A kind of anti-high temperature environment-friendly drilling fluid lubricant and preparation method thereof

An environment-friendly drilling fluid technology, applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems of low high temperature and high pressure resistance, low lubricating performance, etc., to improve lubricating performance, maintain authenticity, Effect of Lubrication Coefficient Reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

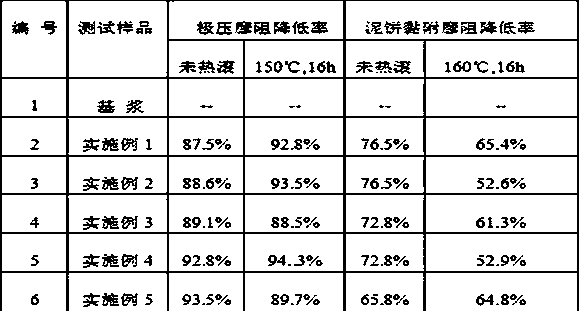

Examples

Embodiment 1

[0030] Prepare each reaction raw material according to following components and mass percentage:

[0031] Turkish red oil: 30%;

[0032] Simethicone: 30%;

[0033] Antiwear agent (T307, T323, T202): 9% (1:1:1);

[0034] Surfactant (sodium dodecylbenzenesulfonate ABS, SP-80): 10%;

[0035] Water: 21%;

[0036] (1) Add simethicone oil to the vegetable oil Turkish red oil in proportion, stir for 30 minutes, the stirring speed is 80 rpm; the stirring temperature is 35°C;

[0037] (2) Pre-mix the two surfactants and the three anti-wear agent mixtures in proportion, stir and react for 60 minutes, and then mix with the base oil in step (1);

[0038] (3) Finally, add water in proportion, continue to stir and react, and obtain the oil-based drilling fluid lubricant product of the present invention through filtration.

Embodiment 2

[0040] Prepare each reaction raw material according to following components and mass percentage:

[0041] Turkish red oil: 30%;

[0042] Simethicone: 30%;

[0043] Antiwear agent (T307, T323, T202): 9% (1:1:1);

[0044] Surfactant (sodium dodecylbenzenesulfonate ABS, SP-80): 10%;

[0045] Water: 21%;

[0046] (1) Add simethicone oil to the vegetable oil Turkish red oil in proportion, stir for 30 minutes, the stirring speed is 80 rpm; the stirring temperature is 35°C;

[0047] (2) Pre-mix the two surfactants and the three anti-wear agent mixtures in proportion, stir and react for 60 minutes, and then mix with the base oil in step (1);

[0048] (3) Finally, add water in proportion, continue to stir and react, and obtain the oil-based drilling fluid lubricant product of the present invention through filtration.

Embodiment 3

[0050] Prepare each reaction raw material according to following components and mass percentage:

[0051] Turkish red oil: 35%;

[0052] Simethicone: 25%;

[0053] Antiwear agent (T307, T323, T202): 9% (1:1:1);

[0054] Surfactant (sodium dodecylbenzenesulfonate ABS, SP-80): 10%;

[0055] Water: 21%;

[0056] (1) Add simethicone oil to vegetable oil Turkish red oil in proportion, stir for 30 minutes, stirring speed is 80 rpm; stirring temperature is 35°C;

[0057](2) Pre-mix the two surfactants and the three anti-wear agent mixtures in proportion, stir and react for 60 minutes, and then mix with the base oil in step (1);

[0058] (3) Finally, add water in proportion, continue to stir and react, and obtain the oil-based drilling fluid lubricant product of the present invention through filtration.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com