Low-fluorescence lubricant for drilling fluid and preparation method of low-fluorescence lubricant

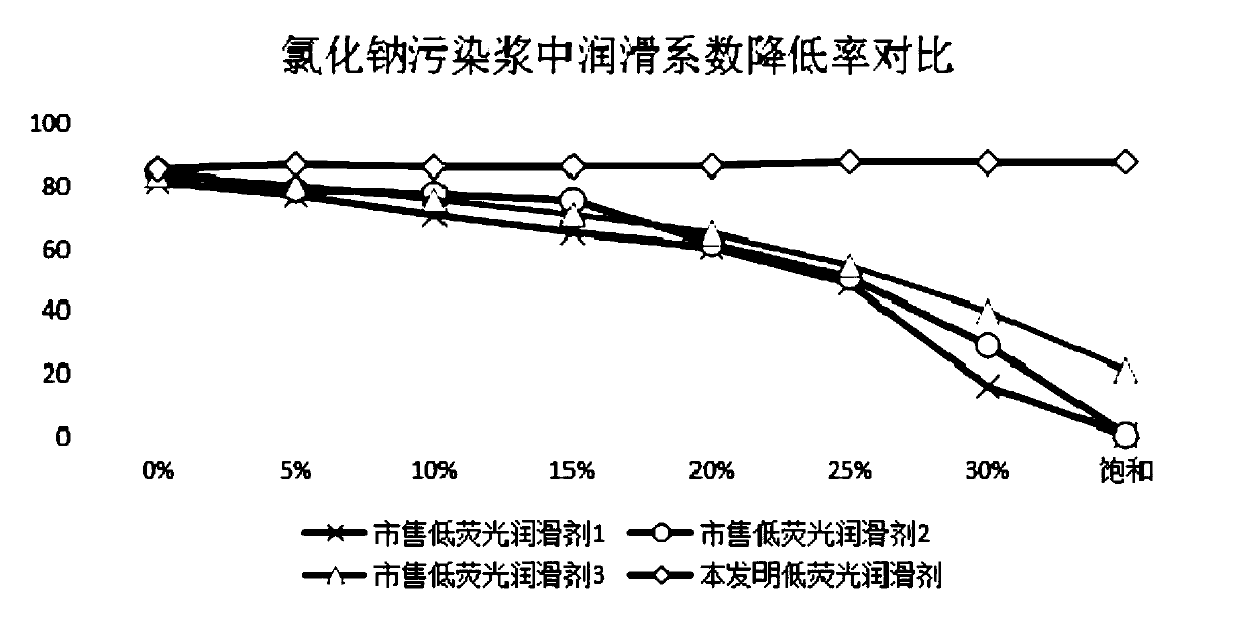

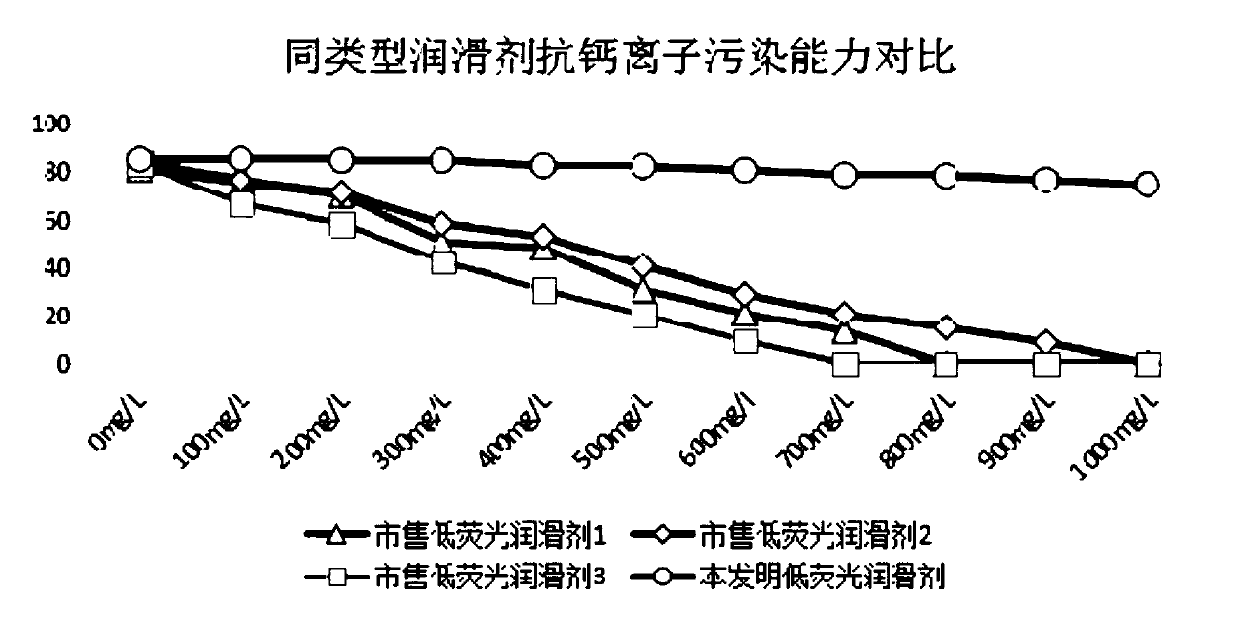

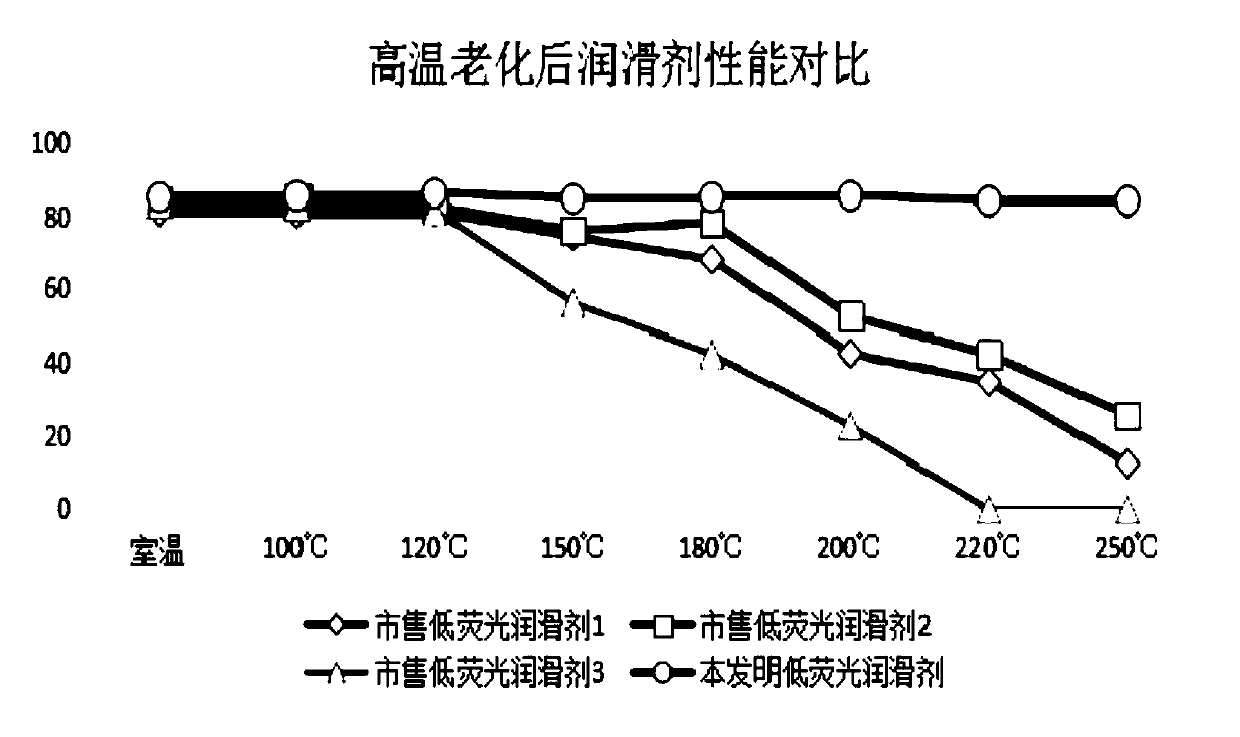

A lubricant and low-fluorescence technology, applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems of decreased lubricating performance, lack of anti-calcium ion pollution ability, poor anti-salt pollution ability, etc., to achieve lubricity High, low fluorescence level, the effect of improving the success rate and effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0065] The mass fraction of industrial coconut oil in the fixed formula is 20%, the mass fraction of the additive (the formula selected by the additive in this test is a mixture of urea and sodium hydroxide according to the mass ratio of 3:1) is 10%, and the mass fraction of demineralized water is 10%. 10%, the mass fraction of industrial oleic acid is respectively 25%, 26%, 27%, 28%, 29%, and 30%, and the remaining ingredients are supplemented with industrial white oil. The temperature resistance, salt resistance and calcium ion pollution resistance of the samples were tested respectively. The specific experimental results are:

[0066] Such as Figure 4 As shown, with the increase of the mass fraction of industrial oleic acid, the anti-salt pollution ability of the lubricant used in this embodiment also increases. When the amount of industrial oleic acid exceeds 28%, the anti-salt pollution ability of the sample reaches the maximum . Such as Figure 5 As shown, with the ...

Embodiment 2

[0068] The mass fraction of industrial oleic acid in the fixed formula is 30%, the mass fraction of the additive (the formula selected by the additive in this test is a mixture of urea and sodium hydroxide according to the mass ratio of 3:1) is 10%, and the mass fraction of softened water is 10%. 10%, industrial coconut oil mass fractions are respectively 15%, 16%, 17%, 18%, 19%, 20%1, and all the other ingredients are supplemented with industrial white oil. The temperature resistance, salt resistance and calcium ion pollution resistance of the samples were tested respectively. The specific experimental results are:

[0069] Such as Figure 6 Shown, along with the increase of industrial coconut oil mass fraction in the present embodiment adopts the anti-sodium chloride pollution ability of lubricant almost no change. Such as Figure 7 As shown, along with the increase of the mass fraction of industrial coconut oil, the anti-calcium ion pollution ability of the lubricant use...

Embodiment 3

[0071] The mass fraction of industrial oleic acid in the fixed formula is 30%, the mass fraction of demineralized water is 10%, the mass fraction of industrial coconut oil is 20%, the additive (the formula that additive is selected in this test is urea and sodium hydroxide according to the quality Ratio 3:1 mixture) mass parts are respectively 5%, 6%, 7%, 8%, 9%, 10%, and the remaining ingredients are supplemented with industrial white oil. The temperature resistance, salt resistance and calcium ion pollution resistance of the samples were tested respectively.

[0072] The specific experimental results are:

[0073] Such as Figure 9 As shown, with the increase of the mass fraction of the additive, the anti-sodium chloride pollution ability of the lubricant used in this embodiment hardly changes. Such as Figure 10 As shown, with the increase of the mass fraction of additives, the anti-calcium ion pollution ability of the lubricant used in this embodiment has almost no chan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com