Microcrystalline cellulose used as temporary protective plugging agent for drilling fluid reservoir and preparation method thereof

A microcrystalline cellulose and reservoir protection technology, which is applied in the directions of drilling compositions, chemical instruments and methods, etc., can solve the difficulty of unsealing asphaltenes or oil-soluble resins, poor pore sealing, logging and environmental protection. impact and other issues, to achieve the effect of low cost, low environmental pollution and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

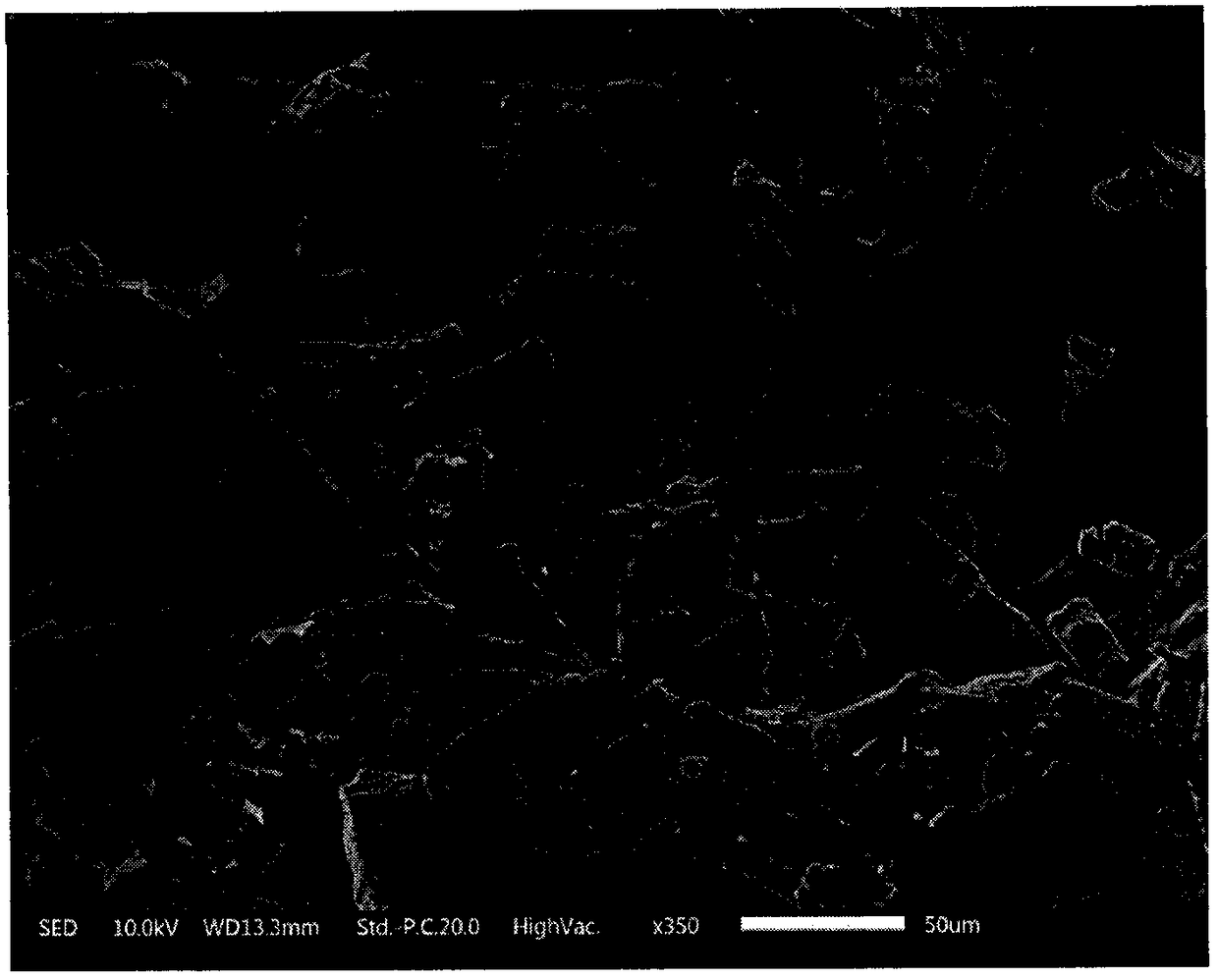

Image

Examples

Embodiment 1

[0027] Add 75g of oxalic acid dihydrate into a three-necked round-bottomed flask at 20°C, then add 100g of water and 1g of ferric chloride hexahydrate, stir for 5min, add 5g of dry bleached poplar wood pulp, and use an oil bath Raise the temperature to 100°C, and maintain the mechanical stirring at 100°C for 3h at a stirring speed of 300r / min. Then the reaction solution is directly centrifuged without cooling, the centrifuge speed is set to 3000r / min, and the running time is 3min. After centrifugation, the supernatant is removed into a round bottom flask, and about 50g of water is removed by distillation under reduced pressure, and then heated at 95°C. Heated for 5 minutes under the same conditions, then naturally cooled to 20°C, allowed to stand for 1 hour, filtered with suction, and the filter cake was naturally air-dried to recover oxalic acid dihydrate. After the above centrifugation, the precipitated part was dispersed with 200 mL of distilled water, and then centrifuged ...

Embodiment 2

[0029] Add 35g of oxalic acid dihydrate into a three-necked round-bottomed flask at 20°C, then add 100g of water and 2g of ferric chloride hexahydrate, stir for 5min, add 10g of dry bleached spruce wood pulp, and use oil The temperature of the bath was raised to 95° C. and maintained at 95° C. with mechanical stirring for 5 h at a stirring speed of 300 r / min. Then the reaction solution is directly centrifuged without cooling, the centrifuge speed is set to 4000r / min, and the running time is 3min. After centrifugation, the supernatant is removed into a round bottom flask, and about 50g of water is removed by distillation under reduced pressure, and then the reaction solution is heated at 95°C. Heated for 5 minutes under the same conditions, then naturally cooled to 20°C, allowed to stand for 1 hour, filtered with suction, and the filter cake was naturally air-dried to recover oxalic acid dihydrate. After the above centrifugation, the precipitated part was dispersed with 300 mL ...

Embodiment 3

[0031] Add 55g of oxalic acid dihydrate into a three-necked round-bottomed flask at 20°C, then add 100g of water and 2g of aluminum chloride hexahydrate, stir for 5 minutes, add 10g of dry bleached eucalyptus pulp, and use an oil bath Raise the temperature to 95°C, and maintain mechanical stirring at 95°C for 4 hours at a stirring speed of 300r / min, then directly centrifuge the reaction solution without cooling, set the centrifuge speed to 4000r / min, and run for 3min. After centrifugation Remove the supernatant to a round-bottomed flask, distill off about 60g of water under reduced pressure, then heat at 85°C for 5 minutes, then naturally cool to 10°C, let stand for 1h, filter with suction, and dry the filter cake naturally to recover dihydrate oxalic acid. After the above centrifugation, the precipitated part was dispersed in 300 mL of distilled water, and then centrifuged under the condition that the centrifuge speed was 3000r / min and the running time was 3min, and the super...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com