Temperature-resistance drilling fluid drill-feeding plugging agent and its preparation method

A plugging-while-drilling and drilling fluid technology, which is applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems of increased frictional torque of drilling fluid, thickening of drilling fluid, and poor temperature resistance, etc. Lubrication coefficient, reduced friction coefficient, and good reservoir protection characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

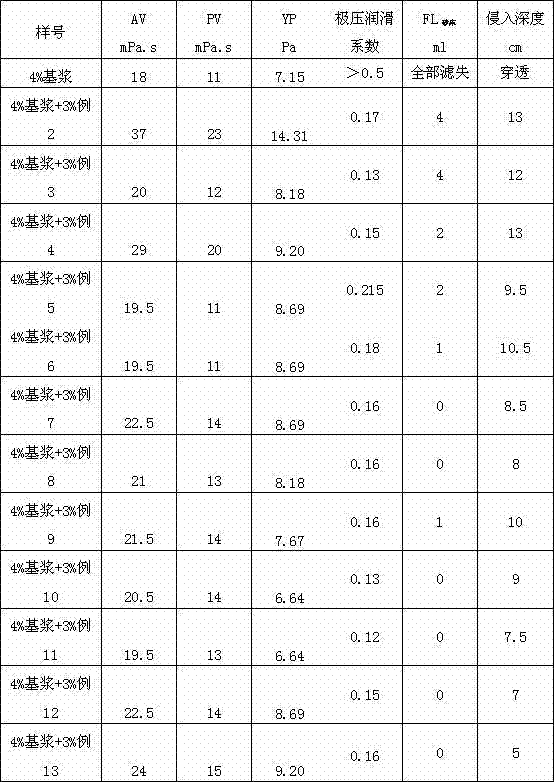

Examples

Embodiment 1

[0037] Completely dissolve 50g of acrylamide, 0.01g of N,N'-methylenebisacrylamide, 0.008g of disodium edetate, 2g of OP-10 and 0.3g of sodium dodecylbenzenesulfonate in 215g of deionized water . Then add 4g of vinyltriethoxysilane to the above solution for ultrasonic emulsification for 15min, and then add 2.5g of ammonium persulfate solution with a mass fraction of 1% and 2.5g of ammonium persulfate solution with a mass fraction of 1% for 20 min. Sodium bisulfate solution, continue to pass nitrogen for 15 minutes, seal and place in a water-soluble pot at 45°C to initiate polymerization. After reacting for 9 hours, the reaction product is taken out, dried, pulverized and sieved to obtain silicon-based gel deformed particles with a mesh number of 80-200 mesh.

Embodiment 2

[0039] Get drying by weight, 50 parts of 80 mesh rice husks after pulverizing, 20 parts of wollastonite, 20 parts of walnut shells, 5 parts of talcum powder, 5 parts of 100 mesh organogel filling particles of embodiment 1, in mixer Mix in medium for 30 minutes, and mix evenly to obtain a finished product.

Embodiment 3

[0041] Take 50 parts by weight of dried and crushed 80-mesh corn stalks, 20 parts of wollastonite, 25 parts of walnut shells, 5 parts of talcum powder, 6 parts of 150-mesh organogel filling particles in Example 1, and put them in a mixer Mix for 40 minutes, and mix evenly to obtain a finished product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com