Treatment agent for polyolefin-based synthetic fibers, and polyolefin-based synthetic fiber

A synthetic fiber, polyolefin-based technology, applied in the field of polyolefin-based synthetic fibers, to achieve the effects of excellent initial hydrophilicity and excellent carding machine passability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

[0025] Hereinafter, 1st Embodiment of the polyolefin-type synthetic fiber processing agent (henceforth a processing agent) which actualized this invention is demonstrated. The processing agent of this embodiment contains the following polyoxyalkylene derivative and the following linear hydrocarbon.

[0026] The polyoxyalkylene derivative is one in which at least one selected from ethylene oxide and propylene oxide is added in a ratio of 5 to 100 moles with respect to 1 mole of aliphatic monohydric alcohol having 24 to 60 carbon atoms. compound.

[0027] The straight-chain hydrocarbon is a straight-chain hydrocarbon having 10 to 100 carbon atoms.

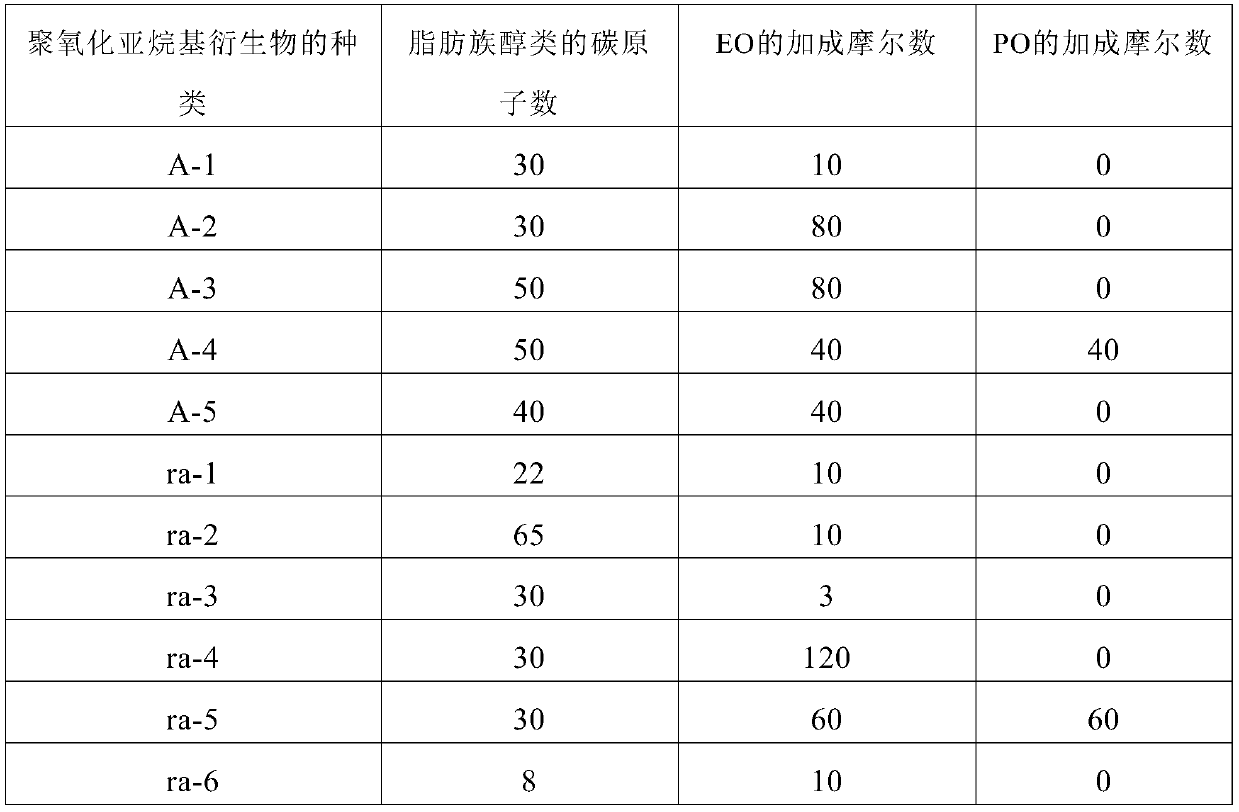

[0028] The polyoxyalkylene derivative used in the treatment agent of this embodiment is a polyoxyalkylene derivative selected from ethylene oxide and A compound of at least one kind of propylene oxide. The aliphatic monohydric alcohol having 24 to 60 carbon atoms is not particularly limited, and examples thereof include tetracosan...

no. 2 Embodiment approach

[0038]Next, a second embodiment of a polyolefin-based synthetic fiber (hereinafter referred to as a synthetic fiber) which is an embodiment of the present invention will be described. The synthetic fiber of this embodiment is a polyolefin type synthetic fiber to which the processing agent of 1st Embodiment adhered. Polyolefin-based synthetic fibers are not particularly limited, and examples thereof include polyolefin-based fibers such as polyethylene fibers, polypropylene fibers, and polybutene fibers. These may be used individually by 1 type, and may use it in combination of 2 or more types. In addition, it is a composite fiber having a core-sheath structure, and either or both of the core and the sheath are polyolefin-based fibers, such as polyethylene / polypropylene composite fibers in which the sheath is polyethylene fibers, polyethylene / polyester Composite fibers, etc.

[0039] The ratio of the treatment agent (excluding the solvent) of the first embodiment to the above-...

Embodiment

[0045] Examples and the like are given below in order to more specifically describe the configuration and effects of the present invention, but the present invention is not limited to these Examples. In addition, in description of a following Example and a comparative example, a part shows a mass part, and % shows a mass %.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com