly-containing sludge (moisture content: 23%, oil content: 20% , solid content rate: 57%), added to a beaker containing 150mL of detergent solution, the mass content of detergent is 1.1%; heated in a water bath at 70°C, mechanically stirred at a stirring speed of 400rpm for 1h, stood for 30min, waited for oil, The water and sediment are layered, and the oil film is thicker on the surface, and the water phase is yellow and turbid; the upper layer of oil is scraped off, and the sediment is discharged after reaching the standard. For oil recovery, the recovery rate of crude oil can reach 93.75% by weighing, and the oil content of sludge can be reduced to 0.94%.

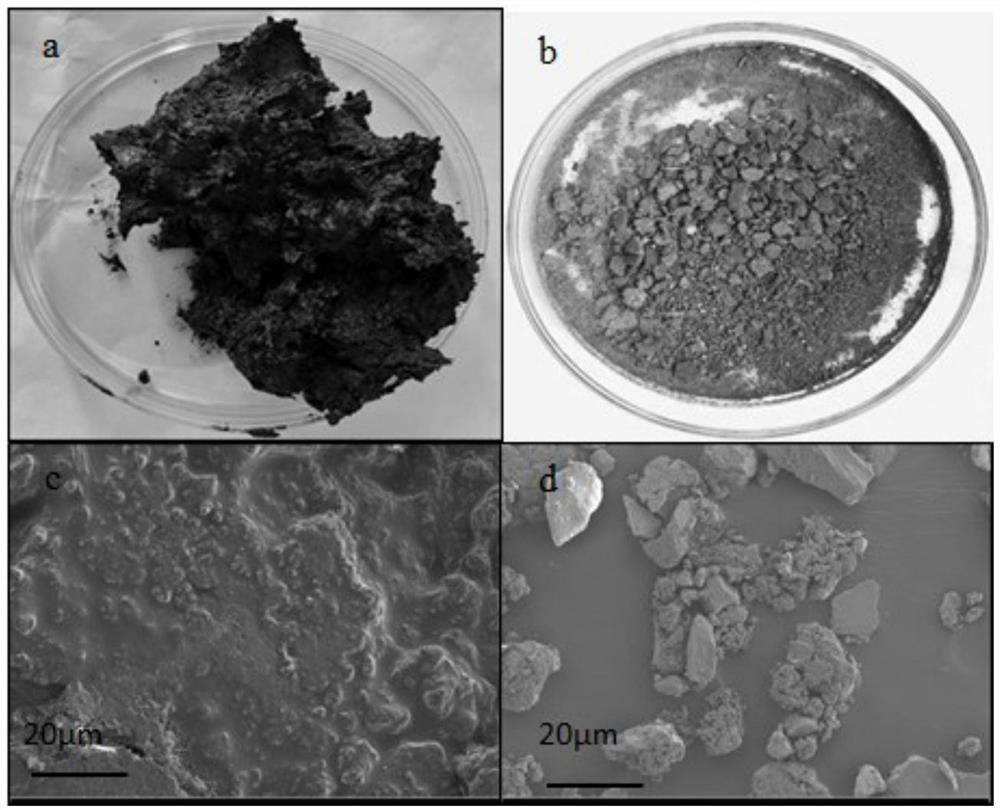

[0031] Such as figure 1As shown, comparing the oil sludge before and after treatment macroscopically, it can be seen that the oil sludge before treatment is black, ...

Embodiment 2

[0033] Dissolve sodium silicate: SP169: rhamnolipid in water at a mass ratio of 15:1:0.5, mix well to obtain a cleaning agent solution for later use; take 20g of poly-containing sludge (moisture content: 23%, oil content: 20% , solid content rate: 57%), added to a beaker containing 150mL of detergent solution, the mass content of detergent is 1.1%; heated in a water bath at 70°C, mechanically stirred at a stirring speed of 400rpm for 1h, stood for 30min, waited for oil, The water and sediment are layered, and the oil film is thicker on the surface, and the water phase is yellow and turbid; the upper layer of oil is scraped off, and the sediment is discharged after reaching the standard. For oil recovery, the recovery rate of crude oil can reach 92.58% by weighing, and the oil content of sludge can be reduced to 1.10%.

Embodiment 3

[0035] Dissolve sodium silicate: SP169: rhamnolipid in water at a mass ratio of 10:1:0.5, mix well to obtain a cleaning solution for later use; take 20g of poly-containing sludge (moisture content: 23%, oil content: 20% , solid content rate: 57%), added to a beaker containing 150mL of detergent solution, the mass content of detergent is 1.1%; heated in a water bath at 70°C, mechanically stirred at a stirring speed of 400rpm for 1h, stood for 30min, waited for oil, The water and sediment are layered, and the oil film is thicker on the surface, and the water phase is yellow and turbid; the upper layer of oil is scraped off, and the sediment is discharged after reaching the standard. For oil recovery, the recovery rate of crude oil can reach 93.75% by weighing, and the oil content of sludge can be reduced to 0.94%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com