Marine cylinder oil compound additive and its production method and marine cylinder oil prepared from marine cylinder oil compound additive

A compound additive and cylinder oil technology, applied in the direction of additives, petroleum industry, lubricating composition, etc., to achieve good moisture resistance and excellent moisture resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] Example 1: The weight percentage distribution ratio of the composite additive is: 69.5 parts of 300TBN calcium naphthenate, 13.9 parts of sulfurized calcium phenate, 10.4 parts of succinimide, 4.5 parts of zinc dialkyl dithiophosphate, carbamic acid 0.7 parts of zinc, 1.0 parts of benzotriazole, and the alkali value of calcium naphthenate is 320 mgKOH / g.

[0015] The production method of the composite additive: add 300TBN calcium naphthenate, calcium sulfide alkylphenate, succinimide, zinc dialkyldithiophosphate, zinc carbamate, and benzotriazole in sequence to stainless steel to adjust the above ratio. In the combined kettle, stir and heat up to 90°C, and continue to stir for 8 hours until the compound additive is clear and transparent.

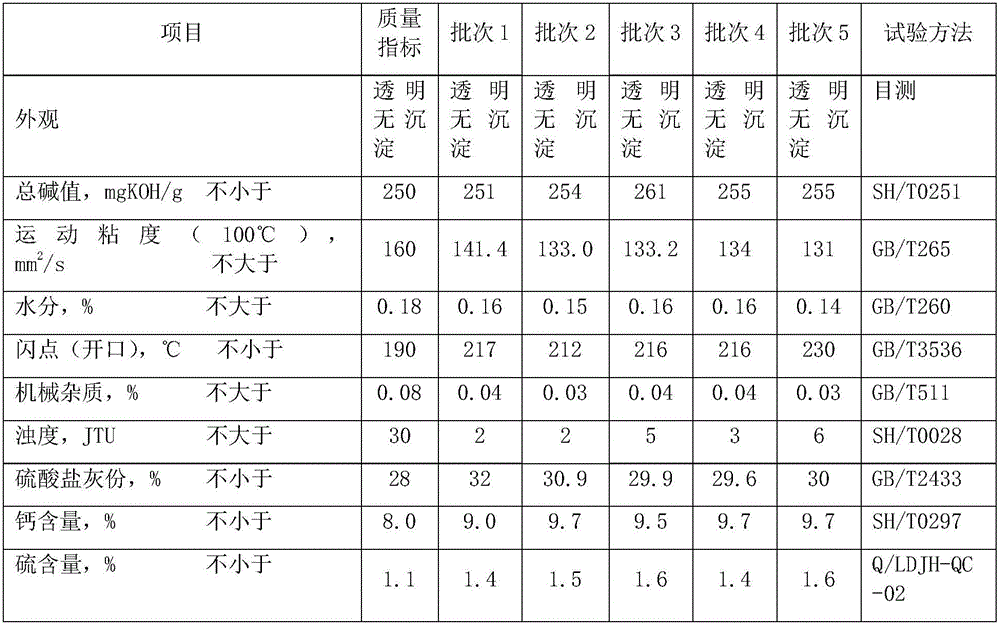

[0016] The main quality index of the marine cylinder oil compound additive that present embodiment makes is as follows: Table 1

[0017] Table 1

[0018] project Quality Index experiment method Exterior transpare...

Embodiment 2

[0019] Embodiment 2: The weight percent distribution ratio of composite additives is: 73.2 parts of 300TBN calcium naphthenate, 11.7 parts of sulfurized alkyl phenate calcium, 14.8 parts of succinimide, 8.1 parts of dialkyl zinc dithiophosphate, alkyl 3.6 parts of diphenylamine, the alkali value of calcium naphthenate is 280mgKOH / g.

[0020] The production method of the composite additive: Add 300TBN calcium naphthenate, sulfurized calcium alkylphenate, succinimide, zinc dialkyl dithiophosphate, and alkylated diphenylamine in the above ratio into a stainless steel mixing kettle in sequence, and stir Raise the temperature to 80°C and continue to stir for 6 hours until the compound additive is clear and transparent.

Embodiment 3

[0021] Embodiment 3: The proportion by weight of the composite additive is: 63.2 parts of 300TBN calcium naphthenate, 20.9 parts of sulfurized alkyl phenate calcium, 12.5 parts of succinimide, 7.5 parts of dialkyl zinc dithiophosphate, 7.5 parts of alkyl 4.3 parts of diphenylamine, the alkali value of calcium naphthenate is 290mgKOH / g.

[0022] The production method of the composite additive: Add 300TBN calcium naphthenate, sulfurized calcium alkylphenate, succinimide, zinc dialkyl dithiophosphate, and alkylated diphenylamine in the above ratio into a stainless steel mixing kettle in sequence, and stir Raise the temperature to 85°C and continue to stir for 7 hours until the compound additive is clear and transparent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com