Wall surface spraying device for building

A spraying device and construction technology, applied in construction, building construction, etc., can solve problems such as waste of plastering liquid, dripping liquid, potential safety hazards of plastering workers, etc., and achieve the effect of improving the use effect, simple structure, and good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

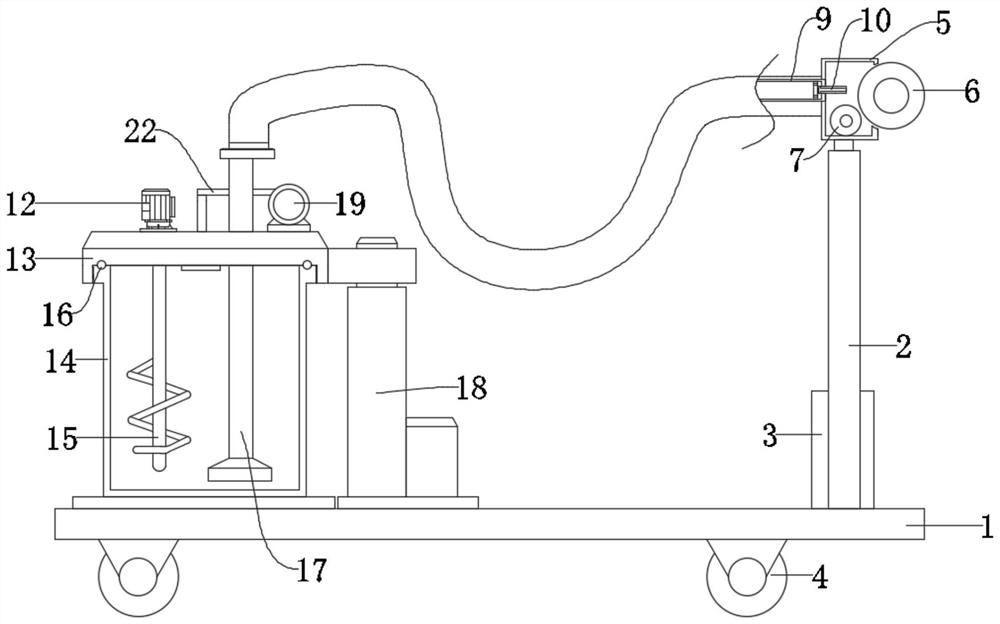

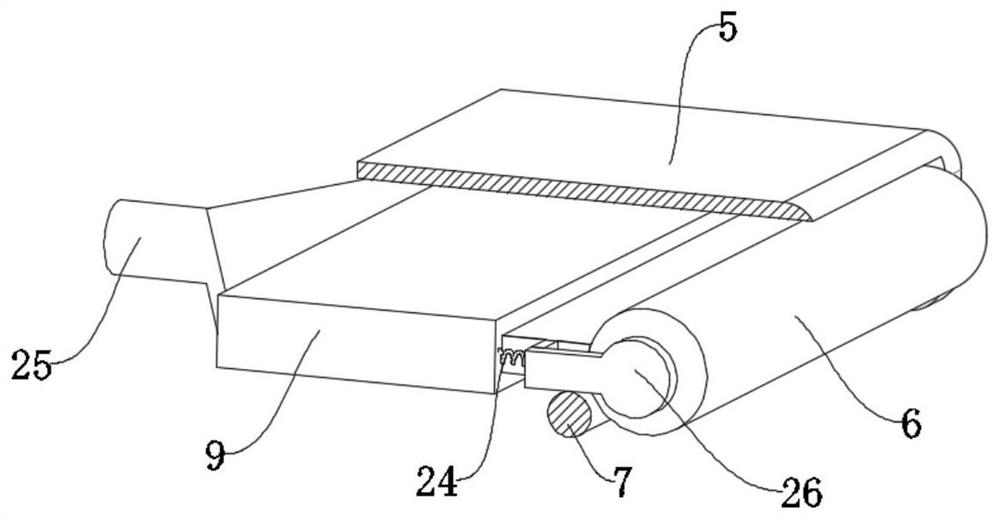

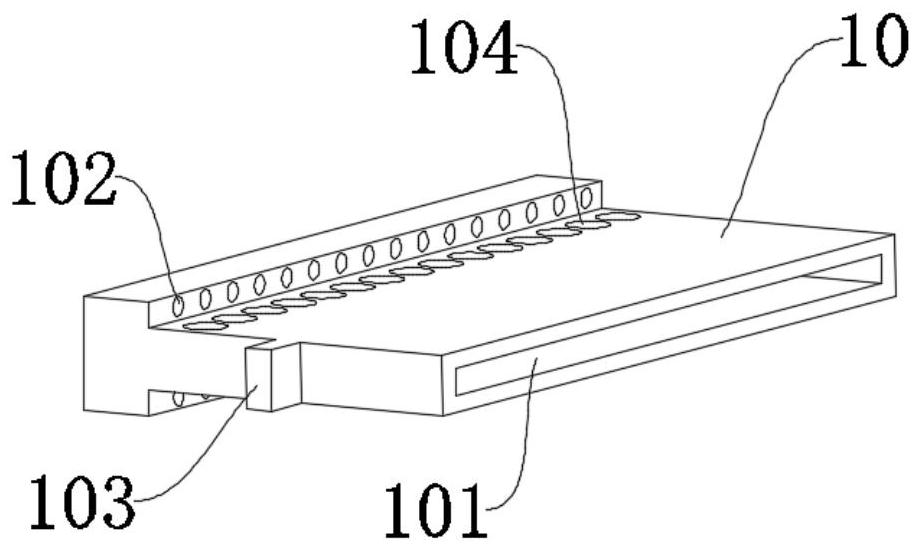

[0021]SeeFigure 1-3, A wall spraying device for construction, including a bottom plate 1, a paint bucket 14 and a spraying device are arranged on the bottom plate 1, an upper cover 13 is arranged above the paint bucket 14, and the upper cover 13 and the paint bucket 14 pass between The threaded connection further facilitates the replacement of the paint bucket 14; the spraying device includes a feeding assembly and a painting assembly, and the feeding assembly is arranged on the upper cover 13, and further provides paint for the painting assembly; The painting assembly described includes a discharge plate 9, a piston plate 10, a protective cover 5, a painting wheel 6, an absorption wheel 7 and a discharge pipe 25. One end of the discharge pipe 25 is connected to the supply assembly. The other end is connected to the discharge plate 9. The inside of the discharge plate 9 is a hollow structure, which further facilitates the filling of the discharge plate 9 with paint; the piston plate...

Embodiment 2

[0029]In order to avoid the precipitation and solidification of the paint in the paint bucket 14 and further affect the actual spraying effect, this embodiment has made the following improvements on the basis of the first embodiment. The improvement is that a stirring is arranged on the upper cover 13 The stirring device includes a motor 12 and a stirring rod 15. The motor 12 is fixedly installed on the upper cover 13, and the stirring rod 15 is fixedly connected with the rotating shaft of the motor 12, and the rotation of the motor 12 further drives the stirring rod The rotation of 15 in the paint bucket 14 realizes the mixing of paint, avoids solidification and mixing, and improves the actual use effect.

[0030]The working principle of this embodiment: the rotation of the motor 12 further drives the rotation of the stirring rod 15 in the paint bucket 14 to realize the stirring of the paint, avoid solidification and mixing, and improve the actual use effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com