Moisture-regain-resistant drawing pigment and preparation method thereof

A painting and pigment technology, applied in the direction of art paints and coatings, can solve the problems of easy moisture-proof softening of paint films, short holding time of paintings, fading and other problems, and achieve the advantages of speeding up film forming time, improving stability and improving fineness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

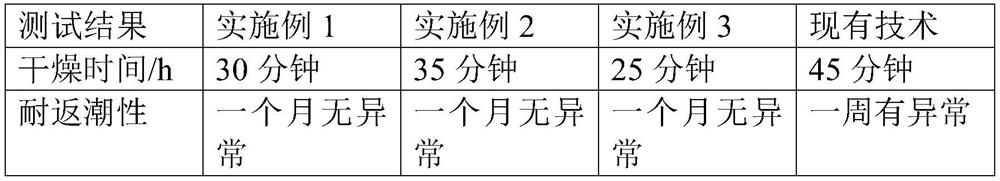

Examples

Embodiment 1

[0019] A paint paint resistant to dampness, comprising the following raw material components in parts by weight: 60 parts of acrylic emulsion, 5 parts of diatomaceous earth, 10 parts of talcum powder, 8 parts of toner, 8 parts of vegetable gum, 5 parts of hydroxyethyl cellulose 8 parts, moisturizing agent 8 parts, dispersant 0.3 parts, film former 3 parts, preservative 0.03 parts, water 12 parts.

[0020] A kind of preparation method of the anti-humidity painting pigment, comprises the steps:

[0021] (1) Weigh the diatomite, talcum powder and toner of the formula and place them in a high mixer for mixing. After the mixing is completed, place them in a ball mill for the first grinding. The grinding time is 2 hours to obtain the mixture A;

[0022] (2) Add water capable of wetting the mixture A in step (1), and grind it for the second time in a ball mill for 1 hour to obtain mixture B;

[0023] (3) Add the dispersant, film-forming agent, humectant and the remaining amount of w...

Embodiment 2

[0027] A paint paint resistant to dampness, comprising the following raw material components in parts by weight: 50 parts of acrylic acid emulsion, 8 parts of diatomaceous earth, 8 parts of talcum powder, 10 parts of toner, 5 parts of vegetable glue, and 8 parts of carboxymethyl cellulose 6 parts, 6 parts of humectant, 0.4 part of dispersant, 8 parts of film former, 0.05 part of preservative, 15 parts of water.

[0028] A kind of preparation method of the anti-humidity painting pigment, comprises the steps:

[0029] (1) Weigh the diatomite, talcum powder and toner of the formula amount and place them in a high-mixer for mixing. After the mixing is completed, place them in a ball mill for the first grinding. The grinding time is 3 hours to obtain the mixture A;

[0030] (2) Add water capable of wetting the mixture A in step (1), and grind it for the second time in a ball mill for 2 hours to obtain mixture B;

[0031] (3) Add the dispersant, film-forming agent, humectant and th...

Embodiment 3

[0035] A paint paint resistant to dampness, comprising the following raw material components in parts by weight: 55 parts of acrylic emulsion, 10 parts of diatomaceous earth, 5 parts of talcum powder, 12 parts of toner, 10 parts of vegetable gum, 3 parts of hydroxyethyl cellulose 3 parts of carboxymethyl cellulose, 5 parts of humectant, 0.5 part of dispersant, 5 parts of film former, 0.06 part of preservative, 10 parts of water.

[0036] A kind of preparation method of the anti-humidity painting pigment, comprises the steps:

[0037] (1) Weigh the diatomite, talcum powder and toner of the formula and place them in a high mixer for mixing. After the mixing is completed, place them in a ball mill for the first grinding. The grinding time is 2 hours to obtain the mixture A;

[0038] (2) Add water capable of wetting the mixture A in step (1), and grind it for the second time in a ball mill for 2 hours to obtain mixture B;

[0039] (3) Add the dispersant, film-forming agent, humec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com