High-performance water-based drilling fluid formulation

A water-based drilling fluid, high-performance technology, applied in drilling compositions, chemical instruments and methods, etc., can solve the problems of reduced drilling speed, easy formation of cuttings beds, stuck drill accidents, etc., and achieve excellent lubrication, Increase dispersion and reduce downhole friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

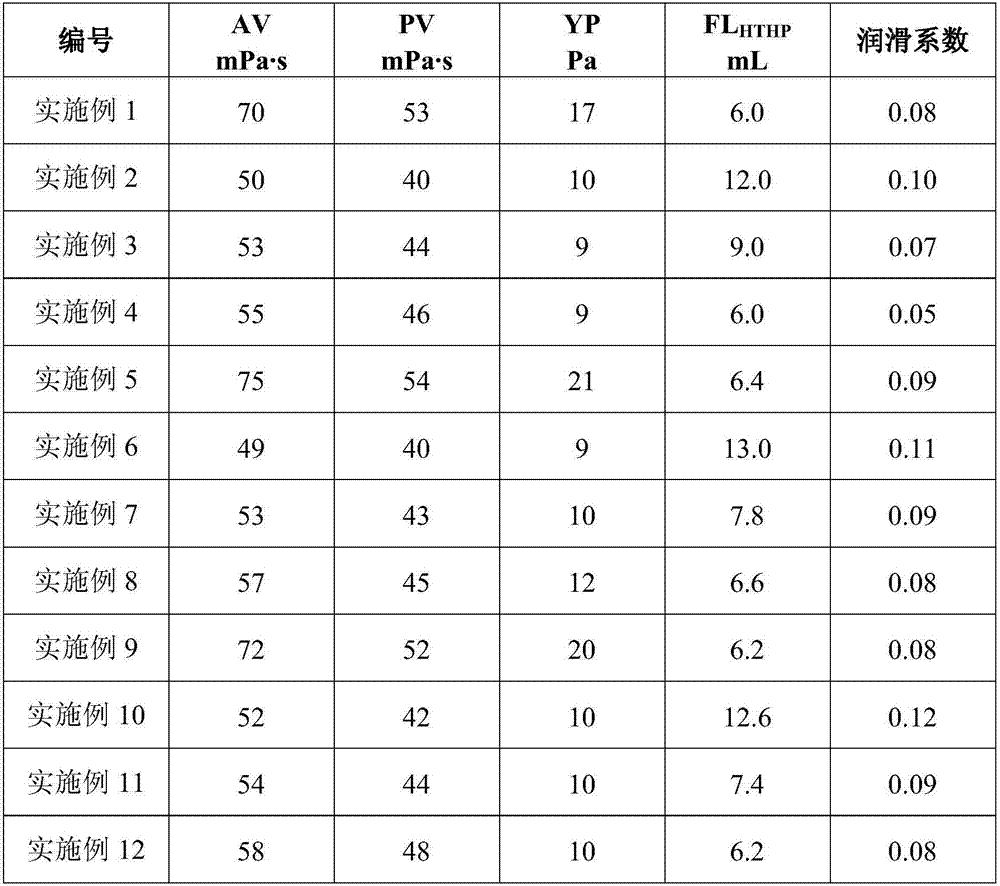

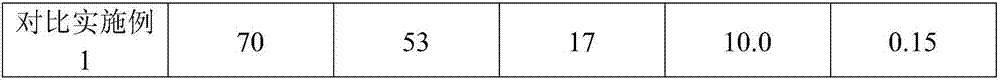

Examples

Embodiment 1

[0022] A high-performance water-based drilling fluid is composed of the following components by weight:

[0023] 100 parts of fresh water, 3 parts of bentonite, 0.2 parts of polyacrylamide potassium salt, 2 parts of polyanionic cellulose, 1 part of lubricating fluid loss reducer, 2 parts of modified vegetable oil, 2 parts of SOTEX potassium salt, 7 parts of KCl, 0.5 part of D230 , 0.3 parts of NaOH, 60 parts of barite;

[0024] The preparation method of described lubricating fluid loss additive is as follows:

[0025] 3 parts by weight of graphene oxide was ultrasonically dispersed in 60 parts by weight of ethanol, 28 parts by weight of amino-containing imidazoline borate oleate was added, and the reaction was carried out at 80° C. for 8 h. After the reaction was completed, suction filtration was performed, and deionized water Wash and dry the product.

Embodiment 2

[0027] A high-performance water-based drilling fluid is composed of the following components by weight:

[0028] 100 parts of fresh water, 3 parts of bentonite, 0.2 part of polyacrylamide potassium salt, 1 part of lubricating fluid loss reducer, 2 parts of SOTEX potassium salt, 7 parts of KCl, 0.5 part of D230, 0.3 part of NaOH, 60 parts of barite;

[0029] The preparation method of described lubricating fluid loss additive is as follows:

[0030] 3 parts by weight of graphene oxide was ultrasonically dispersed in 60 parts by weight of ethanol, 28 parts by weight of amino-containing imidazoline borate oleate was added, and the reaction was carried out at 80° C. for 8 h. After the reaction was completed, suction filtration was performed, and deionized water Wash and dry the product.

Embodiment 3

[0032] A high-performance water-based drilling fluid is composed of the following components by weight:

[0033] 100 parts of fresh water, 3 parts of bentonite, 0.2 part of polyacrylamide potassium salt, 2 parts of lubricating fluid loss reducer, 2 parts of SOTEX potassium salt, 7 parts of KCl, 0.5 part of D230, 0.3 part of NaOH, 60 parts of barite;

[0034] The preparation method of described lubricating fluid loss additive is as follows:

[0035] 3 parts by weight of graphene oxide was ultrasonically dispersed in 60 parts by weight of ethanol, 28 parts by weight of amino-containing imidazoline borate oleate was added, and the reaction was carried out at 80° C. for 8 h. After the reaction was completed, suction filtration was performed, and deionized water Wash and dry the product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com