Patents

Literature

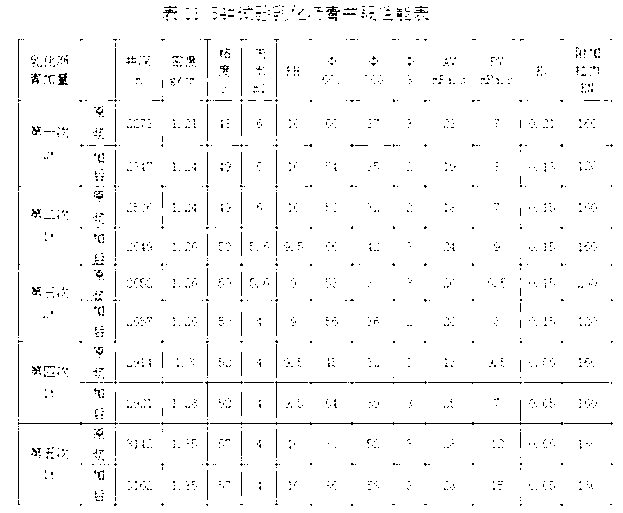

37results about How to "Reduce the lubrication coefficient" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

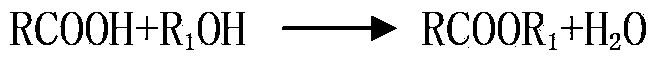

Drilling fluid lubricant prepared from waste plant oil and preparation method thereof

InactiveCN104371674AImprove protectionHigh flash pointDrilling compositionActive agentReaction temperature

The invention provides a drilling fluid lubricant prepared from waste plant oil and a preparation method thereof. The lubricant is composed of the following raw materials in parts by weight: 70 to 80 parts of waste plant oil, 10 to 20 pats of lower alcohols, 1 to 5 parts of surfactant, and 1 to 5 parts of high temperature resistant processing agent. The preparation method comprises the following steps: step a, carrying out a pretreatment on raw materials: removing impurities from waste plant oil; step b, carrying out esterification conversion: adding lower alcohols and the waste plant oil preprocessed in step a into a reactor with / without a catalyst to carry out esterification reactions or ester exchange reactions, wherein the reaction temperature is 60 to 120 DEG C, and the reaction time is 3 to 8 hours; step c, refining and separating the reaction products: precipitating and separating the reaction products obtained in the step b, and then refining the reaction products to obtain a refined product; step d, carrying out performance improvement: adding the surfactant and the high temperature resistant processing agent so as to obtain a finished product.

Owner:CHINA PETROCHEMICAL CORP +1

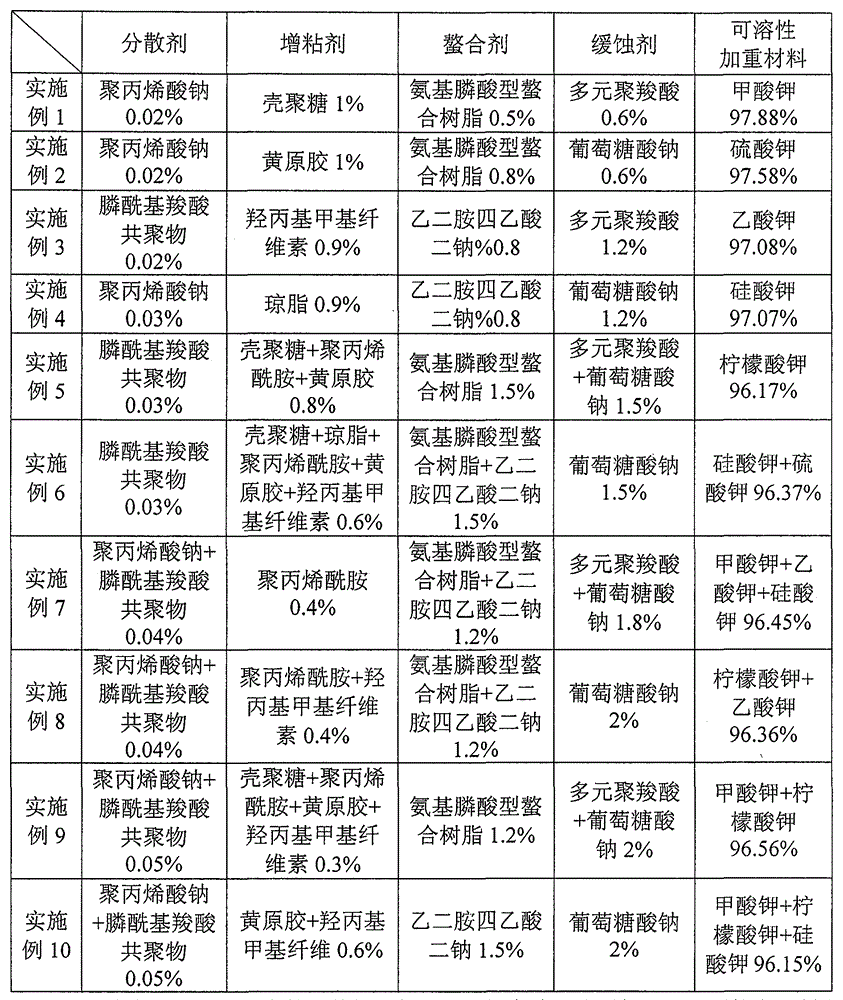

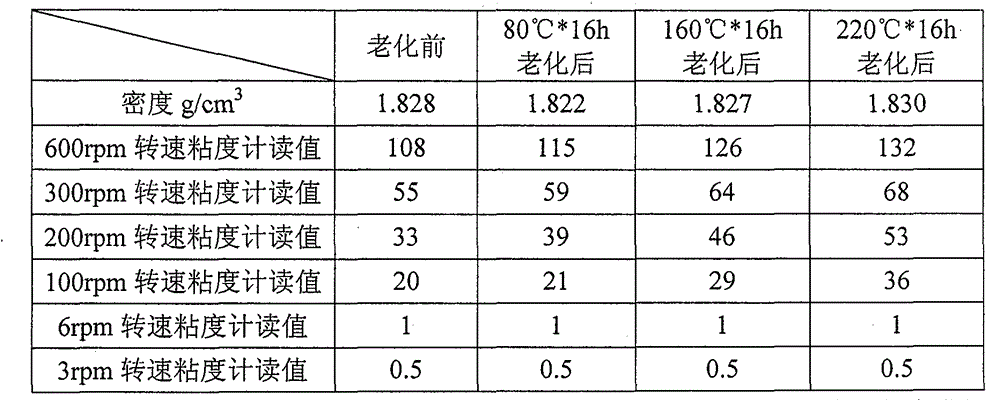

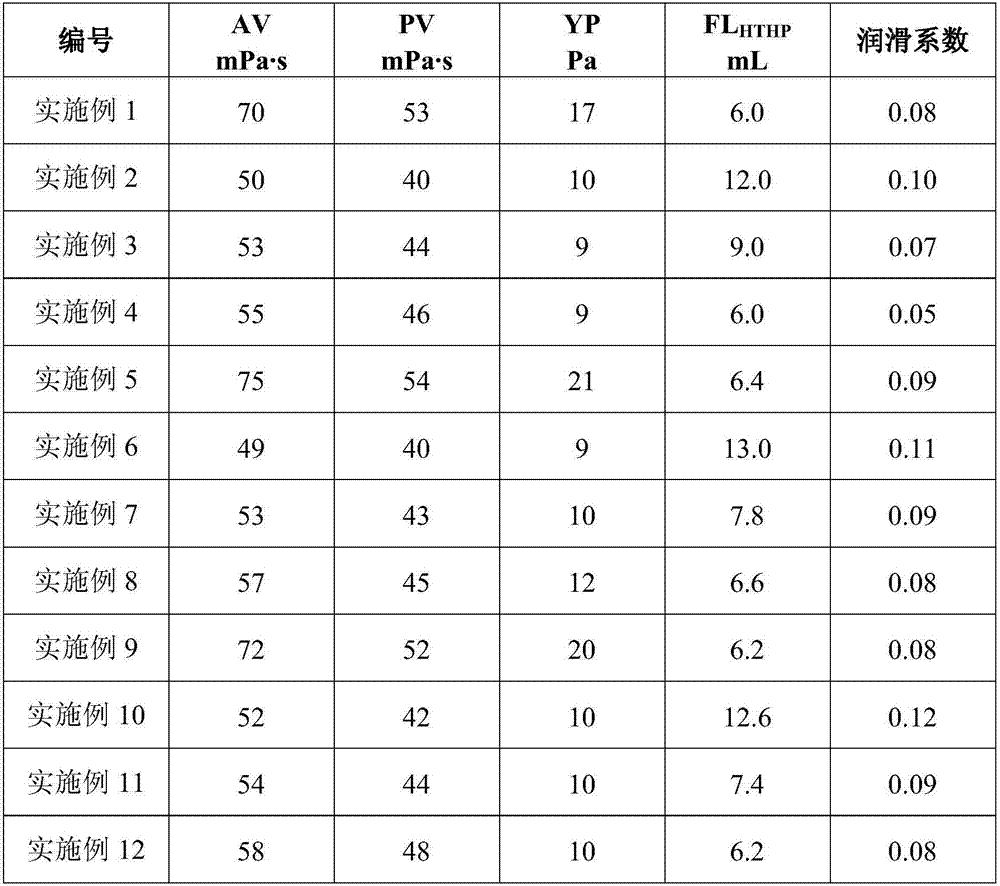

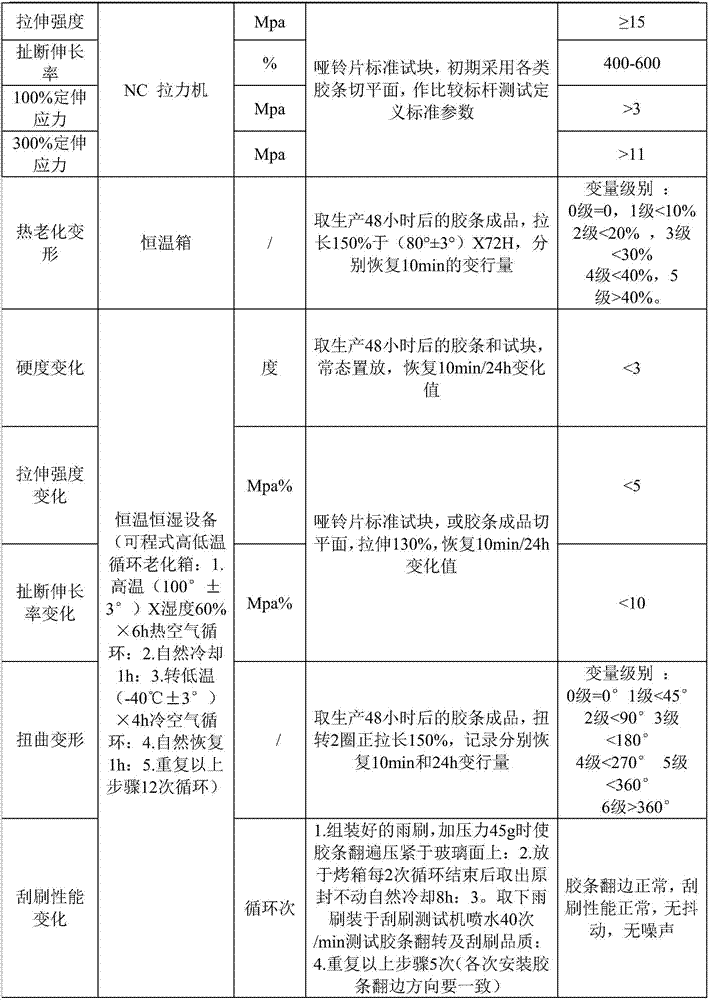

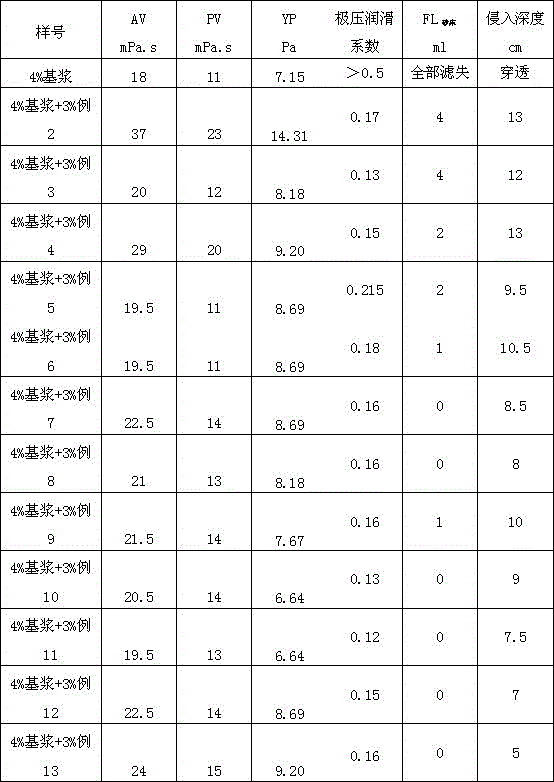

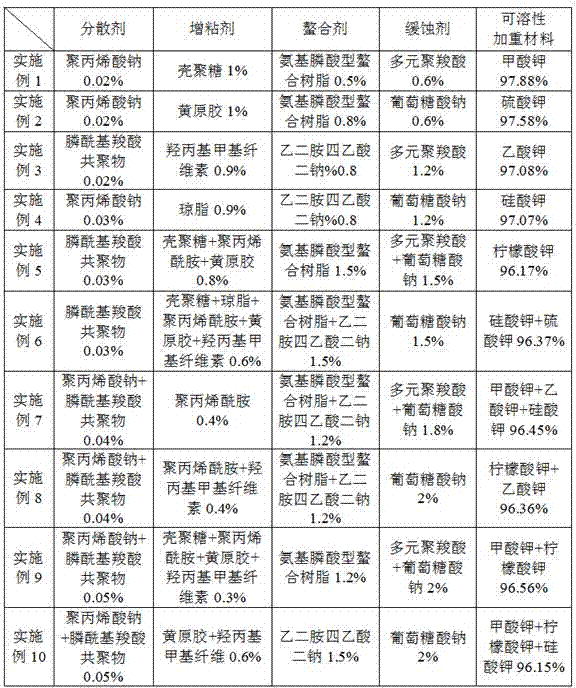

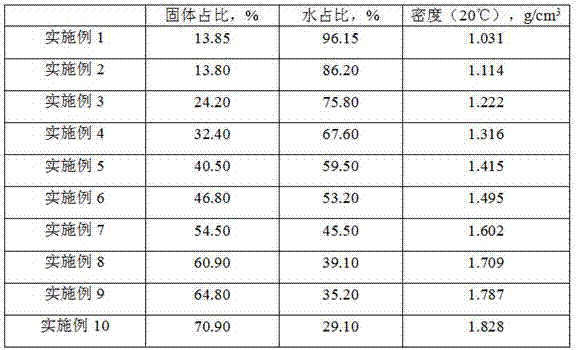

Environment-friendly high-density solid-free weighting agent and preparation method

ActiveCN104610937AWide range of densitiesReduce pollutionDrilling compositionCarboxylic acidPotassium formate

An environment-friendly high-density solid-free weighting agent comprises components in parts by weight as follows: 0.02-0.05 parts of a dispersant, 0.3-1 part of a tackifier, 0.5-1.2 parts of chelating agent, 0.6-2 parts of a corrosion inhibitor and the balance of soluble weighting materials, wherein the dispersant is one or two of sodium polyacrylate and copolymer of phosphono and carboxylic acid; the tackifier is one or more of chitosan, agar, polyacrylamide, xanthan gum and hydroxypropyl methyl cellulose; the chelating agent is one or two of aminophosphonic acid chelate resin and ethylenediamine tetraacetic acid disodium; the corrosion inhibitor is one or two of multiple polycarboxylate and sodium gluconate; the soluble weighting materials are one or more of potassium formate, potassium citrate, potassium acetate, potassium silicate and potassium sulfate. The process steps are as follows: the raw materials are taken in weight proportion, mixed and uniformly stirred; the raw materials are added to water and dissolved at the high temperature of 70-80 DEG C; a product is evaporated to dryness, and solid is obtained; the obtained solid is ground into powder, and the solid weighting agent is obtained.

Owner:成都西油华巍科技有限公司

Temperature-resistance drilling fluid drill-feeding plugging agent and its preparation method

InactiveCN103937471AEffective blockingDoes not affect rheological parametersDrilling compositionSodium bisulfateVegetable fibers

The invention relates to a temperature-resistance drilling fluid drill-feeding plugging agent and its preparation method, the drill-feeding plugging agent comprises the following components by weight: 30-80 parts of vegetable fiber, 10-40 parts of mineral fiber, 10-40 parts of fruit shell, 0-10 parts of powdered steatile, and 3-10 parts of silicon-based gel deformation particles. The silicon-based gel deformation particles enable emulsification and dispersion of 1.4-2.5 parts of vinyltriethoxysilane monomer according to weight to an aqueous solution composed of 18-24 parts of acrylamide, 0.0025-0.005 parts of N,N'-methylene bisacrylamide, 0.7-1.25 parts of OP-10 and 0.1-0.17 parts of sodium dodecyl benzene sulfonate, 0.003 parts of disodium ethylene diamine tetraacetate, 0.009-0.12 parts of ammonium persulfate and 0.009-0.012 parts of sodium bisulfate, a process of micellar copolymerization is carried out, a polymer is dried, granulated and crushed to obtain the silicon-based gel deformation particles with average particle size of 80-200 meshes; easy-leakage highly-permeable stratum and micro crack are effectively plugged, rheological parameter of the drilling fluid is not influenced, frictional resistance coefficient of the drilling fluid is reduced, a storage layer is protected, and the drill-feeding plugging agent is suitable for plugging the easy-leakage stratum and the storage layer.

Owner:中国石油天然气股份有限公司冀东油田分公司钻采工艺研究院

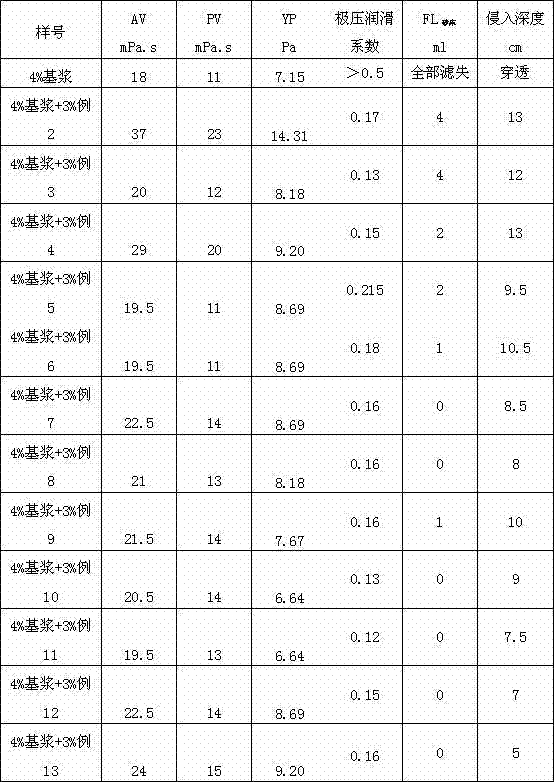

High-performance water-based drilling fluid formulation

ActiveCN107573911AWith restraintEnhanced inhibitory effectDrilling compositionWater basedDirectional well

The invention discloses a high-performance water-based drilling fluid. The high-performance water-based drilling fluid is prepared from the following components in parts by weight: 100 parts of freshwater, 2 to 6 parts of bentonite, 0.2 to 0.6 part of coating agent, 0 to 5 parts of fluid loss agents, 1 to 6 parts of lubricating fluid loss agents, 0 to 4 parts of lubricant, 2 to 6 parts of anti-collapse blocking agent, 6 to 8 parts of shale inhibitor, 0.2 to 0.4 part of pH adjusting agent, and 60 parts of weighting agents; the lubricating fluid loss agents are boric acid ester modified graphene oxide, a high-performance water-based drilling fluid system provided by the invention has the characteristics of strong inhibition, strong plugging and the like, and at the same time has the advantages of low lubrication coefficient and small downhole friction resistance, thus being suitable for construction operations of directional wells and large displacement wells.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Drilling shaft lining stabilizer

InactiveCN101362938AReduce mud cake lubrication coefficientOutstanding lubricity and rebound effectDrilling compositionChemistryEther

The invention discloses a boring well wall stabilizer which is mainly used for solving the technical problem that storage layer is damaged due to unstable well wall and expansion of clay during the boring process; the well wall stabilizer consists of 20-35 parts of diallyldimethylammonium chloride, 2-5 parts of diallyldimethylammonium chloride-acrylamide polymer, 1-5 parts of non-ionic surfactant OP-10, 1-2 parts of fluoride-bearing alkyl ethoxy ether alcohol non-ionic surfactant, 1-3 parts of cellulose, 1-5 parts of KCl and 45-74 parts of water, according to the weight parts. The stabilizer can stabilize the well wall, greatly reduces the expansion rate of the clay at storage layer and eliminates the damages on the storage layer.

Owner:XI'AN PETROLEUM UNIVERSITY

Graphene resistance-reducing agent for fracturing fluid

InactiveCN106085385AReduce frictionGood resistance reduction effectDrilling compositionPhosphateFiltration

The invention discloses a graphene resistance-reducing agent for a fracturing fluid. The graphene resistance-reducing agent comprises the following raw materials by weight: 1 to 50 parts of graphene, 5 to 60 parts of a surfactant and 1 to 60 parts of a wetting agent, wherein the surfactant is a nonionic surfactant or anionic surfactant and is one or more selected from a group consisting of alkylphenol polyoxyethylene ether, stearyl alcohol polyoxyethylene polyoxypropylene ether, polyether phosphate, dodecylbenzene sulfonic acid and fatty alcohol ether sodium sulfate-AES. The graphene resistance-reducing agent has the advantages of good resistance-reducing performance, few components, small filtration loss, high viscosity, environment friendliness and good compatibility; through addition of graphene or modified graphene, a lubrication coefficient can be effectively decreased, frictional resistance between the fracturing fluid and a crack wall is lowered and filtration loss is reduced; thus, construction pressure in the process of fracture is reduced, and the graphene resistance-reducing agent is applicable to large-scale large-discharge volume fracture technology. The graphene or modified graphene resistance-reducing agent has good compatibility with a reservoir in the process of fracture and acidification, does not contain mineral oil and poses no pollution to the reservoir and environment.

Owner:CARBORN TIME TECH CO LTD

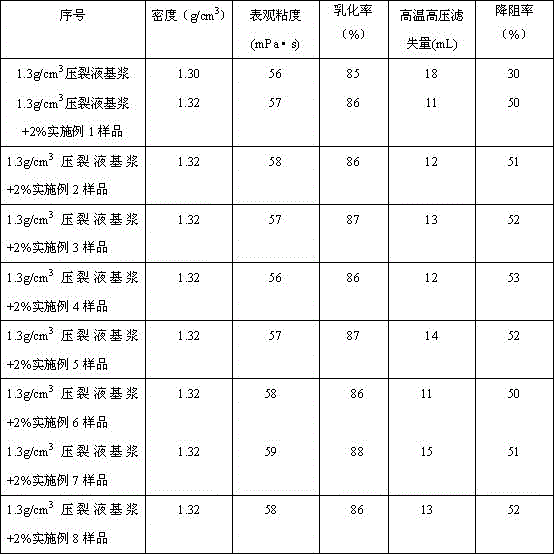

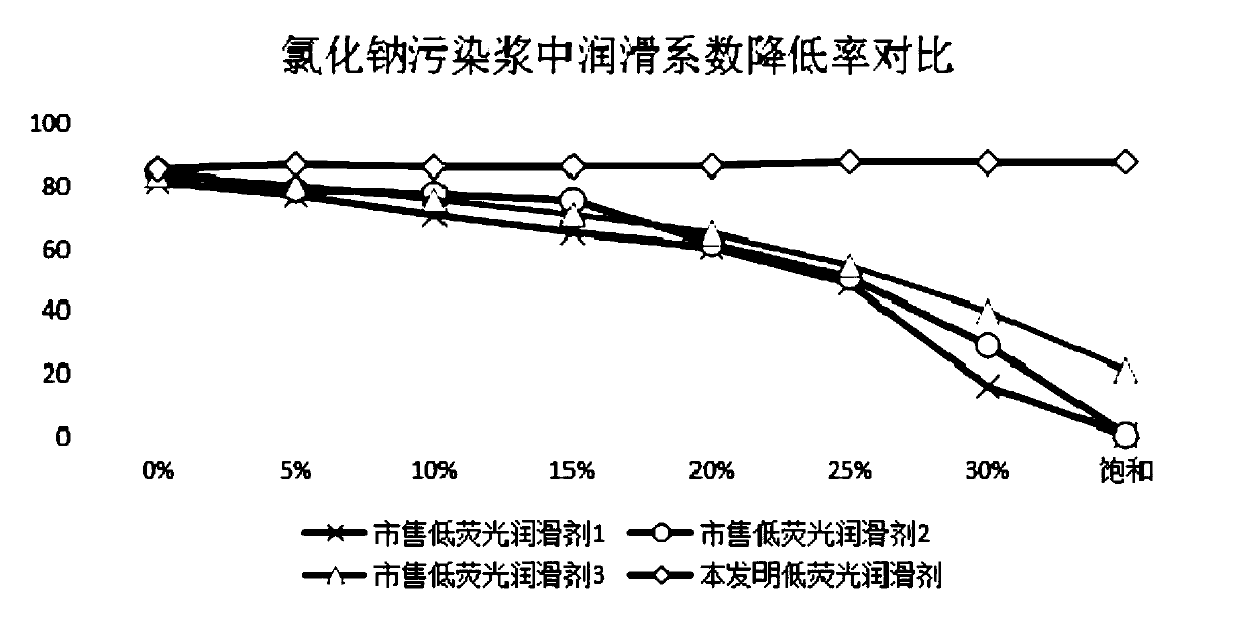

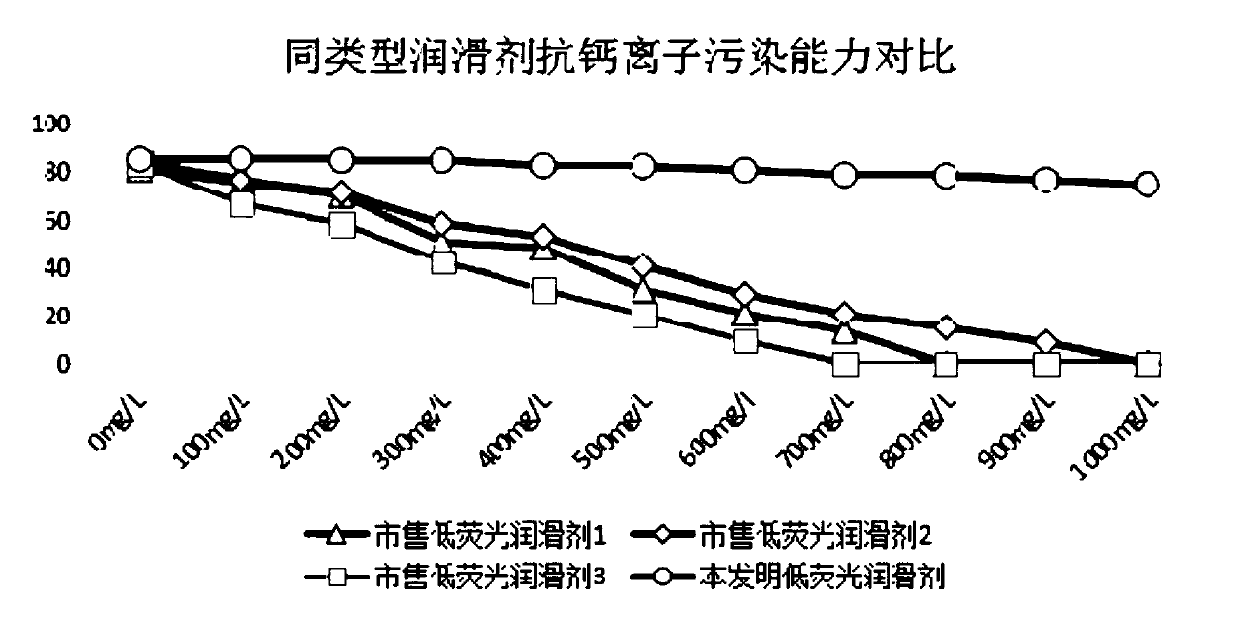

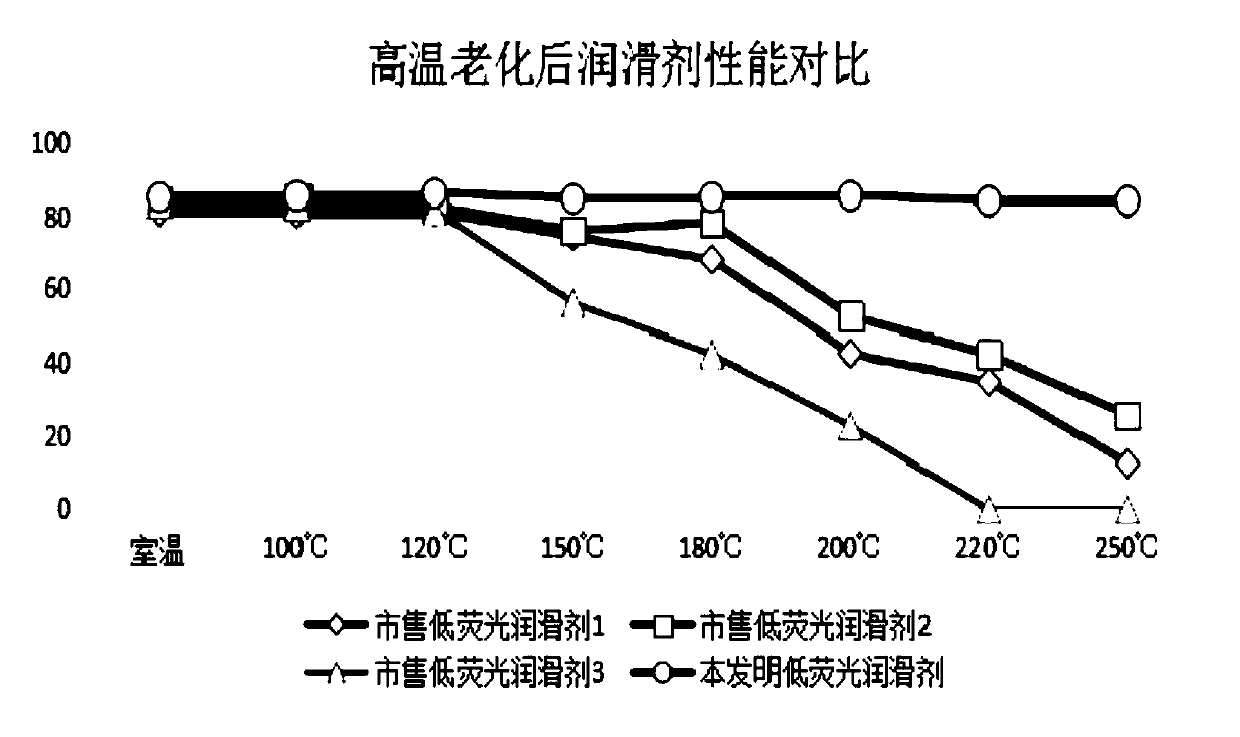

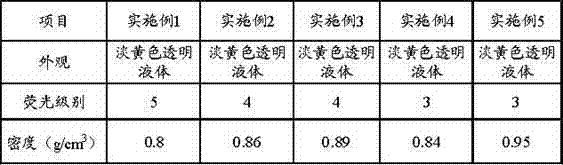

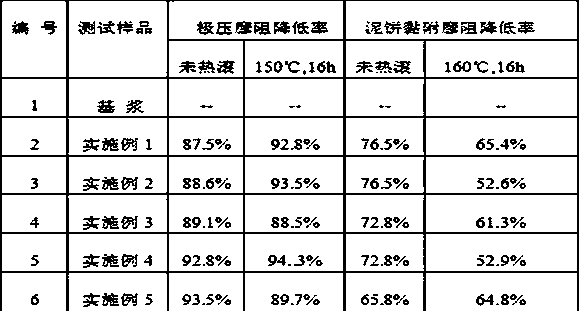

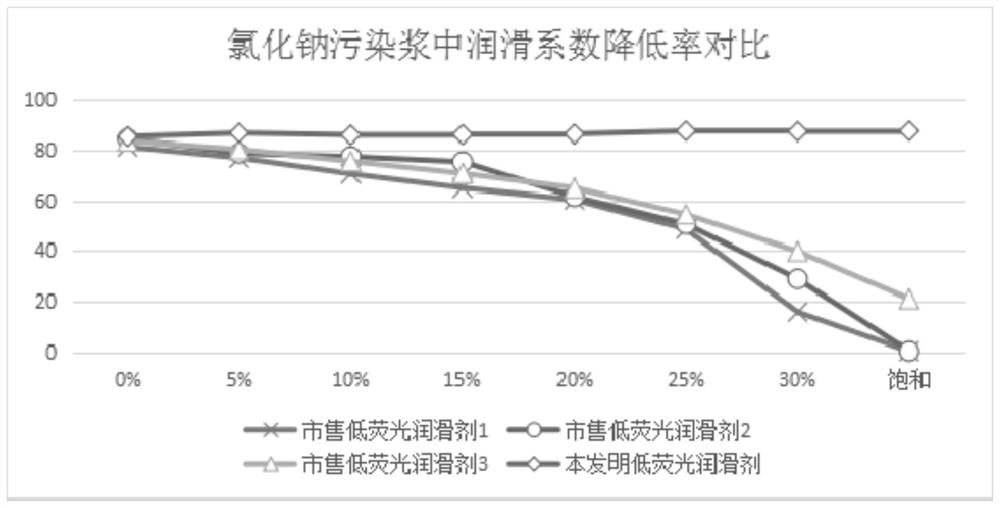

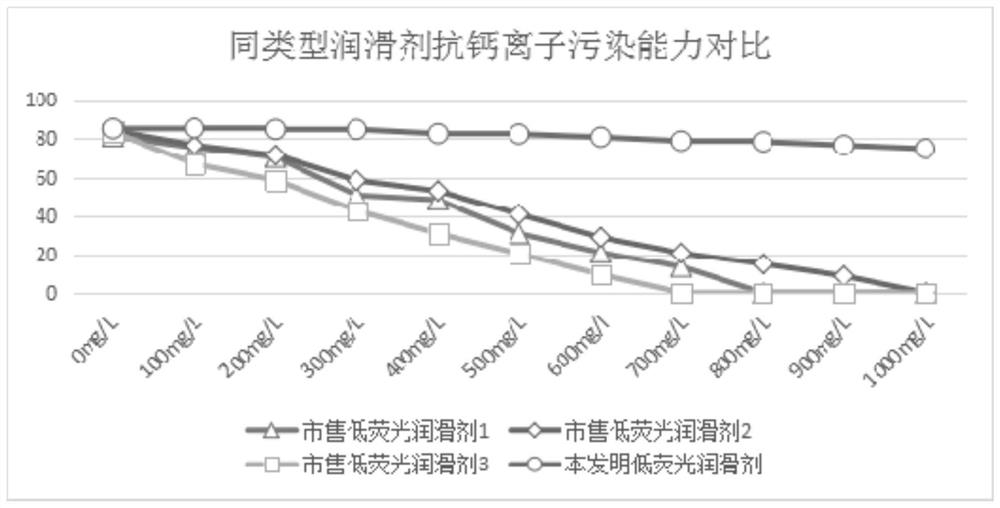

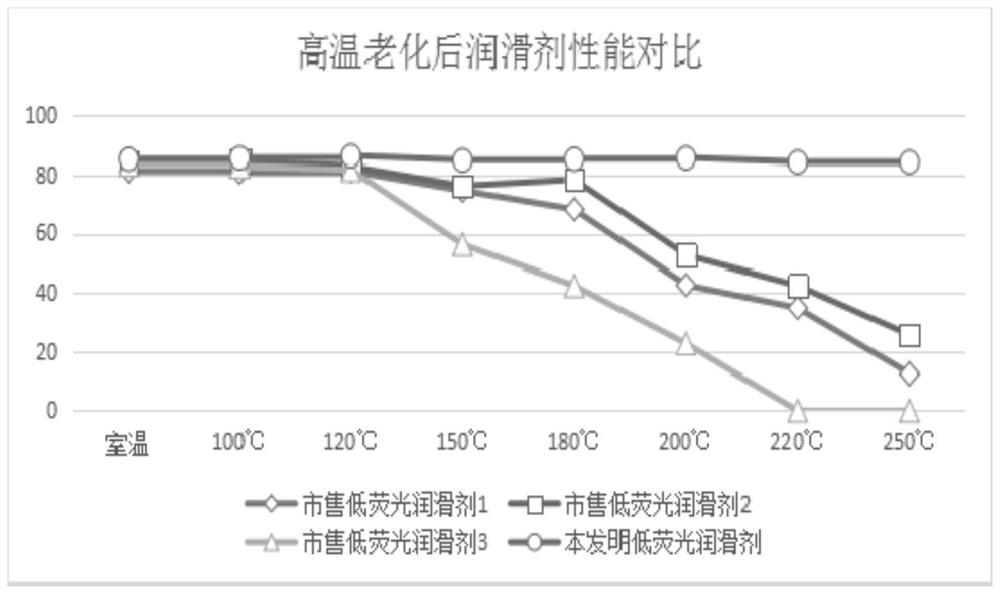

Low-fluorescence lubricant for drilling fluid and preparation method of low-fluorescence lubricant

The invention discloses a low-fluorescence lubricant for drilling fluid and a preparation method of the low-fluorescence lubricant, and solves the problems that an existing low-fluorescence lubricanthas poor salt pollution resistance, does not have calcium ion pollution resistance and has greatly reduced lubricating property in a high-temperature environment. The lubricant comprises the raw material of a mixed solution composed of, in parts by mass, 25-30% of industrial oleic acid, 15-20% of industrial coconut oil, 35-45% of industrial white oil, 10% of softened water and 5-10% of an additive.

Owner:XINJIANG TARIM OILFIELD CONSTR ENG

Environment-friendly high-temperature-resistant and high-salt-resistant lubricant for water-based drilling fluid as well as preparation method and application thereof

ActiveCN114752364AImprove adsorption capacityGuaranteed stabilityDrilling compositionPtru catalystHorizontal wells

The invention provides an environment-friendly high-temperature-resistant and high-salt-resistant lubricant for water-based drilling fluid and a preparation method and application thereof.The preparation method comprises the following steps that polyhydric alcohol is heated to a first reaction temperature, boric acid is added, a heat preservation reaction is conducted under nitrogen protection, and an intermediate product is obtained; directly adding long-chain fatty acid and a catalyst into the obtained intermediate product, and heating to a second reaction temperature for reaction; and after the reaction is finished, cooling to obtain the environment-friendly high-temperature-resistant and high-salt-resistant lubricant. The lubricant can effectively reduce the lubrication coefficient of the drilling fluid under the conditions of high temperature and high salt, is good in environmental protection property and biodegradability, can be applied to drilling of a deep stratum complex structure well, and solves the problems of large friction resistance and serious backing pressure in the process of drilling a deep horizontal well, a highly-deviated well and the like by using the existing water-based drilling fluid.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

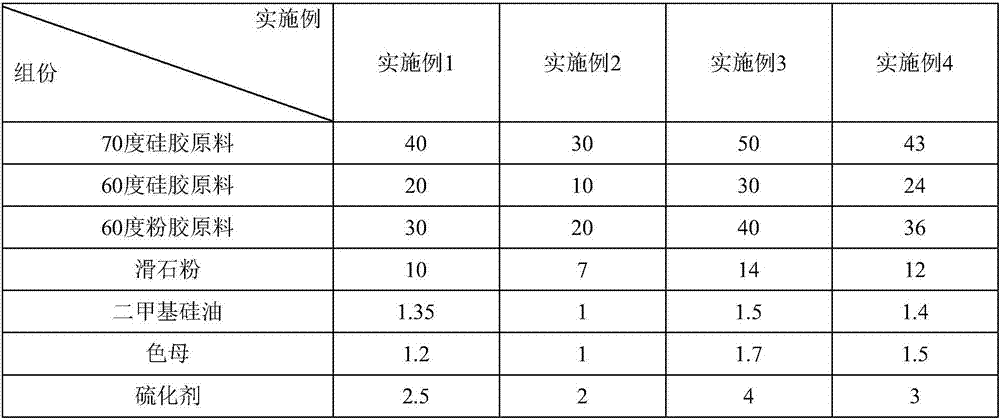

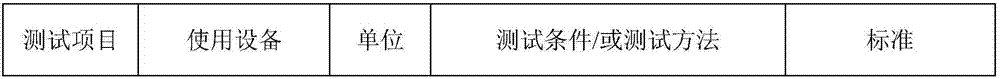

Silica gel film plating windshield wiper rubber strip and preparation method thereof

The invention relates to a silica gel film plating windshield wiper rubber strip and a preparation method thereof. The silica gel film plating windshield wiper rubber strip is prepared from the following ingredients in parts by weight: 30 to 50 parts of 70-DEG C silicon rubber raw materials, 10 to 30 parts of 60-DEG C silicon rubber raw materials, 20 to 40 parts of 60-DEG C powder rubber raw materials, 7 to 14 parts of talcum powder, 1 to 1.5 parts of simethicone, 1 to 1.7 parts of color masterbatch and 2 to 4 parts of vulcanizing agents. The silica gel film plating windshield wiper rubber strip has the advantages that the formula is simple; the preparation cost is low; the excellent mechanical intensity, ozone resistance and atmosphere aging resistance performance are realized; the friction coefficient is low; the use temperature is wide; the long-time use can be realized at -40 DEG C (or lower temperature) to +100 DEG C (or higher temperature).

Owner:XIAMEN METO AUTO PARTS IND

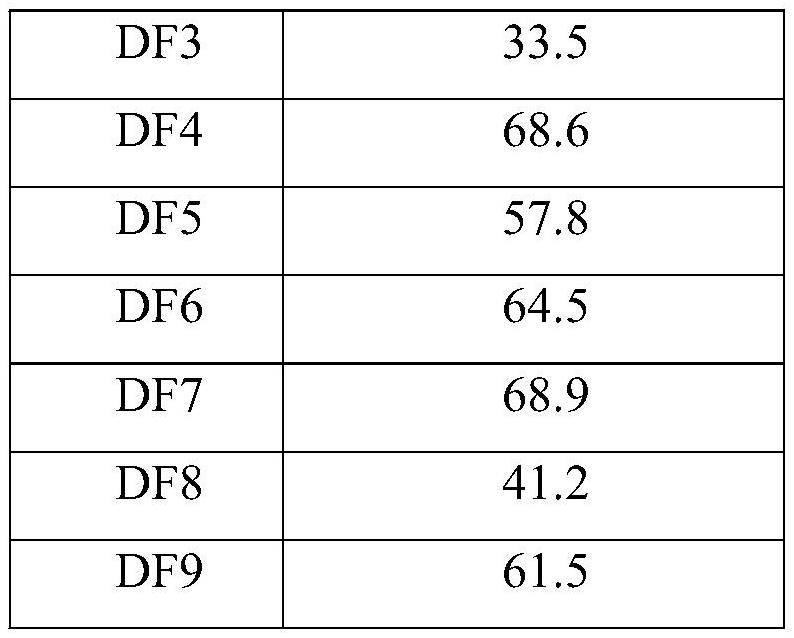

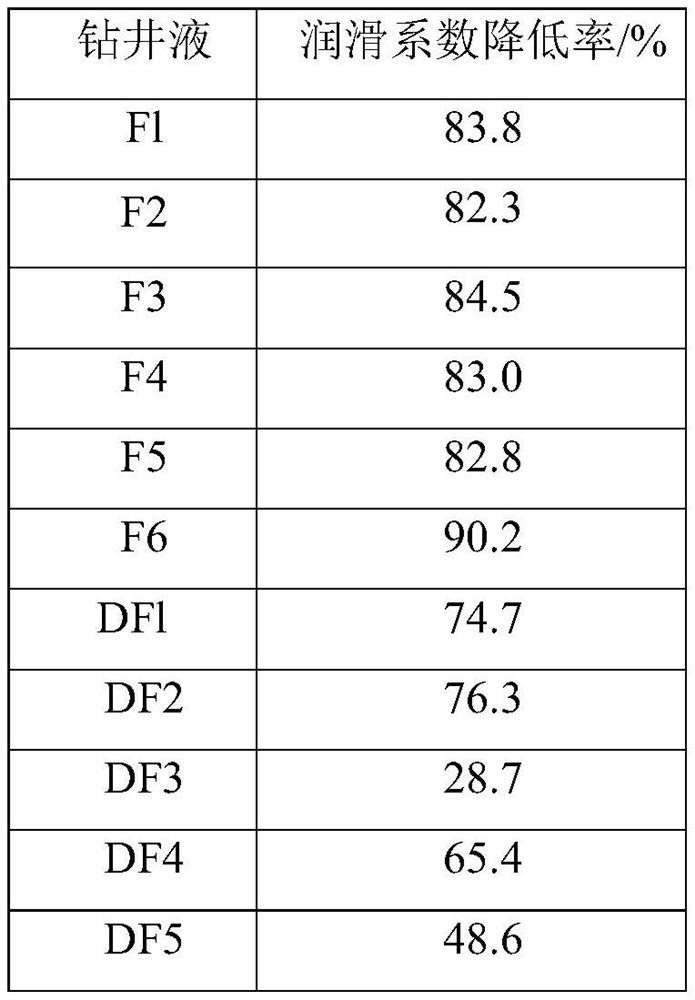

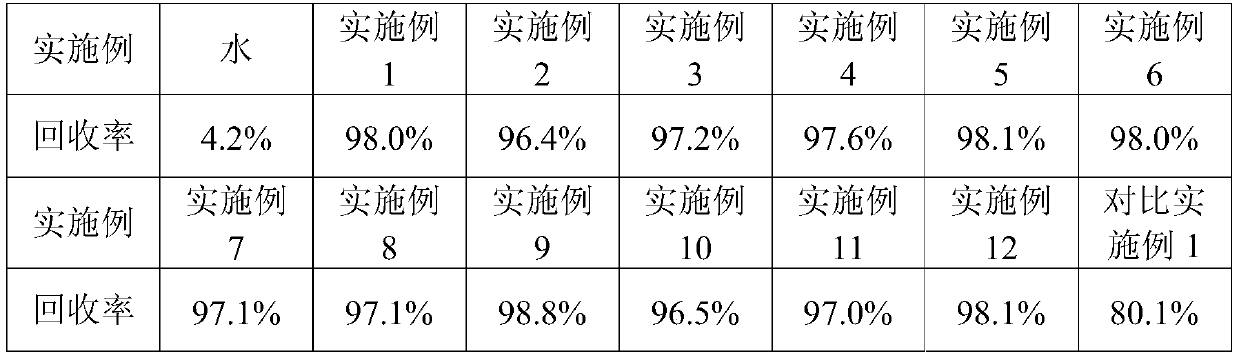

Anti-blocking lubricant for drilling fluid and preparing method

InactiveCN102492403AImprove the lubrication effectNo fluorescenceDrilling compositionReduction rateFluorescence

Disclosed are anti-blocking lubricant for drilling fluid and a preparing method. The anti-blocking lubricant for drilling fluid is characterized by including the following components, by weight percentage, 97.5% of No.10 white oil, 2% of oleic acid formic ester and 0.5% of emulsifier (SOP (standard operation procedure)-80). The manufacturing method includes steps of adding 97.5% of the No.10 white oil into a reactor, slowly mixing the same until the temperature rises to 25 DEG C, then adding 2% of the oleic acid formic ester and mixing uniformly slowly as heating in a manner of controlling the temperature to be no higher than 45 DEG C and mixing time to be not less than 30 minutes, finally, adding 0.5% of the emulsifier (SOP-80) and mixing continuously for one hour while heating again and controlling the temperature to be no higher than 50 DEG C. The anti-blocking lubricant for drilling fluid is high in lubricating performance, free of fluorescence and affection on geological logging data, capable of effectively preventing blocking of a drill during drilling and filling the blank of the field in home and abroad and reduction rate of lubrication coefficient is higher than 80%.

Owner:LANGFANG QINGXING CHEM

Temperature-resistant drilling fluid plugging agent and preparation method thereof

InactiveCN103937471BEffective blockingDoes not affect rheological parametersDrilling compositionSodium bisulfateVegetable fibers

The invention relates to a temperature-resistance drilling fluid drill-feeding plugging agent and its preparation method, the drill-feeding plugging agent comprises the following components by weight: 30-80 parts of vegetable fiber, 10-40 parts of mineral fiber, 10-40 parts of fruit shell, 0-10 parts of powdered steatile, and 3-10 parts of silicon-based gel deformation particles. The silicon-based gel deformation particles enable emulsification and dispersion of 1.4-2.5 parts of vinyltriethoxysilane monomer according to weight to an aqueous solution composed of 18-24 parts of acrylamide, 0.0025-0.005 parts of N,N'-methylene bisacrylamide, 0.7-1.25 parts of OP-10 and 0.1-0.17 parts of sodium dodecyl benzene sulfonate, 0.003 parts of disodium ethylene diamine tetraacetate, 0.009-0.12 parts of ammonium persulfate and 0.009-0.012 parts of sodium bisulfate, a process of micellar copolymerization is carried out, a polymer is dried, granulated and crushed to obtain the silicon-based gel deformation particles with average particle size of 80-200 meshes; easy-leakage highly-permeable stratum and micro crack are effectively plugged, rheological parameter of the drilling fluid is not influenced, frictional resistance coefficient of the drilling fluid is reduced, a storage layer is protected, and the drill-feeding plugging agent is suitable for plugging the easy-leakage stratum and the storage layer.

Owner:中国石油天然气股份有限公司冀东油田分公司钻采工艺研究院

A kind of environment-friendly high-density non-solid phase weighting agent and preparation method thereof

ActiveCN104610937BSuitable for a wide temperature rangeLow viscosityDrilling compositionCarboxylic acidChelating resin

An environment-friendly high-density solid-free weighting agent comprises components in parts by weight as follows: 0.02-0.05 parts of a dispersant, 0.3-1 part of a tackifier, 0.5-1.2 parts of chelating agent, 0.6-2 parts of a corrosion inhibitor and the balance of soluble weighting materials, wherein the dispersant is one or two of sodium polyacrylate and copolymer of phosphono and carboxylic acid; the tackifier is one or more of chitosan, agar, polyacrylamide, xanthan gum and hydroxypropyl methyl cellulose; the chelating agent is one or two of aminophosphonic acid chelate resin and ethylenediamine tetraacetic acid disodium; the corrosion inhibitor is one or two of multiple polycarboxylate and sodium gluconate; the soluble weighting materials are one or more of potassium formate, potassium citrate, potassium acetate, potassium silicate and potassium sulfate. The process steps are as follows: the raw materials are taken in weight proportion, mixed and uniformly stirred; the raw materials are added to water and dissolved at the high temperature of 70-80 DEG C; a product is evaporated to dryness, and solid is obtained; the obtained solid is ground into powder, and the solid weighting agent is obtained.

Owner:成都西油华巍科技有限公司

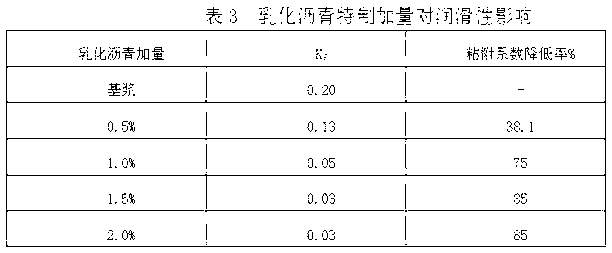

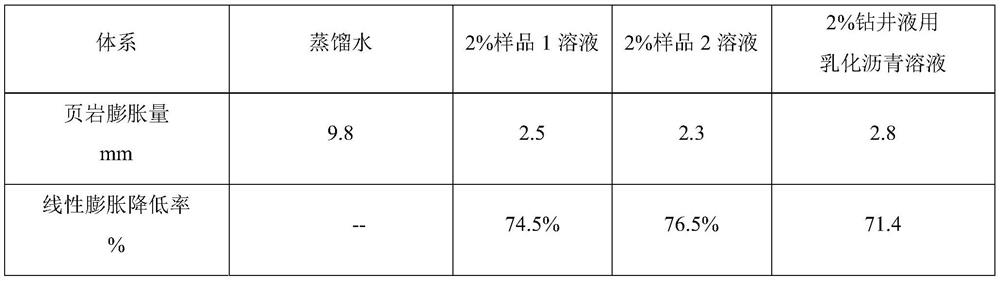

Emulsified asphalt for drilling fluids

The invention discloses an emulsified asphalt for drilling fluids, and belongs to the technical field of the oilfield chemical engineering. The emulsified asphalt is composed of 75-80mass% of petroleum asphalt, 5-10mass% of extreme pressure lubricating oil, 0.8-1.2mass% of a dispersant IW, 0.8-1.2mass% of fluorocarbon FC-3b, 0.8-1.2mass% of polyether 330N, 10mass% of diesel oil, 0.8-1.2mass% of polyethylene glycol, and 0.8-1.2mass% of a quaternary ammonium salt. A preparation method of the emulsified asphalt comprises a step of fully stirring the above raw materials at normal temperature for uniform mixing, and a step of emulsifying by a colloid mill. The emulsified asphalt is a pure oil base, has a good anti-sloughing lubrication property, has an increased temperature resistance, has no water, and is suitable for water-based drilling fluids and organic salt weighting drilling fluids. The emulsified asphalt is convenient to transport, store and use in winter.

Owner:CHANGZHOU KEDI CEMENT SLURRY

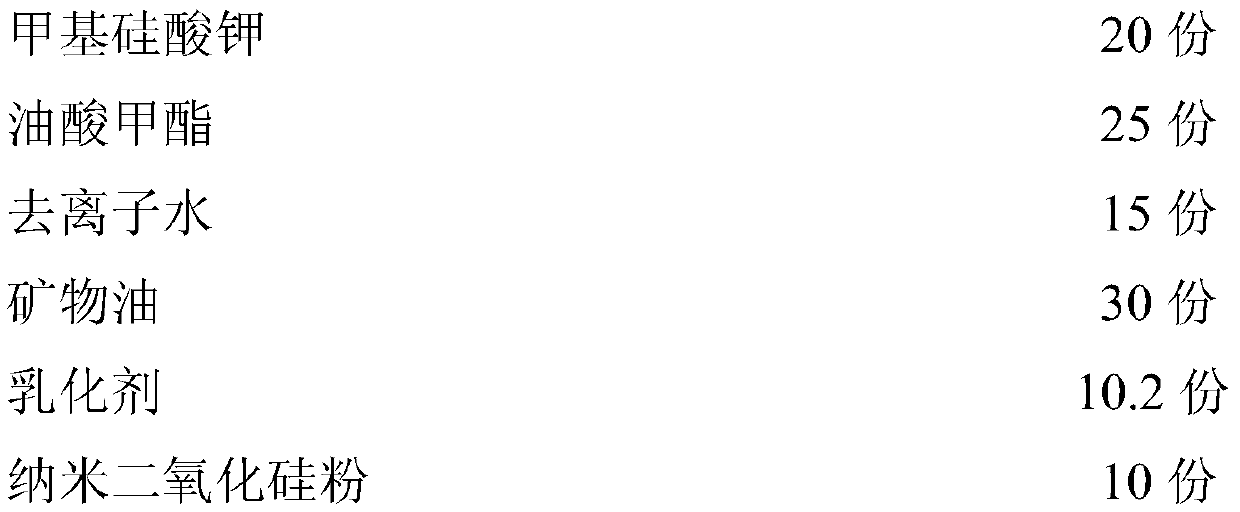

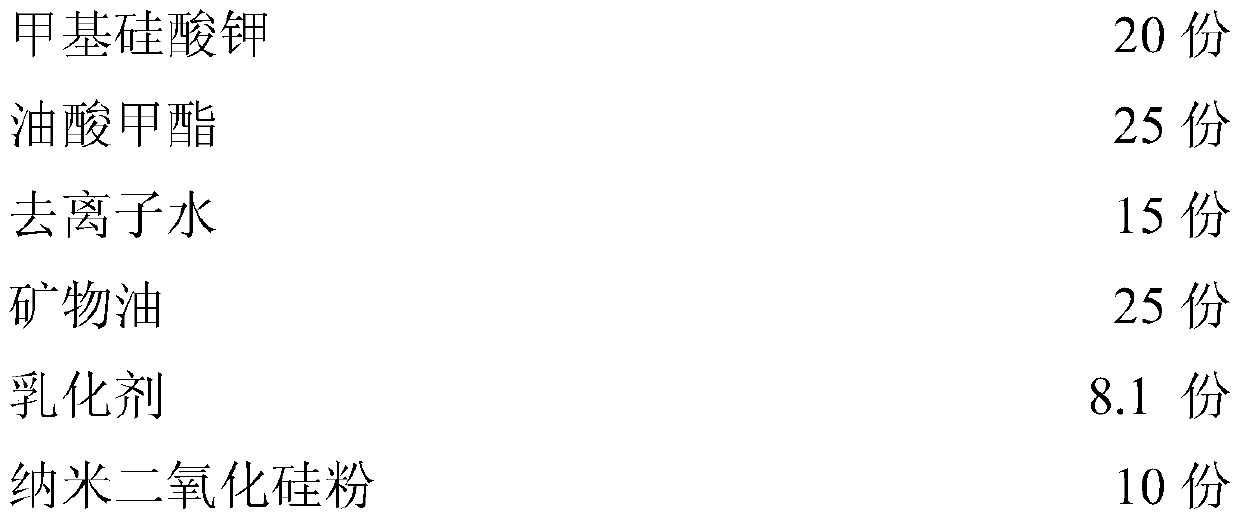

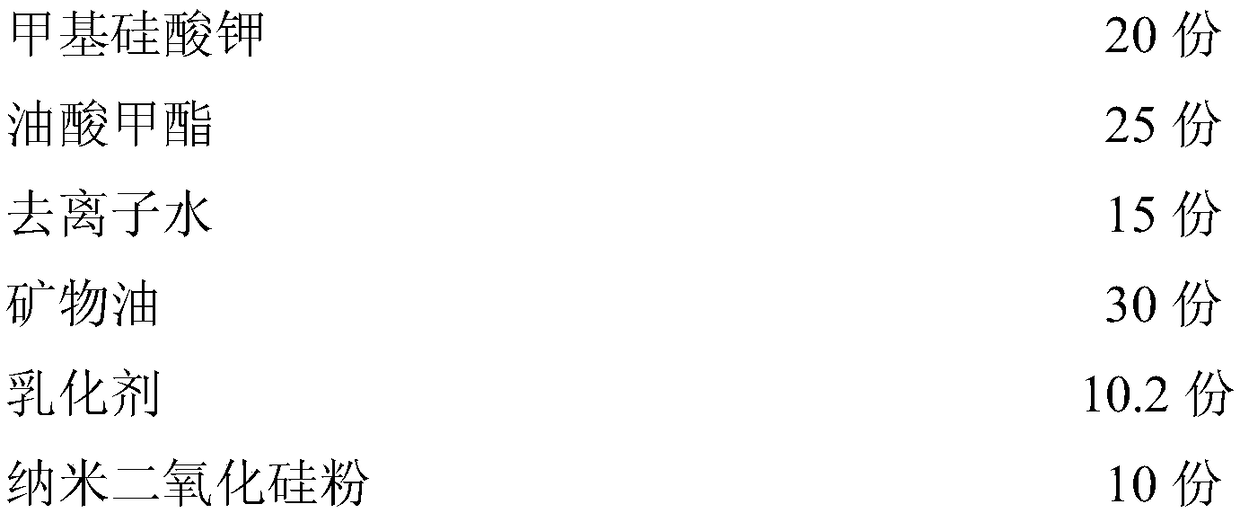

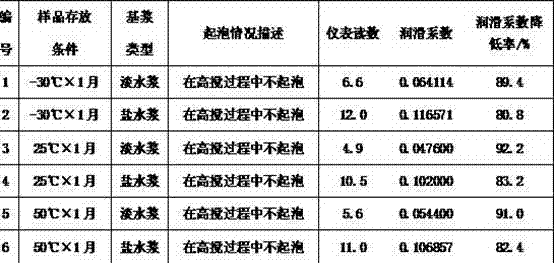

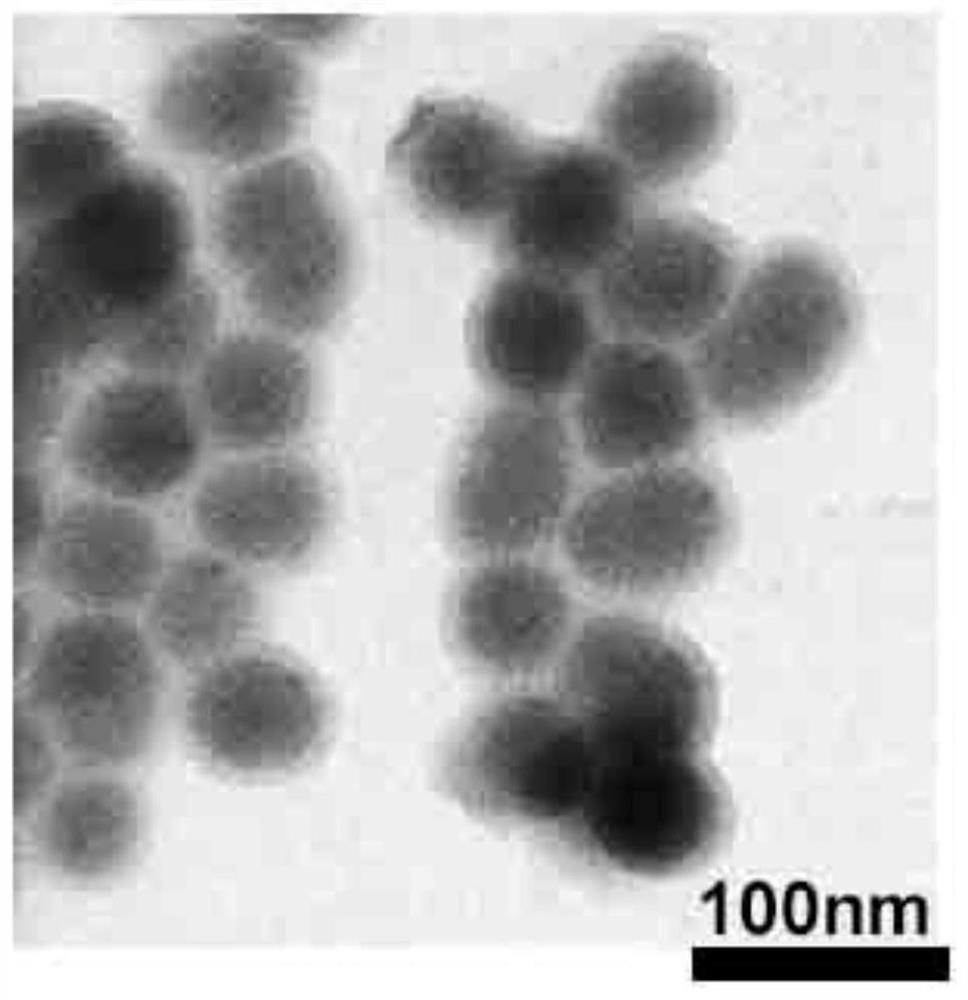

Lubrication inhibitor nano-ester hydrate for drilling fluid and preparation method thereof

ActiveCN108893100BImprove performanceReduce the lubrication coefficientDrilling compositionWell drillingPotassium trimethylsilanolate

The invention discloses a lubrication inhibitor nanometer ester-group hydrate used for drilling fluid and a preparation method thereof. The lubrication inhibitor nanometer ester-group hydrate used fordrilling fluid is prepared from potassium trimethylsilanolate, methyl oleate, deionized water, mineral oil, an emulsifying agent and nanosilicon dioxide powder. The preparation method includes the steps that the potassium trimethylsilanolate, methyl oleate, deionized water, mineral oil and emulsifying agent are added into a reaction kettle and sufficiently mixed and stirred; the materials in thereaction kettle are heated, and emulsifying is performed; at certain temperature, the nanosilicon dioxide powder is added, the mixture is sufficiently mixed and stirred, and the hydrate is obtained after cooling. The lubrication inhibitor nanometer ester-group hydrate is good in performance and simple in technology, has high lubrication restraining capacity, ensures that the drilling fluid keeps good lubrication performance in a drill tool, reduces backing pressure of a drilling machine, keeps drilling speed, effectively restrains hydration dispersion of well wall clay, has good restraining performance and compatibility, effectively avoids or reduces downhole complex accidents, improves well drilling quality and efficiency, and is suitable for kinds of drilling fluid systems.

Owner:石家庄华莱鼎盛科技有限公司

Lubrication inhibitor nanometer ester-group hydrate used for drilling fluid and preparation method thereof

ActiveCN108893100AImprove performanceReduce the lubrication coefficientDrilling compositionWell drillingPotassium trimethylsilanolate

The invention discloses a lubrication inhibitor nanometer ester-group hydrate used for drilling fluid and a preparation method thereof. The lubrication inhibitor nanometer ester-group hydrate used fordrilling fluid is prepared from potassium trimethylsilanolate, methyl oleate, deionized water, mineral oil, an emulsifying agent and nanosilicon dioxide powder. The preparation method includes the steps that the potassium trimethylsilanolate, methyl oleate, deionized water, mineral oil and emulsifying agent are added into a reaction kettle and sufficiently mixed and stirred; the materials in thereaction kettle are heated, and emulsifying is performed; at certain temperature, the nanosilicon dioxide powder is added, the mixture is sufficiently mixed and stirred, and the hydrate is obtained after cooling. The lubrication inhibitor nanometer ester-group hydrate is good in performance and simple in technology, has high lubrication restraining capacity, ensures that the drilling fluid keeps good lubrication performance in a drill tool, reduces backing pressure of a drilling machine, keeps drilling speed, effectively restrains hydration dispersion of well wall clay, has good restraining performance and compatibility, effectively avoids or reduces downhole complex accidents, improves well drilling quality and efficiency, and is suitable for kinds of drilling fluid systems.

Owner:石家庄华莱鼎盛科技有限公司

Drilling shaft lining stabilizer

InactiveCN101362938BPlay a stabilizing roleReduce the lubrication coefficientDrilling compositionAlcoholEther

The invention discloses a boring well wall stabilizer which is mainly used for solving the technical problem that storage layer is damaged due to unstable well wall and expansion of clay during the boring process; the well wall stabilizer consists of 20-35 parts of diallyldimethylammonium chloride, 2-5 parts of diallyldimethylammonium chloride-acrylamide polymer, 1-5 parts of non-ionic surfactantOP-10, 1-2 parts of fluoride-bearing alkyl ethoxy ether alcohol non-ionic surfactant, 1-3 parts of cellulose, 1-5 parts of KCl and 45-74 parts of water, according to the weight parts. The stabilizer can stabilize the well wall, greatly reduces the expansion rate of the clay at storage layer and eliminates the damages on the storage layer.

Owner:XI'AN PETROLEUM UNIVERSITY

Surfactant for drilling fluid and preparation method of surfactant

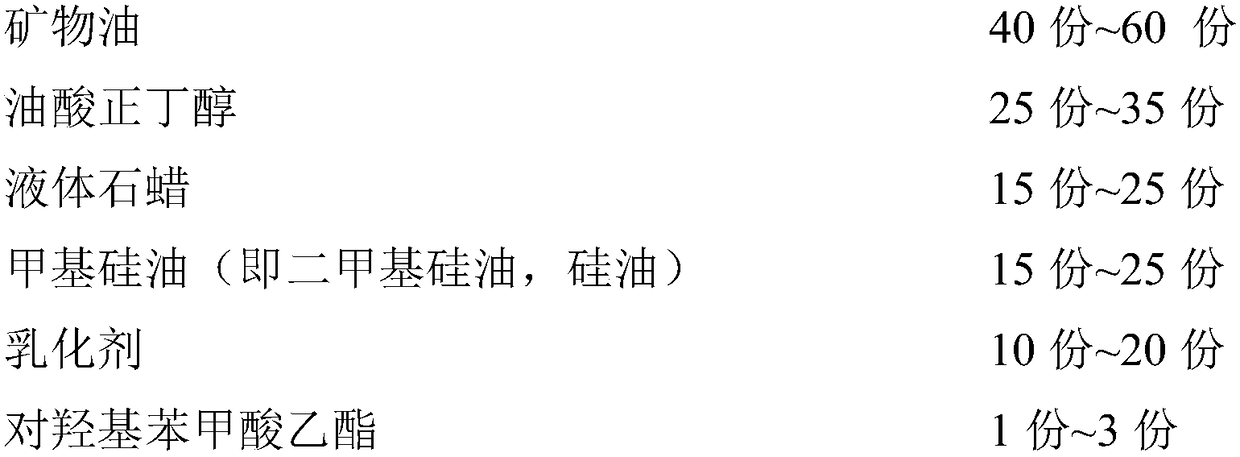

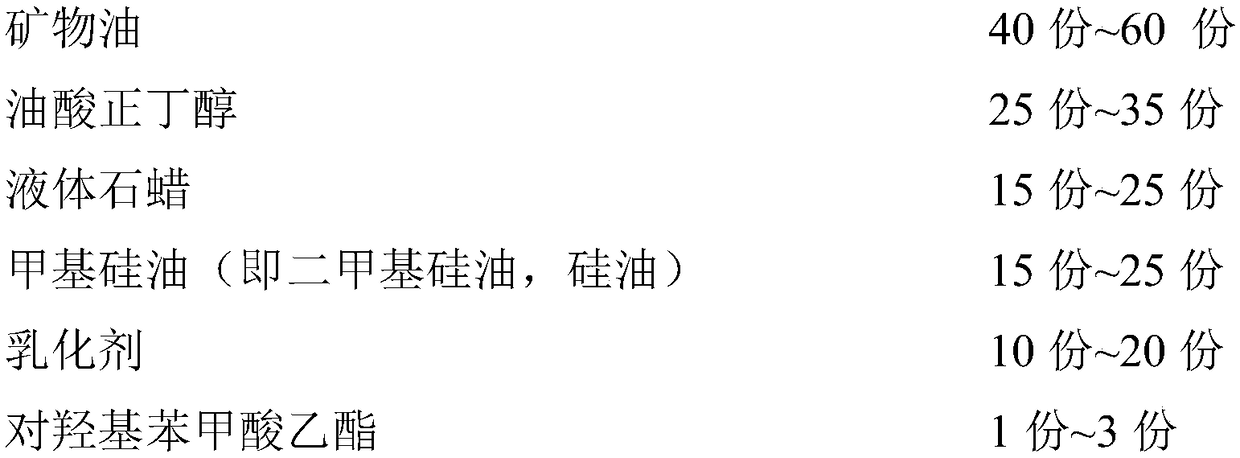

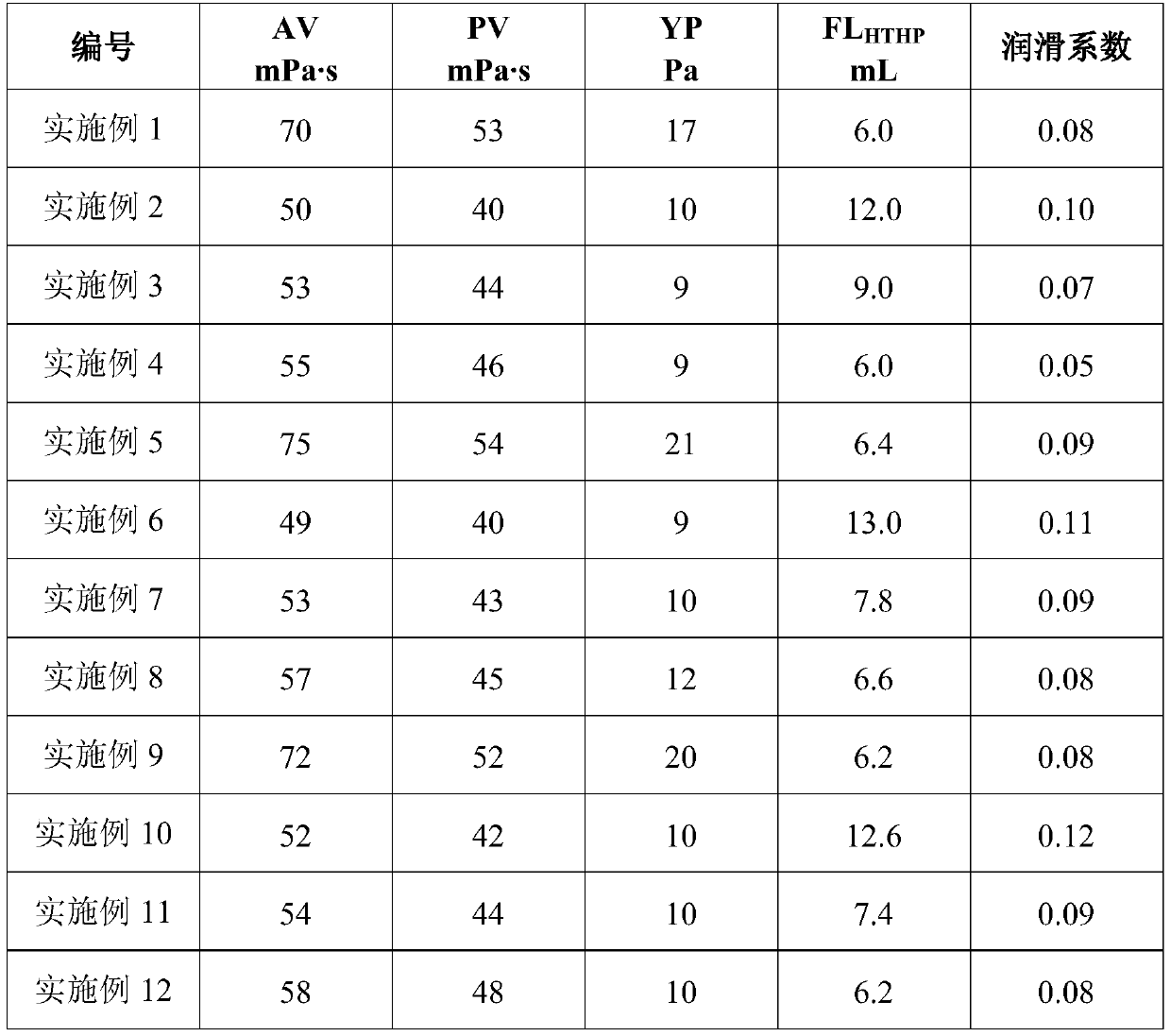

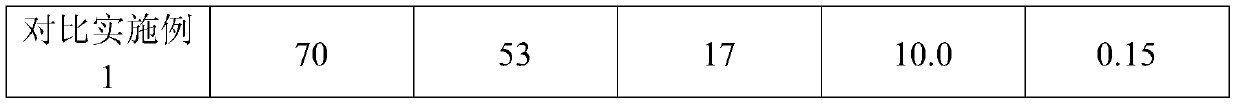

ActiveCN108441177AImprove performanceReduce the lubrication coefficientDrilling compositionEthyl hydroxybenzoateHigh resistance

The invention provides a surfactant for drilling fluid and a preparation method of the surfactant. The surfactant is prepared from raw materials as follows: mineral oil, n-butyl alcohol oleate, liquidparaffin, methyl silicone oil, an emulsifier and ethyl p-hydroxybenzoate, wherein the mineral oil is one or two of No.5 white oil and No.7 white oil. The preparation method comprises steps as follows: the mineral oil, n-butyl alcohol oleate, liquid paraffin, methyl silicone oil and the emulsifier are added to a reactor and are sufficiently mixed and stirred; the materials in the reactor are heated and emulsified; ethyl p-hydroxybenzoate is added at certain temperature, the materials are sufficiently mixed and stirred, and the surfactant is obtained after cooling. The surfactant is good in performance and prepared with a simple process, has higher resistance to compression and guarantees that the drilling fluid has lower circulating density and higher suspended rock debris carrying capacity at the shaft bottom under high pressure, complex underground accidents are avoided or reduced effectively, and drilling quality and efficiency are improved; the surfactant still has good performanceat high temperature, can be resistant to 10% compound brine pollution and has good inhibiting performance for lubrication.

Owner:石家庄华莱鼎盛科技有限公司

Surfactant for drilling fluid and preparation method thereof

ActiveCN108441177BImprove performanceReduce the lubrication coefficientDrilling compositionEthyl hydroxybenzoateHigh resistance

The invention provides a surfactant for drilling fluid and a preparation method of the surfactant. The surfactant is prepared from raw materials as follows: mineral oil, n-butyl alcohol oleate, liquidparaffin, methyl silicone oil, an emulsifier and ethyl p-hydroxybenzoate, wherein the mineral oil is one or two of No.5 white oil and No.7 white oil. The preparation method comprises steps as follows: the mineral oil, n-butyl alcohol oleate, liquid paraffin, methyl silicone oil and the emulsifier are added to a reactor and are sufficiently mixed and stirred; the materials in the reactor are heated and emulsified; ethyl p-hydroxybenzoate is added at certain temperature, the materials are sufficiently mixed and stirred, and the surfactant is obtained after cooling. The surfactant is good in performance and prepared with a simple process, has higher resistance to compression and guarantees that the drilling fluid has lower circulating density and higher suspended rock debris carrying capacity at the shaft bottom under high pressure, complex underground accidents are avoided or reduced effectively, and drilling quality and efficiency are improved; the surfactant still has good performanceat high temperature, can be resistant to 10% compound brine pollution and has good inhibiting performance for lubrication.

Owner:石家庄华莱鼎盛科技有限公司

Drag inhibitor/reducer for drilling fluid and preparation method of drag inhibitor/reducer

InactiveCN104194744AGood drag reduction effectReduce the adhesion coefficientDrilling compositionVulcanizationHorizontal wells

The invention relates to a drag inhibitor / reducer for a drilling fluid and a preparation method of the drag inhibitor / reducer. The drag inhibitor / reducer is prepared from the following components in percentage by weight: 0.5-2% of cationic gemini surfactant, 1-2% of quaternary ammonium cationic surfactant, 0.5-1% of vulcanized oil, 20-25% of glucoside water solution and the balance of white oil. The preparation method comprises the steps of adding the vulcanized oil into the white oil at the temperature of 50-60 DEG C, and stirring for 1-2h; then, sequentially adding the cationic gemini surfactant and the quaternary ammonium cationic surfactant, and stirring for 2-4h; next, adding the glucoside water solution, and stirring for 2-4h; and finally, controlling the temperature at 100-120 DEG C, and concentrating for 1h to obtain the drag inhibitor / reducer for the drilling fluid. The drag inhibitor / reducer is suitable for reducing frictional resistance in the drilling processes of horizontal wells and large-displacement wells, and has a better effect in solid-free, low-solid and clay-free drilling fluid systems.

Owner:克拉玛依市金鑫科技有限公司

A high-performance water-based drilling fluid formula

ActiveCN107573911BWith restraintEnhanced inhibitory effectDrilling compositionWater basedDirectional well

The invention discloses a high-performance water-based drilling fluid. The high-performance water-based drilling fluid is prepared from the following components in parts by weight: 100 parts of freshwater, 2 to 6 parts of bentonite, 0.2 to 0.6 part of coating agent, 0 to 5 parts of fluid loss agents, 1 to 6 parts of lubricating fluid loss agents, 0 to 4 parts of lubricant, 2 to 6 parts of anti-collapse blocking agent, 6 to 8 parts of shale inhibitor, 0.2 to 0.4 part of pH adjusting agent, and 60 parts of weighting agents; the lubricating fluid loss agents are boric acid ester modified graphene oxide, a high-performance water-based drilling fluid system provided by the invention has the characteristics of strong inhibition, strong plugging and the like, and at the same time has the advantages of low lubrication coefficient and small downhole friction resistance, thus being suitable for construction operations of directional wells and large displacement wells.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Low fluorescent lubricating agent for drilling fluid and method for preparing low fluorescent lubricating agent

ActiveCN103013464BImprove the lubrication effectReduce the lubrication coefficientDrilling compositionWater basedVegetable oil

The invention discloses a low fluorescent lubricating agent for drilling fluid and a method for preparing the low fluorescent lubricating agent. The low fluorescent lubricating agent is prepared from the following materials by weight percent: 30%-70% of swill-cooked dirty oil, 10%-30% of natural fatty acid, 10%-30% of vegetable oil, 1%-10% of oleic acid, 1%-3% of dodecylbenzene sulfonic acid and 1%-3% of polyvinyl alcohol. The method for preparing the low fluorescent lubricating agent comprises the following steps: accurately weighing the materials in a ratio, then putting the materials into a reactor, heating to 40-60 DEG C and stirring for 1-2hours at constant temperature. The method is simple in polymerization process and is suitable for industrial production; the low fluorescent lubricating agent for the drilling fluid is high in performance cost ratio, small in dosage and excellent in lubricating performance, is suitable for various water-base mud systems; and the low fluorescent lubricating agent is fluorescent-free and pollution-free, does not interfere geological logging work, dose not foam, dose not stick sieves, dose not influence other drilling fluid performances and dose not increase viscosity and water loss.

Owner:河北华运鸿业化工有限公司

Illegal cooking oil lubricant and preparation method thereof

The invention discloses an illegal cooking oil lubricant and a preparation method thereof. The illegal cooking oil lubricant comprises the following components in percentage by weight: 40%-60% of illegal cooking oil, 0.5%-1.5% of sodium sulfite, 1%-3% of sorbide oleate, 0.02%-0.04% of antioxidants, 0.2%-0.3% of extreme-pressure antiwear agents, 0.05%-0.1% of formaldehyde, 1.0%-1.2% of sodium hydroxide and the balance of water. Through the illegal cooking oil lubricant disclosed by the invention, the problem that torque and friction resistance are reduced through lubrication in the drilling process of a horizontal well is effectively solved, moreover, a new way is provided for the recycling of the illegal cooking oil, and the preparation cost of the lubricant can be reduced.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

A kind of solid lubricant and its preparation method and application

ActiveCN113845889BImprove surface activityImprove the lubrication effectDrilling compositionPentaerythritolPolybutylene

Owner:北京培康佳业技术发展有限公司

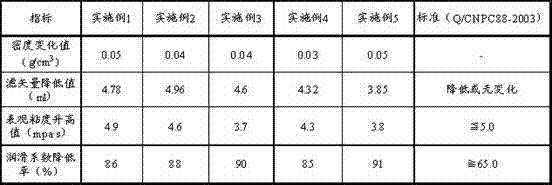

A kind of anti-high temperature environment-friendly drilling fluid lubricant and preparation method thereof

ActiveCN107556988BGuarantee authenticityGood water solubilityDrilling compositionThermodynamicsActive agent

The invention relates to a high-temperature-resistant environment-protecting type drilling fluid lubricating agent. The high-temperature-resistant environment-protecting type drilling fluid lubricating agent mainly solves the problems that in the existing drilling process, the lubricating property is not high, high-temperature resistance and high-pressure resistance are low, and the drilling exploitation requirements of a deep well and an extradeep well are difficult to meet. The high-temperature-resistant environment-protecting type drilling fluid lubricating agent is characterized by comprising the following components in percentage by mass: 20 to 35 percent of plant oil, 20 to 40 percent of silicon oil, 5 to 10 percent of an anti-wear agent, 10 to 20 percent of a surfactant and 15 to 30percent of water. The preparation method of the drilling fluid lubricating agent comprises the following steps: (1) adding the silicon oil into the plant oil and performing stirring reaction; (2) mixing the surfactant and the anti-wear agent mixture according to the proportion in advance, performing stirring reaction, and mixing with the base oil in the step (1); (3) adding the water according tothe proportion, continuously performing stirring reaction and filtering to obtain a product. The high-temperature-resistant environment-protecting type drilling fluid lubricating agent can resist 150-DEG C temperature, is simple in synthesis process and convenient for on-site application, meets the environment-protecting requirement and is a high-performance liquid lubricating agent.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

A kind of low fluorescence lubricant for drilling fluid and its preparation method

The invention discloses a low-fluorescence lubricant for drilling fluid and a preparation method thereof, which solves the problems that the existing low-fluorescence lubricant has poor anti-salt pollution ability, does not have anti-calcium ion pollution ability, and the lubricating performance will be greatly reduced in a high-temperature environment. The raw material of the lubricant is a mixed liquid composed of industrial oleic acid, industrial coconut oil, industrial white oil, demineralized water and additives; the mass fraction of industrial oleic acid is 25-30%; the mass fraction of industrial coconut oil is 15-30%. 20%, the mass fraction of industrial white oil is 35-45%, the mass fraction of demineralized water is 10%, and the mass fraction of additives is 5-10%.

Owner:XINJIANG TARIM OILFIELD CONSTR ENG

Preparation method for seawater corrosion resistant type self-lubricating material

InactiveCN106825550AImprove corrosion resistanceExtend the lifespanTransportation and packagingMetal-working apparatusMaterials preparationFriction effect

The invention discloses a preparation method for a seawater corrosion resistant type self-lubricating material, and belongs to the technical field of self-lubricating material preparation. The preparation method is characterized in that polyethylene is cracked and polyethylene wax is collected; a nickel basal body layer is deposited on a polyethylene wax surface layer through the electro-deposition effect; copper is replaced and covered to a nickel surface, so that a double-layer clad structure is formed; in a self-lubricating process, a self-friction material is cracked as a result of the friction effect to release inner-layer polyethylene wax; a high temperature generated by friction is absorbed by the polyethylene wax, so that the polyethylene wax is molten and coated to the surface of a self-friction material copper-nickel composite, and therefore, a lubricating protective film layer is formed; and while lubricating efficiency is improved, point corrosion caused by deposition of pollutants in seawater is effectively prevented, and lubricating efficiency of the self-lubricating material is improved.

Owner:仇颖莹

Nano lubricant for drilling fluid as well as preparation method and application of nano lubricant

ActiveCN113265023AThe preparation technology route is simpleMild reaction conditionsDrilling compositionFluorine containingMaterials science

The invention discloses a nano lubricant for drilling fluid and a preparation method and application thereof, and the preparation method mainly comprises the following steps: adding an anionic monomer, a fluorine-containing monomer and a solvent into a reaction device, uniformly stirring, then adding an initiator in an inert gas atmosphere for reaction, cooling to room temperature after the reaction is finished, and then carrying out post-treatment to obtain the nano lubricant for drilling fluid. The preparation method has the characteristics of simple preparation route, mild reaction conditions, high product purity, simple post-treatment operation and easy realization of large-scale production; the surface of the nano lubricant is provided with an anionic functional group and a fluorine-containing functional group, the anionic functional group and the fluorine-containing functional group have a synergistic effect to reduce the frictional resistance between the drilling fluid and a well wall, the lubricating property is obviously improved, the nano lubricant has dispersion stability and lubricating property, and when the addition amount of the nano lubricant in the drilling fluid is 1%, the reduction rate of the lubricating coefficient is greater than 81%; meanwhile, by introducing fluorine-containing functional groups, the high-temperature-resistant performance is achieved, and the temperature resistance reaches 195 DEG C or above.

Owner:SOUTHWEST PETROLEUM UNIV

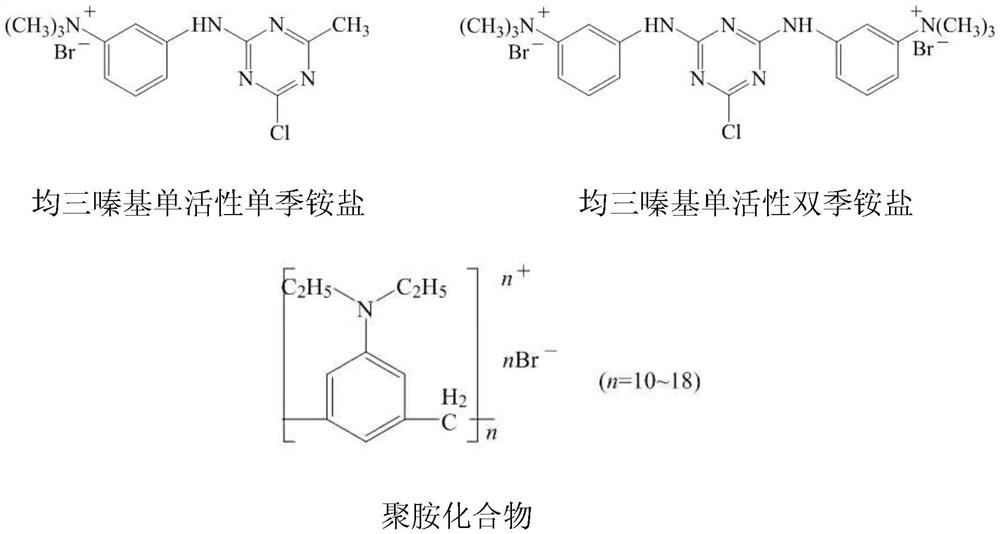

Anti-collapse blocking agent cation modified asphalt for drilling fluid

InactiveCN112430397ACreate pollutionImprove performanceDrilling compositionBuilding insulationsActive agentPetroleum engineering

Anti-collapse blocking agent cationic modified asphalt for a drilling fluid is prepared from the following raw materials: petroleum asphalt powder, a modifier, a surfactant, a stabilizer and high-boiling-point solvent oil. The modifier is triazinyl single-activity monoquaternary ammonium salt, s-triazinyl single-activity biquaternary ammonium salt and a polyamine compound; and the surfactant is hexadecyl trimethyl ammonium chloride, hexadecyl trimethyl ammonium bromide, Tween 80, Tween 60 and OP-10. The preparation method comprises the following steps: adding the high-boiling-point solvent oiland the petroleum asphalt powder into a reaction kettle, and conducting heating, stirring and dissolving to obtain an asphalt glue solution; adding a surfactant and a modifier into the asphalt glue solution, and conducting reacting to obtain a colloid; adding a stabilizer to obtain a gelatinous product; and conducting cooling to a solidified state, and conducting crushing to obtain a final product. The plugging performance is good, wall collapse can be inhibited, complex drilling accidents are effectively avoided or reduced, and the drilling quality and the drilling efficiency are improved.

Owner:石家庄华莱鼎盛科技有限公司

A kind of composite resin lubricating anti-slump agent for drilling fluid and preparation method thereof

ActiveCN108641684BImprove the lubrication effectHigh temperature resistanceDrilling compositionVegetable oilActive agent

The invention discloses a compound resin lubricating anti-collapse agent for drilling fluid. The compound resin lubricating anti-collapse agent is prepared from the following raw materials in parts bymass: 40-60 parts of vegetable oil for industry purpose, 1-2 parts of an alkali solution, 15-30 parts of petroleum resin and 5-8 parts of a surfactant. The compound resin lubricating anti-collapse agent takes the vegetable oil for industry purpose as a raw material, contains the petroleum resin product and has low production cost, no or low toxicity on organisms and no pollution to the environment. A prepared product can effectively reduce friction resistance and torque in a drilling process, reduces occurrence of sticking of drill tools and other complicated accidents in a down hole, has good lubricating properties and strong temperature resistance as compared with other drilling fluid treatment agents, can effectively substitute for bitumen products, is more favorable for large-scale popularization and application, has obvious economic benefits, improves the anti-collapse sealing performance of a drilling fluid system, and effectively solves the problems of low lubricating coefficient of drilling fluid and insufficient sealing performance of the anti-collapse agent.

Owner:LANGFANG QINGXING CHEM

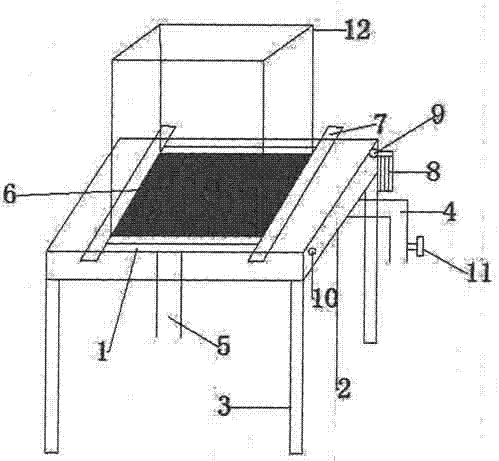

Automatic mixed gas filtering device

InactiveCN103566646ANo pollutionIncrease elasticityMoving filtering element filtersMixed gasImpurity

The invention discloses an automatic mixed gas fixing device. The automatic mixed gas fixing device comprises a filtering groove (1), a supporting frame (2), a bracket (3), a discharge tube (4) and an impurity output tube (5), wherein the bracket (3) is fixedly provided with the filtering groove (1) consisting of the supporting frame (2); the upper part of the filtering groove (1) is provided with a filtering frame (7) with a filtering screen (6); an electric motor (8) is connected with the supporting frame (2) through bolts (9); a vibration button (10) is arranged on the left side of the supporting frame (2); a feed barrel (12) is arranged on the filtering frame (7); the discharge tube (4) is provided with an adjusting valve (11) has the functions of regulation of liquid discharging speed and control on switching on and off. According to the automatic fixing device, the electric motor (8) is adopted for driving the filtering screen (6) to automatically vibrate so as to achieve the effects of filtering coating and removing impurities; the automatic fixing device is high in filtering speed, good in effect, time-saving and labor-saving; the filtering screen (6) can be disassembled automatically, and is convenient to clean.

Owner:CHANGZHOU CHANGYU PRACTICAL GAS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com