Illegal cooking oil lubricant and preparation method thereof

A technology of waste oil and lubricant, which is applied in the directions of chemical instruments and methods, drilling compositions, etc., to achieve the effects of improving lubricating properties, stable rheological properties, and improving lubricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

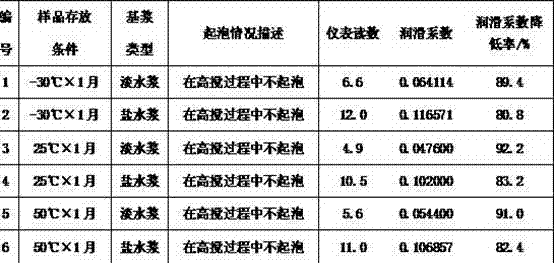

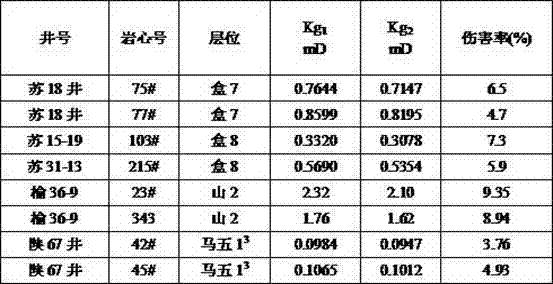

Image

Examples

Embodiment 1

[0027] A gutter oil lubricant, comprising the following components in weight percent: 45% to 55% of gutter oil, 0.8% to 1.2% of sodium sulfite, 1.5% to 2.5% of sorbitan oleate, and 0.025% to 0.035% of antioxidant , extreme pressure antiwear agent 0.22%~0.28%, formaldehyde 0.07%~0.09%, caustic soda 1.0%~1.2%, and the balance is water.

[0028] A preferred embodiment of the present invention is that, in the waste oil, the vegetable oil content is 40%-70%, and the animal oil content is 30%-60%. Waste oil in the prior art is applicable, and this is a preferred embodiment, but not limited thereto.

[0029] Another preferred embodiment of the present invention is that the sodium sulfite is 2.0% of the weight of waste oil, which is preferred, but not limited thereto.

[0030] In the present invention, the sorbitan oleate is preferably sorbitan oleate Span-80, and other types of sorbitan oleate can also be selected.

[0031] In the present invention, the antioxidant is preferably an...

Embodiment 2

[0038] This embodiment is basically the same as the above-mentioned embodiment, the main difference is:

[0039] A waste oil lubricant, comprising the following components in percentage by weight: waste oil 40%, sodium sulfite 0.5%, sorbitan oleate 1%, antioxidant 0.02%, extreme pressure antiwear agent 0.2%, formaldehyde 0.05% %, caustic soda 1.0%, and the balance is water.

[0040] A preparation method of waste oil lubricant, comprising the steps of:

[0041] a. Add waste oil into the closed reaction kettle and start stirring. When the temperature of the reaction kettle reaches 50°C, stir and slowly and evenly add sodium sulfite to react for 90 minutes;

[0042] b. Add sorbitan oleate, stir and react for 20 minutes, add water, then adjust the pH value to 8, stir and react for 8 minutes;

[0043] c. Add extreme pressure anti-wear agent, antioxidant and formaldehyde respectively and stir for 8 minutes to prepare waste oil lubricant for water-based drilling fluid.

[0044] In...

Embodiment 3

[0046] The embodiment is basically the same as the above-mentioned embodiment, the main differences are:

[0047] A waste oil lubricant, comprising the following components in percentage by weight: waste oil 60%, sodium sulfite 1.5%, sorbitan oleate 3%, antioxidant 0.04%, extreme pressure antiwear agent 0.3%, formaldehyde 0.1 %, caustic soda 1.2%, and the balance is water.

[0048] A preparation method of waste oil lubricant, comprising the steps of:

[0049] a. Add waste oil into the closed reaction kettle and start stirring. When the temperature of the reaction kettle reaches 45°C, stir and slowly and evenly add sodium sulfite to react for 70 minutes;

[0050]b. Add sorbitan oleate, stir and react for 15 minutes, add water, then adjust the pH value to 7.5, stir and react for 5 minutes;

[0051] c. Add extreme pressure anti-wear agent, antioxidant and formaldehyde respectively and stir for 5 minutes to prepare waste oil lubricant for water-based drilling fluid.

[0052] In...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com