Graphene resistance-reducing agent for fracturing fluid

A technology of graphene and drag-reducing agent, which is applied in the field of graphene drag-reducing agent for fracturing fluid, can solve the problems of insufficient drag-reducing performance of polyethylene oxide, failure of hydraulic fracturing to meet technical requirements, high production cost, etc., and achieve Good environmental protection compatibility, less components, and the effect of reducing friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

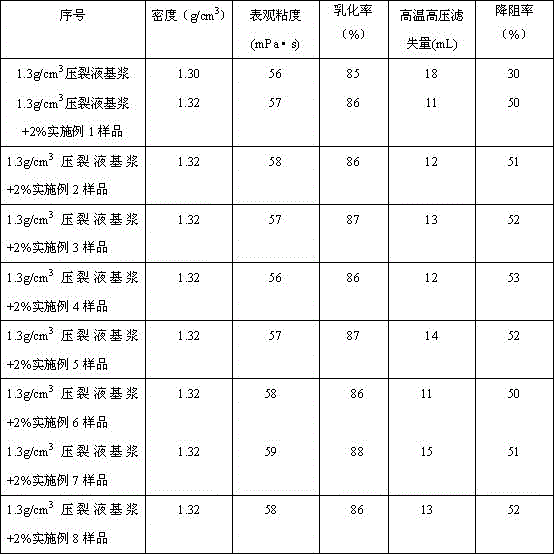

Examples

Embodiment 1

[0024] A graphene drag-reducing agent for fracturing fluid, the raw materials in parts by weight include: 5 parts of graphene powder, 10 parts of alkylphenol polyoxyethylene ether, and 20 parts of AE1910.

Embodiment 2

[0026] A graphene drag-reducing agent for fracturing fluid, the raw materials in parts by weight include: 10 parts of graphene powder, 15 parts of stearyl polyoxyethylene polyoxypropylene ether, and 12 parts of SP169.

Embodiment 3

[0028] A graphene drag-reducing agent for fracturing fluid, the raw materials in parts by weight include: 20 parts of graphene powder, 20 parts of dodecylbenzenesulfonic acid, and 16 parts of AE1910.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com