A kind of composite resin lubricating anti-slump agent for drilling fluid and preparation method thereof

A technology of lubricating anti-slump agent and composite resin, which is applied in drilling compositions, chemical instruments and methods, etc., can solve the problems of complex drilling fluid composition, increase drilling fluid cost, increase maintenance difficulty, etc., and improve plugging performance. Insufficient, outstanding economic benefits, low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] At 25° C., put 60 parts of industrial vegetable oil for removal of impurities in the reactor in parts by mass, then add 2 parts of 5wt% caustic soda solution under stirring, and hydrolyze for 2 hours (guarantee that the hydrolysis ratio of industrial vegetable oil is not higher than 30%) ), sequentially add 20 parts of C5 hydrogenated petroleum resin and 5 parts of surfactant (surfactant adopts emulsifier OP-10 and OP-15, mixed by 1:1) into the reaction kettle in sequence, fully stirred for 3h, After ensuring uniform emulsification, the composite resin lubricating anti-slump agent for drilling fluid is obtained, and its appearance is a brown emulsified liquid.

Embodiment 2

[0030] At 28° C., put 50 parts of industrial vegetable oil from impurities in the reaction kettle in parts by mass, then add 2 parts of 5wt% caustic soda solution under stirring, and hydrolyze for 3 hours (to ensure that the hydrolysis ratio of industrial vegetable oil is not higher than 30%) ), add 30 parts of C9 hydrogenated petroleum resin and 8 parts of lauryl polyoxyethylene ether in order to the reaction kettle, and fully stir for 5 hours to ensure that the mixing and emulsification is uniform, and the composite resin lubricating anti-slumping agent for drilling fluid is obtained. Appearance is brown-yellow emulsified liquid.

Embodiment 3

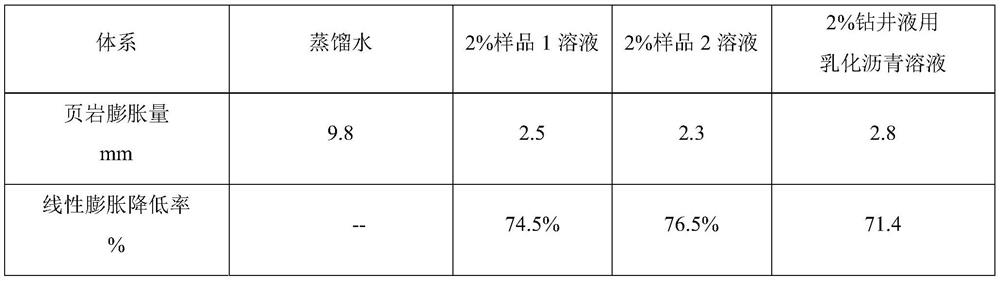

[0032] To test the lubricating performance of the lubricating anti-slump agent, sample 1 and sample 2 prepared in Example 1 and Example 2 were selected for testing. The extreme pressure lubrication coefficients of bentonite base slurry and bentonite slurry with 2% product were tested by Fann extreme pressure lubrication instrument. Taking the emulsified asphalt for drilling fluid as a comparative example, compare the lubricating ability of samples 1 and 2 with the emulsified asphalt for drilling fluid. The test results are shown in Table 1. The lower the extreme pressure lubrication coefficient, the stronger the lubricating ability of the system.

[0033] Table 1 Evaluation results of lubrication coefficient

[0034]

[0035] As can be seen from Table 1, the lubricating ability of sample 1 and sample 2 is equivalent to the lubricating ability of using emulsified asphalt for drilling fluid, and the lubricating performance of the lubricating anti-slump agent prepared by the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com