Patents

Literature

30results about How to "Excellent moisture resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Wide-range flame-retarding canvas and preparation method thereof

The invention discloses a wide-range flame-retarding canvas. The wide-range flame-retarding canvas includes a fire retardant fabric base material; a layer of flame-retarding primer is coated on the fire retardant fabric base material, and the flame-retarding coating is coated on the flame-retarding primer; the formula and dosage of the flame-retarding primer according to part by weight are: 20-40 parts of ammonium polyphosphate APP, 5-15 parts of melamine MEL, 10-20 parts of dipentaerythritol DPER, 0.5-2 parts of wetting agent, 0.5-2 parts of antifoaming agent, 10-30 parts of pure acrylic emulsion, 40-50 parts of ethylene-vinyl acetate copolymer emulsion, 20-30 parts of 70% of titanium dioxide powder syrup, 0.5-2 parts of brightening agent, 100-110 parts of water, and 5-8 parts of thickening agent. The wide-range flame-retarding canvas can be printed by compatible solvent type, weak solvent type and UV solidifying type inks, and has excellent smoothness and fineness, coating firmness, good weather resistance, moisture-resisting humidity and exquisite grain line and inkjet resolution rate. Meanwhile, the wide-range flame-retarding canvas can satisfy the foreign canvas flame-retarding standard and reach the highest flame-retarding standard B1 grade at home.

Owner:江苏耐斯数码科技股份有限公司

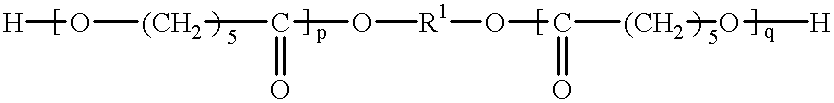

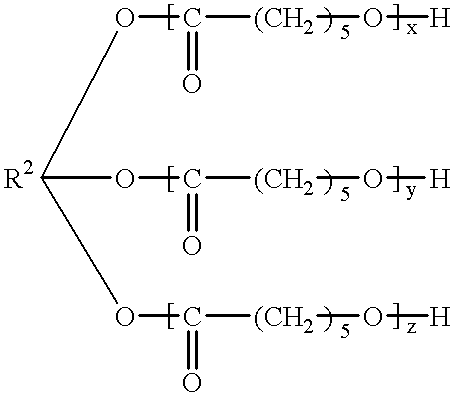

Ultraviolet-curable adhesive for bonding optical disks

InactiveUS6335382B1High water retainabilityExcellent moisture resistanceImpression capsOrganic chemistryChemistryOxygen atom

Owner:NAGASE CHIBA

Anticorrosion type spraying quick-setting rubber asphalt waterproof coating

InactiveCN102965015AEnvironmentally friendly and pollution-freeGood acid and alkali resistanceConjugated diene hydrocarbon coatingsNatural rubber coatingsBitumen emulsionSpray coating

The invention relates to an anticorrosion type spraying quick-setting rubber asphalt waterproof coating. The coating is an anticorrosion type water-based spraying coating prepared by adding a preservative into a liquid rubber asphalt mastic emulsion component which is prepared from modified-emulsified asphalt and high-molecular polymer rubber latex, and then mixing the liquid rubber asphalt mastic emulsion component with a coagulating agent component in proportion. Besides environmentally-friendly and non-pollution properties, the anticorrosion coating provided by the invention has the advantages of excellent acid-base resistance property, water resisting property, hot brine resisting property, heat and humidity resisting property and temperature change resisting property, accords with the requirement on heavy corrosion protection in the anticorrosion coating and can be widely used for heavy corrosion protection coating on the surface of concrete, metal and wood and the like in various buildings and structures, over-ground, underground or underwater steel structures, chemical engineering machines, pipelines, tanks, ships, bridges, docks and the like.

Owner:SHANDONG NORTH CHUANGXIN WATERPROOF SCI & TECH GRP CO LTD

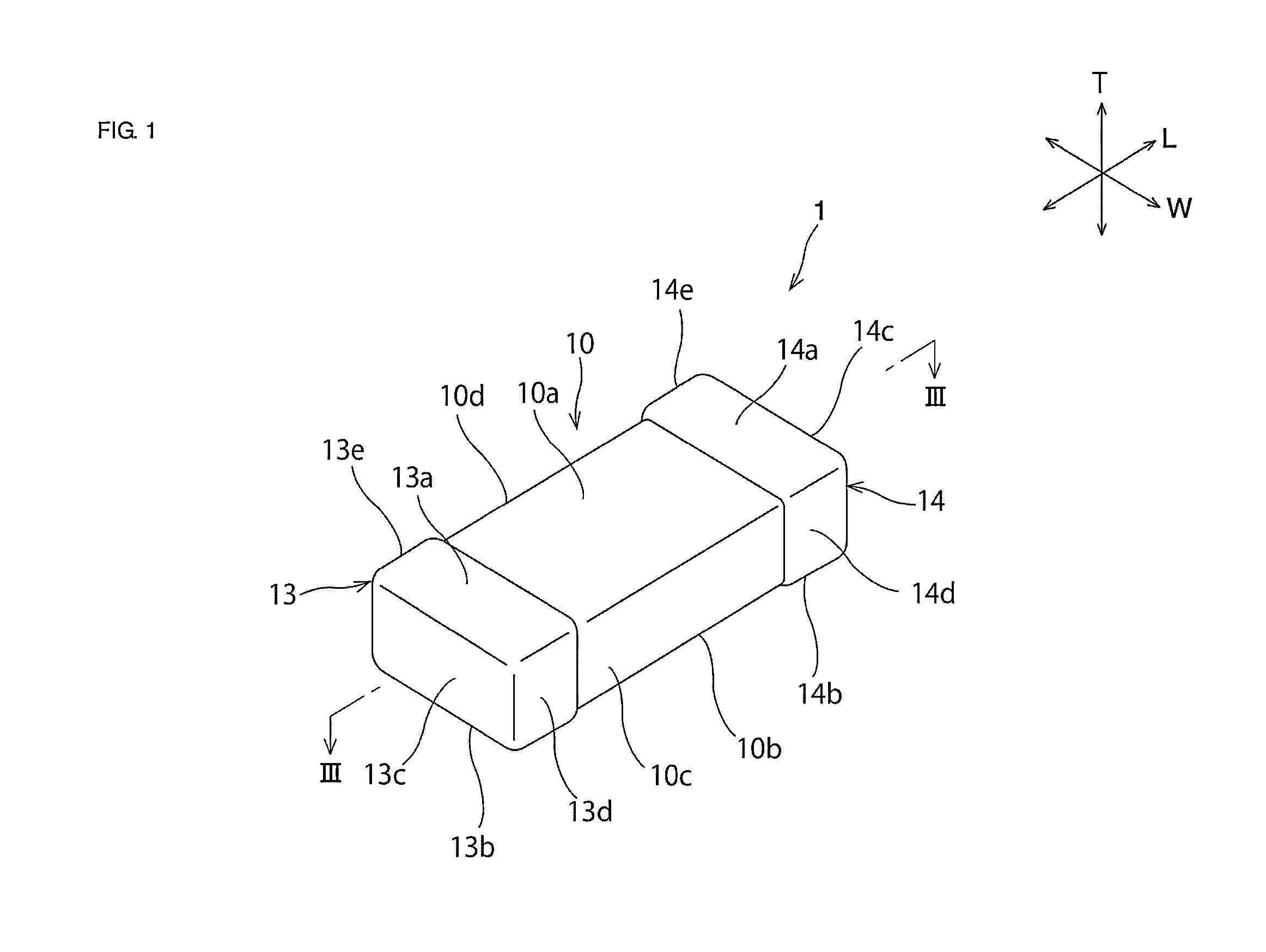

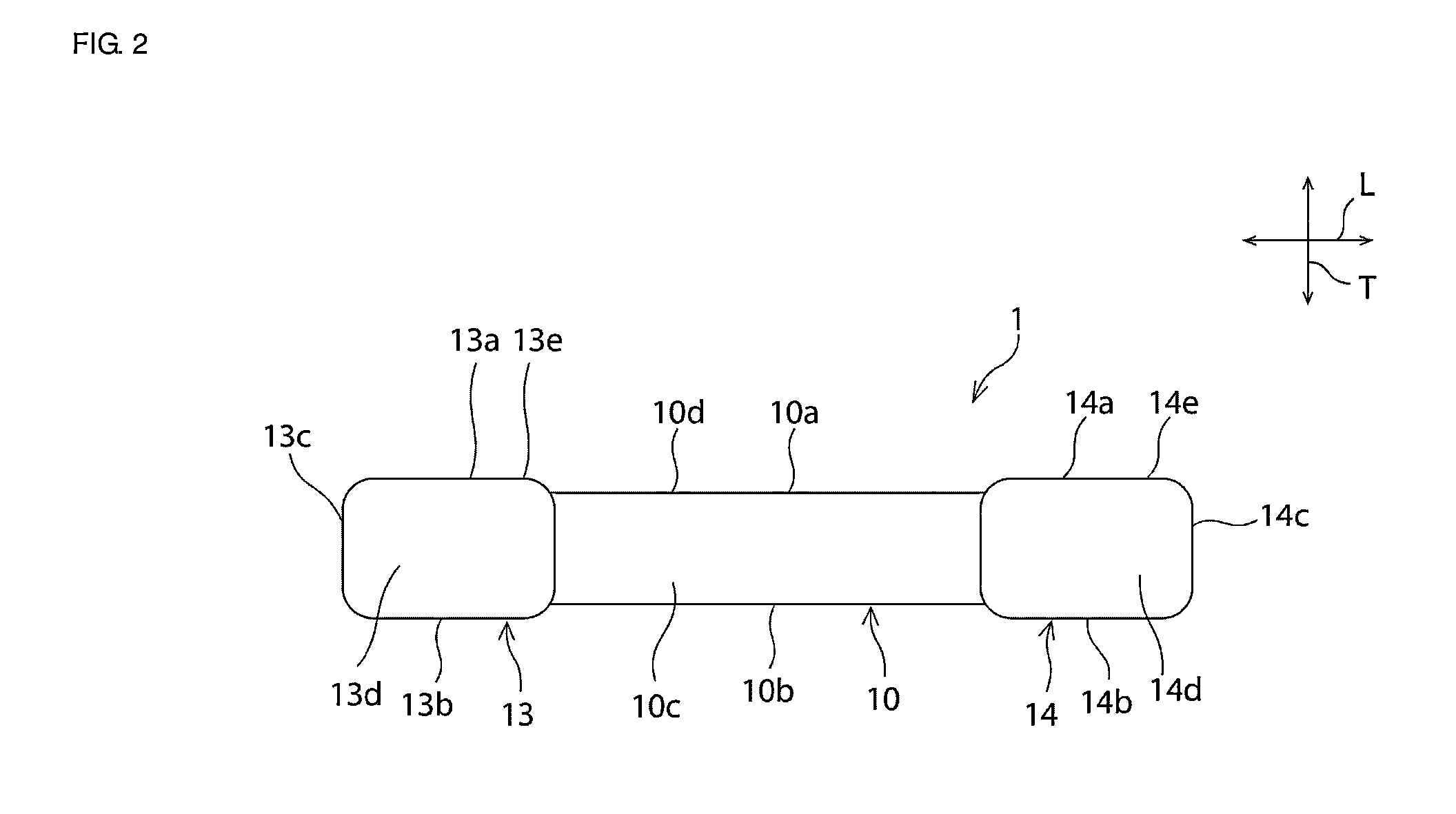

Ceramic electronic component

ActiveUS20140292141A1Excellent moisture resistanceImprove moisture resistancePiezoelectric/electrostriction/magnetostriction machinesCurrent responsive resistorsMetallurgyMetal powder

A ceramic electronic component includes a ceramic body, inner electrodes, a glass coating layer, and outer electrodes. The glass coating layer extends from an exposed portion of one of the inner electrodes at a first end surface to a first principal surface. The outer electrodes are each constituted by a plating film disposed directly above the glass coating layer. The glass coating layer includes a glass medium and metal powder particles that define conductive paths. The metal powder particles have an elongated or substantially elongated shape and are dispersed in the glass medium. The dimension of a portion of the glass coating layer located on the first principal surface in the length direction, is larger than that of a portion of the glass coating layer located on the first end surface in the thickness direction.

Owner:MURATA MFG CO LTD

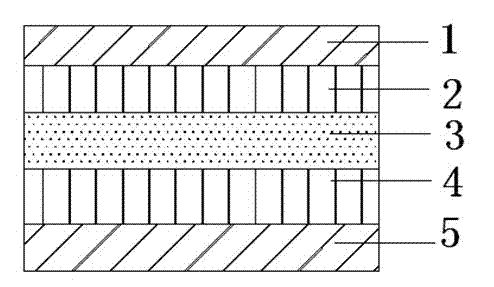

Five-layer co-extrusion packaging material having high moisture barrier and barrier properties and preparation method thereof

InactiveCN103753914ASolve the barrier performance is easy to declineExcellent moisture resistanceFlexible coversWrappersPolymer chemistryCo extrusion

The invention provides a multi-layer co-extrusion packaging material having high moisture barrier and barrier properties and a preparation method of the multi-layer co-extrusion packaging material; and the five-layer co-extrusion packaging material disclosed by the invention comprises a polyethylene layer having high intensity and good adaptation as the first layer, a barrier layer as the second layer, an ultra-fine and ultra-strong water absorbent modified polyethylene layer as the third layer, a barrier layer as the fourth layer and a high-speed thermal sealing layer having excellent chemical stability as the fifth layer, wherein various layers are contacted with each other in sequence. In the multi-layer co-extrusion packaging material having high moisture barrier and barrier properties disclosed by the invention, the ultra-fine and ultra-strong water absorbent modified polyethylene layer has the strong function of absorbing moisture; other layers respectively have good barrier, thermal sealing and printable properties; in addition, by means of reasonable structural design and material selection, various layers have excellent packaging material having high moisture barrier and barrier properties. The five-layer co-extrusion packaging material disclosed by the invention has excellent moisture barrier property; simultaneously, other barrier properties (barrier of oxygen, nitrogen and the like) are also excellent; furthermore, the cost can be effectively reduced; and the processing technique is simple.

Owner:HEFEI GENIUS NEW MATERIALS

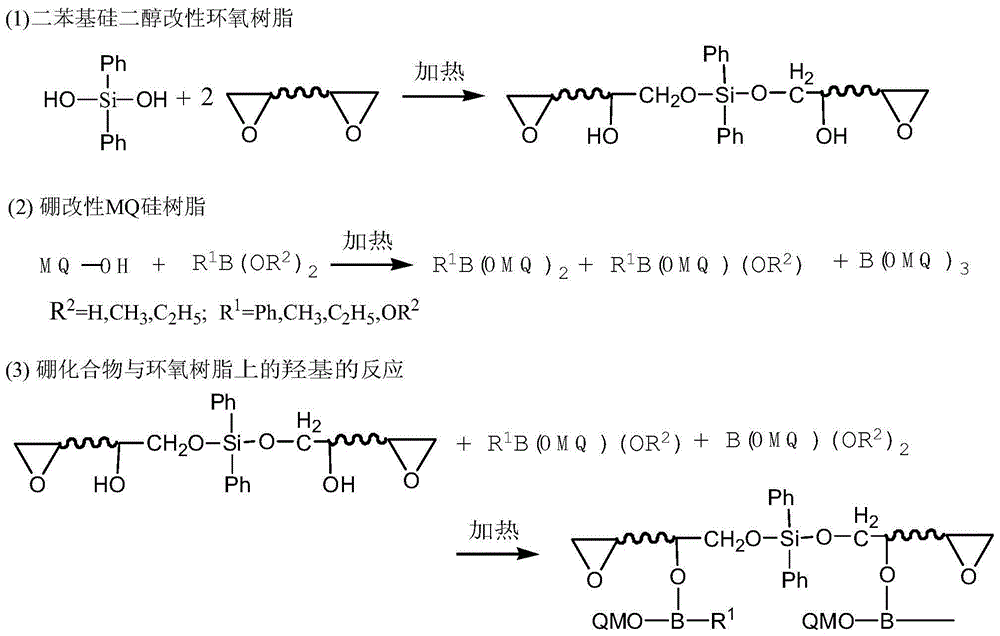

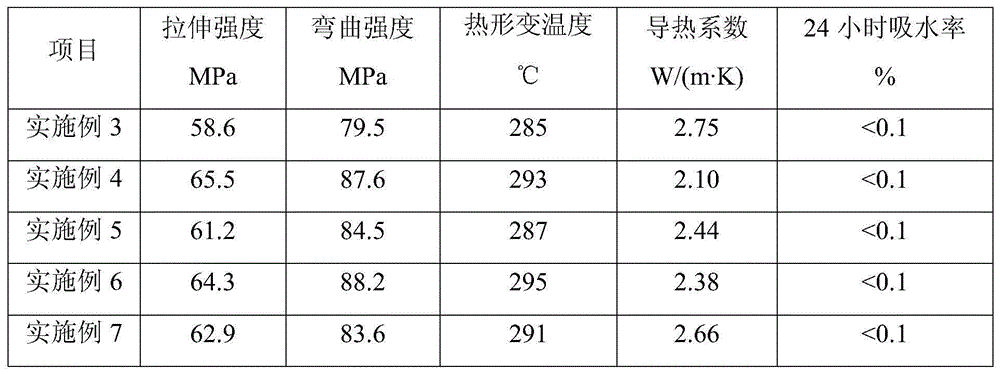

High-temperature-resistant high-thermal-conductivity boron-dopedorganosilicon epoxy pouring sealant as well as preparation method and application thereof

ActiveCN104479606AGood compatibilityExcellent moisture resistanceNon-macromolecular adhesive additivesOther chemical processesHeat conductingDiphenylsilanediol

The invention discloses a high-temperature-resistant high-thermal-conductivity boron-doped organosilicon epoxy pouring sealant as well as a preparation method and an application thereof. The pouring sealant comprises a component A and a component B, wherein the component A comprises 100 parts of diphenylsilanediol modified epoxy resin, 1-5 parts of anacetylacetone metal complex and 20-100 parts of boron-modified methyl MQ silicon resin; the component B comprises 100 parts of liquid anhydride and 50-100 parts of boron nitride heat-conducting ceramic powder. The prepared boron-doped organosilicon epoxy composite material has excellent moistureresistance and heat resistance, high mechanical strength and the high heat-conducting property and is suitable to be used as a high-temperature-resistant high-thermal-conductivity insulating moisture-resistant packaging protection material.

Owner:GUANGZHOU CHEM CO LTD CHINESE ACADEMY OF SCI

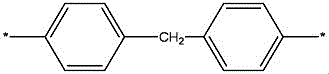

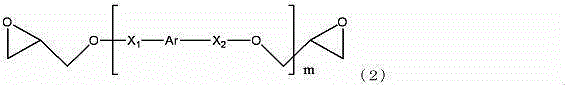

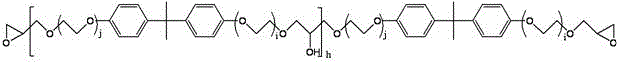

Flexible epoxy resin composition

ActiveCN105473634AExcellent moisture resistanceHigh peel strengthNon-macromolecular adhesive additivesOther chemical processesMoisture resistanceTris

Provided is a one-component thermosetting composition in which low-temperature curability and maintenance of adhesive strength are both obtained at the same time, and low-temperature curability and moisture resistance are both obtained at the same time. Specifically, a one-component-type thermosetting resin composition is provided containing tris(3-mercaptopropyl)isocyanurate and an epoxy resin containing an epoxy compound represented by formula (1) or formula (2) or a polymer thereof. (In formula (1) and formula (2), X, X1, and X2 may be mutually the same or different and are divalent non-aromatic hydrocarbon groups including two or more -(CH2)- units in a main backbone thereof (except when X is -O-CH2-CH(-OH)-CH2-); Ar, Ar1, and Ar2 may be mutually the same or different and are divalent aromatic-containing hydrocarbon groups including divalent aromatic groups in a main backbone thereof; and n and m are each independently an integer of 1-20).

Owner:AJINOMOTO CO INC

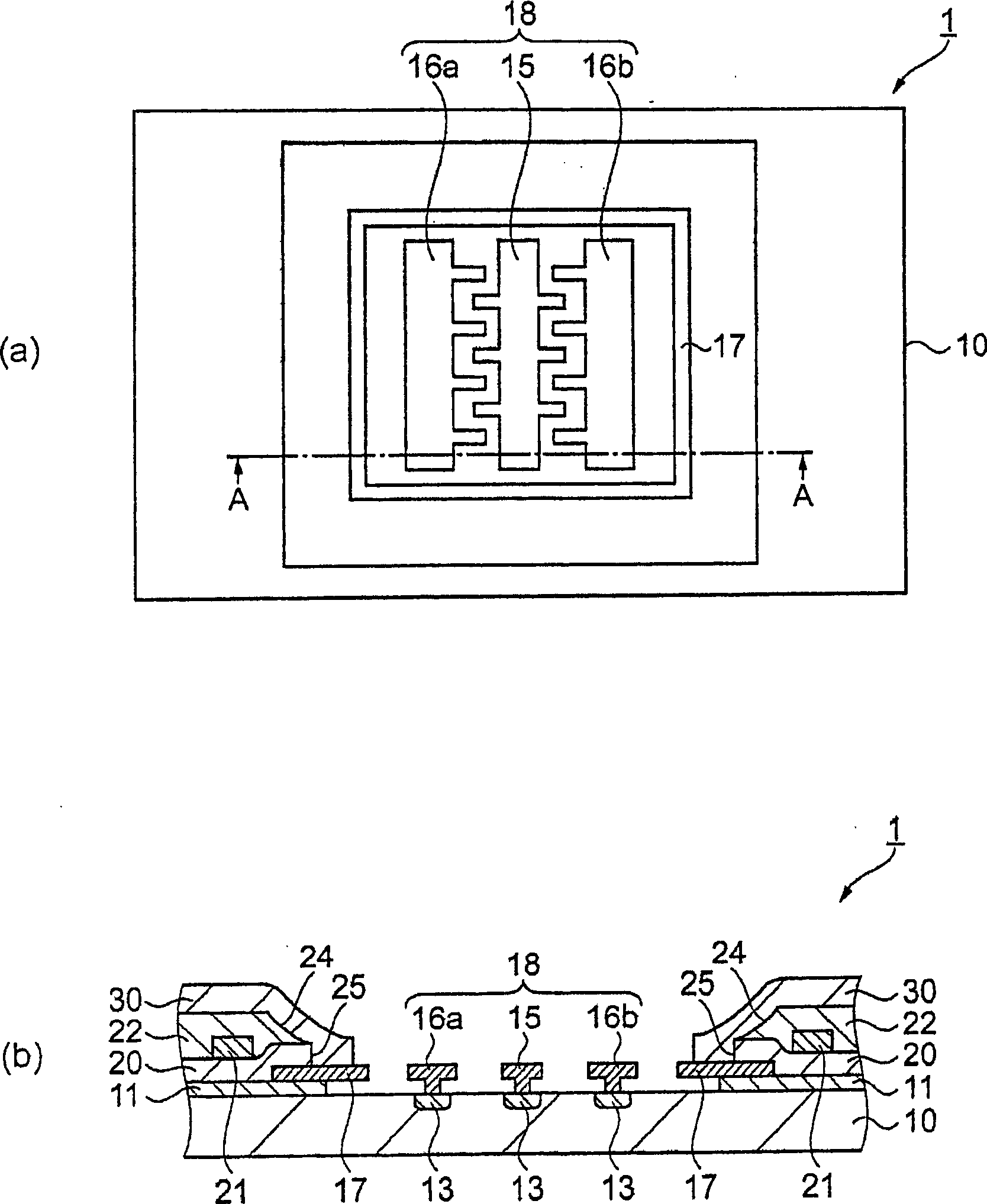

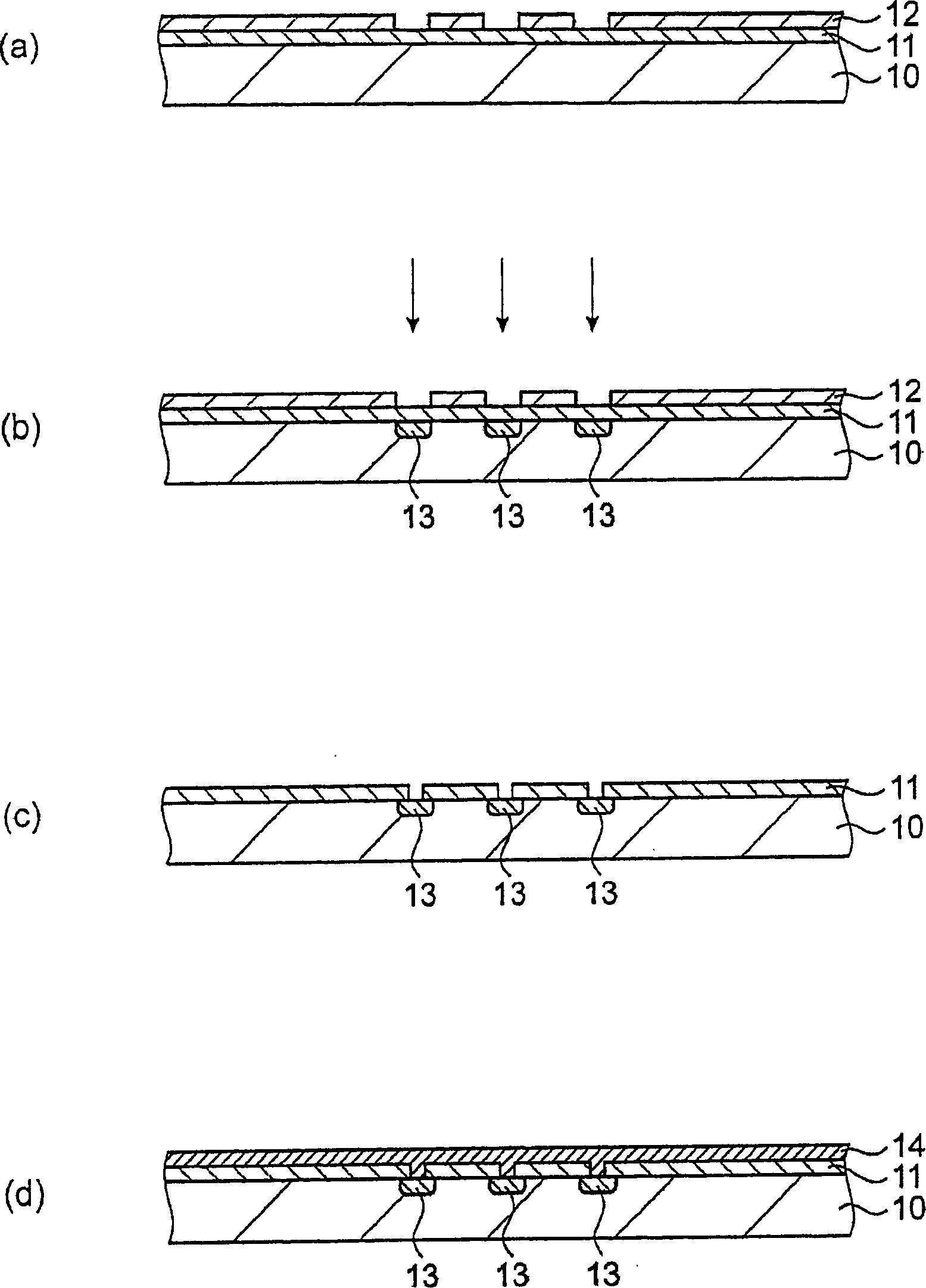

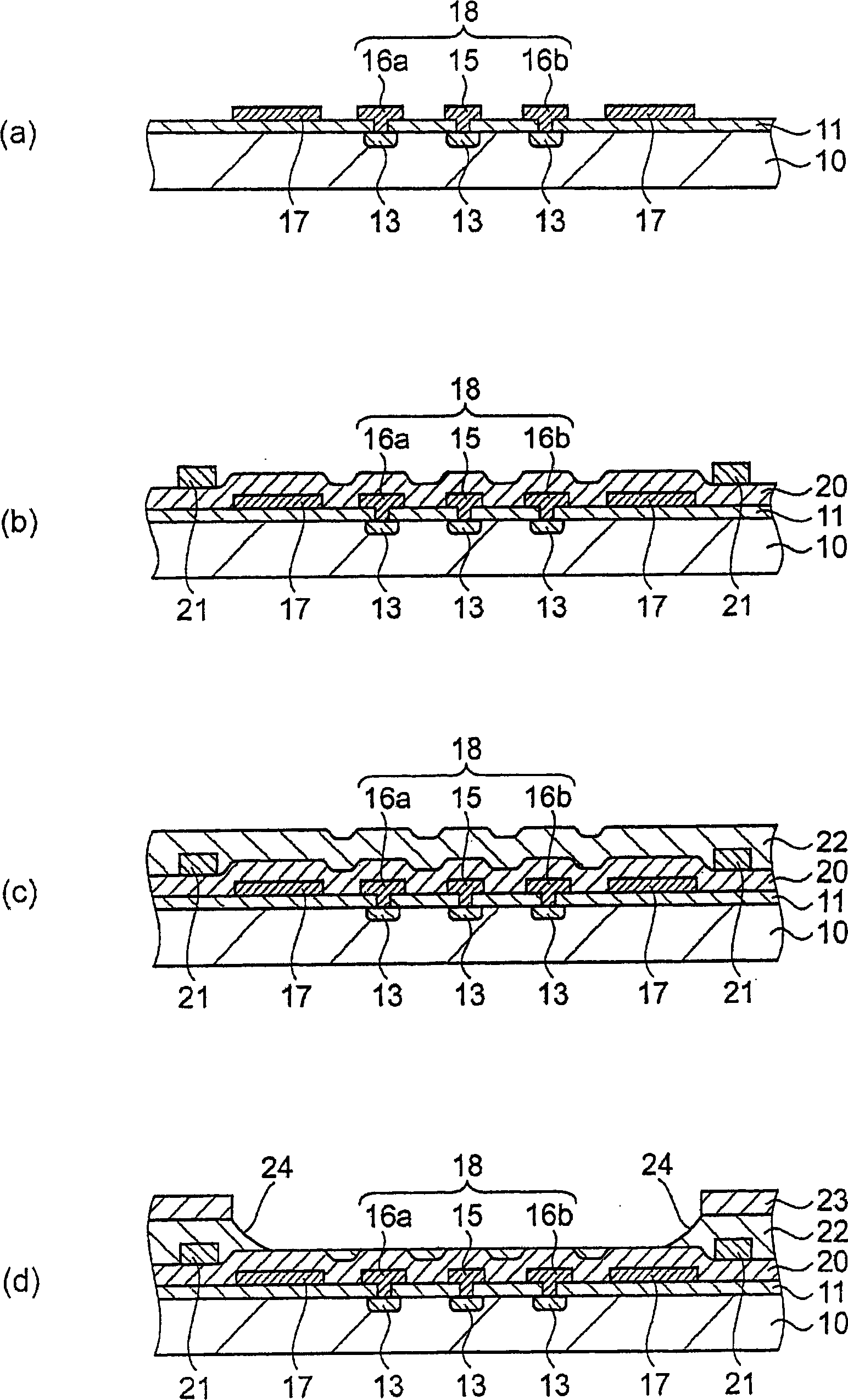

Mems device and manufacturing method of mems device

InactiveCN1821050AExcellent moisture resistanceImprove reliabilityDecorative surface effectsChemical vapor deposition coatingSilicon nitrideEngineering

A MEMS device includes a wiring laminated through an interlayer insulating film on a semiconductor substrate, the interlayer insulating film partially opened up to an upper portion of the substrate, and a structure disposed in the opening, wherein on a sidewall of the interlayer insulating film exposed in the opening that faces the structure and on a surface of the uppermost layer of the interlayer insulating film, a silicon nitride film is formed.

Owner:SEIKO EPSON CORP

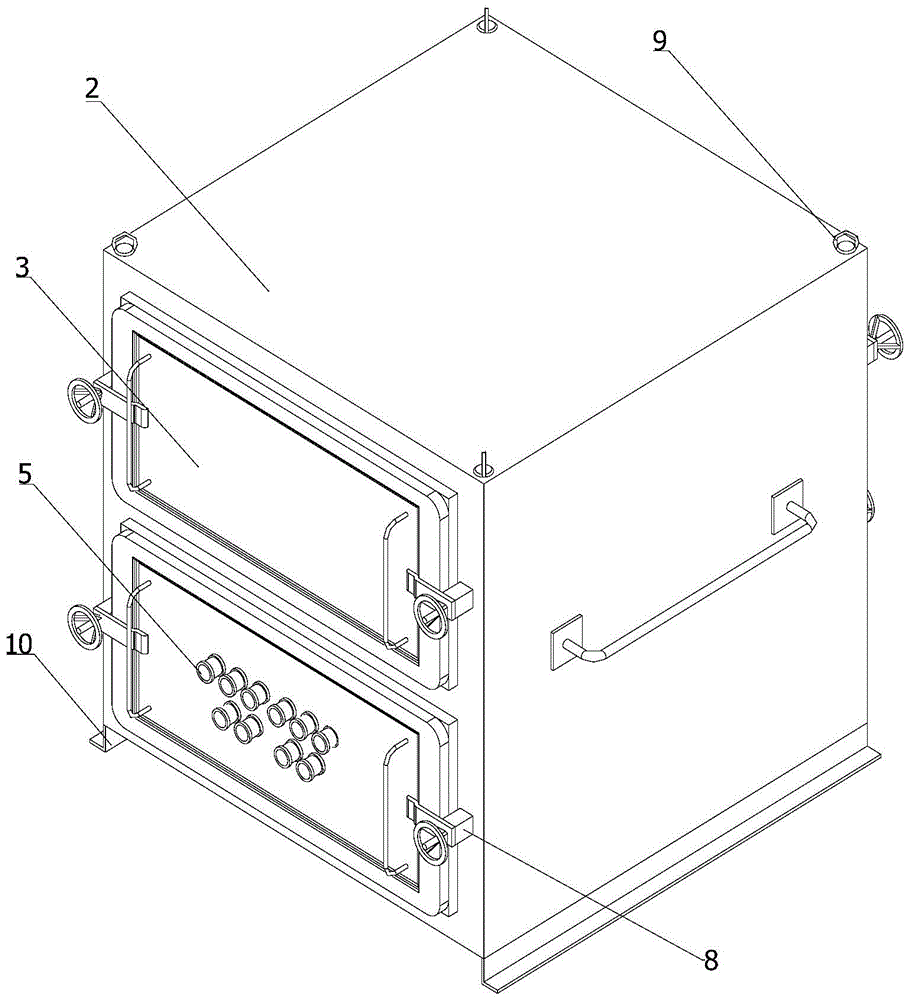

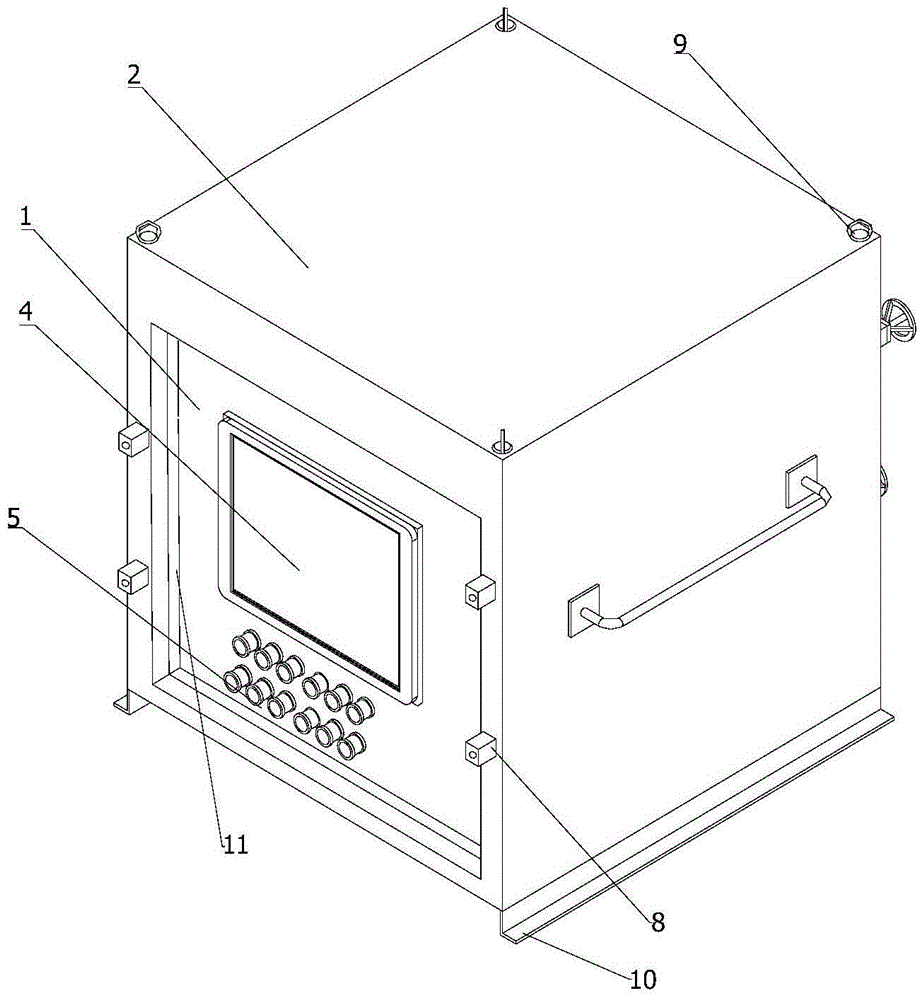

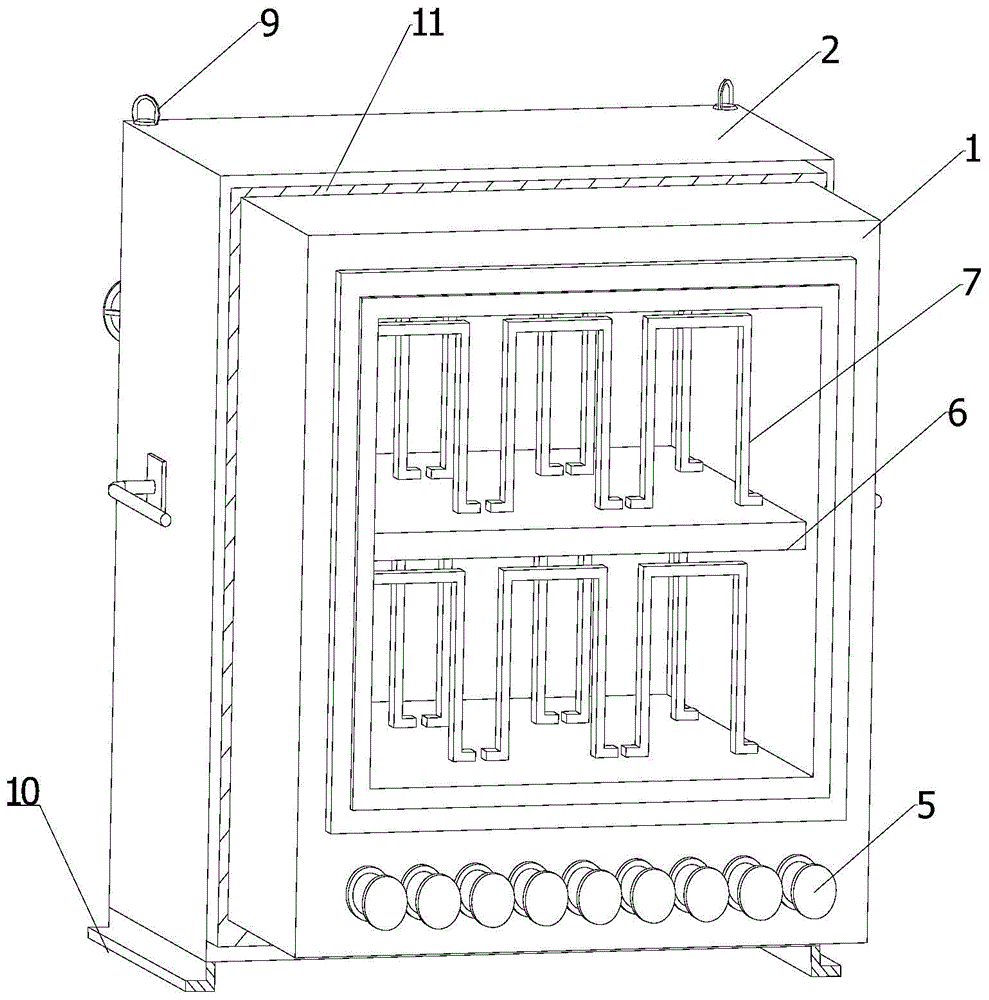

Double-layer moisture-proof electromagnetic shielding box

ActiveCN105050373AGood insulation performanceExcellent moisture resistanceMagnetic/electric field screeningEngineeringMoisture

The invention provides a double-layer moisture-proof electromagnetic shielding box and belongs to the shielding equipment field. The double-layer moisture-proof electromagnetic shielding box comprises an inner-layer box body and an outer-layer box body; a space between the inner-layer box body and the outer-layer box body is filled with a moisture-proof insulating material; the front side and the back side of the outer-layer box body are respectively provided with an upper outer-layer shielding door and a lower outer-layer shielding door; the four outer-layer shielding doors are detachably connected with the outer-layer box body respectively; the two lower outer-layer shielding doors are respectively provided with a plurality of waveguide tubes; the front side wall of the inner-layer box body is provided with an inner-layer shielding door and a plurality of waveguide tubes, wherein the plurality of waveguides tube are located below the inner-layer shielding door; the rear side wall of the inner-layer box body is provided with two inner-layer shielding doors, wherein the lower inner-layer shielding door is provided with a plurality of waveguide tubes; and a plurality of layers of separation boards are arranged in the inner-layer box body. With the double-layer moisture-proof electromagnetic shielding box of the invention adopted, the technical problems of poor moisture-proof effect and poor interior insulation effect of a shielding box in the prior art can be solved.

Owner:CHANGZHOU HUAMING ELECTRONICS EQUIP +1

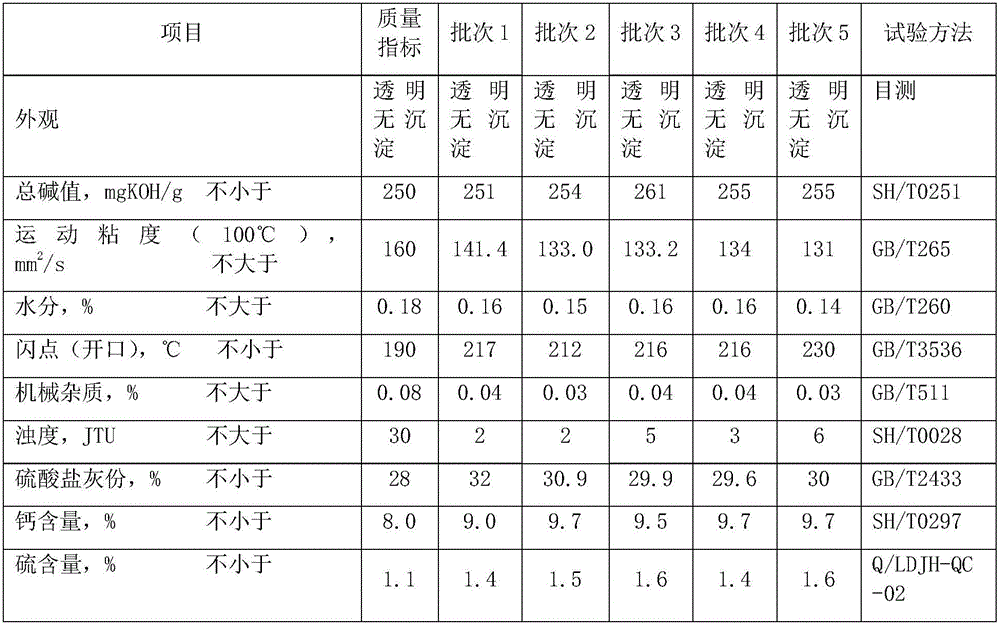

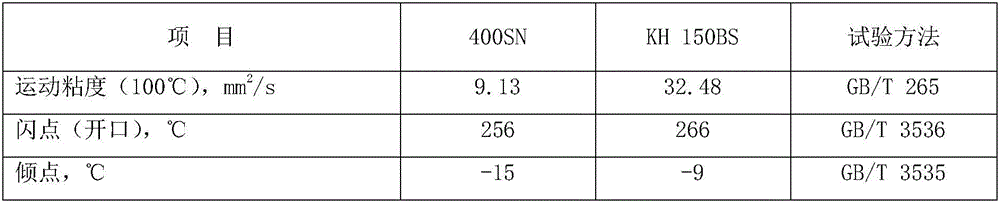

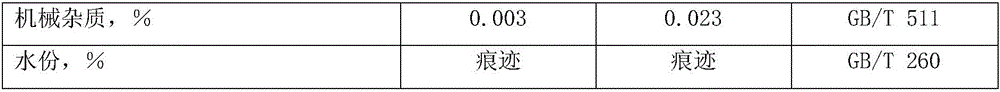

Marine cylinder oil compound additive and its production method and marine cylinder oil prepared from marine cylinder oil compound additive

InactiveCN106544080AExcellent moisture resistanceGood moisture resistanceAdditivesChemistryQuality level

The invention discloses a marine cylinder oil compound additive and its production method and marine cylinder oil prepared from the marine cylinder oil compound additive. The compound additive adopts naphthenate as a main agent. Compared with sulfonate, sulfurized alkyl phenate and salicylate, naphthenate has excellent water resistance, a high acid neutralization speed and good diffusibility. The marine cylinder oil compound additive is a good raw material for production of marine cylinder oil. The naphthenate as a main agent and sulfurized alkyl phenate and salicylate as auxiliary agents display their respective advantages and produce synergism so that the compound additive has good water resistance, diffusibility, a high acid neutralization speed, abrasion resistance and cleanliness. The 70TBN marine cylinder oil prepared from the marine cylinder oil compound additive reaches a foreign reference oil quality level in physical and chemical analysis and simulation assessment.

Owner:XINJIANG KUITUN NEW PETROCHEM

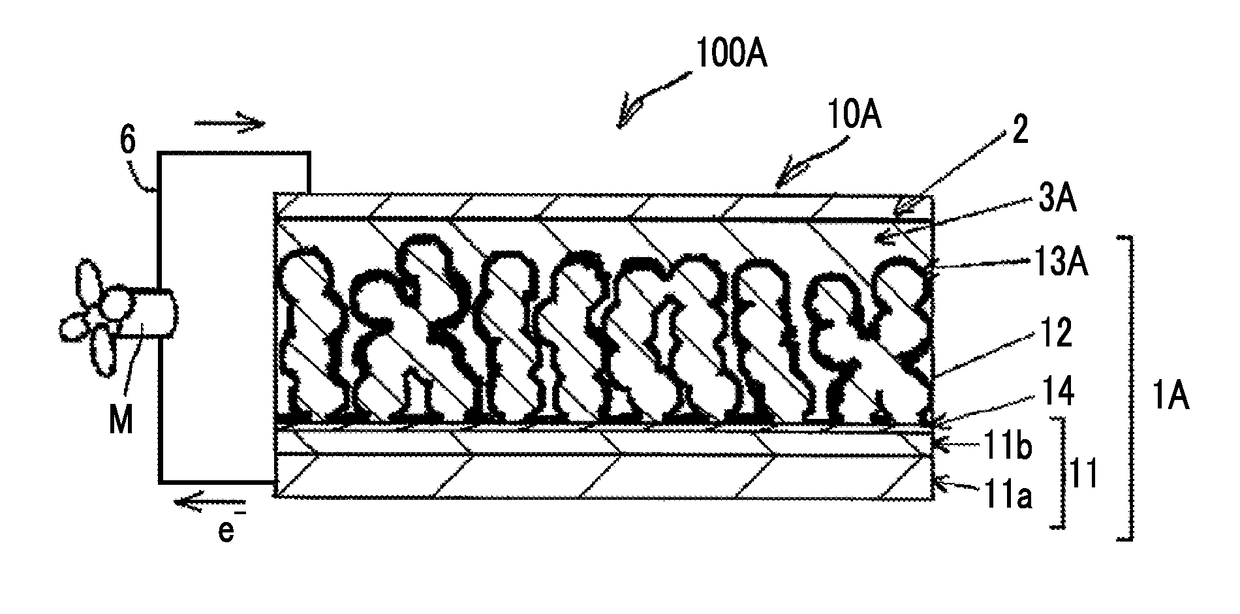

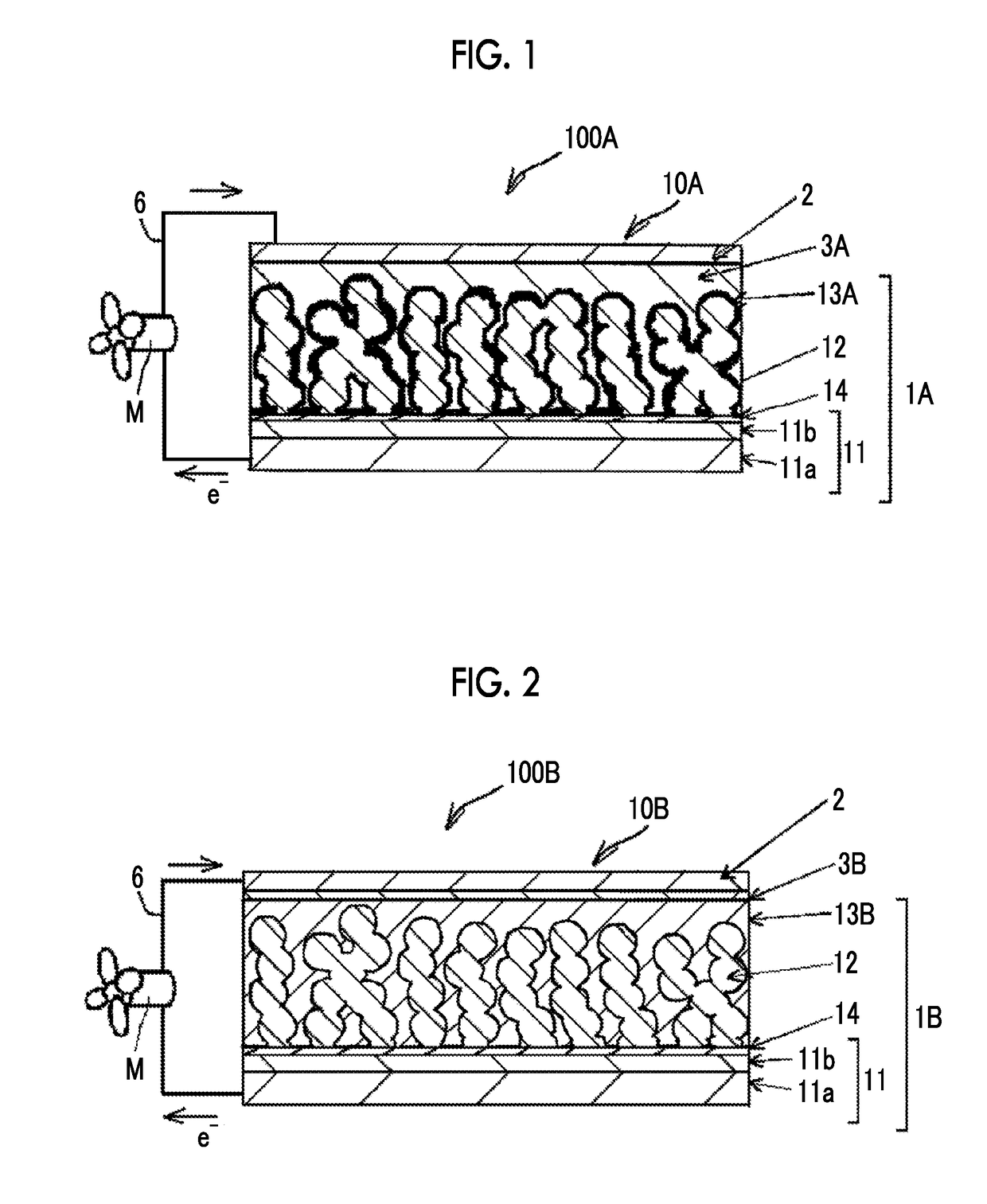

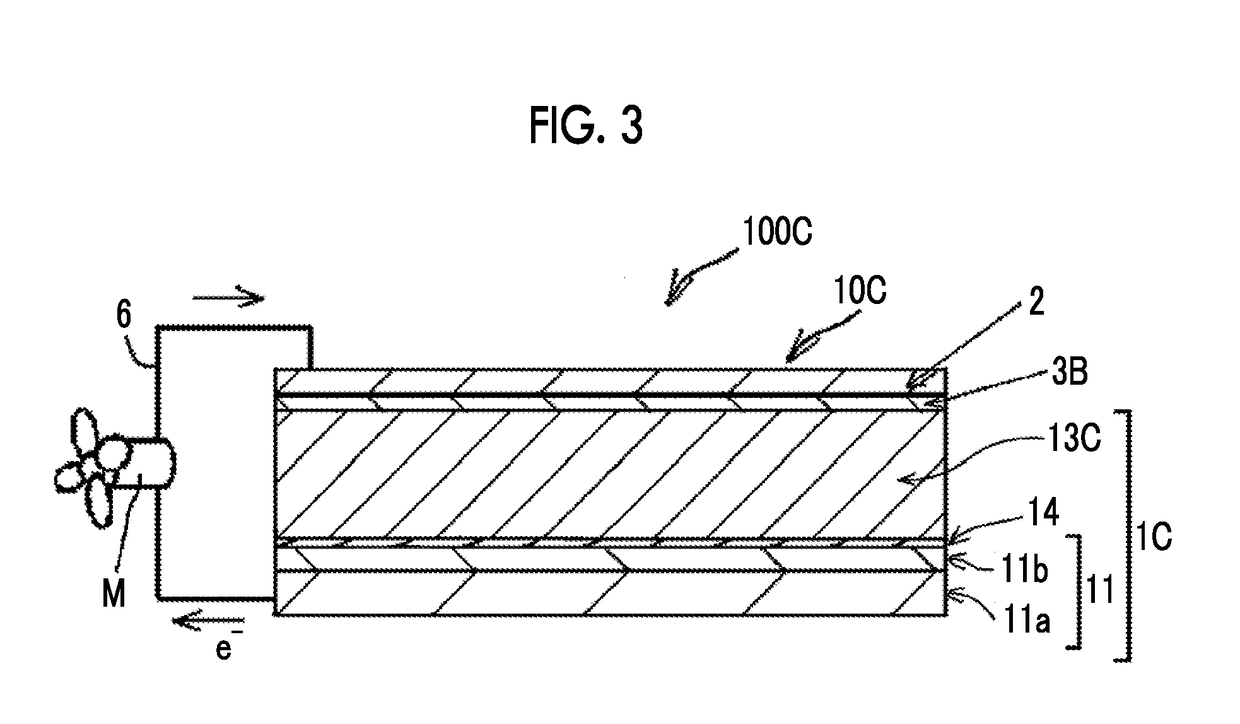

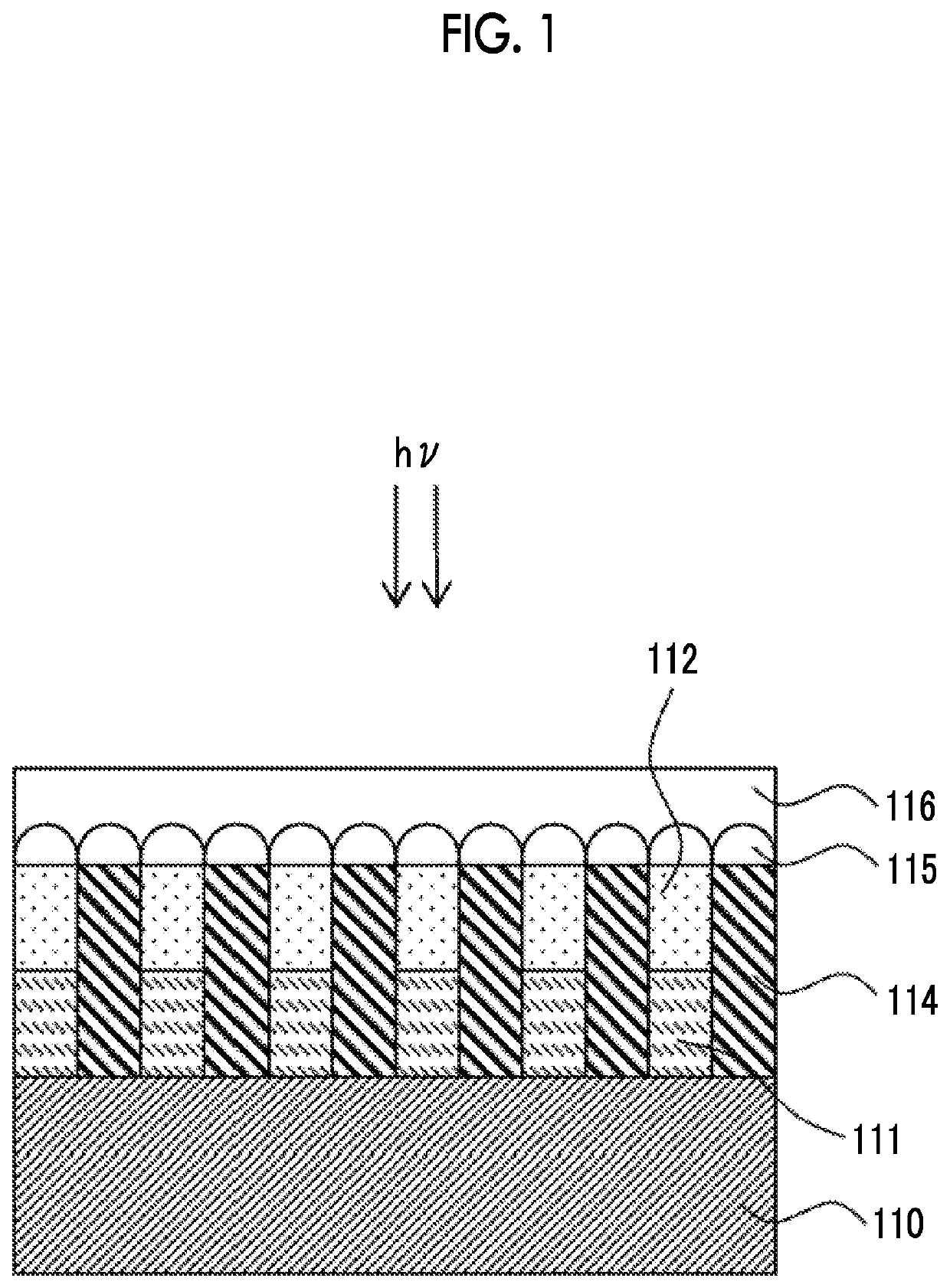

Photoelectric conversion element, solar cell, and method for manufacturing photoelectric conversion element

InactiveUS20170256364A1Stable cell performanceExcellent moisture resistanceLight-sensitive devicesFinal product manufactureIonOrganic solvent

A photoelectric conversion element including: a first electrode having a photosensitive layer including a light absorber on a conductive support; a second electrode facing the first electrode; and a hole transport layer provided between the first and the second electrodes, in which the light absorber includes a compound having a perovskite-type crystal structure having a cation of Group 1 element of the periodic table or a cationic organic group A, a cation of a metallic atom M that is not Group 1 element of the periodic table, and an anion of an anionic atom X, and an organic solvent content per cubic millimeter of the hole transport layer is 1×10−10 to 1×10−7 mol, a solar cell using this photoelectric conversion element, and a method for manufacturing a photoelectric conversion element including a step of applying a hole-transporting material solution and drying the solution at 40° C. to 180° C.

Owner:FUJIFILM CORP

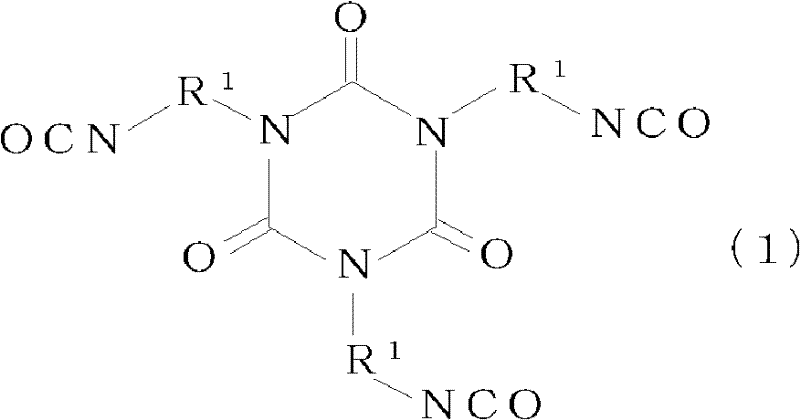

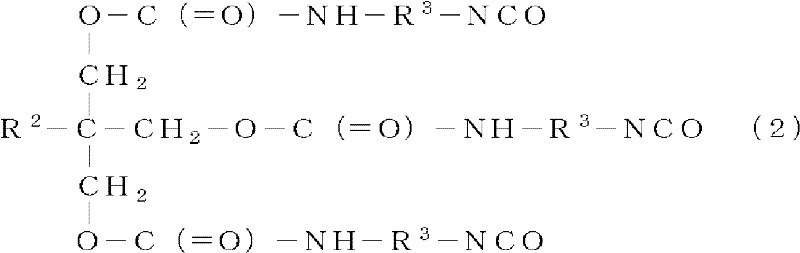

Non-water-based for plastic film provided with active energy line curing film and plastic film provided with active energy line curing film

InactiveCN102408823AExcellent moisture resistanceGood dryingSynthetic resin layered productsPolyurea/polyurethane coatingsChemical compoundEngineering

The invention provides a novel base coat capable of forming a base coat layer and characterized by non-water base, adhesiveness and moisture resistance of the base coat layer and the curing film and plastic film formed by an active energy line curing film are excellent. As the base coat, a composition comprising the following ingredients is provided: a branched polyester resin (A) provided with a hydroxyl group, a compound (B) provided with an active energy line polymerizability functional group and a hydroxyl group, and a polyisocyanate (C) provided with at least three isocyanate groups.

Owner:ARAKAWA CHEM IND LTD

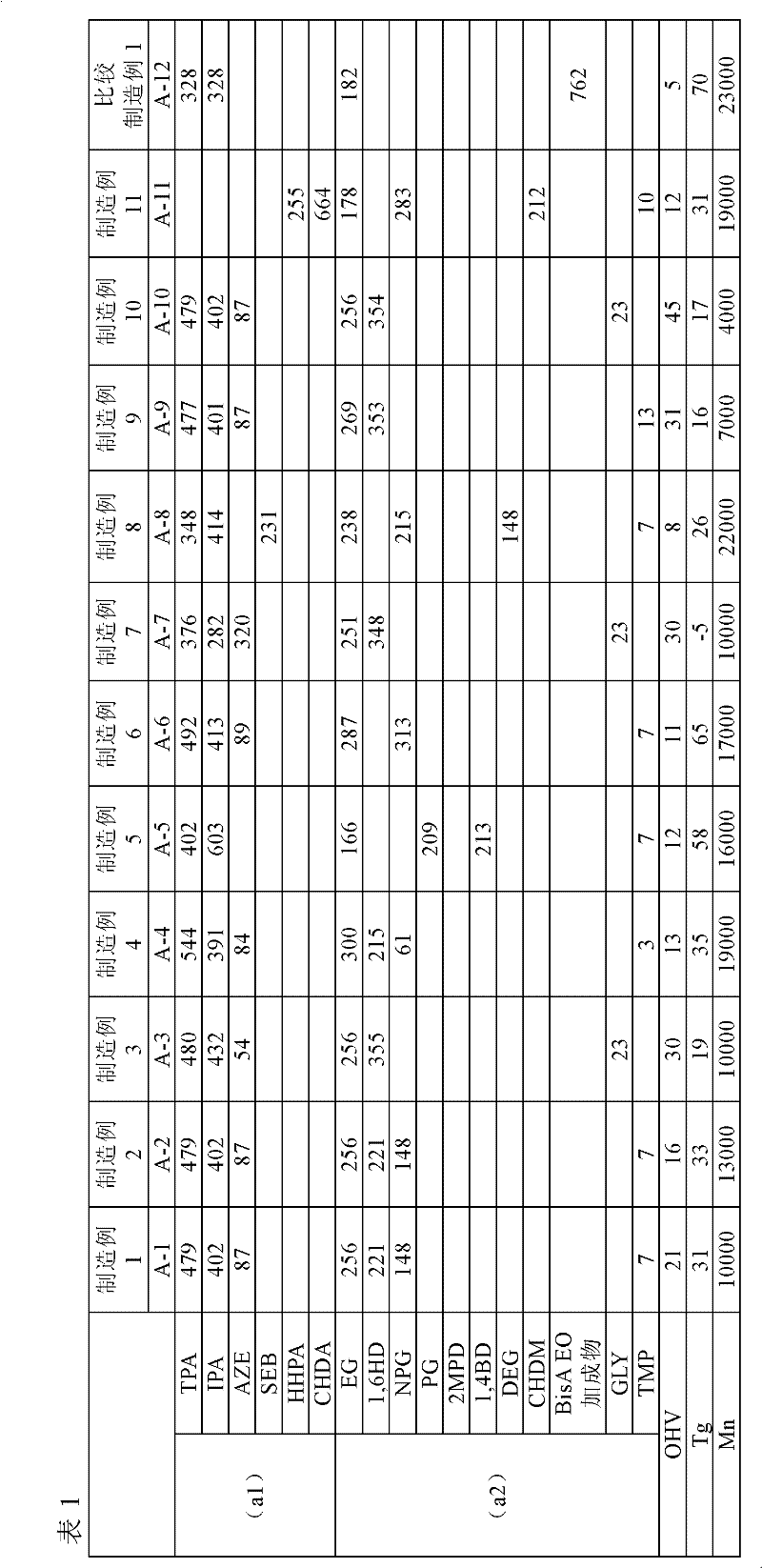

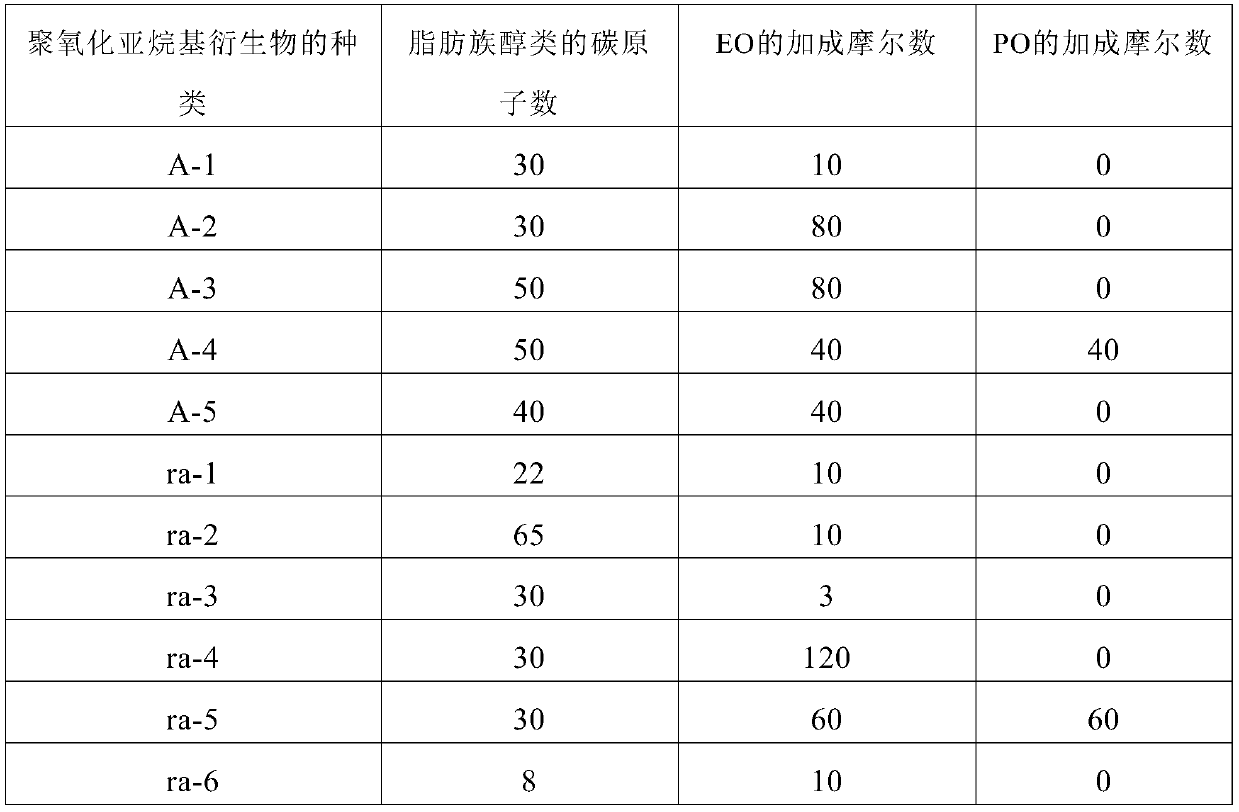

Treatment agent for polyolefin-based synthetic fibers, and polyolefin-based synthetic fiber

ActiveCN111247289AImprove passabilityExcellent initial hydrophilicityFibre typesPolymer sciencePolyolefin

A treatment agent for polyolefin-based synthetic fibers according to the present invention is characterized by comprising a polyoxyalkylene derivative as mentioned below and a linear hydrocarbon compound as mentioned below. The polyoxyalkylene derivative is a compound in which at least one oxide selected from ethylene oxide and propylene oxide is added at a ratio of 5 to 100 moles relative to 1 mole of a monovalent aliphatic alcohol having 24 to 60 carbon atoms. The linear hydrocarbon compound is a linear hydrocarbon compound having 10 to 100 carbon atoms. A polyolefin-based synthetic fiber according to the present invention is characterized by having, attached thereto, the treatment agent for polyolefin-based synthetic fibers.

Owner:TAKEMOTO YUSHI KK

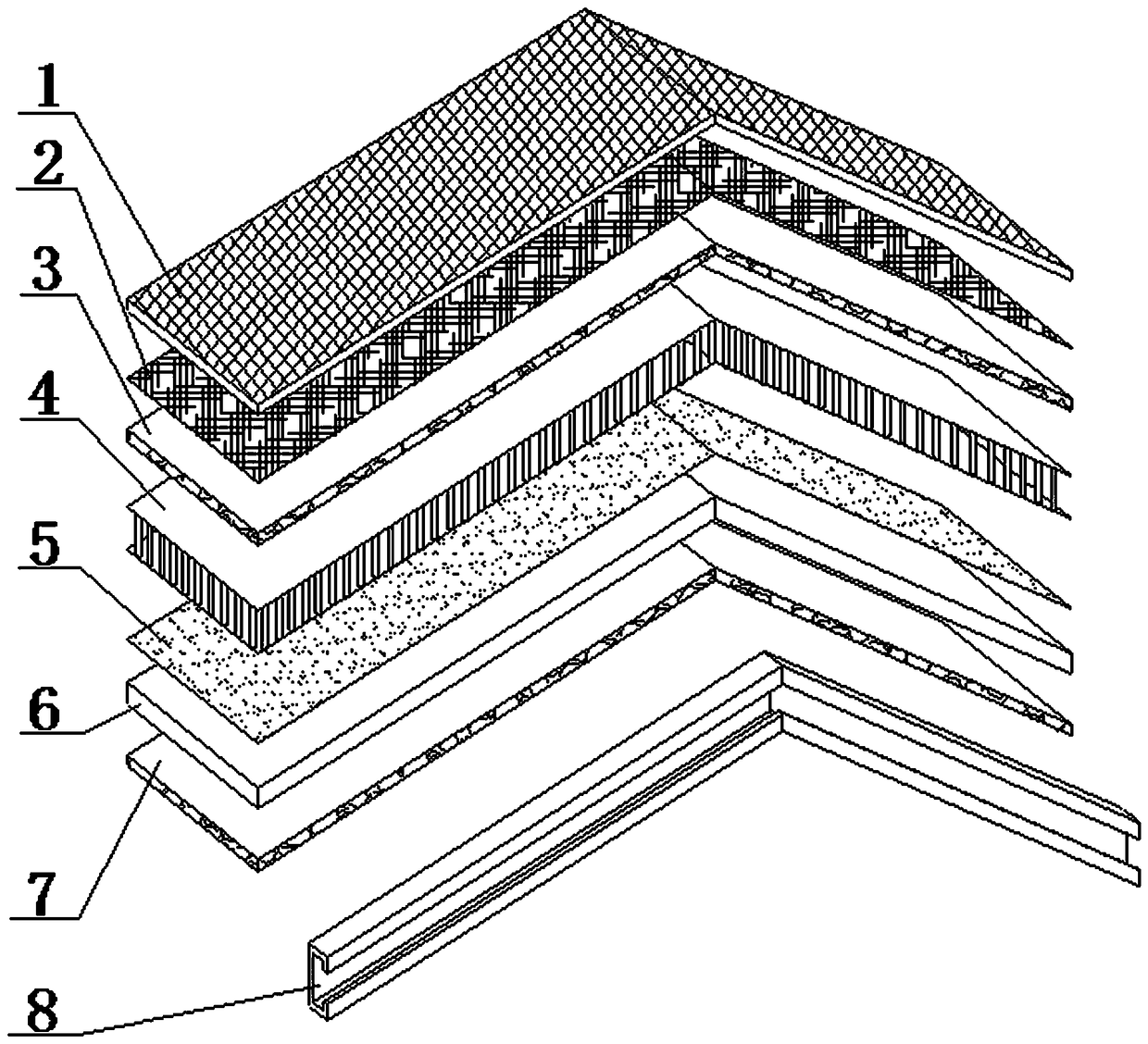

Roof of light steel structure house

PendingCN109339327AReasonable structureGood wind and shock resistanceBuilding roofsBuild-up roofsEarthquake resistanceThermal insulation

The invention discloses a roof of a light steel structure house. The roof from inside to outside is a light steel keel, roof OSB boards, an insulating layer, a ventilation layer, roof OSB boards, a waterproof layer and roof asphalt tiles. The light steel keel is filled with heat preservation and thermal insulation material, a wooden keel is placed in the middle of the ventilation layer, and breathing paper is pasted close to the insulating layer. The roof of the light steel structure house is reasonable in structure, light and solid, capable of achieving heat preservation and thermal insulation, capable of achieving sound insulation and flame resistance, capable of achieving water insulation and wind resistance, good in wind resistance and earthquake resistance effect and capable of withstanding certain pressure without deformation and displacement.

Owner:黎金莲

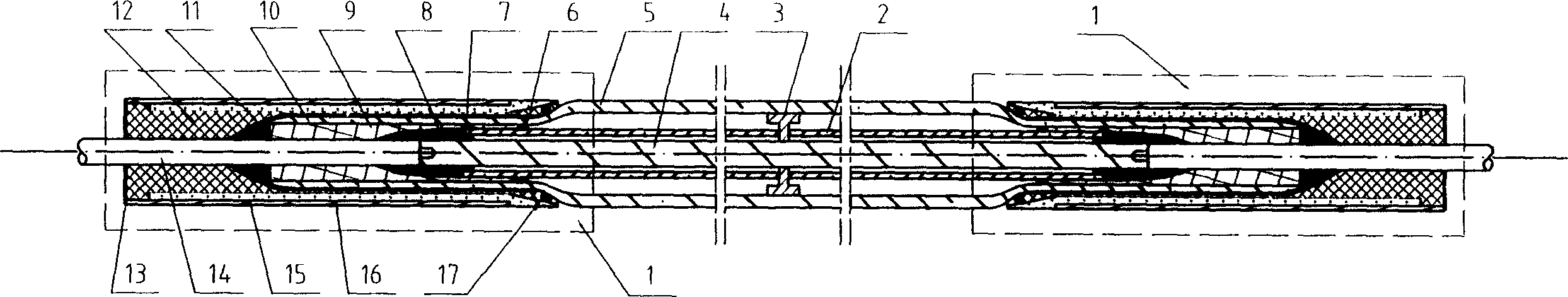

Moisture-regain-resistant drawing pigment and preparation method thereof

InactiveCN112442293AGood water permeabilityImprove water absorptionArtist's paintsPlant GumsMoisture regain

The invention discloses a moisture-regain-resistant drawing pigment in the technical field of pigments. The pigment is prepared from the following raw material components in parts by weight: 50-60 parts of acrylic emulsion, 5-10 parts of diatomite, 5-10 parts of talcum powder, 8-12 parts of toner, 5-10 parts of vegetable gum, 5-8 parts of thickener, 5-8 parts of humectant, 0.3-0.5 part of dispersing agent, 3-8 parts of film-forming agent, 0.03-0.06 part of preservative and 10-15 parts of water. The moisture-regain-resistant drawing pigment of the invention can absorb moisture in the air, so that the moisture regain resistance of the pigment is improved, and the fading time of the pigment is prolonged.

Owner:扬州市创开轩文化用品有限公司

Insulating material for power maintenance protective garment

ActiveCN105506829AImprove practicalityImprove insulation performanceFibre typesHeating/cooling textile fabricsYarnPolyester

The invention relates to an insulating material for a power maintenance protective garment. The insulating material is a polyester terphthalate fiber fabric which comprises warps and wefts, the weight of the polyester terphthalate fiber fabric is 15-30g / m<2>, any one of the warps and the wefts is 90 or more in denier and thicker than the other one, and yarn density of the thicker yarns in a unit length is smaller than that of other yarns in the unit length. At least one of the warps and the wefts is formed by twin yarns with filament diameter being 0.005-0.010mm. The insulating material for the power maintenance protective garment is an electrical insulating fabric with an excellent insulating performance and excellent anti-mildew, anti-dampness and chemical resistance performances and has the advantages of high weather resistance, high strength, abrasion resistance, heat conduction, antibacterial performance, freeness of toxicity and environment friendliness.

Owner:YONGKANG ELECTRIC POWER EQUIP FACTORY +1

Moisture-proof and antibacterial coating

InactiveCN106009940AExcellent moisture resistanceGood antibacterial abilityAntifouling/underwater paintsPaints with biocidesPolypropyleneChemistry

The invention discloses a moisture-proof and antibacterial coating, which comprises the following components in proportions: 18-20 parts of hydroxyethyl cellulose; 13-18 parts of cyclic olefin copolymer; 15-22 parts of silver-zinc titanium dioxide; and 12-22 parts of tributyl phosphate. 14 parts; 8-14 parts of polypropylene; 6-10 parts of calcium carbonate; 4-7 parts of antioxidant; 2-3 parts of dispersant; 2-5 parts of thickener. Through the above method, the moisture-proof and antibacterial coating of the present invention can be well attached to various substrates, and has superior moisture-proof and antibacterial ability, and will not harm human health, and will not be caused by other external factors. Peeling and fading.

Owner:SUZHOU MINGXUAN FLOORING COATINGS

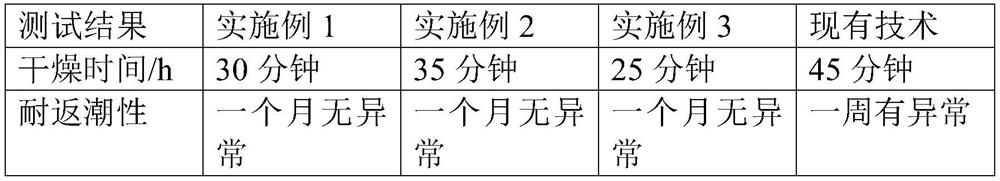

High power and high capacity pulse dummy lamp

InactiveCN1671015AGuaranteed uptimeAvoid Vertical ShakeLaser detailsGas discharge lampsEngineeringCopper

A high power high load pulse imitation lamp, which contains lamp tube and two symmetrically set same lamp adapters, wherein a hollow ring set in center of lamp tube penetrated with solid copper bar, two same quartz tubes set between solid copper bar and lamp tube, the outer layer of lamp adapter is metal sleeve, electrode lead wire with copper connector set in lamp adapter center position, they are all adopted the multi-layer structure. Said invention has advantages of simple structure, low cost, easy installation, safety and long service life.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

Anti-freezing white latex

InactiveCN109837042ANo freezingExcellent water resistanceMonocarboxylic acid ester polymer adhesivesNon-macromolecular adhesive additivesSodium bicarbonateChemical industry

The invention relates to the technical field of chemical industry production, particularly to an anti-freezing white latex capable of resisting low temperature, wherein the anti-freezing white latex comprises, by weight, 90-110 parts of polyvinyl acetate, 60-80 parts of vinyl acetate, 30-40 parts of polyvinyl alcohol, 10-15 parts of acrylic acid, 6-13 parts of butyl acrylate, 10-15 parts of ammonium persulfate, 30-40 parts of diethylene glycol dibenzoate, 15-25 parts of sodium bicarbonate, 10-15 parts of dibutyl phthalate, 0.5-3 parts of an emulsifier, and 60-80 parts of water, wherein the acrylic acid is sulfuric acid acrylic acid, and the polyvinyl alcohol is polyvinyl butanol.

Owner:菏泽双鑫装饰材料有限公司

PVC thin film laminated waterproof fabric

InactiveCN107904979AGood waterproof effectExcellent moisture resistanceTextile decorationBrown iron oxideN-Butyl acetate

The invention discloses a PVC thin film laminated waterproof fabric. The PVC thin film laminated waterproof fabric comprises a fabric layer, a coating layer, a thin film layer and an adhesive pressinglayer; the specific formula of each layer of the material is as follows: the fabric layer is prepared from the following components in percentage by mass: 50 to 75 percent of polyacrylic acid-2-ethylhexyl ester fibres, 20 to 40 percent of polymethyl methacrylate fibres and 20 to 35 percent of polyester fibres; the coating layer comprises the following components in percentage by mass: 40 to 60 percent of butyl acetate, 15 to 25 percent of dibutyltin dilaurate, 10 to 15 percent of iron oxide red, and 10 to 20 percent of polyacrylamide; the thin film layer is prepared from the following components in percentage by mass: 40 to 60 percent of PVDF, 30 to 40 percent of sulfonyl succinate and 20 to 35 percent of alumina powder; the adhesive pressing layer is prepared from the following components in percentage by mass: 45 to 85 percent of hydrogenated nitrile rubber, 8 to 16 percent of zinc oxide and 20 to 30 percent of acetone. According to the PVC thin film laminated waterproof fabric, awaterproof effect can be improved through a four-layer structure; the thin film layer arranged on the coating layer can prevent the coating from being worn greatly after long-term use.

Owner:CHENGDU JIELEI SHADING ENG CO LTD

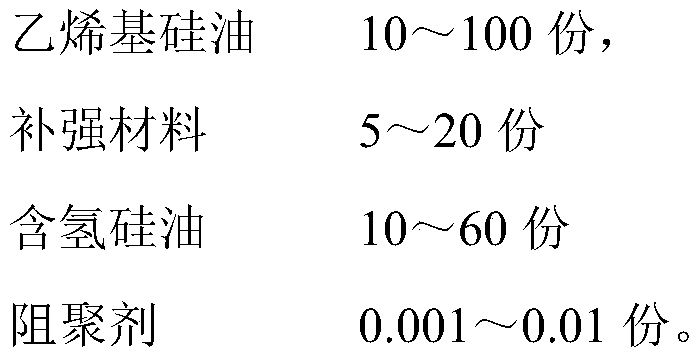

High pressure resistant silicone gel for IGBTs and preparation method thereof

InactiveCN110862692AHigh dielectric strengthSolve the technical problems that cannot meet the potting requirements of IGBT high-voltage modulesSilicone GelsPolymer science

The invention discloses high pressure resistant silicone gel for IGBTs. The silicone gel includes multiple components which are an A component and a B component with the mass ratio being (1 : 1)-(6 :1); the A component includes vinyl silicone oil, modified silicone oil and a catalyst; and the B component includes the vinyl silicone oil, a reinforcing material, hydrogen-containing silicone oil anda polymerization inhibitor. A preparation method of the silicone gel is also disclosed. The dielectric strength of the silicone gel is high (the dielectric strength is greater than or equal to 30 KV / mm), so that the technical problems, that silicone gel on the market cannot satisfy the encapsulation requirements of IGBT high-voltage modules, can be solved.

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

Low-temperature-resistant white latex

InactiveCN109836863ANo freezingExcellent water resistanceCoatingsSodium bicarbonateChemical industry

The invention relates to the technical field of chemical industry production, particularly to a low-temperature-resistant white latex, which comprises, by weight, 300 kg of polyvinyl acetate, 100 kg of vinyl acetate, 80 kg of polyvinyl alcohol, 30 kg of ethylene dimethacrylate, 10 kg of dibutyl phthalate, 35 kg of alkenyl ethyl methacrylate, 15 kg of sodium bicarbonate, 5 kg of an emulsifier, 20 kg of methylol acrylamide, and 55 kg of water, wherein the emulsifier is sodium tetradecylbenzene sulfonate, the polyvinyl alcohol is polyvinyl propanol, the polyvinyl alcohol is polyvinyl octanol, andthe polyvinyl alcohol is a mixture of polyvinyl propanol and polyvinyl octanol.

Owner:菏泽双鑫装饰材料有限公司

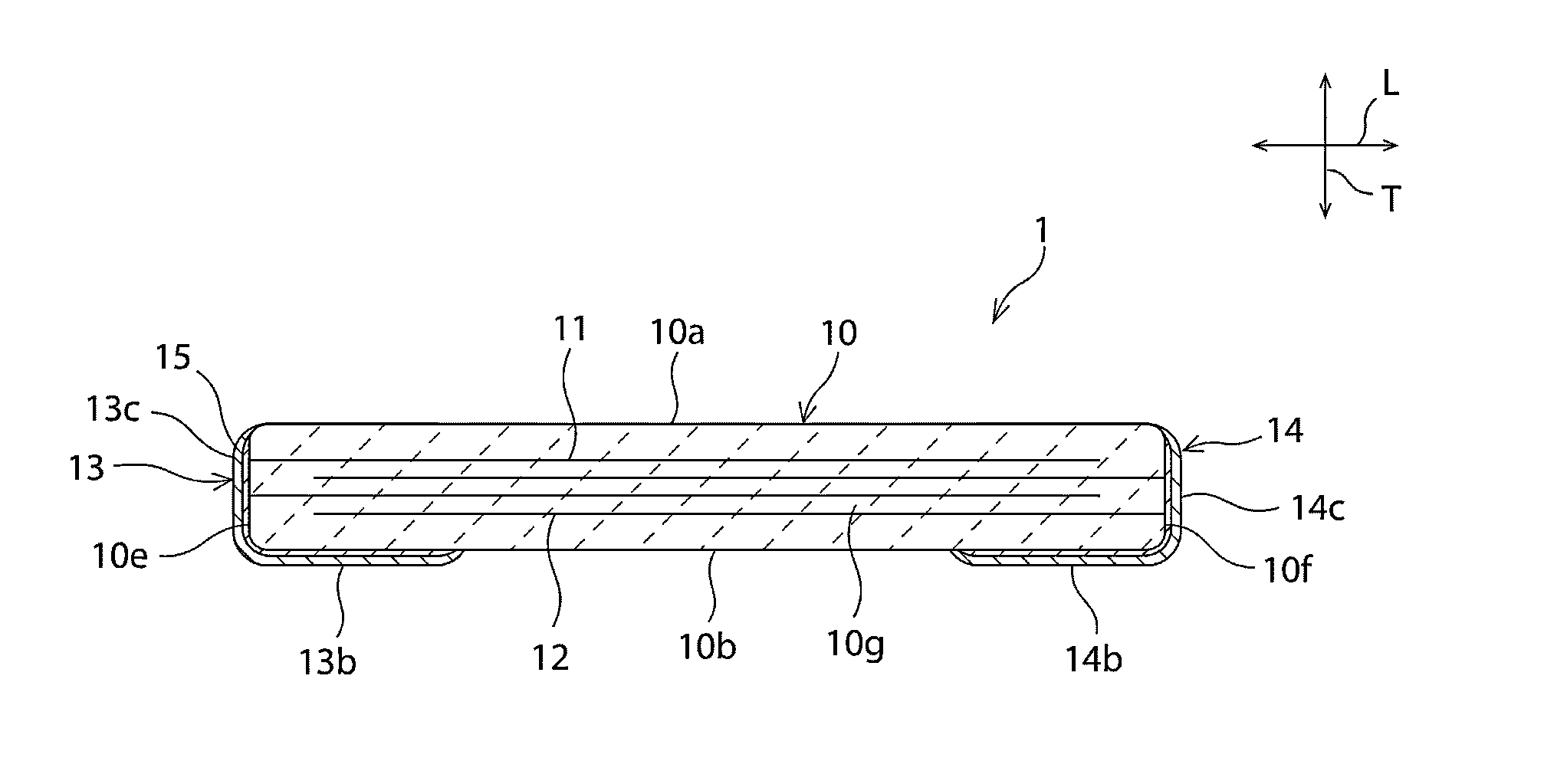

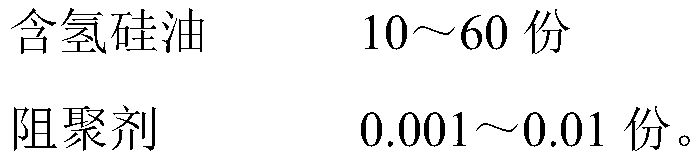

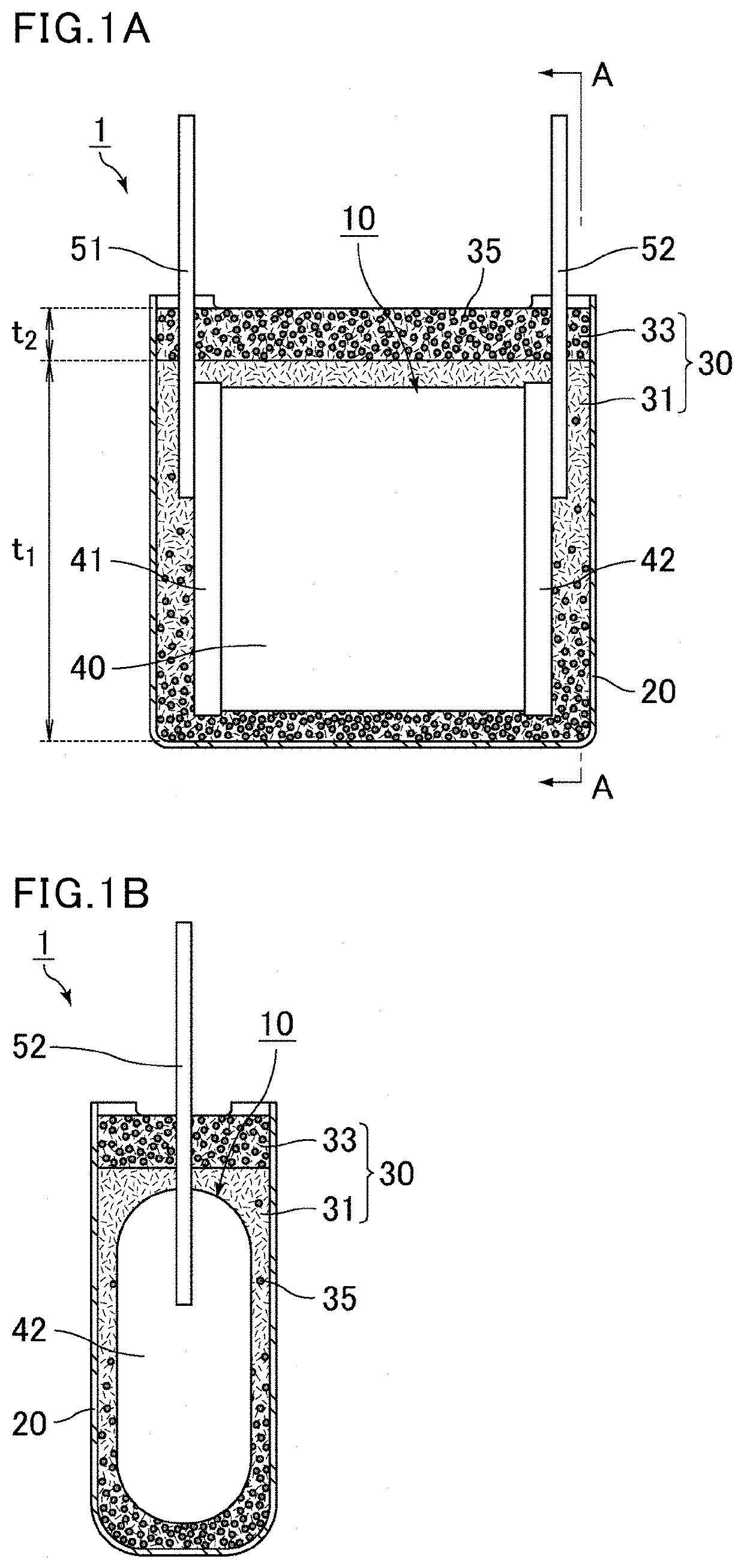

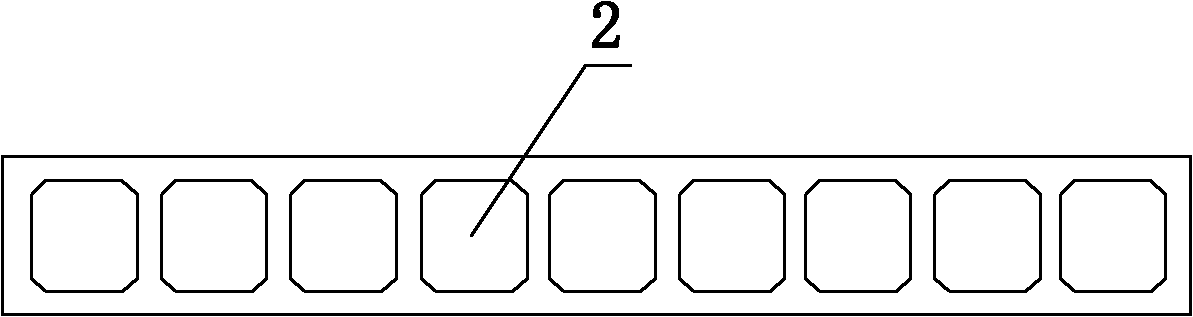

Film capacitor

PendingUS20220115183A1Excellent moisture resistanceProduction cost be suppressStacked capacitorsFixed capacitor housing/encapsulationFilm capacitorMaterials science

A film capacitor that includes: an outer case defining an opening; a capacitor element within the outer case, the capacitor element including one or more metallized films, each metallized film including a resin film and a metal layer on a surface of the resin film; and a filling resin that fills a space between the capacitor element and the outer case, wherein the filling resin includes a first filling resin layer surrounding the capacitor element and a second filling resin layer disposed closer to the opening of the outer case than the first filling resin layer, the first filling resin layer and the second filling resin layer are made of the same resin and each contain a filler, and a filler content of the second filling resin layer is higher than a filler content of a portion of the first filling resin layer opposing the second filling resin layer.

Owner:MURATA MFG CO LTD

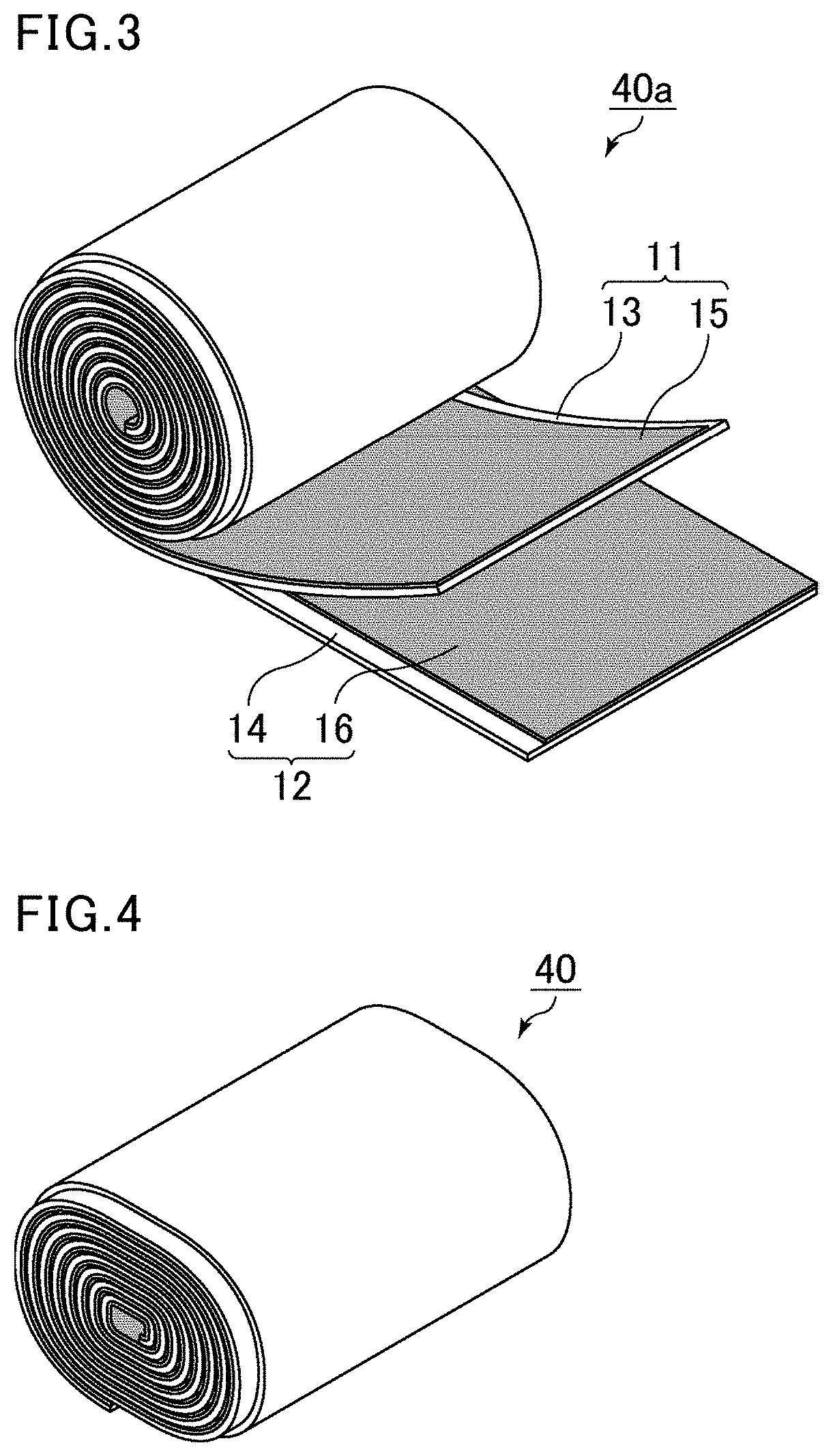

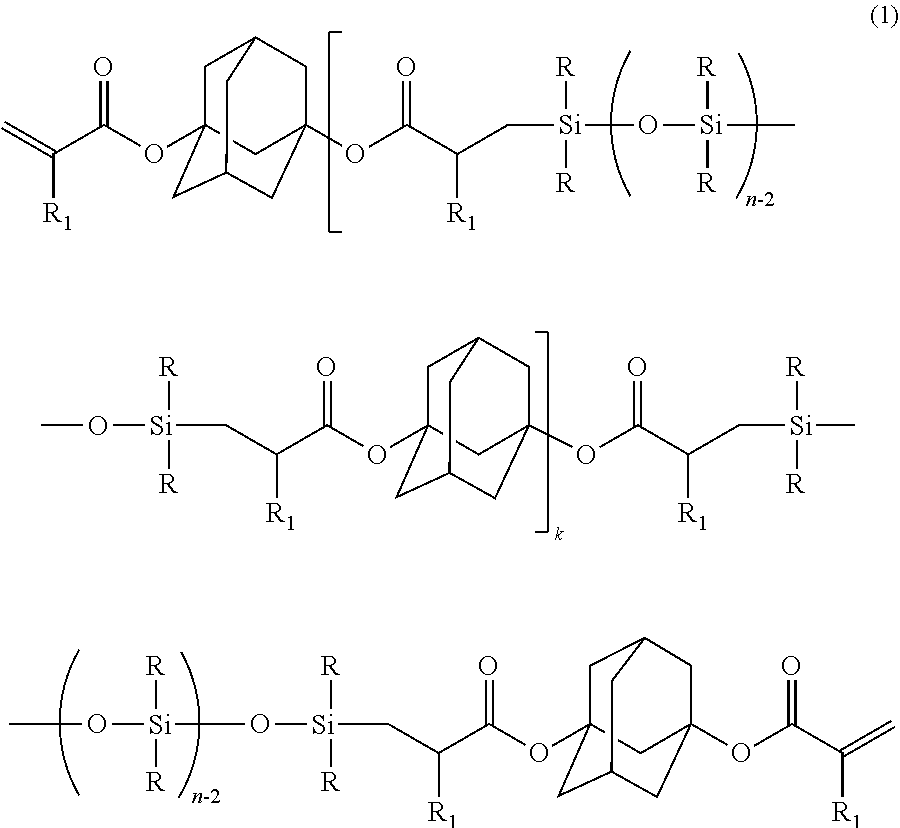

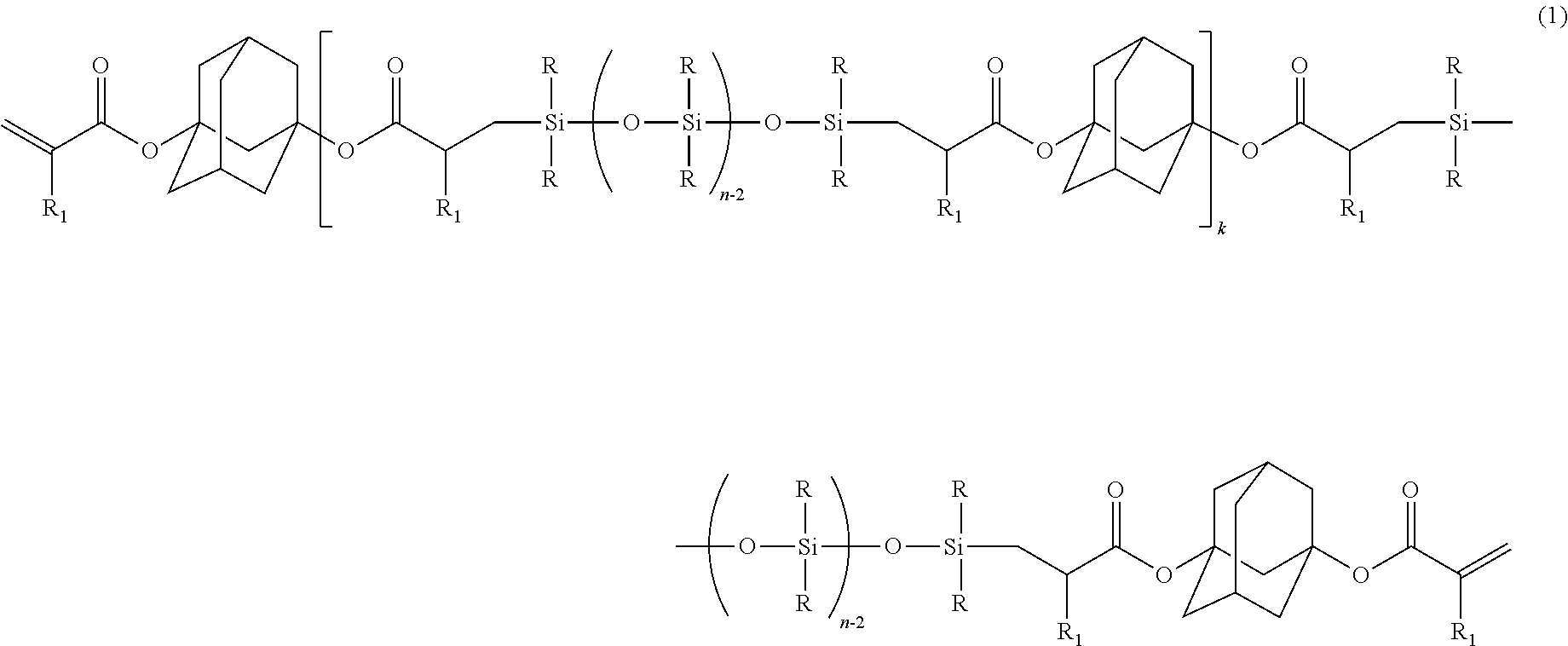

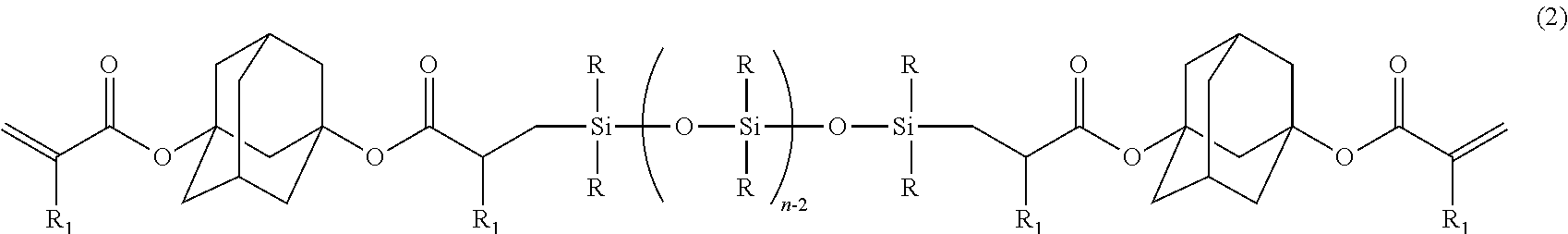

Silicone-modified adamantane derivative, photo-radically curable resin composition, and method for preparing photo-radically curable resin composition

ActiveUS20120136086A1Suppression of recrystallizationExcellent moisture resistanceSilicon organic compoundsCoatingsPhenyl groupChemistry

There is disclosed a silicone-modified adamantane derivative represented by the following general formula (1),Wherein each R1 independently represents a hydrogen atom or methyl group; each R independently represents a methyl group or phenyl group; n represents an integer from 2 to 1,000; and k represents a number of 0 to 2. There can be a photo-radically curable resin composition by adopting a novel and specific silicone-modified adamantane derivative, which composition is cured by photoirradiation even at a lower intensity of illumination, thereby enabling to obtain a cured product exhibiting not only an excellent moisture resistance but also an excellent adhesiveness to various substrates.

Owner:SHIN ETSU CHEM IND CO LTD

Butadiene styrene rubber-containing interior decoration strip

InactiveCN106700161AExcellent moisture resistanceFormula cost control is reasonableChemistryButadiene-styrene rubber

The invention discloses a butadiene styrene rubber-containing interior decoration strip which consists of the following raw materials in parts by weight: 80-90 parts of styrene butadiene rubber, 18-22 parts of decabromodiphenyl ether, 55-65 parts of water, 8-10 parts of white oil, 1-3 parts of ethylene glycol lauryl amide, 6-8 parts of kaolin, 4-6 parts of a fluorescent whitening agent, and 3-4 parts of a polyurethane environmental-protection catalyst. The butadiene styrene rubber is used as a main material, so the interior decoration strip has excellent performance of light weight, high strength, damp prevention, thermal insulation, good processability and the like, and has significant social and economic benefits.

Owner:袁智豪

Method for preparing quick-dry long-term anti-rust oil

The invention relates to the technical field of anti-rust oil and discloses a method for preparing quick-dry long-term anti-rust oil. The method comprises the following steps: taking a blending kettleaccording with the volume specification according to the usage amount of materials needing to be blended, adding kerosene and petroleum ether into the blending kettle, raising the temperature to 45 DEG C by a heating device, and taking the materials for later use; and sequentially adding barium petroleum sulfonate, pentaerythritol oleate, sodium tetradecyl stearate and dioctyl phthalate into theblending kettle, and stirring with the previous prepared materials. According to the method for preparing the quick-dry long-term anti-rust oil, the aging resistance of the anti-rust oil can be effectively improved, and a certain effect of protecting aging of heat and oxygen is achieved, so that the metal surface can be fully protected even if in a long-term exposure process. The pour point can beimproved, the evaporation rate is increased, and the production cycle of the product is shortened, so that the anti-rust oil can achieve a rapid drying effect, and the preparation efficiency of the product is improved.

Owner:苏州功业肆点零智能科技有限公司

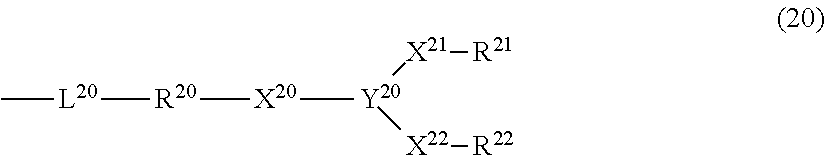

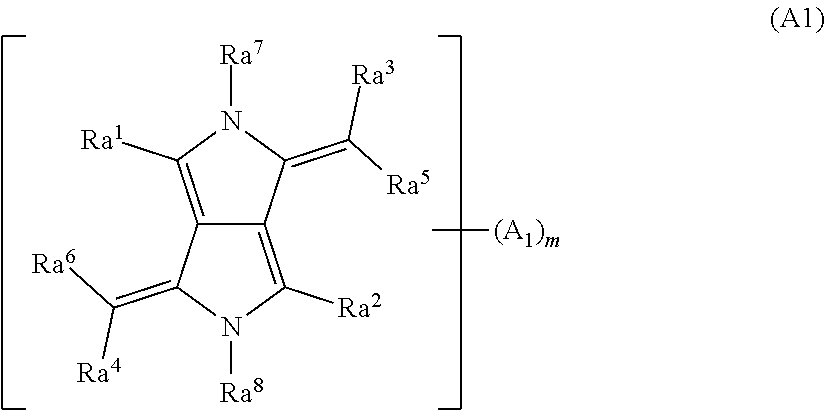

Curable composition, cured film, optical filter, solid image pickup element, image display device, infrared sensor, dispersing auxiliary agent, dispersion, and method of manufacturing dispersion

InactiveUS20200115382A1Excellent moisture resistanceExcellent dispersibilityMethine/polymethine dyesGroup 3/13 element organic compoundsAcid groupInfrared

Provided are a curable composition, a cured film, an optical filter, a solid image pickup element, an image display device, an infrared sensor, a dispersing auxiliary agent, a dispersion, and a method of manufacturing a dispersion. With the curable composition, a cured film having excellent moisture resistance in which the formation of an aggregate derived from a compound having a colorant skeleton is suppressed can be formed. This curable composition includes: a compound A having a structure in which at least one functional group selected from an acid group having a pKa of 3 or lower and a Clog P value of −1.1 or higher, an anionic group obtained by dissociating one or more hydrogen atoms from the acid group, or a salt of the acid group is bonded to a π-conjugated structure of a colorant skeleton and having a maximum absorption wavelength in a wavelength range of 650 to 1200 nm; a curable compound; and a solvent.

Owner:FUJIFILM CORP

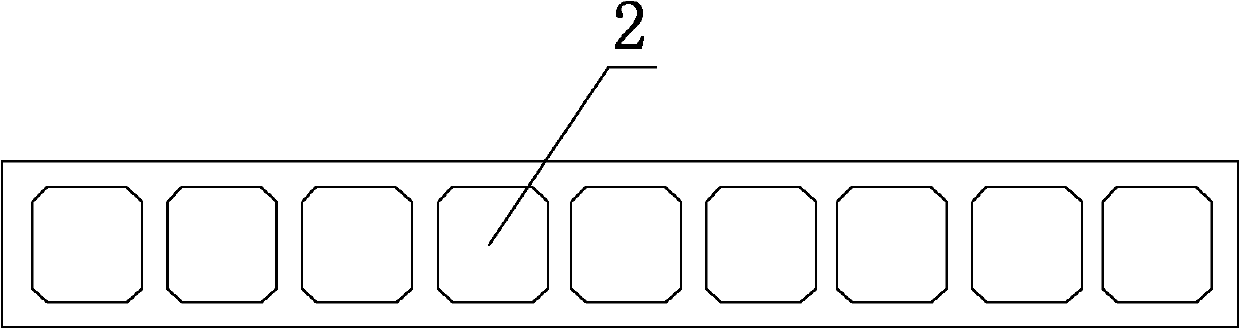

Plastic building template

InactiveCN101922232AAct as reinforcementStable structureForming/stuttering elementsFireproofingCorrosion

The invention relates to a plastic building template. The plastic building template comprises a cuboid body; and a through hole is formed inside the body along the long-side direction. The plastic building template replaces the traditional building template and has the advantages of humidity resistance, corrosion resistance, fireproofing, acid-alkali resistance, impact resistance, high strength, long service life and the like, while having the common use of the traditional building template; and moreover, the plastic building template can be recycled and the cost is greatly reduced.

Owner:常州市天绿塑业有限公司

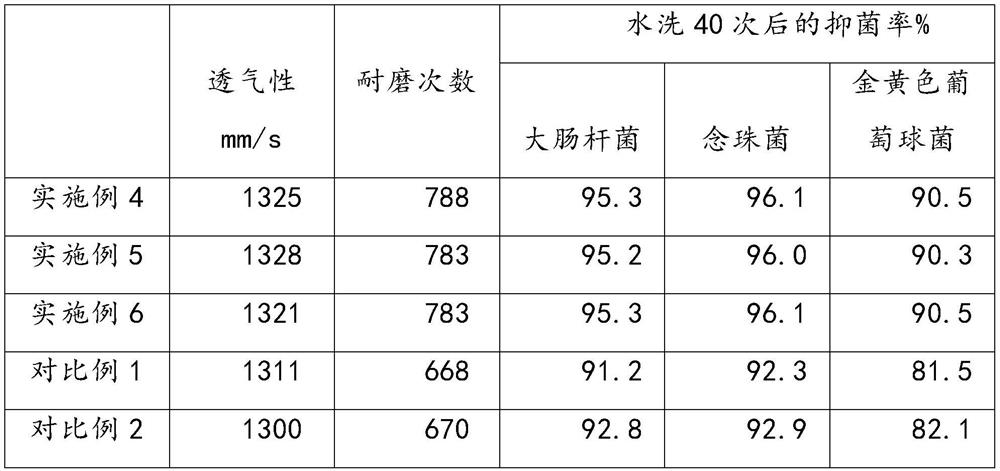

Wear-resistant textile fabric and preparation method thereof

PendingCN114753151AHigh strengthExcellent moisture resistanceBiochemical fibre treatmentAbrasion resistant fibresHemp fiberFlexible fiber

The invention relates to a wear-resistant textile fabric and a preparation method thereof. The wear-resistant textile fabric is formed by blending and weaving the following fibers in parts by weight: 55-75 parts of cotton fibers, 35-50 parts of composite nylon fibers, 10-15 parts of polyester fibers and 15-20 parts of Shengma fibers. Through the procedures of blowing, cotton carding, drawing, roving, spinning, yarn steaming and spooling, cotton fibers and Shengma fibers are blended into first yarn, and composite nylon fibers and polyester fibers are blended into second yarn; the first yarn and the second yarn are soaked in the size, then taken out, subjected to padding, dried and waxed, and then the first yarn and the second yarn are woven into gray fabric of a double-face tissue structure in a fixed knitting needle arrangement mode, a triangular arrangement mode and a threading mode; the gray fabric is subjected to desizing, water washing, preshrinking and setting treatment to be made into the textile fabric, the prepared fabric has good softness performance through spinning of the flexible fibers, and the prepared fabric can be endowed with good moisture permeability and perspiration performance by adding the cotton fibers.

Owner:ANHUI HENGYI TEXTILE TECH CO LTD

Ultraviolet-resistant high-density folded awning fabric

InactiveCN107904976AGood waterproof effectExcellent moisture resistanceTextiles and paperPolyethylene polyaminePolyvinylidene fluoride

The invention discloses an ultraviolet-resistant high-density folded awning fabric which comprises a cloth layer, a coating layer, a film layer and a taped layer, wherein the cloth layer specificallycomprises the following components in percentage by mass: 45-75% of a poly-2,6-naphthalic acid ethylene glycol fiber, 15-45% of a poly-di-n-pentyl ether fiber and 35-45% of a poly-succinic acid butynediester fiber; the coating layer specifically comprises the following components in percentage by mass: 35-62% of methyl methacrylate, 14-24% of gallotannic acid, 11-13% of aniline blue and 14-25% ofcrylic acid-2-ethylhexyl acrylate; the film layer specifically comprises the following components in percentage by mass: 50-70% of PVDF (Polyvinylidene Fluoride), 20-30% of chlorinated polyethylene and 20-35% of polyethylene polyamine; the taped layer specifically comprises the following components in percentage by mass: 55-80% of chlorinated polyethylene rubber, 8-16% of acetone and 25-35% of paraffin. Due to the four-layer structure, a relatively good waterproof effect is achieved, and in addition, due to the film layer on the coating layer, the consequence that a coating is relatively seriously worn in long-term use, is avoided.

Owner:CHENGDU JIELEI SHADING ENG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com