Patents

Literature

56results about How to "Wide range of densities" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

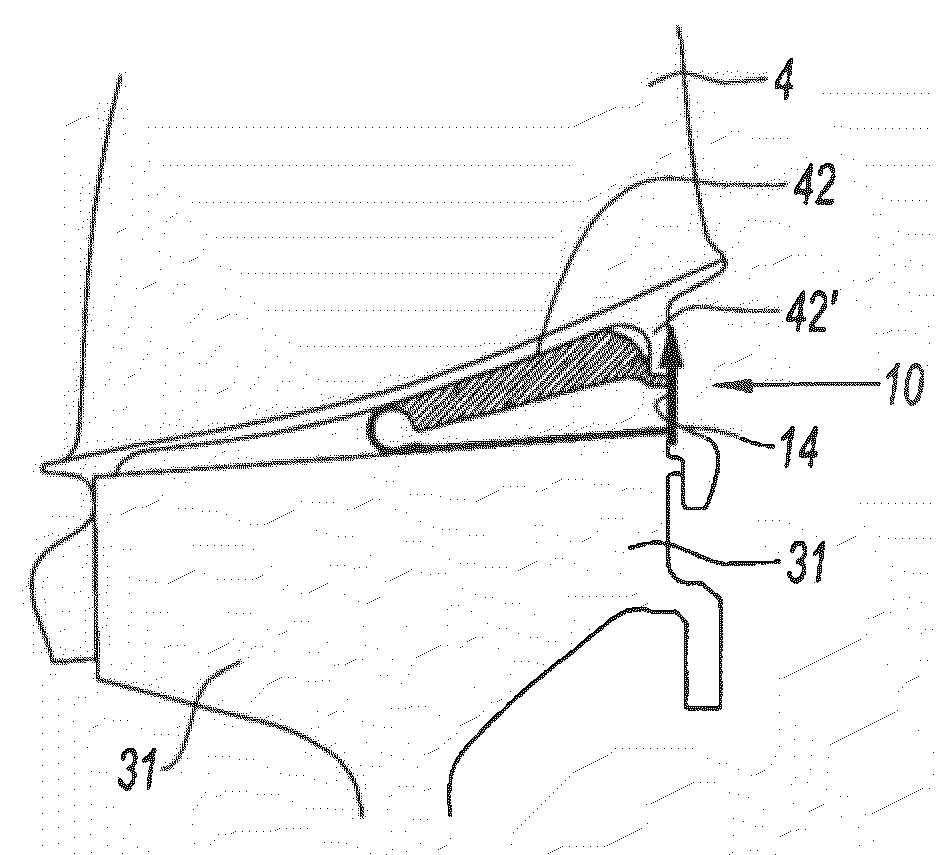

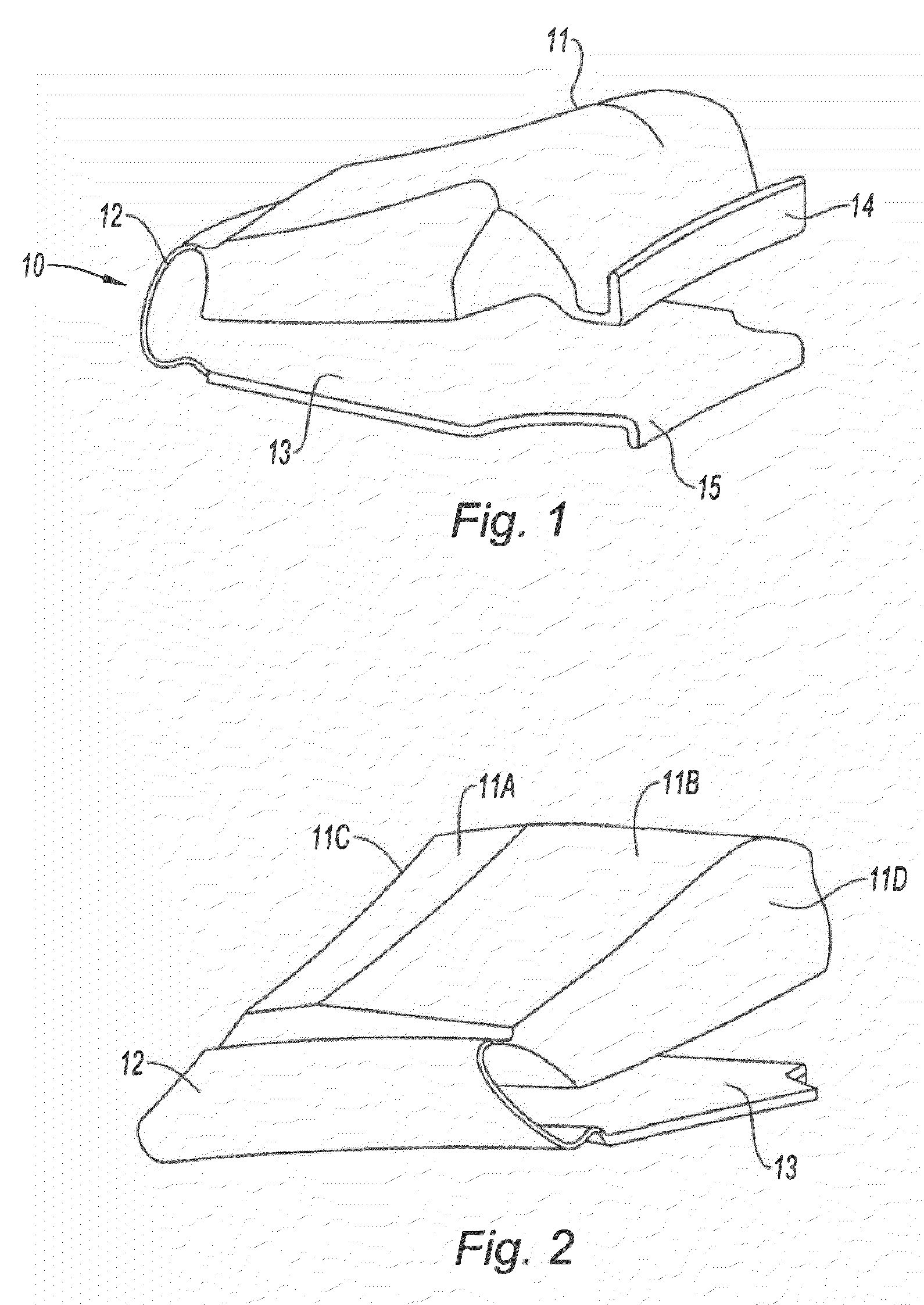

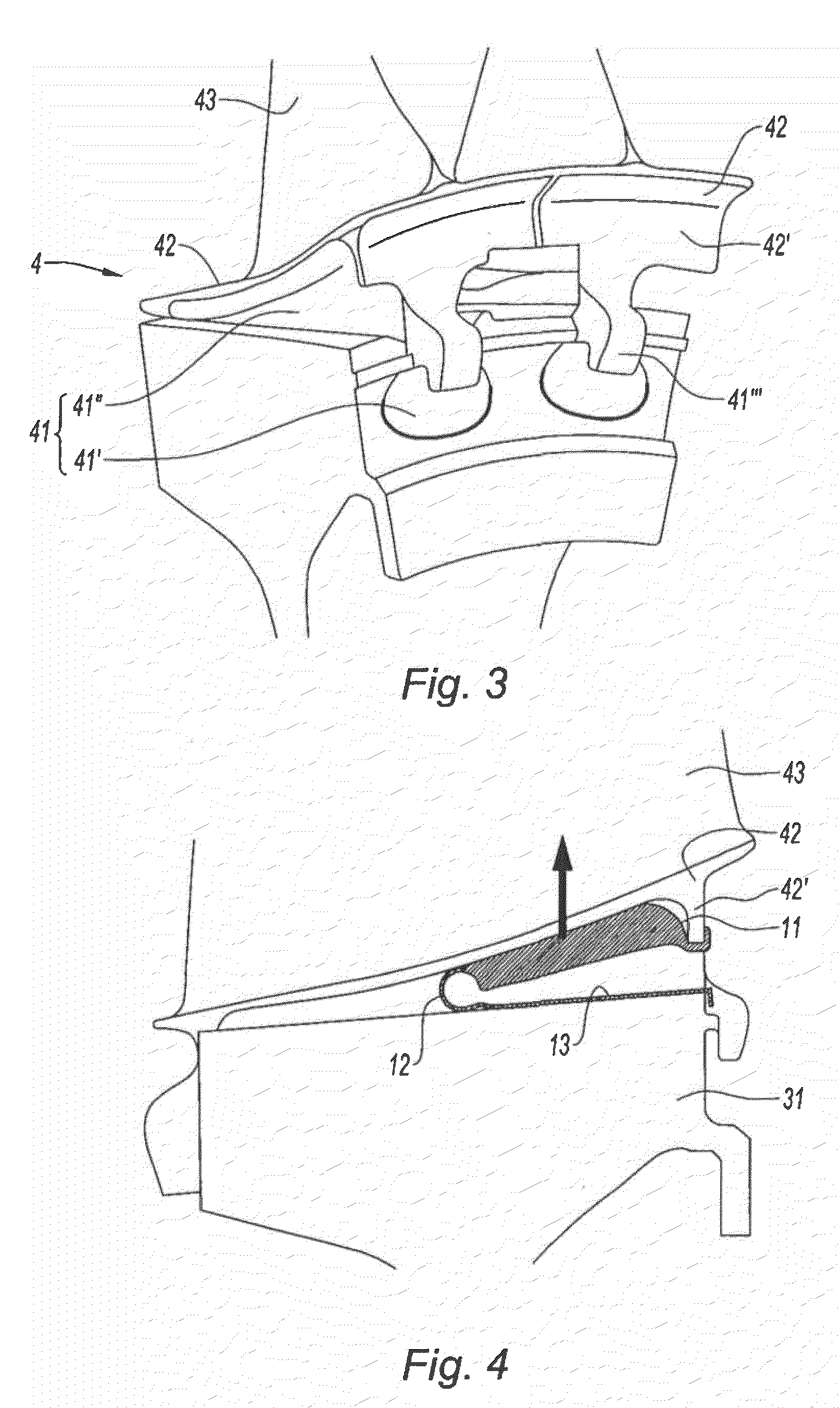

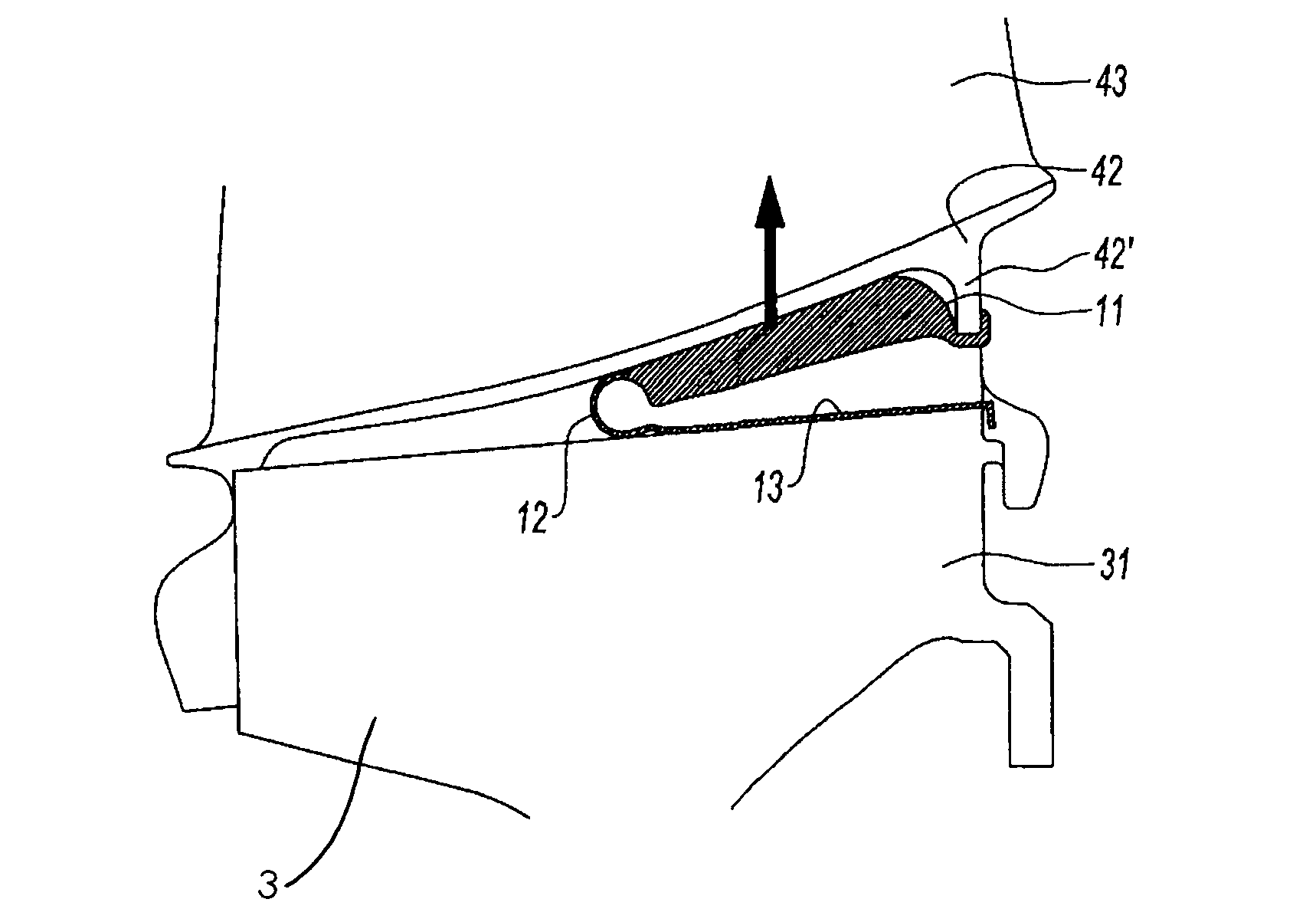

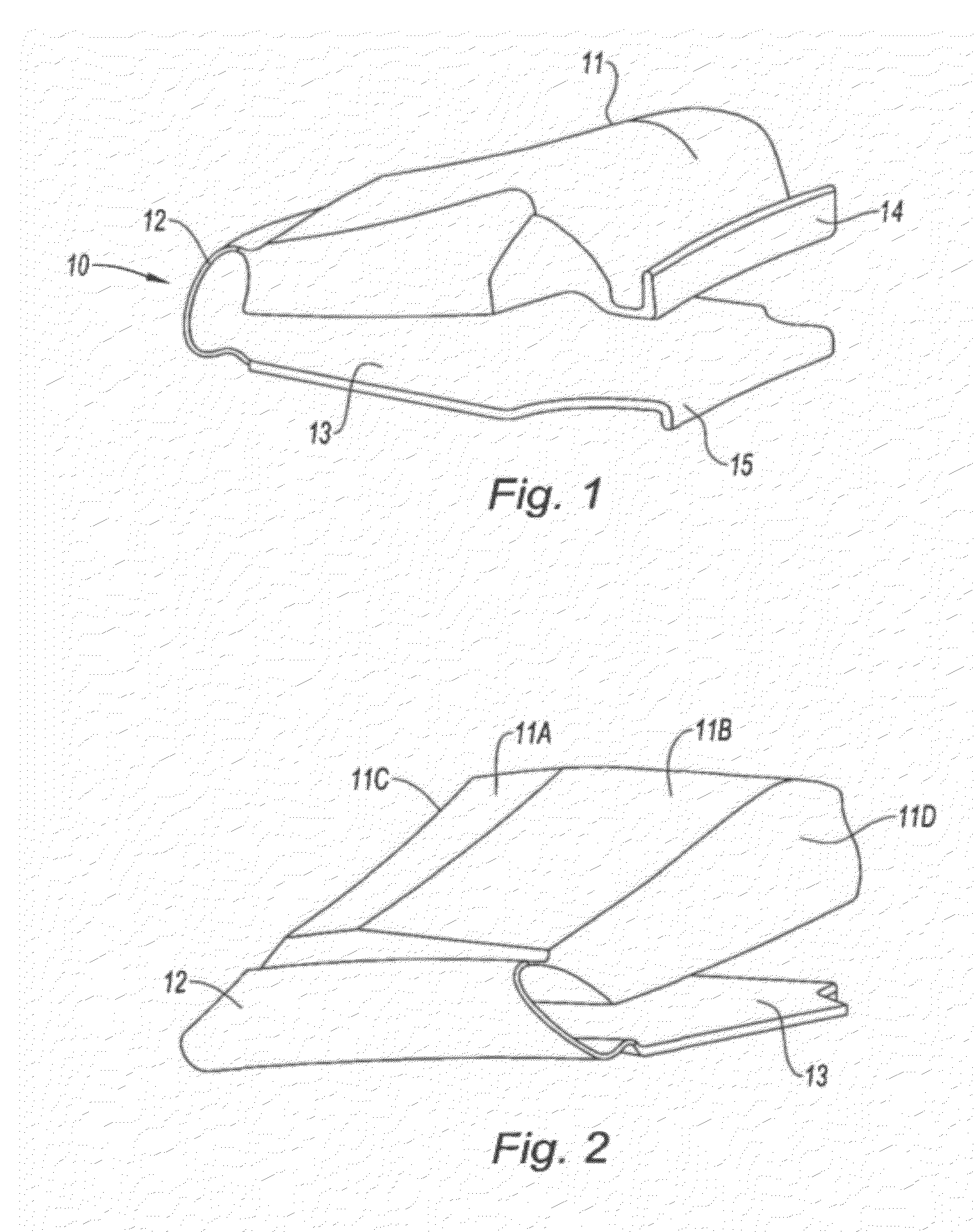

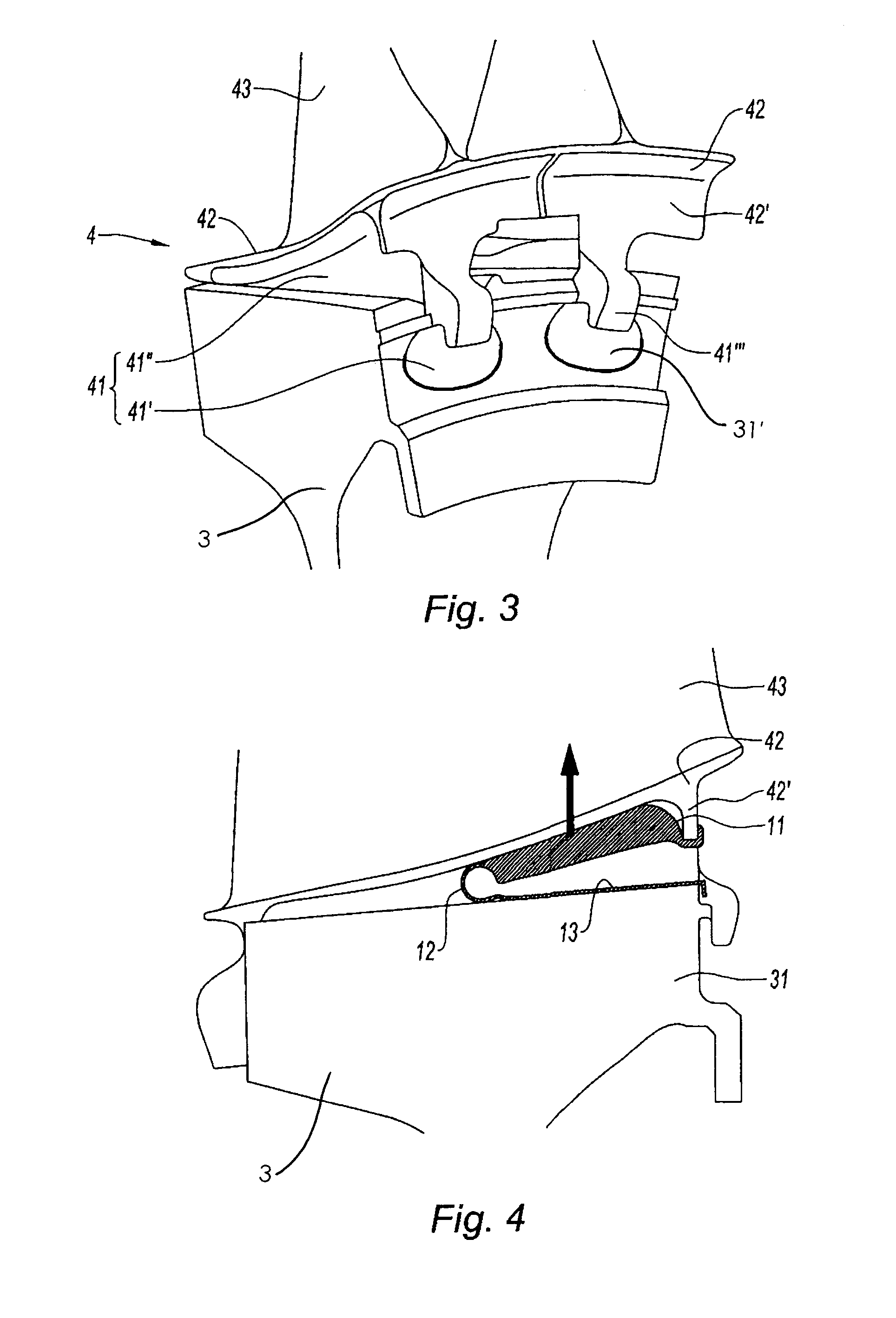

Damper for turbomachine vanes

The present invention relates to a turbomachine vane damper constructed so as to be housed between the lower face of the platforms of two adjacent turbomachine vanes and the rim of the rotor disk on which the vanes are mounted. This damper is noteworthy in that it comprises a weight (11), a bearing plate (13) and a spring (12), the spring connecting the weight to the bearing plate.

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

Process for making ceramic insulation

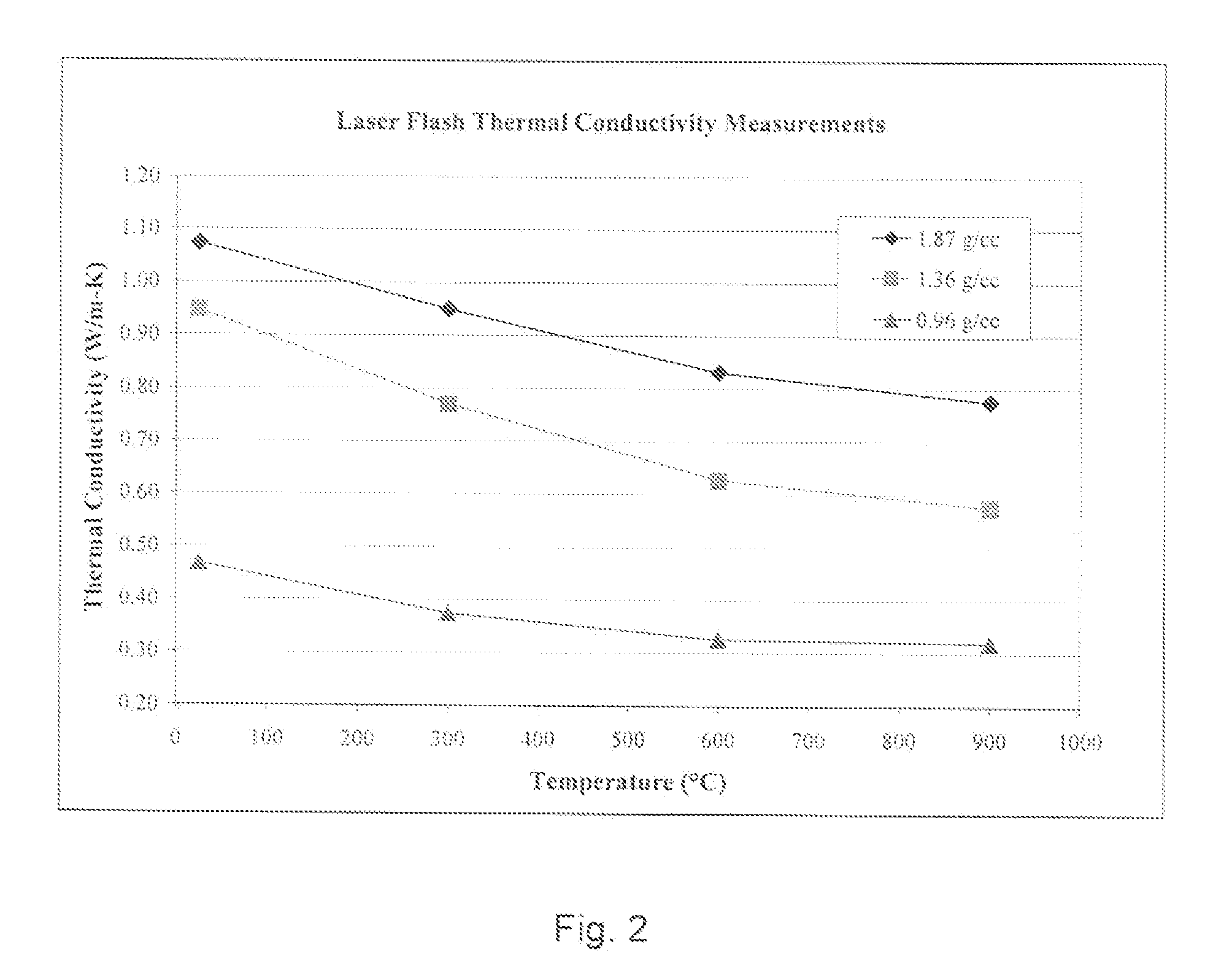

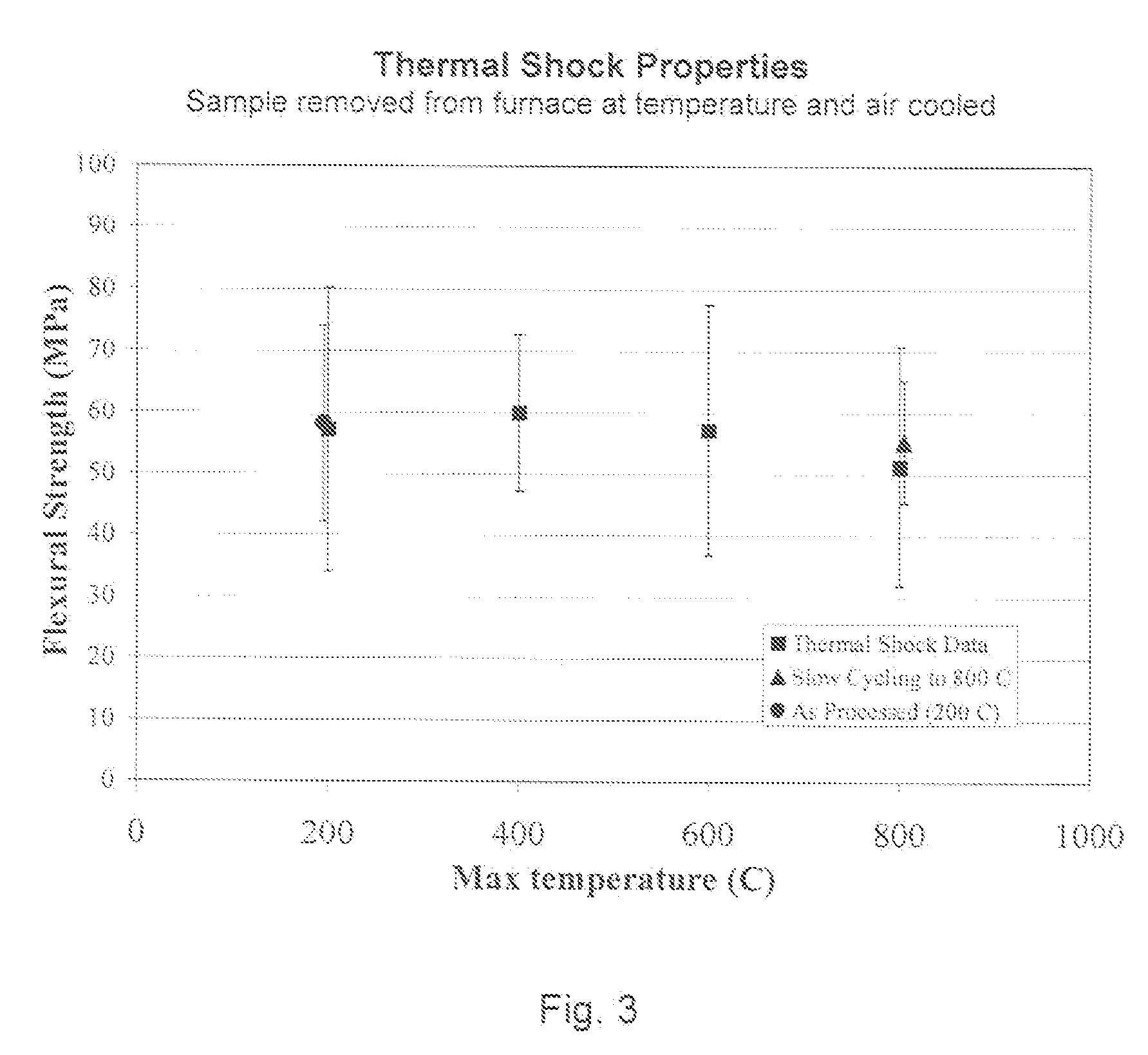

InactiveUS20090295045A1Low costImprove performanceFinal product manufactureCeramic shaping apparatusPorosityFuel cells

A method is provided for producing insulation materials and insulation for high temperature applications using novel castable and powder-based ceramics. The ceramic components produced using the proposed process offers (i) a fine porosity (from nano-to micro scale); (ii) a superior strength-to-weight ratio; and (iii) flexibility in designing multilayered features offering multifunctionality which will increase the service lifetime of insulation and refractory components used in the solid oxide fuel cell, direct carbon fuel cell, furnace, metal melting, glass, chemical, paper / pulp, automobile, industrial heating, coal, and power generation industries. Further, the ceramic components made using this method may have net-shape and / or net-size advantages with minimum post machining requirements.

Owner:CERAMTEC

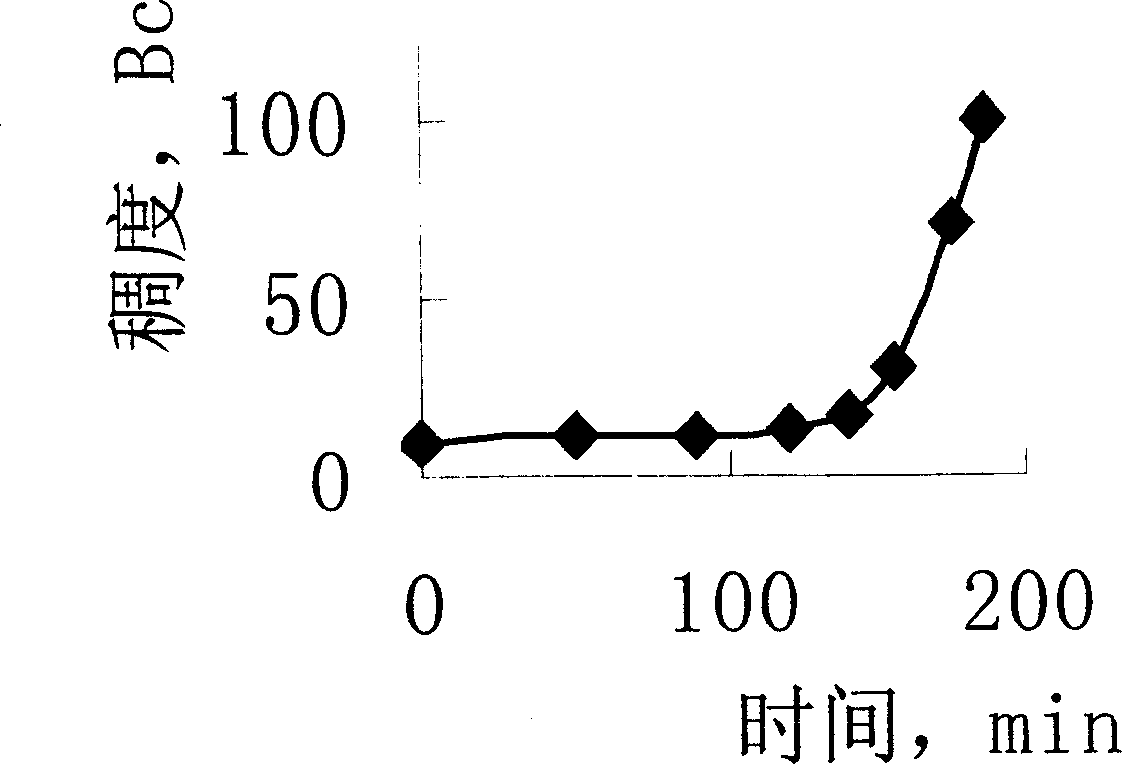

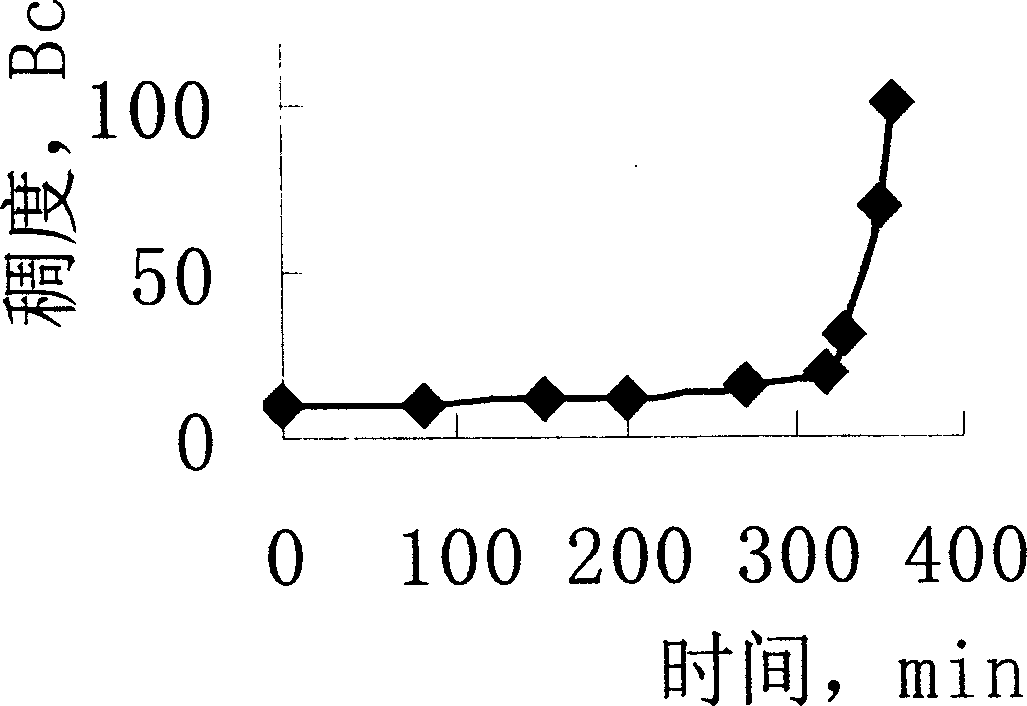

Anti-pollution high efficiency isolation liquid and preparing method

The present invention relates to anti-pollution high efficiency isolating liquid for shaft wall cementing operation and its preparation process. The isolating liquid is compounded through adding suspension stabilizer, water reducing agent, tackifier, diluent, viscosity and shearing force increasing agent, weight additive and pH regulator in certain weight proportion into water. One compounding process is a water base process through throwing the said components successively into water in a slurry tank apparatus. One other compounding process is one dry mixture process in a cementing tank apparatus. The isolating liquid has flexible compounding process, high anti-pollution capacity and effective eliminating effect on well wall interface pollutant.

Owner:SOUTHWEST PETROLEUM UNIV

Polyimide precursor solid residuum

InactiveUS6180746B1Particular utility and special effectiveness in preparationUniform foaming actionImidePolymer science

A polyimide precursor solid residuum is an admixture of an aromatic dianhydride or derivative thereof and an aromatic diamine or dervative thereof plus a complexing agent, which is complexed with the admixture by hydrogen bonding. The polyimide precursor solid residuum is effectively employed in the preparation of polyimide foam and the fabrication of polyimide foam structures.

Owner:NASA +1

Environment-friendly high-density solid-free weighting agent and preparation method

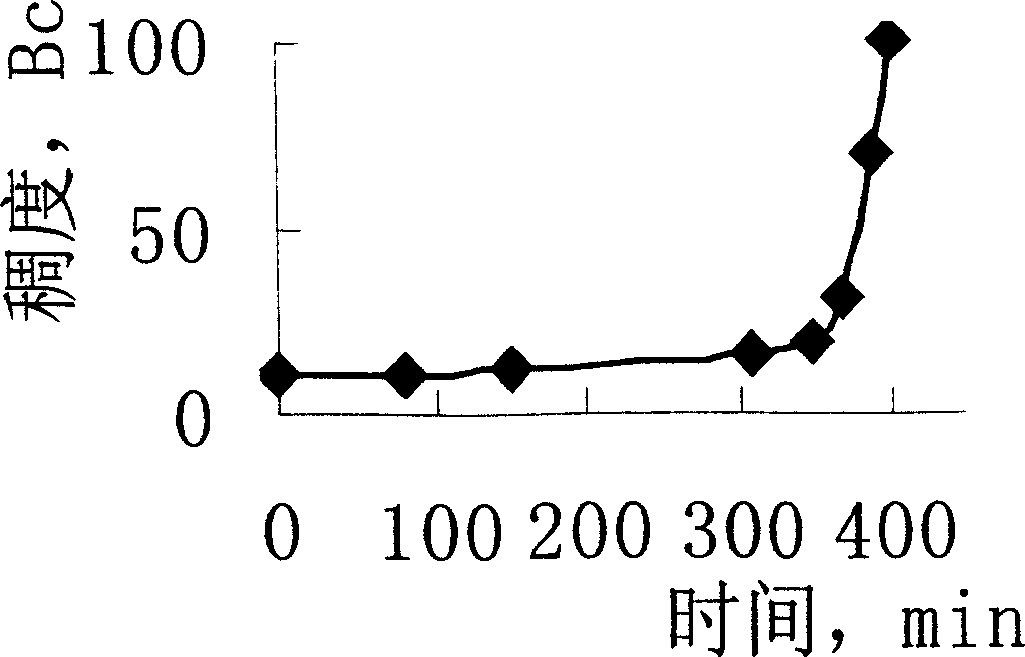

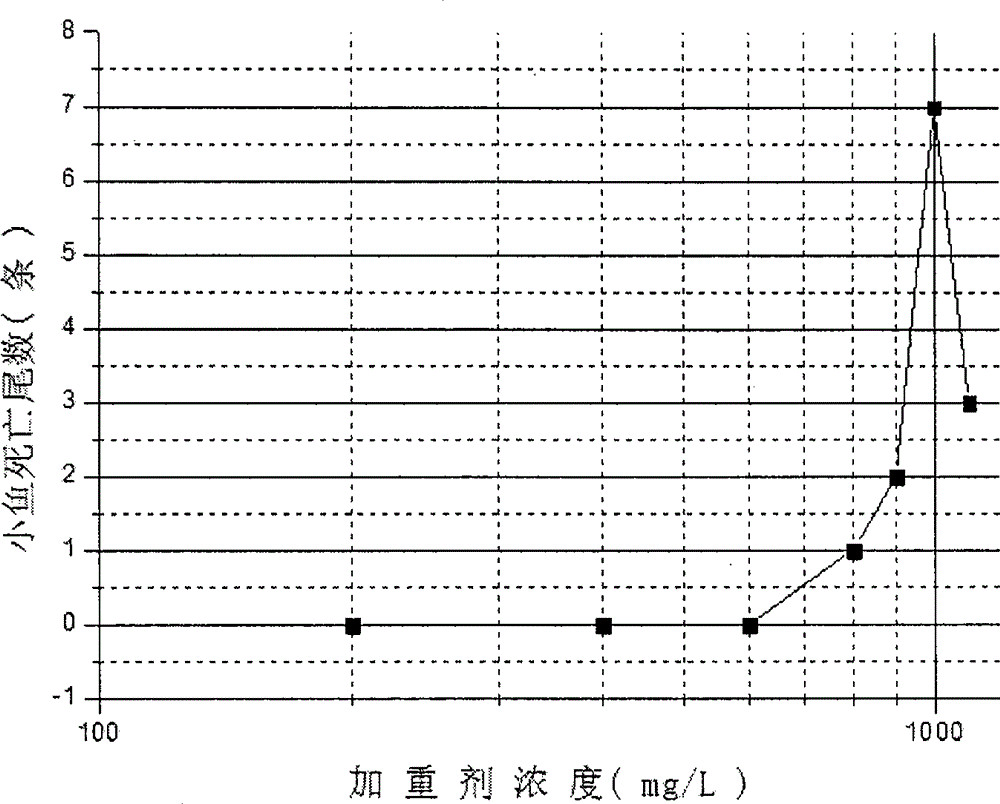

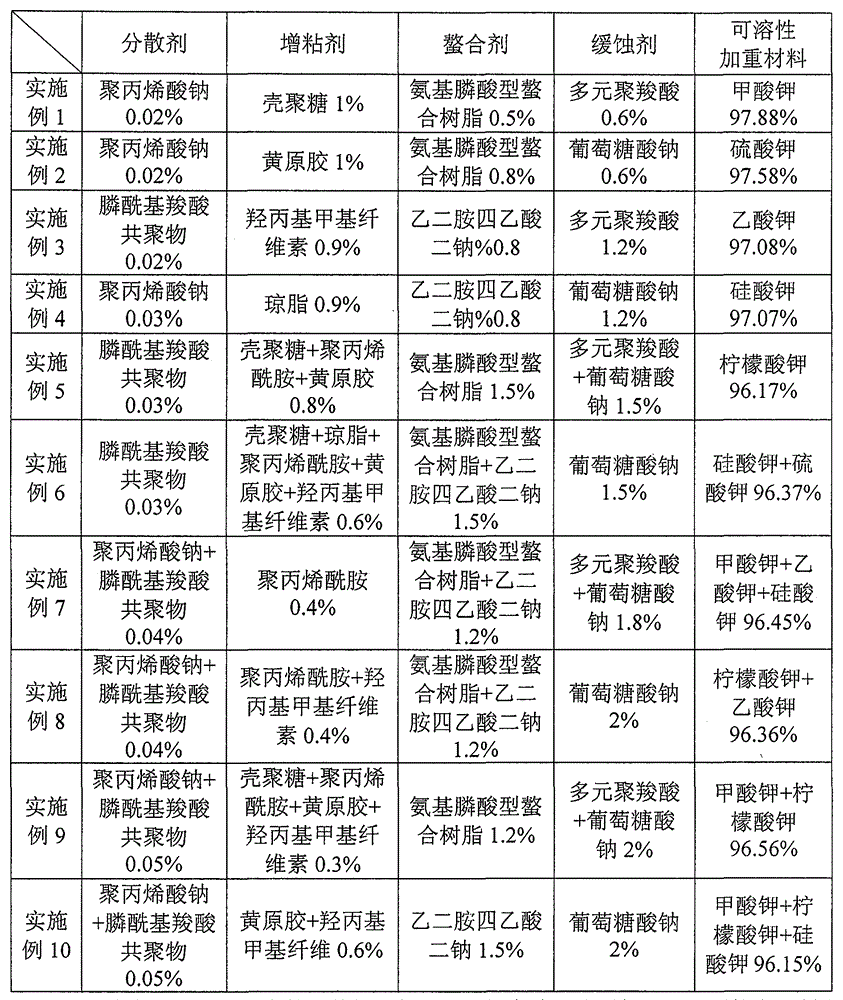

ActiveCN104610937AWide range of densitiesReduce pollutionDrilling compositionCarboxylic acidPotassium formate

An environment-friendly high-density solid-free weighting agent comprises components in parts by weight as follows: 0.02-0.05 parts of a dispersant, 0.3-1 part of a tackifier, 0.5-1.2 parts of chelating agent, 0.6-2 parts of a corrosion inhibitor and the balance of soluble weighting materials, wherein the dispersant is one or two of sodium polyacrylate and copolymer of phosphono and carboxylic acid; the tackifier is one or more of chitosan, agar, polyacrylamide, xanthan gum and hydroxypropyl methyl cellulose; the chelating agent is one or two of aminophosphonic acid chelate resin and ethylenediamine tetraacetic acid disodium; the corrosion inhibitor is one or two of multiple polycarboxylate and sodium gluconate; the soluble weighting materials are one or more of potassium formate, potassium citrate, potassium acetate, potassium silicate and potassium sulfate. The process steps are as follows: the raw materials are taken in weight proportion, mixed and uniformly stirred; the raw materials are added to water and dissolved at the high temperature of 70-80 DEG C; a product is evaporated to dryness, and solid is obtained; the obtained solid is ground into powder, and the solid weighting agent is obtained.

Owner:成都西油华巍科技有限公司

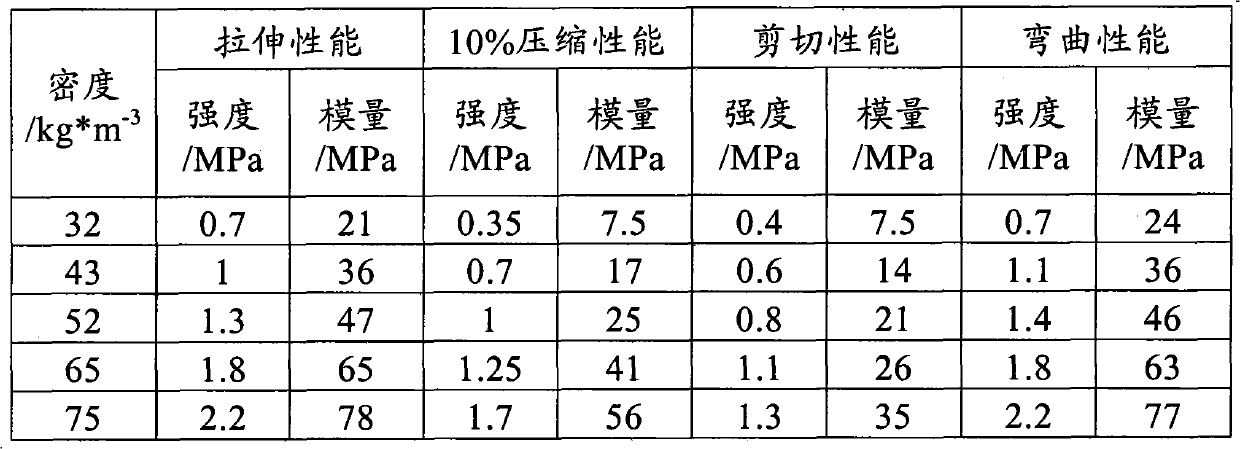

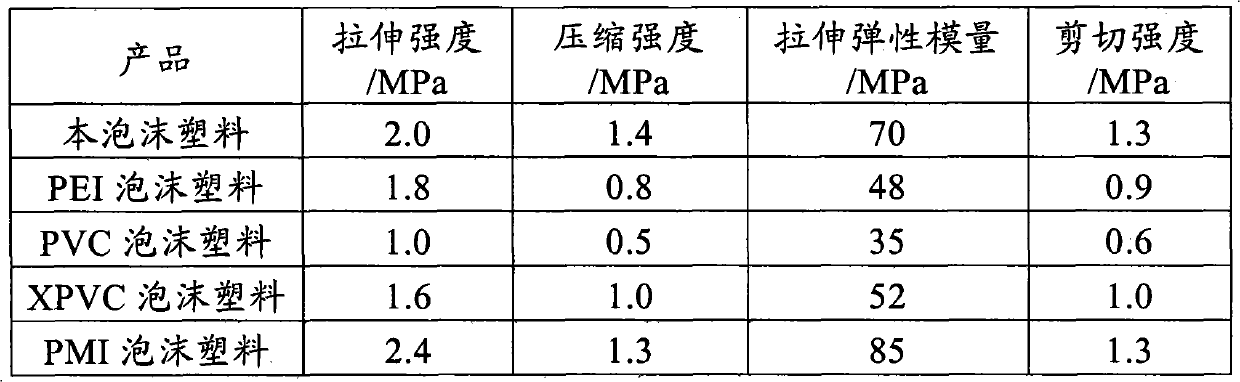

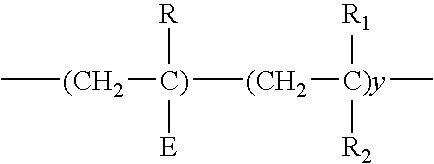

Copolymer foamed plastic and preparation method thereof

The invention relates to copolymer foamed plastic and a preparation method thereof. The copolymer foamed plastic comprises the following raw materials in percentage by weight: 32-72 percent of methacrylic acid, 28-68 percent of acrylonitrile, 0.08-0.50 percent of initiator and 1.0-9.0 percent of foaming agent, wherein the initiator is selected from peroxidated organic acid ester. The method comprises the following preparation steps of: polymerizing for 22-72 hours at a water temperature of 35-65 DEG C; carrying out free foaming on the obtained foamable copolymerization slice in strong circulating heat air at 180-220 DEG C to prepare the copolymer foamed plastic; and carrying out heat treatment on the obtained copolymer foamed plastic in heat air at 120-180 DEG C for 4-12 hours. The acrylonitrile replaces methyl acrylonitrile with high price, and the peroxidated organic acid replaces an azoic compound, so that the cost is controlled and the property of the copolymer foamed plastic is guaranteed.

Owner:保定美沃工程材料科技有限公司

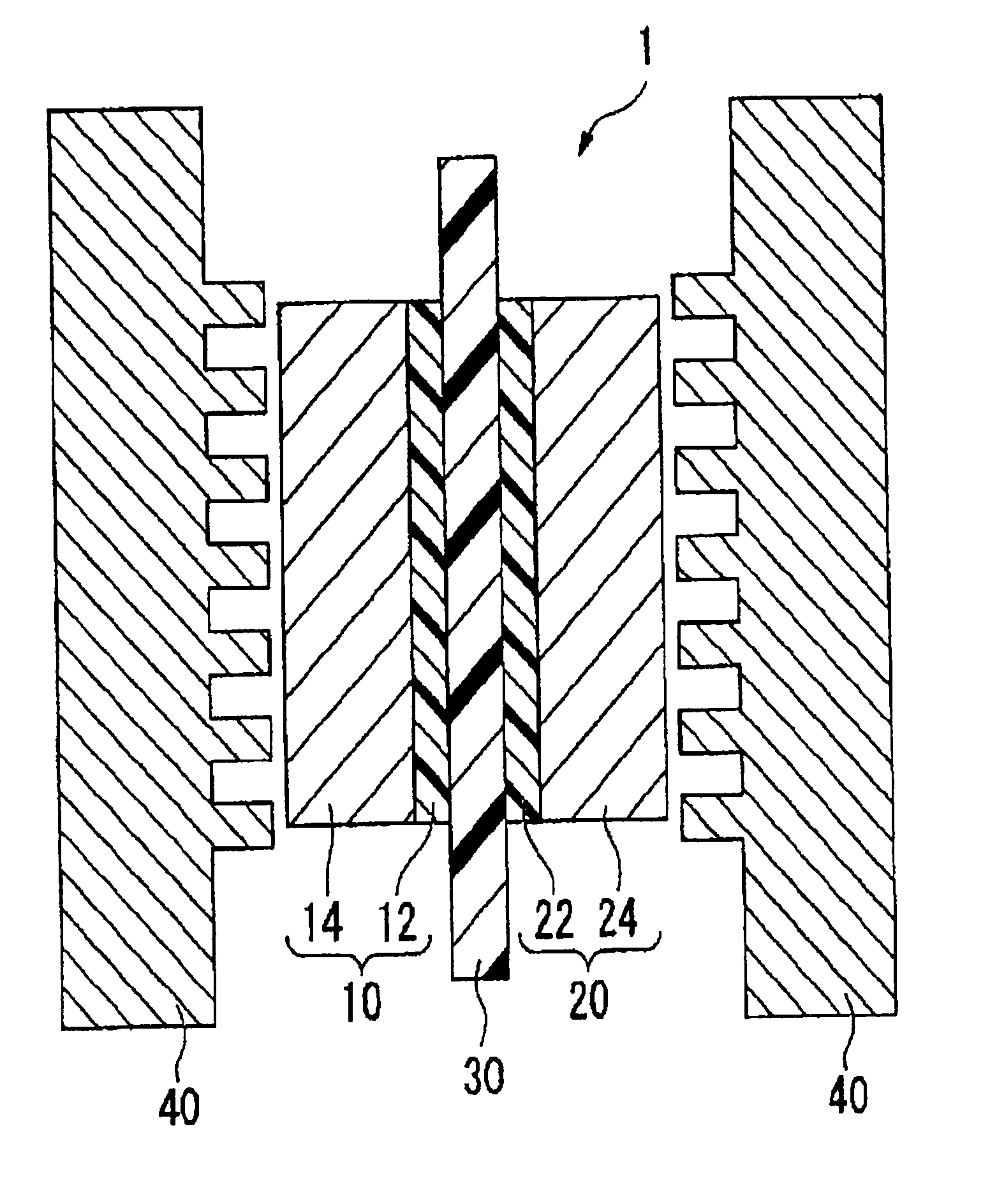

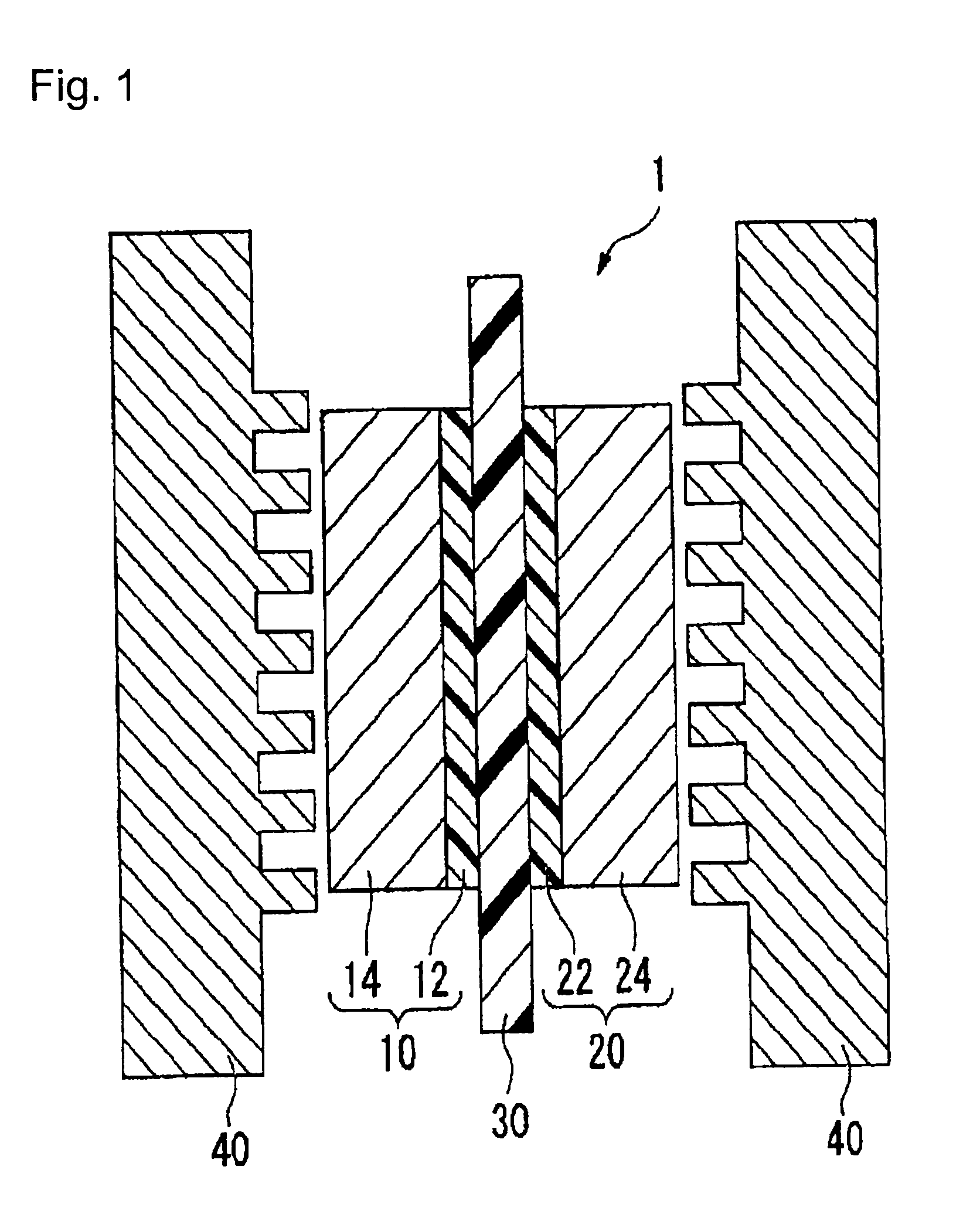

Process for producing membrane/electrode assembly for polymer electrolyte fuel cell and process for producing polymer electrolyte fuel cell

InactiveUS20100003400A1Increase the output voltageWide current density rangeFinal product manufactureCoatingsFiberCarbon fibers

Provided are a process for producing a membrane / electrode assembly for a polymer electrolyte fuel cell and a process for producing a polymer electrolyte fuel cell, capable of achieving a high output voltage in a wide current density range.At least one of an anode and a cathode in a membrane / electrode assembly for a polymer electrolyte fuel cell is formed through a catalyst layer forming step of applying a first coating fluid containing a catalyst and an ion exchange resin, onto a substrate to form a catalyst layer; a gas diffusion layer forming step of applying a second coating fluid containing carbon fibers and an ion exchange resin, onto the catalyst layer to form a gas diffusion layer to serve as an outermost layer of the membrane / electrode assembly for the polymer electrolyte fuel cell; and a peeling step of peeling the substrate off from the catalyst layer. The membrane / electrode assembly for the polymer electrolyte fuel cell is disposed between two separators each having a gas channel formed on a surface thereof so that surfaces of the outermost layers are adjacent to the respective separators, whereby the gas diffusion layer is adjacent to the separator.

Owner:PANASONIC CORP +1

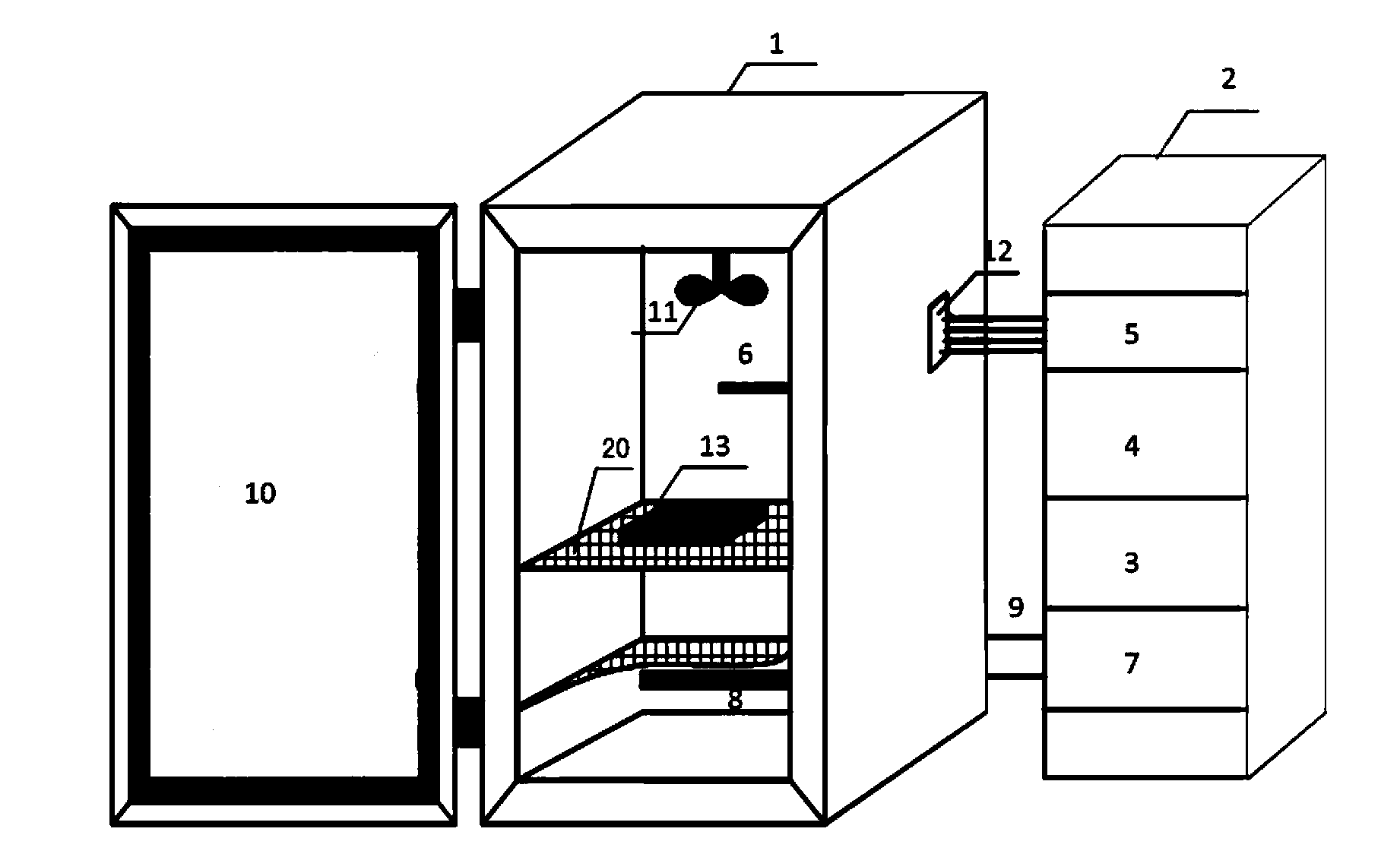

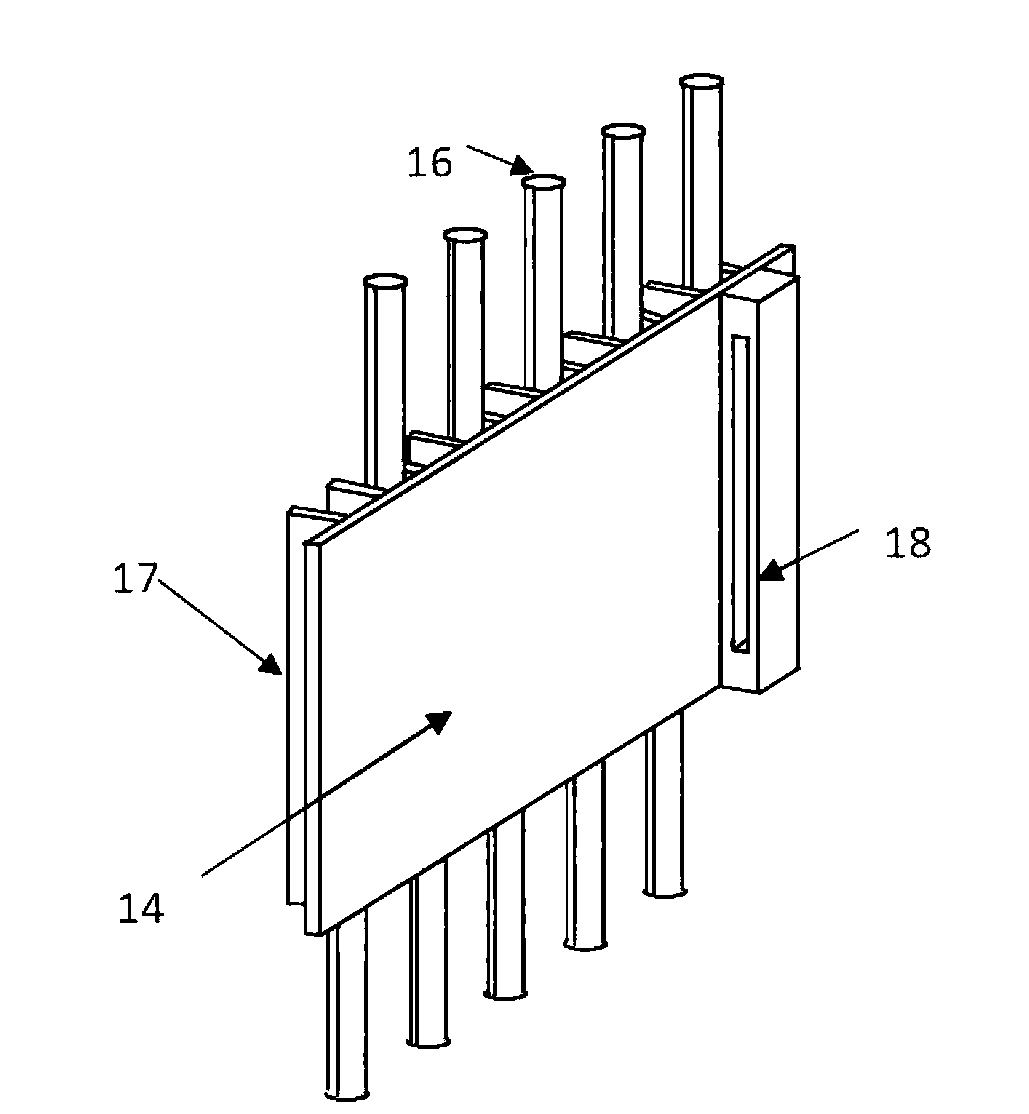

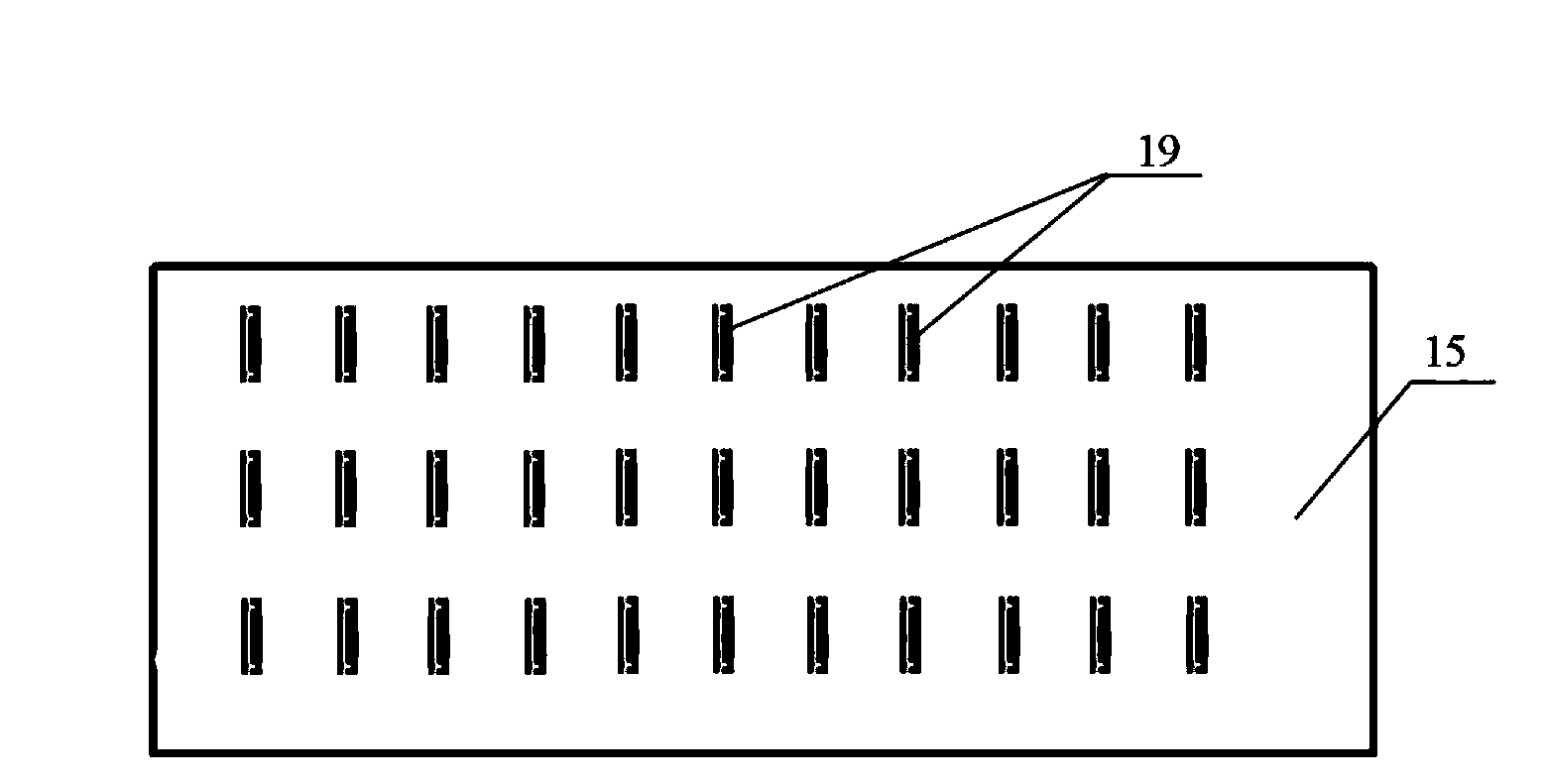

Microelectronic product reliability test platform under force electrothermal multi-field coupling effect

The invention discloses a microelectronic product reliability test platform under a force electrothermal multi-field coupling effect, and belongs to the technical field of a microelectronic product reliability test and assessment device. The test platform is composed of a temperature control system, a current loading system, a signal test and acquisition system, and an experiment box. The temperature control system controls a cooling system and a heater and adjusts the temperature inside the experiment box; the current loading system applies a current load to a microelectronic product to be tested; the signal test and acquisition system tests and acquires currents, voltages, resistance and temperature signals of the microelectronic product to be tested for storage; the running operation of the test platform is controlled by a computer in a unified mode; a low temperature refrigeration system is connected with the experiment box through a refrigeration pipeline; the experiment box is composed of a casing, a heat-insulation layer, an observation window, a heater, a blower fan and a sample support system; and the sample support system is composed of a sample support frame, a test plate and a lead wire connection interface. The platform provided by the invention can realize reliability testing and life prediction of the microelectronic product under a multi-field coupling condition.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

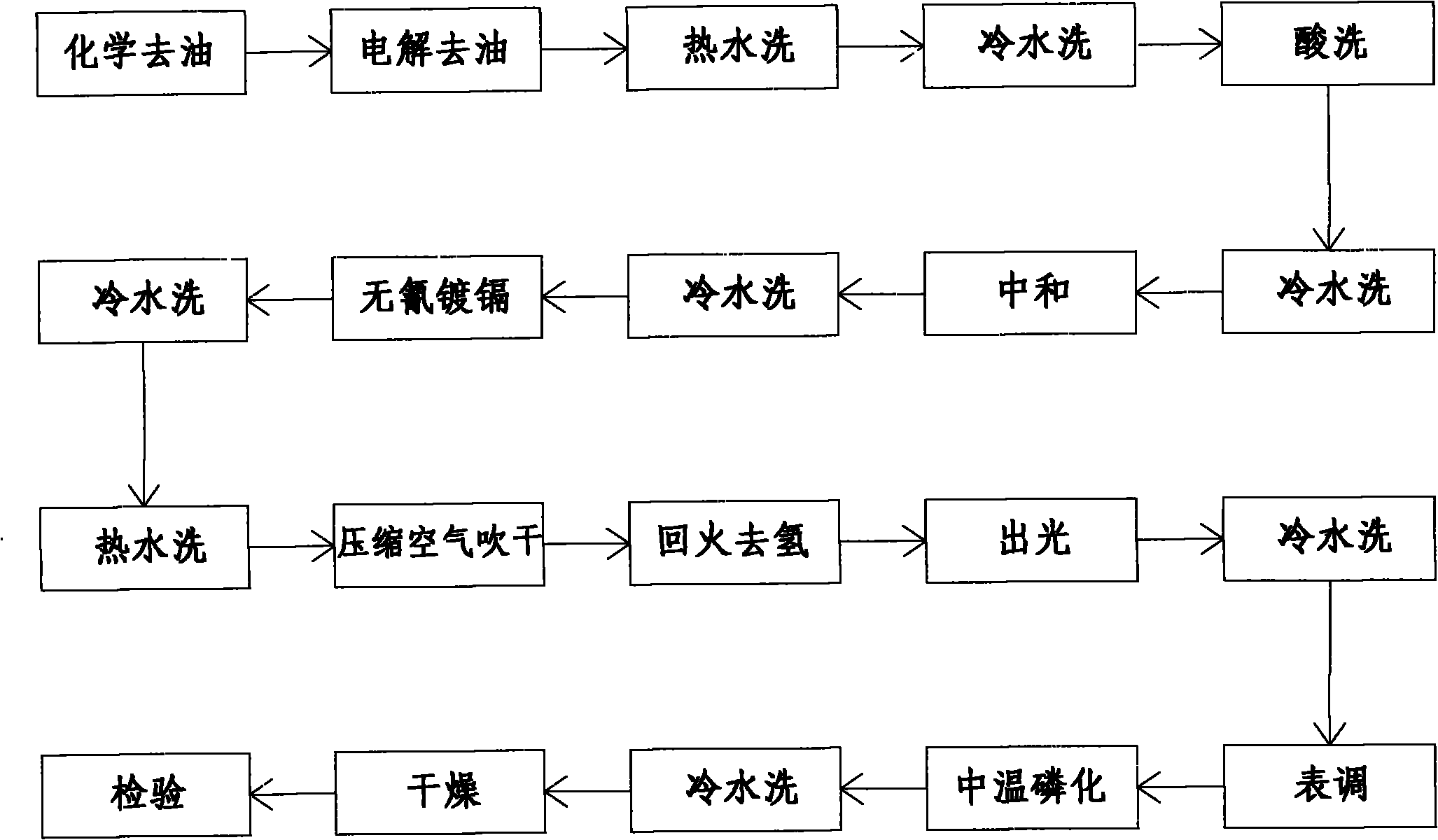

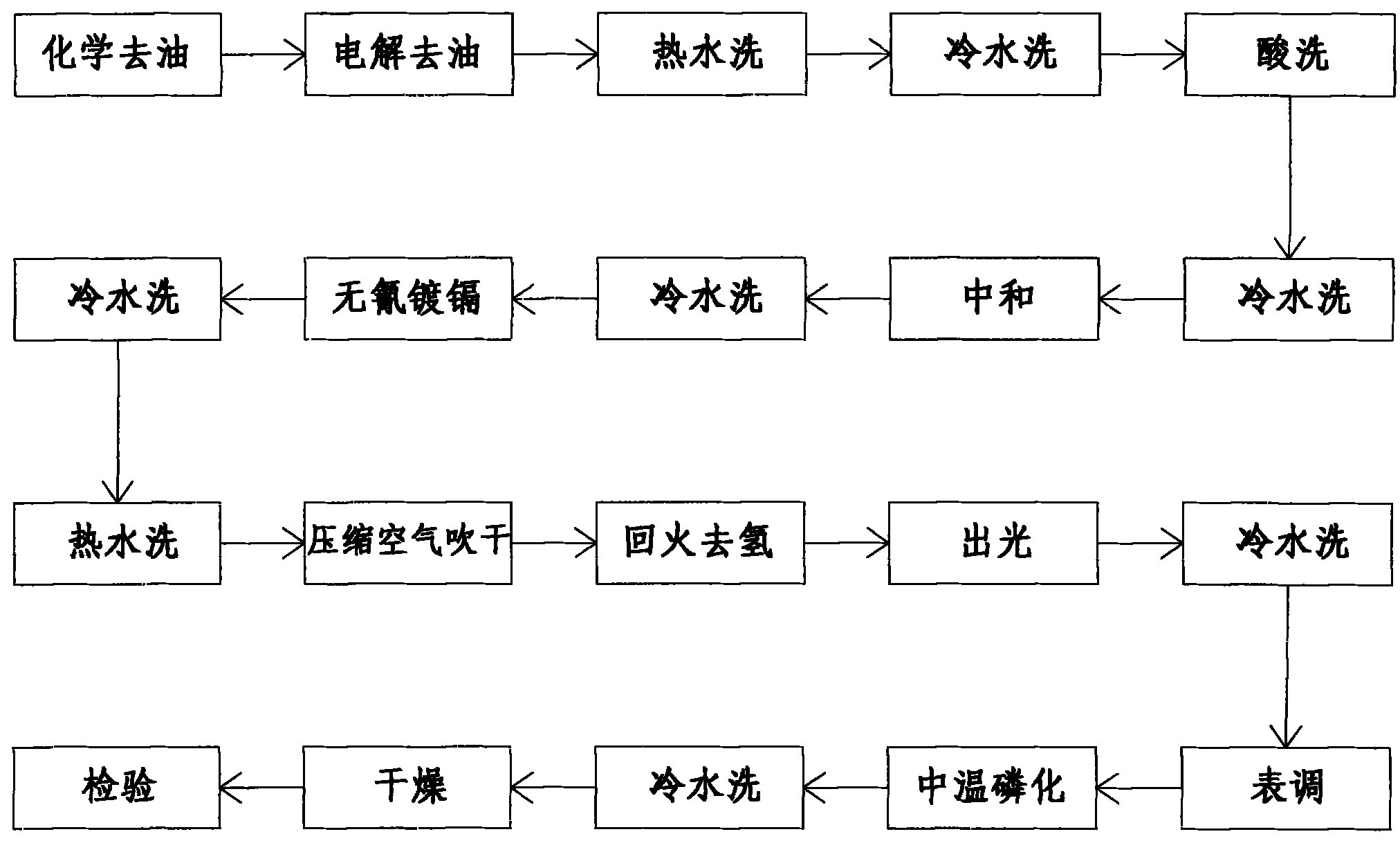

Process for plating cadmium on shaped steel part with deep/blind hole

InactiveCN101942681AWide current density rangeStrong dispersion abilitySuperimposed coating processNitrilotriacetic acidCadmium sulfate

The invention discloses a process for plating cadmium on a shaped steel part with a deep / blind hole, which comprises the following steps of: chemical oil removal, electrolytic oil removal, hot water washing, cold water washing, acid washing, cold water washing, neutralizing, cold water washing, cyanogen-less cadmium plating, cold water washing, hot water washing, compressed air drying, tempering dehydrogenizing, bright dipping, cold water washing, surface conditioning, middle-temperature phosphating, cold water washing, drying and detection, wherein the formula of each liter of electroplating liquid comprises: 40 to 50g of cadmium sulfate, 180 to 220g of ammonium chloride, 50 to 70g of nitrilotriacetic acid, 25 to 30g of ethylene diamine tetraacetic acid, a main additive, a brightener and a refiner, and the pH value is 6.2 to 6.7. The process effectively improves the quality and stability of special products, guarantees the use performance of the products and prolongs the service life of the products; and the production process is clean and environmentally-friendly, can effectively protect the environment and the physical and metal health of operators and meets the requirements of pollution-free production.

Owner:CHANGAN AUTOMOBILE (GRP) CO LTD

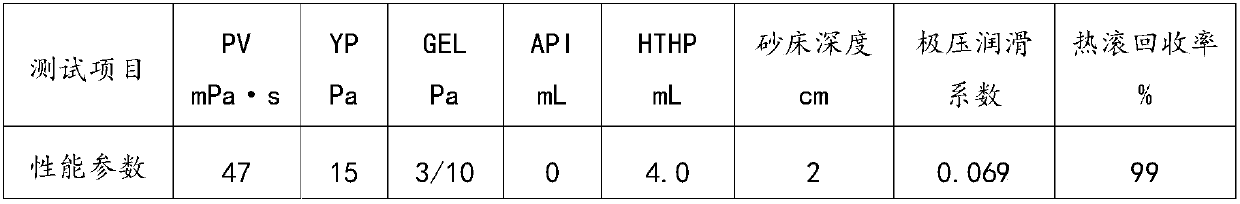

Emulsifying and flushing spacer fluid for improving cementing quality of oil-based drilling fluid and preparation method of emulsifying and flushing spacer fluid

ActiveCN105001841AImprove surface activityTemperature resistanceDrilling compositionGlycosideDiluent

The invention discloses an emulsifying and flushing spacer fluid for improving the cementing quality of an oil-based drilling fluid and a preparation method of the emulsifying and flushing spacer fluid. The spacer fluid is prepared from the following components in parts by weight: 200 parts of water, 5-10 parts of a surfactant, 70-75 parts of base oil, 4-15 parts of a suspension stabilizer, 0.2-3.0 parts of a fluid loss agent, 0.2-2.0 parts of a tackifier, 0.2-5.0 parts of a diluent, 80-400 parts of a weighting agent and 0.05 part of a defoamer, wherein the surfactant is prepared from cocoanut fatty acid diethanolamide CDEA and alkyl glycoside APG in a weight ratio of 1: 2. The emulsifying and flushing spacer fluid which has an emulsifying structure with permeating, dissolving, volume-increasing, carrying functions and the like has a preferable flushing capacity to the oil-based drilling fluid and mud cakes adhered to a casing wall. The surfacant molecules in the spacer fluid can be adsorbed on the surfaces of a casing and a well wall to improve the interfacial wettability, so that cement slurry and the casing and the well wall are better contacted and cemented, and therefore, the first and second interfacial cementation qualities for well cementation are improved.

Owner:SOUTHWEST PETROLEUM UNIV

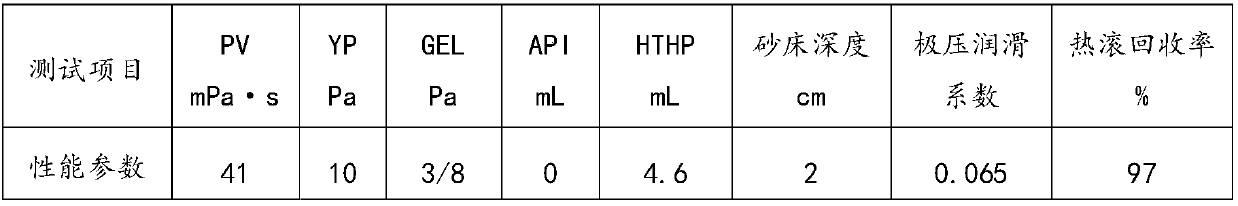

High-performance water-based drilling fluid suitable for long horizontal section of shale gas, and preparation method thereof

The invention provides a high-performance water-based drilling fluid suitable for the long horizontal section of shale gas and a preparation method thereof. agent, anti-slump lubricant, plugging fluid loss reducer, inhibitor, nano plugging agent and speed-increasing lubricant. 1.0g, multifunctional composite agent 1.5-2g, medium molecular weight fluid loss reducer 0.7g-1.5g, high-efficiency coating agent 0.1g-0.3g, anti-slump lubricant 2g-4g, plugging fluid loss reducer 1g-2g , inhibitor 2g-4g, nano-blocking agent 2g-4g, speed-up lubricant 2g-4g, barite 30g-200g. The drilling fluid product of the present invention has shale well wall stability in long horizontal sections, high viscosity at low shear rates, strong sand-carrying ability, strong ability to plug micro-cracks, good lubricity, low filtration loss, low cost, and on-site preparation and maintenance Simple and efficient, low biological toxicity, water-based cuttings can be directly discharged and other characteristics.

Owner:SINOPEC SSC +1

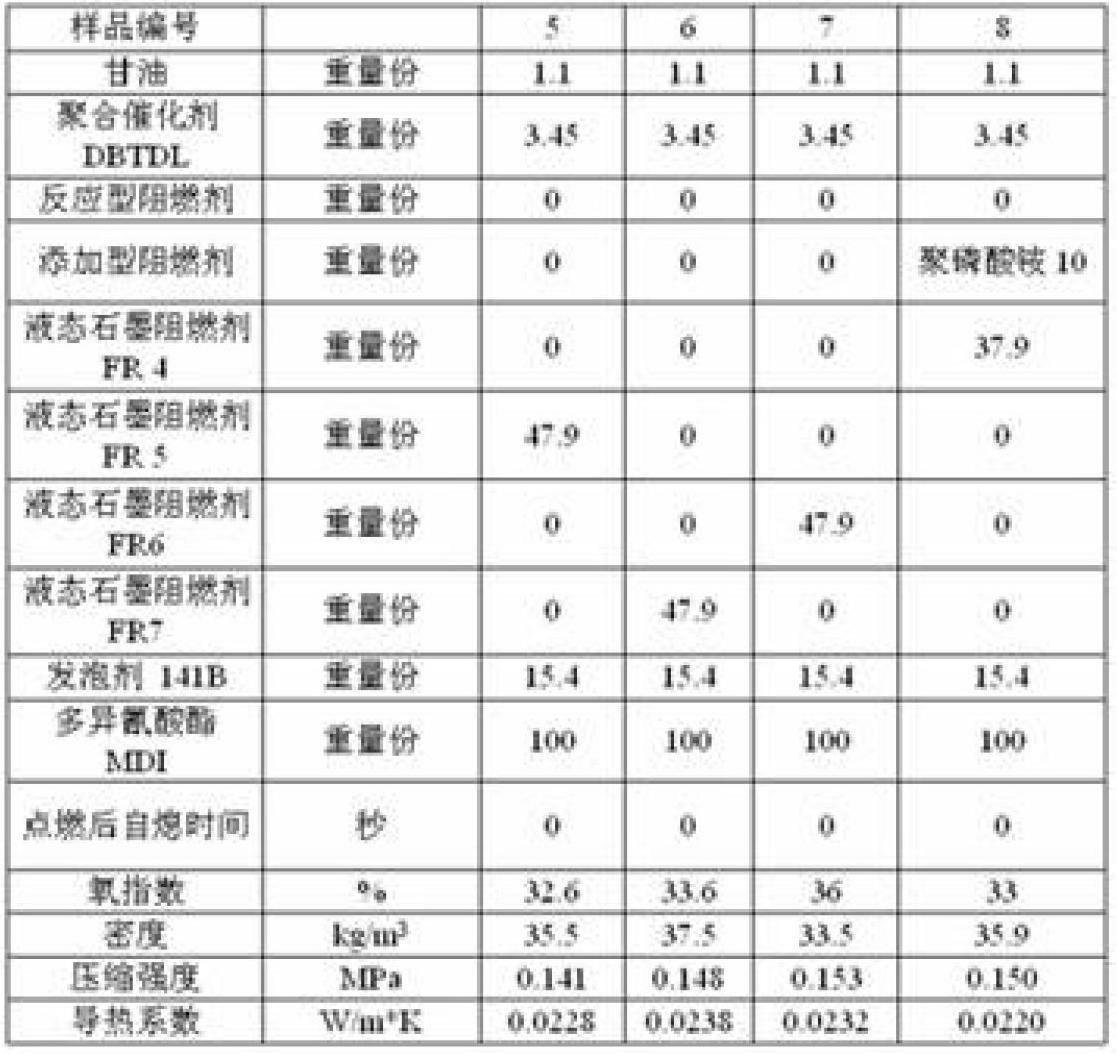

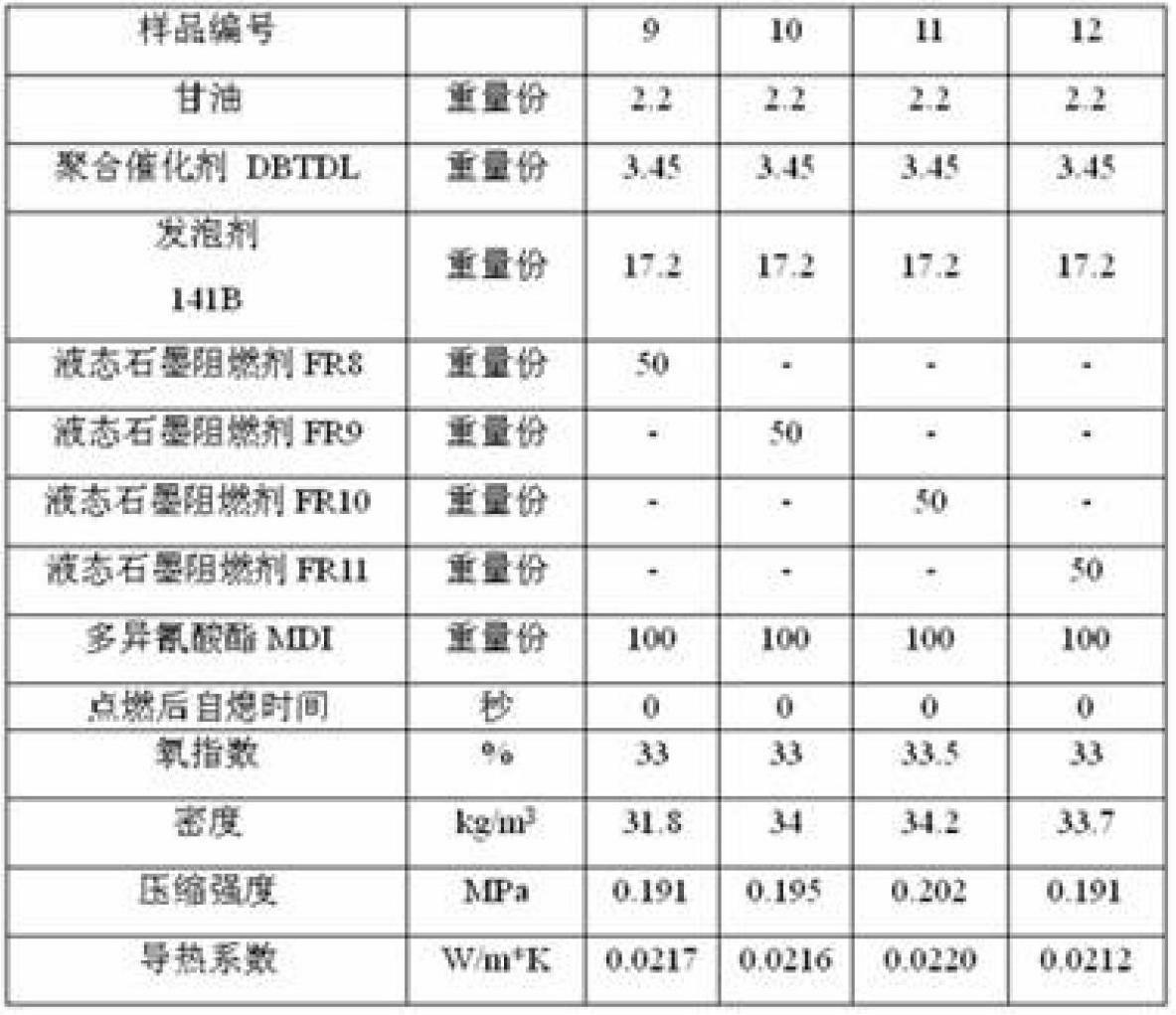

Liquid expanded graphite flame retardant and preparation method for flame-retardant polyurethane foam material

The invention discloses an expanded-graphite-based liquid flame retardant. The expanded-graphite-based liquid flame retardant comprises 100 parts of expansible graphite and 100 to 900 parts of diluent, wherein the diluent is at least one of a phosphate modifier and polyol. The invention also discloses a method for preparing a flame-retardant polyurethane foam material from the expanded-graphite-based liquid flame retardant. The method comprises the following steps of: (a) adding the expanded-graphite-based liquid flame retardant into polyisocyanate, adding a polymerization catalyst and a foaming agent, mixing uniformly, and optionally adding the polyol; and (b) molding to obtain the polyurethane foam material. The expanded-graphite-based flame retardant is a liquid product and is convenient to process and measure, and common phenomena such as viscosity increase, demixing and precipitation when solid expansible graphite is directly mixed into a polyol component are avoided; meanwhile, the flame retardant is favorable for environment friendliness because halogen groups are not contained; and the polyurethane product prepared from the flame retardant has a wide density range and a wide application range.

Owner:HUAFON GROUP +2

Damper for turbomachine vanes

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

Tablets with improved resistance to breakage

InactiveUS20050153863A1Improved dissolution profileImprove fracture resistanceDetergent powders/flakes/sheetsShear modulusMaterials science

The invention relates to a process for making a detergent tablet, comprising the steps of: (a) providing a binder system comprising (i) a binder, and, (ii) optionally, a viscosity modifier, so that the binder system has a shear modulus value G of from 10 to 100 GPa, a phase angle value δ of at least 7°, and a melting point of at least 45° C. at 100 kPa; (b) heating the binder system to above its melting point to form a molten binder system; (c) applying the molten binder system to a base powder comprising a premix of detergent components, to form a detergent composition; and (d) forming the detergent composition into tablets. The present invention is further directed to a tablet composition obtainable by such process and to the use of such a binder system or such a binder, in its molten form for improving the breakage resistance properties of a detergent tablet.

Owner:THE PROCTER & GAMBLE COMPANY

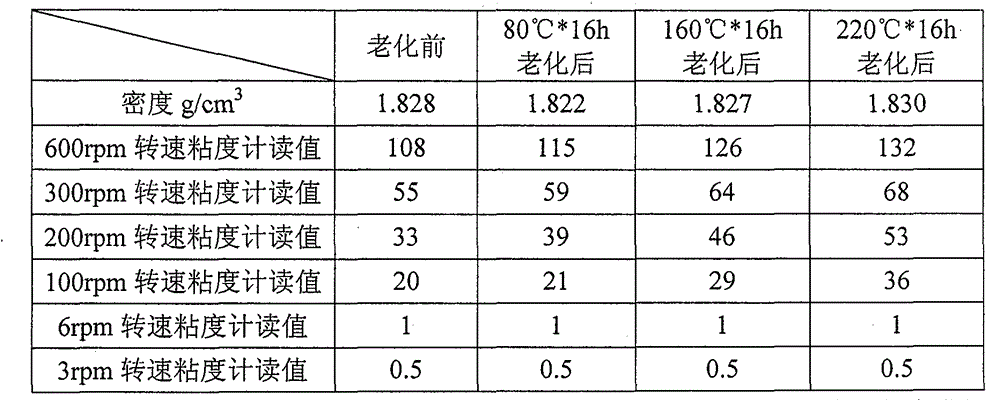

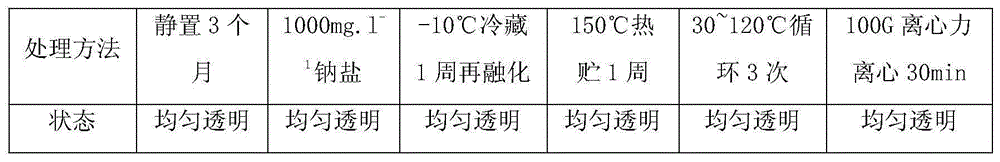

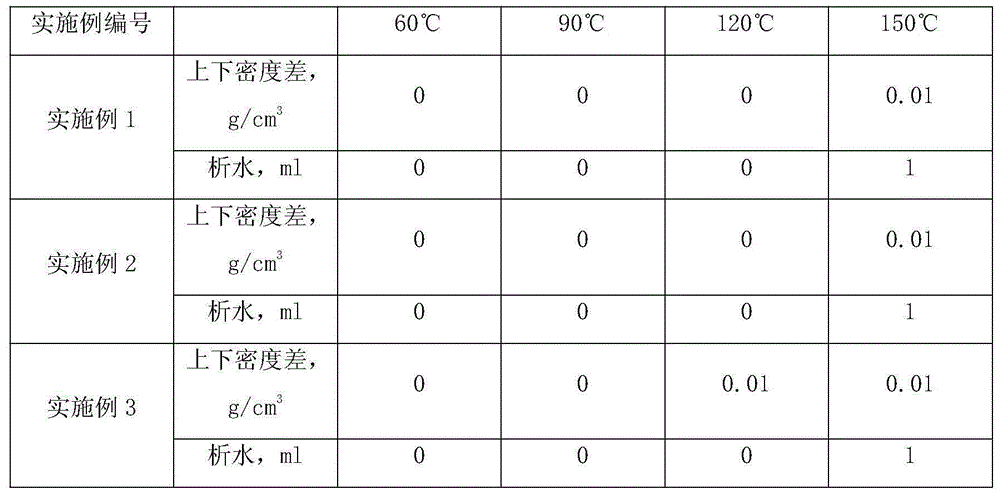

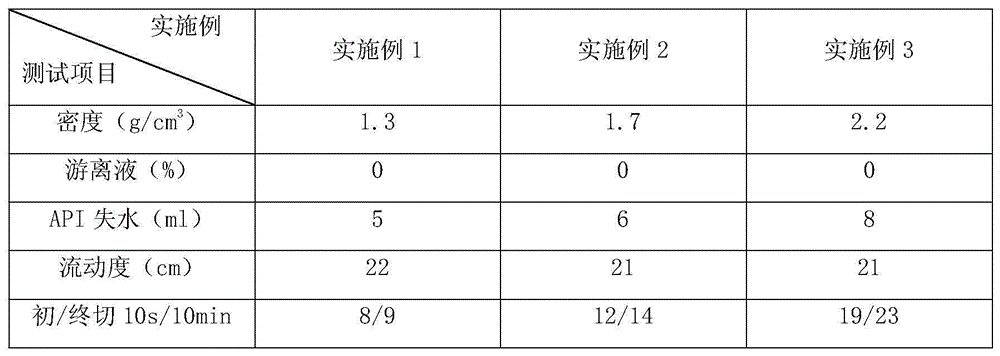

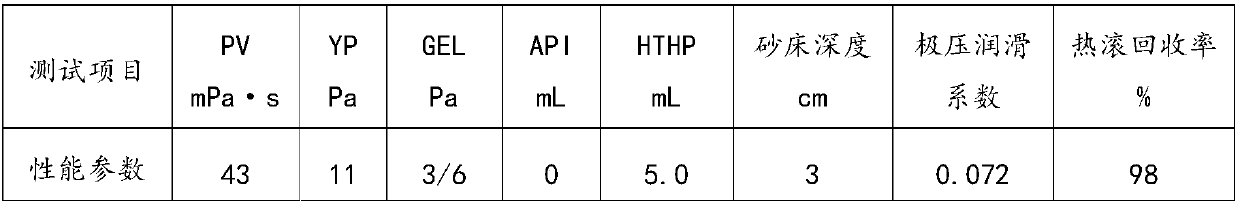

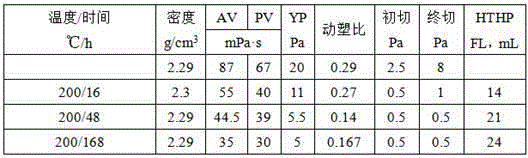

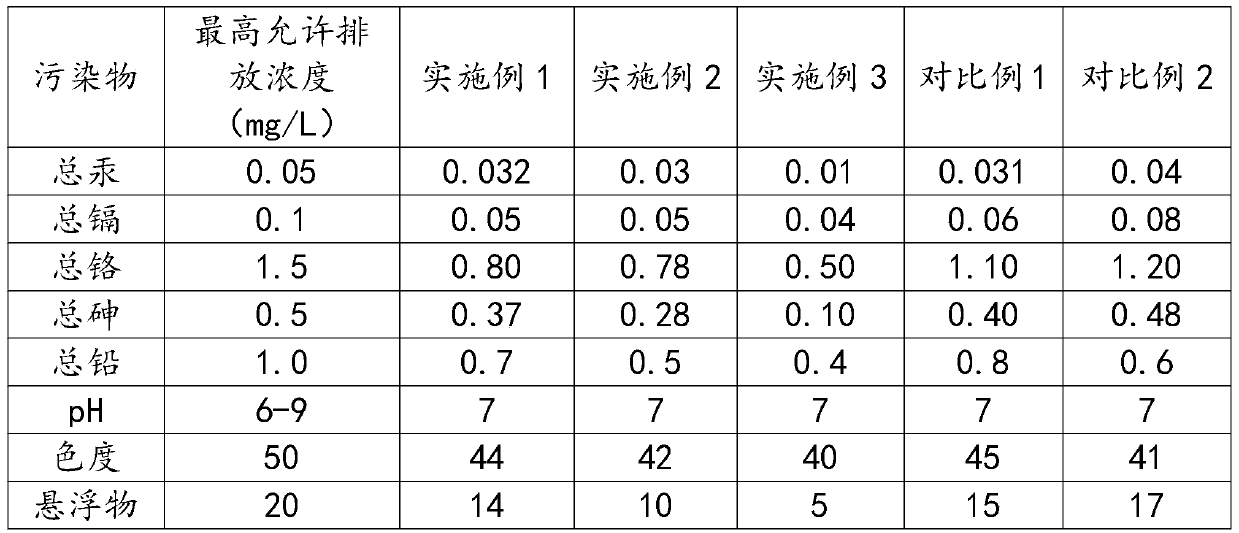

High-temperature-resistant high-density solid-phase-free formate drilling fluid system

The invention discloses a high-temperature-resistant high-density solid-phase-free formate drilling fluid system. The drilling fluid system is prepared from the following compositions in percent by mass: 0.8-1.1% of a tackifier, 0.5-1.0% of a filtrate reducer, 1-2% of a first temporary blocking agent, 1.4-2.2% of a second temporary blocking agent, 0.4-0.9% of a buffering agent, 0.1-0.4% of an anti-oxidant, 45-87% of a weighting agent, and the balance seawater. The system density is 2.0-2.3 g / cm<3>. The drilling fluid system possesses the temperature resistance reaching to 200 DEG C and the density up to 2.3 g / cm<3>, and possesses relatively strong stability, inhibition property, lubricity, storage-layer protection property, degradability, no toxicity and harm to environment under the conditions of high temperature and high density.

Owner:CHINA NAT OFFSHORE OIL CORP +1

Synergistic bead lubricant and methods for providing improved lubrication to drilling fluids for horizontal drilling

InactiveUS8324136B1Reduces torque and dragWide range of densitiesFlushingDrilling compositionWell drillingLubrication

A drilling fluid lubricant and method for drilling using same comprising a blend of beads having varying densities such that the beads provide lubricity at both the top and bottom portions of a horizontal drill string during horizontal, directional, or expanded extended reach drilling.

Owner:GRINDING & SIZING CO INC

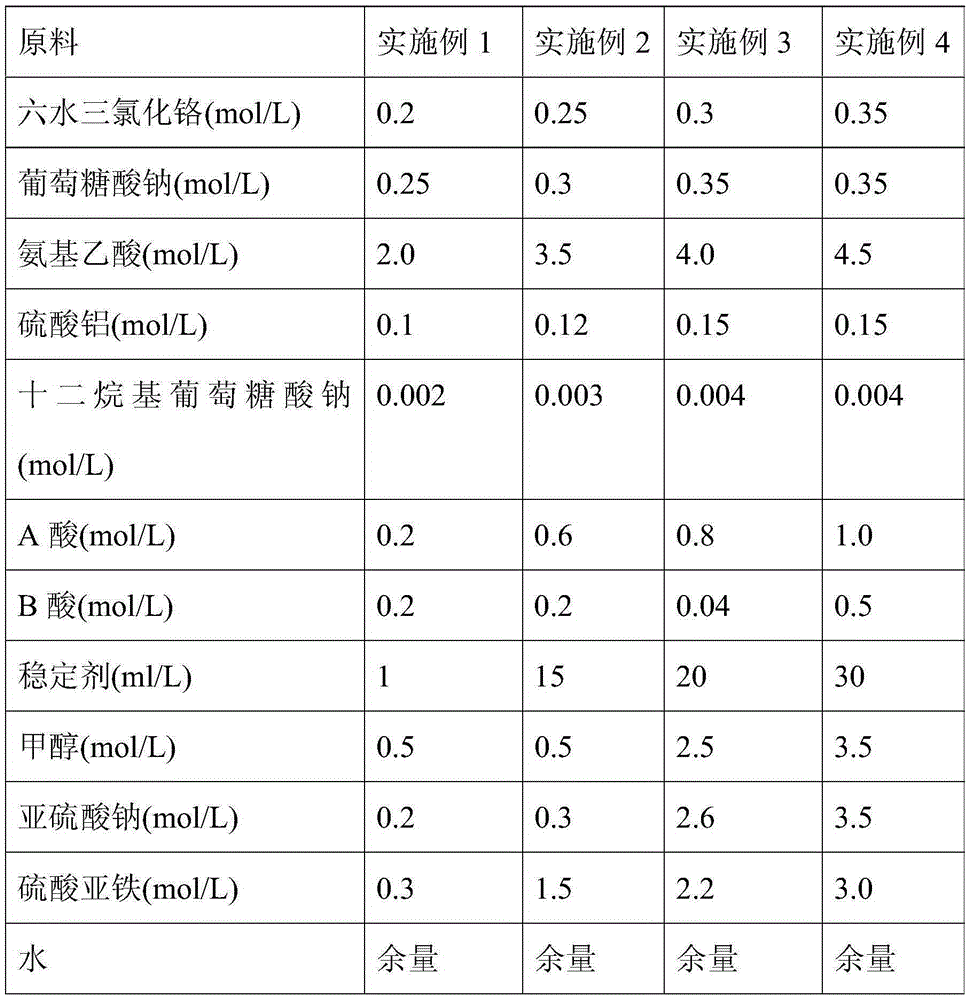

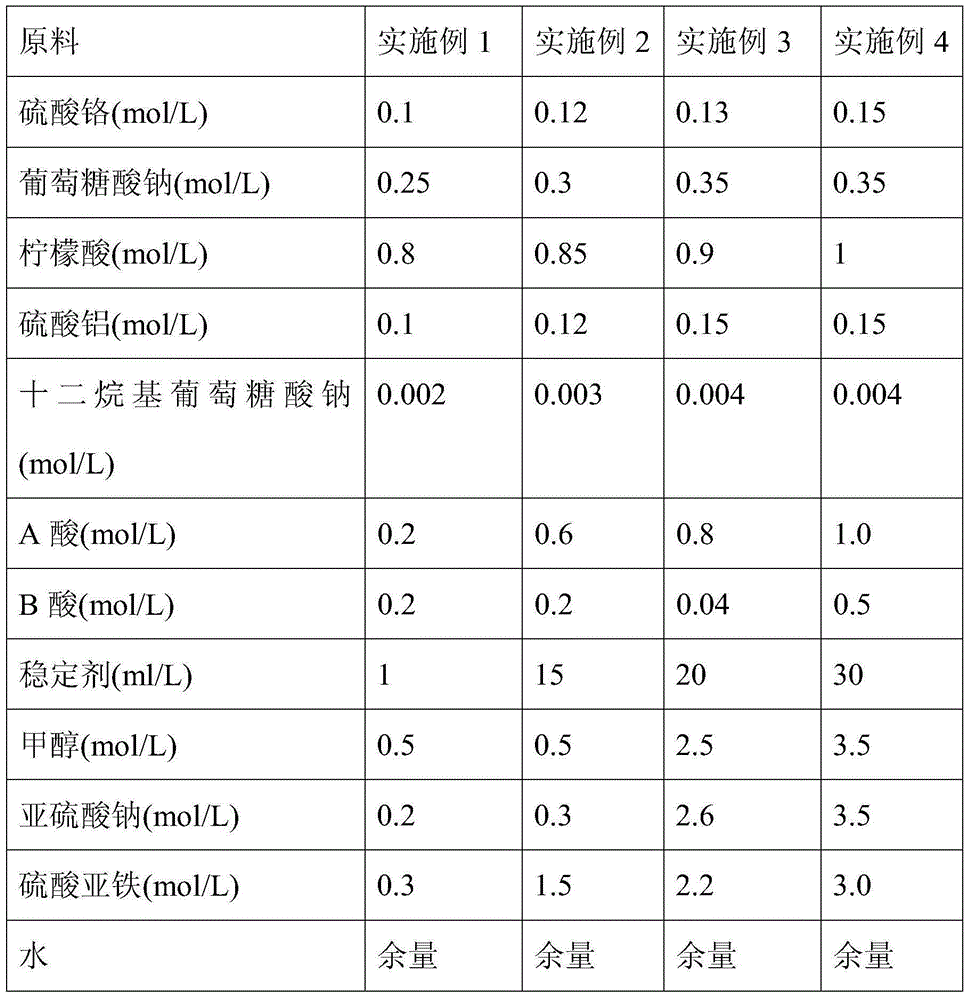

Trivalent chromium electroplate liquid and preparing method thereof

The invention discloses trivalent chromium electroplate liquid and a preparing method thereof. The trivalent chromium electroplate liquid comprises, by concentration, 0.2-0.35 mol / L of hexahydrate chromium trichloride, 0.25-0.35 mol / L of sodium gluconate, 2.0-4.5 mol / L of glycine, 0.1-0.15 mol / L of aluminum sulfate, 0.002-0.004 mol / L of dodecyl sodium gluconate, 0.4-0.8 mol / L of a complexing agent, 15-20 ml / L of stabilizer and the balance solvent water. The stabilizer is a water solution comprising 2-3 mol / L of methyl alcohol, 2-3 mol / L of sodium sulfite and 1-2 mol / L of ferrous sulfate. Compared with the prior art, the electroplate liquid is stable in performance and long in service life, and the quality of a coating is good. Meanwhile, the preparing method is simple, operation is easy, and very good application prospects and high using value are achieved.

Owner:WUXI QIAOYANG MACHINERY MFG

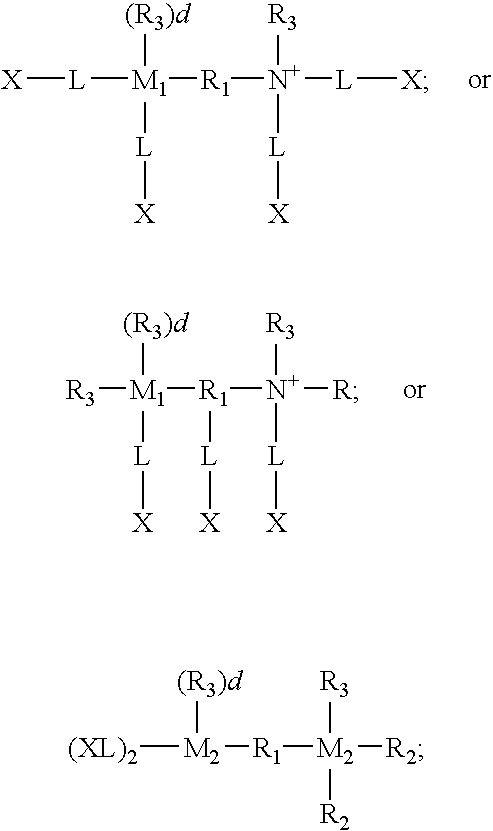

Foamed, lightfast polyurethane reaction mixtures, processes for preparing moldings therewith, and moldings produced thereby

InactiveUS20090203810A1Soft elastic surface behaviourLow shrinkage behaviourPolyolAmmonium carbamate

Foamed, lightfast polyurethane reaction mixtures, and moldings produced therefrom, comprising: (a) an isocyanate component comprising one or more selected from the group consisting of aliphatic isocyanates, aliphatic isocyanate prepolymers and mixtures thereof; (b) a polyol component having an average molecular weight of 1,000-15,000 g / mol and an average functionality of 2 to 8; (c) a chain extension / crosslinking component comprising one or more selected from the group consisting of polyols and polyamines having a molecular weight of 62-500 g / mol and a functionality of 2 to 8; and (e) a blowing agent comprising an ammonium carbamate salt of formula (I) having at least two OH groups:HO—X—N(R1)H2+−O—C(O)—N(R1)—X—OH (I)wherein each R1 independently represents a moiety selected from the group consisting of H, C1-C5 alkyl radicals, and —X—OH groups; wherein each X independently represents a moiety selected from the group consisting of —[CR2R3]n— wherein n represents a number of 2 to 6, —(CR2R3)pO—(—CR2R3p]q— wherein p represents a number of 2 to 4 and q represents a number of 1 to 10, and —(CR2R3)N(R4)CR2R3r]s— wherein r represents a number of 2 to 4 and s represents a number of 1 to 10; wherein each R2 and each R3 independently represents a moiety selected from the group consisting of H and C1-C5 alkyl radicals; and wherein each R4 independently represents a moiety selected from the group consisting of H, C1-C5 alkyl radicals, and —X—OH groups.

Owner:BAYER MATERIALSCIENCE AG

Method for isolating monocytes in bovine peripheral blood

InactiveCN102329774AStable separationReduce unfavorable factors for adherent separationBlood/immune system cellsIsolation effectAnticoagulant

The invention provides a method for optimally isolating monocytes in bovine peripheral blood. ACD-A is taken as an anticoagulant, the method comprises the optimization of centrifugal conditions, the optimization of cell cleaning conditions, the optimization of wall-sticking conditions and the like, and the success rate of the isolation is greatly improved. In the method, a whole set of complete system which comprises the sampling of bovine blood, the isolation of the monocytes in the bovine peripheral blood and the final transformation of the monocytes into macrophages is established for the first time, and the counting and dyeing are not required in the process, so that the time is saved and an isolation effect is improved. The survival rate of the monocytes isolated by the method is high; and the method is high in experimental repeatability and strong in operability, and provides powerful technical support for simply, conveniently and efficiently isolating the monocytes in the bovine peripheral blood.

Owner:CHINA AGRI UNIV

Foam concrete for sewage filtration and preparation method thereof

InactiveCN111003992AHigh densityWide range of densitiesTreatment involving filtrationWater/sewage treatment by sorptionFoam concreteFoaming agent

The invention discloses foam concrete for sewage filtration. The foam concrete comprises the following raw materials in parts by weight: 0-250 parts of a cementing material, 50-300 parts of an admixture, 0-20 parts of a reinforcing agent, 0-10 parts of a water reducing agent, 0-5 parts of a modifier, 0-5 parts of a foaming agent and 50-400 parts of water, the method comprises the following steps:(1) weighing the raw materials; (2) sequentially adding the water, the reinforcing agent, the modifier, the water reducing agent, the admixture and the cementing material, and uniformly stirring; (3)mixing with foaming foam of the foaming agent; and (4) pumping into a mold to obtain the product. According to the invention, a surfactant is used for physical foaming, and the foaming agent is used for modification, so that the foam concrete with high continuous porosity, good permeable effect and high strength can be produced, the sewage treatment effect is excellent, and the pore size can be adjusted according to volume weight or proportion; the foam concrete is naturally cured, the longer the time is, the higher the strength is, and the strength increase is stable.

Owner:张建华

Environment-friendly electro-coppering liquid

The invention discloses an environment-friendly electro-coppering liquid which is characterized by comprising a main binder, an auxiliary binder, a main salt, a conductive salt and a pH value conditioning agent, wherein the binder is disodium ethylene diamine tetraacetate or dipotassium ethylene diamine tetraacetate with a concentration of 100 to 150 g / L, the auxiliary binder is trisodium citrate, tripotassium citrate or potassium sodium tartrate with a concentration of 20 to 35 g / L, the main salt is copper sulphate or basic cupric carbonate with a concentration of 10 to 40 g / L, the conductive salt is sodium nitrate or potassium nitrate with a concentration of 5 to 10 g / L, and the pH value conditioning agent is sodium hydroxide or potassium hydroxide with a concentration of 25 to 50 g / L. The environment-friendly electro-coppering liquid provided by the invention has the following advantages: the electro-coppering liquid is a cyanide-free plating solution which is environment-friendly and nontoxic, easy to operate and maintain and applicable to direct electroplating on the surface of steel wires; the electro-coppering liquid has good polarization performance, high cathodic current efficiency and a wide density scope; and a coating formed by the liquid has good bonding force and is simple to maintain and low in cost.

Owner:NANTONG HUIFENG ELECTRONICS TECH

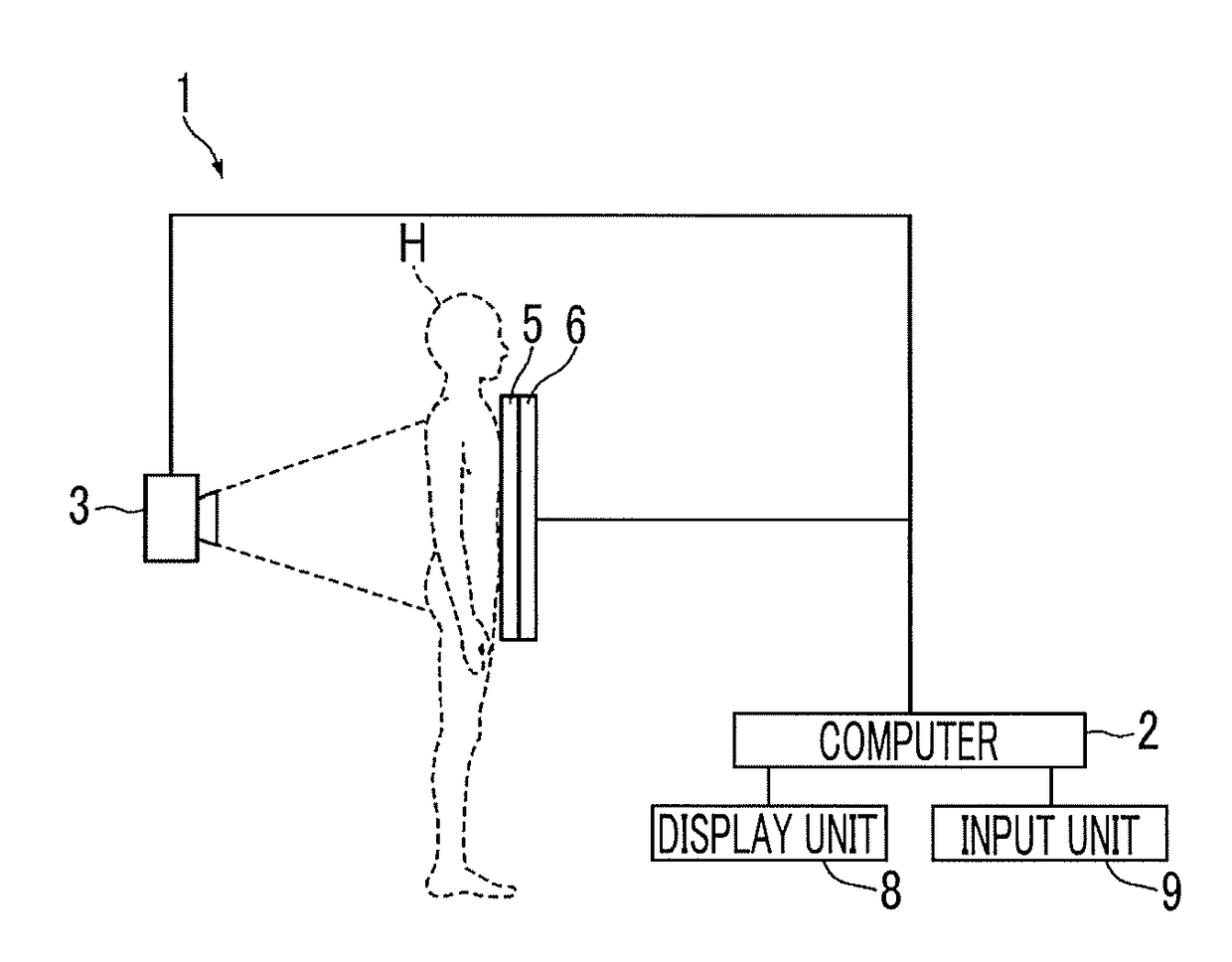

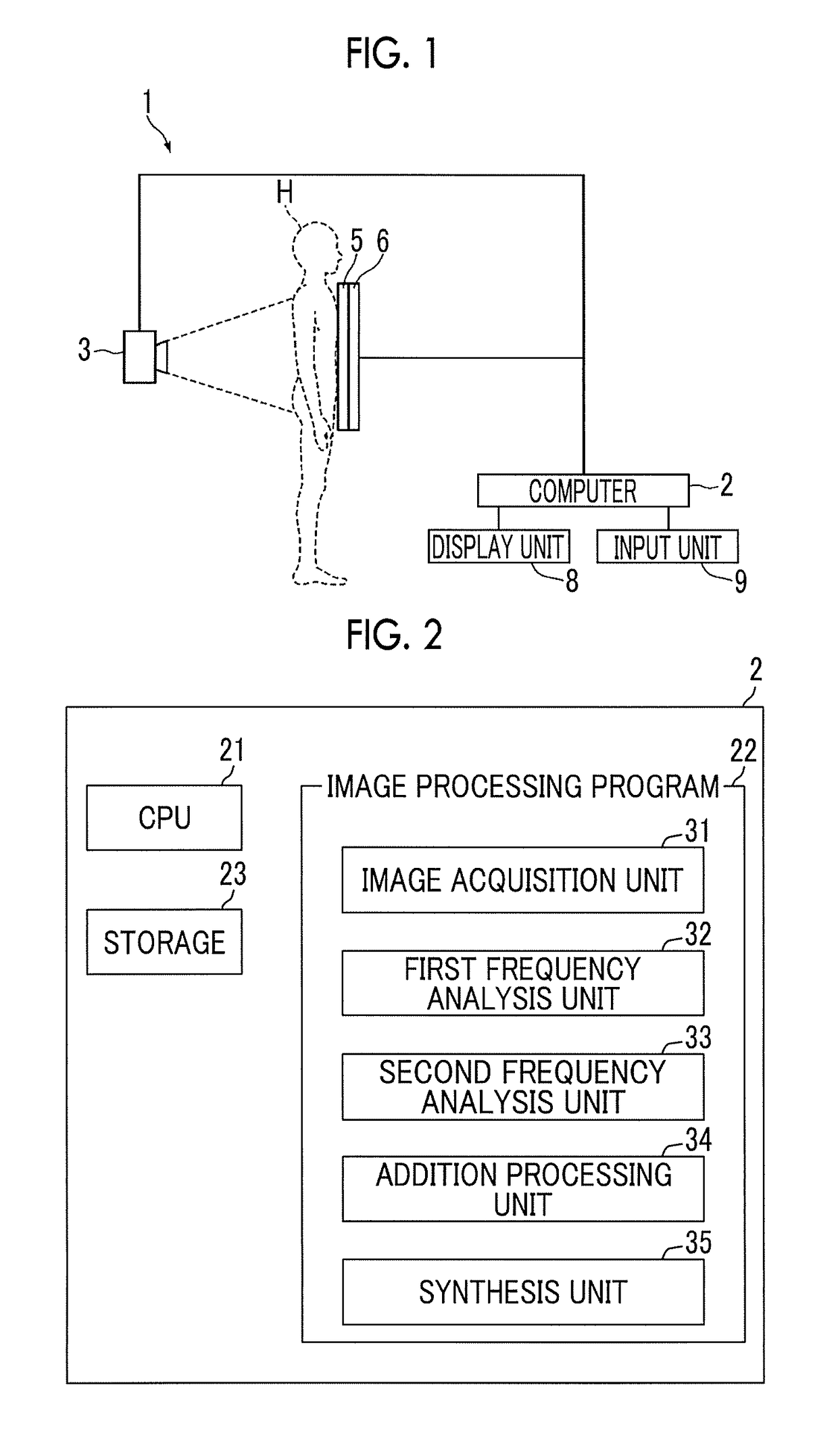

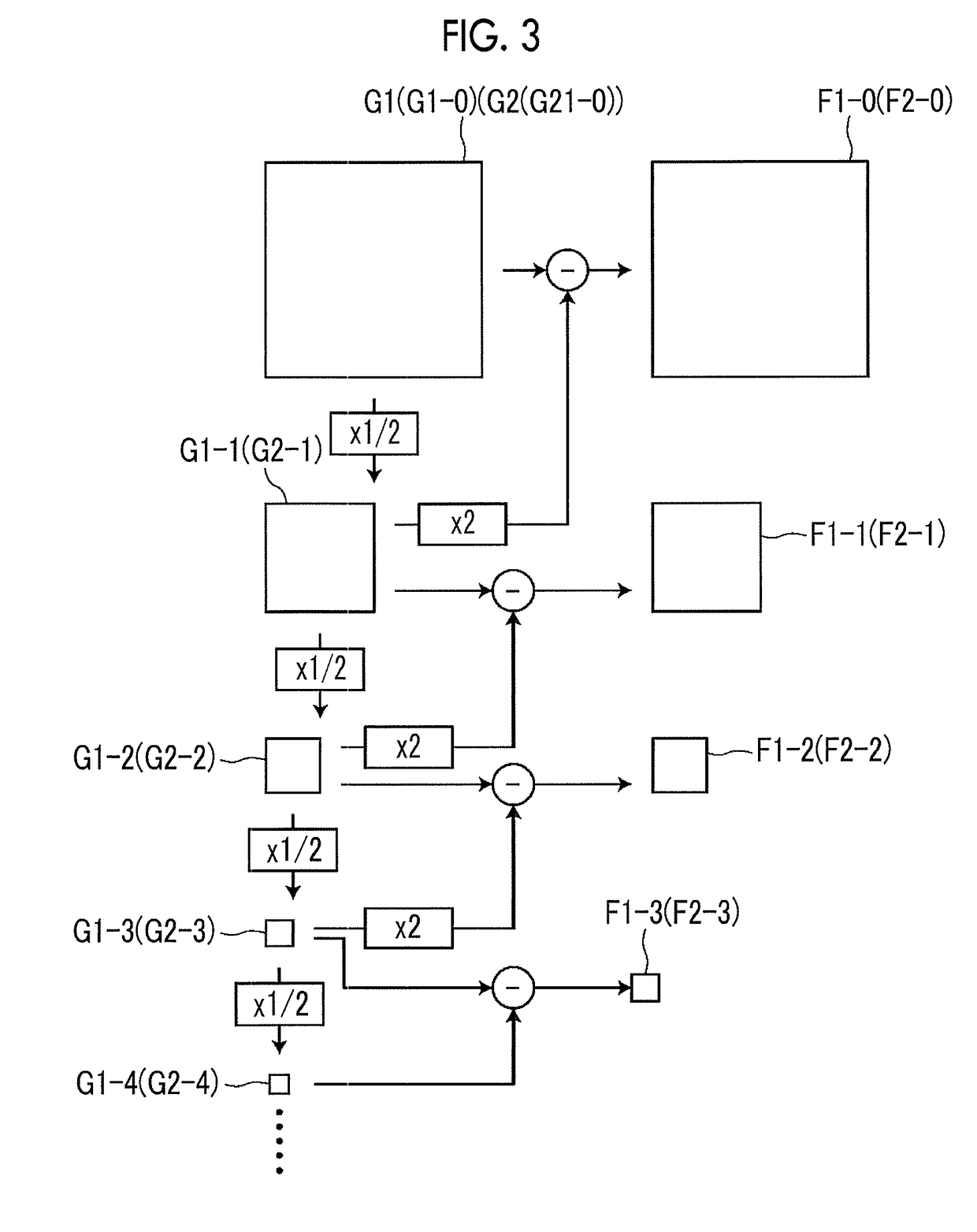

Image processing apparatus, image processing method, and image processing program

ActiveUS20180068422A1Reduce noiseWide range of densitiesImage enhancementImage analysisImaging processingComputer science

An image acquisition unit acquires first and second radiation images from first and second radiation detectors. A first frequency analysis unit generates a first high-frequency component which is a high-frequency component of the first radiation image, and a second frequency analysis unit generates a second high-frequency component and a second low-frequency component which are a high-frequency component and a low-frequency component of the second radiation image. An addition processing unit performs weighting and addition with respect to the first and second high-frequency components to generate an addition high-frequency component, and a synthesis unit synthesizes the addition high-frequency component and the second low-frequency component to generate a processed image.

Owner:FUJIFILM CORP

Gold plating solution

ActiveUS20120132533A1Stable during storageSatisfactory propertyOther chemical processesCoupling contact membersCyanideNitrogenous heterocyclic compound

A gold plating bath and a plating method is disclosed where gold cyanide or salts thereof provide the source of gold, a cobalt compound, and a reaction product of compound containing at least a nitrogen-containing heterocyclic compound and an epihalohydrin. The gold plating bath has high deposition selectivity.

Owner:ROHM & HAAS ELECTRONICS MATERIALS LLC

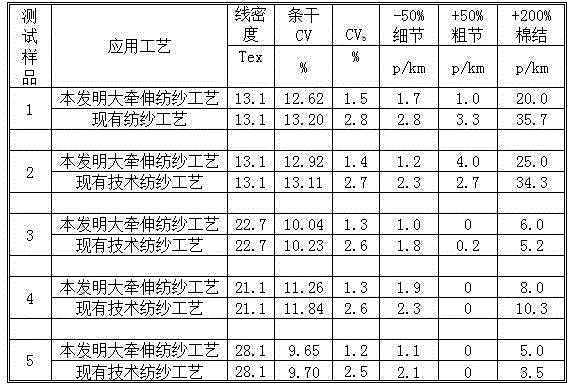

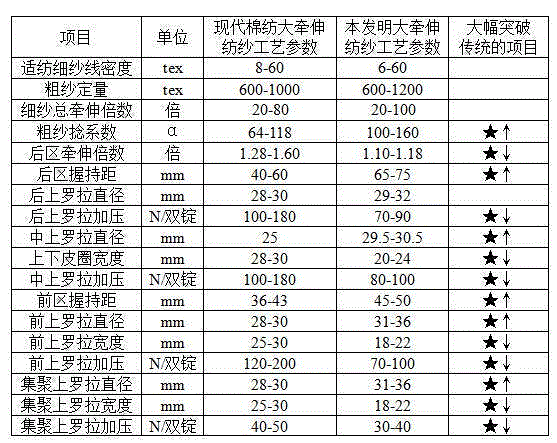

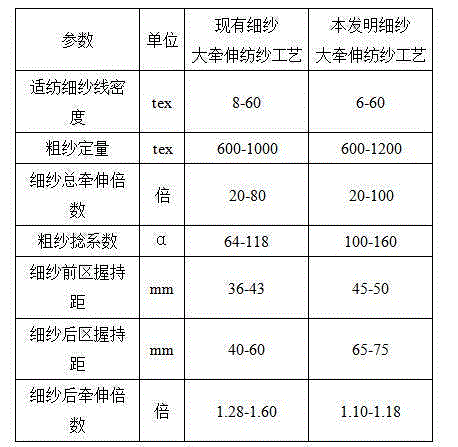

High-draft spinning technology of spinning frame

The invention discloses a high-draft spinning technology of a spinning frame and is applicable to big ration of roving yarn and a spun yarn high-draft spinning technology. One or more pieces of roving yarn are parallelly fed into a drafting system of the spinning frame, the spinnable spun yarn density is 6-60 tex, the ration of the fed roving yarn is 600-1,200 tex, the roving yarn is drafted in parallel state, the total draft multiple of the spinning frame is 20-100 times, and the roving yarn winds around a spool for yarn forming after drafting twisting; for cotton-type staple fiber spinning, the metric twist factor of the roving yarn is 100-160, a front-zone large gripping distance of spun yarn is 45-50 mm, a back-zone large gripping distance of the spun yarn is 65-75 mm, and the small back-zone draft multiple is 1.10-1.18 times. The whole drafting system performance can be optimized by the aid of reasonable configuration of technological parameters, the spinnable spun yarn density range is wider, the ration of the roving yarn is bigger, and the total draft multiple of the spun yarn is larger.

Owner:金轮针布(江苏)有限公司 +1

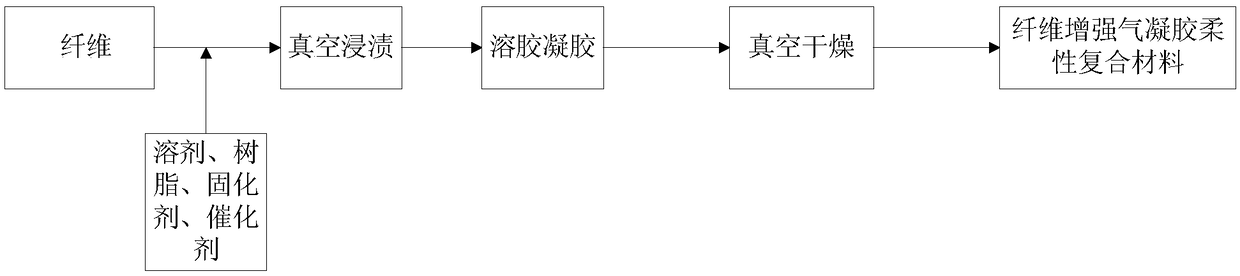

Fiber reinforced flexible aerogel composite material and preparation method thereof

InactiveCN109337380AStrong shape-dimensional abilityImprove machinabilityMaterials preparationResin-Based Composite

The invention relates to a fiber reinforced flexible aerogel composite material and a preparation method thereof, and belongs to the technical field of composite material preparation. According to thecomposite material, fiber-reinforced flexible aerogel which has the advantages of being high in strength, good in toughness, strong in shape retention ability and good in processing ability when being compared with existing resin-based composite materials is adopted, so that the problems that the traditional fiber-reinforced aerogel composite materials are limited in shaping size, poor in toughness and difficult to process are solved, and the application field of the fiber-reinforced aerogel is greatly expanded.

Owner:BEIJING SATELLITE MFG FACTORY

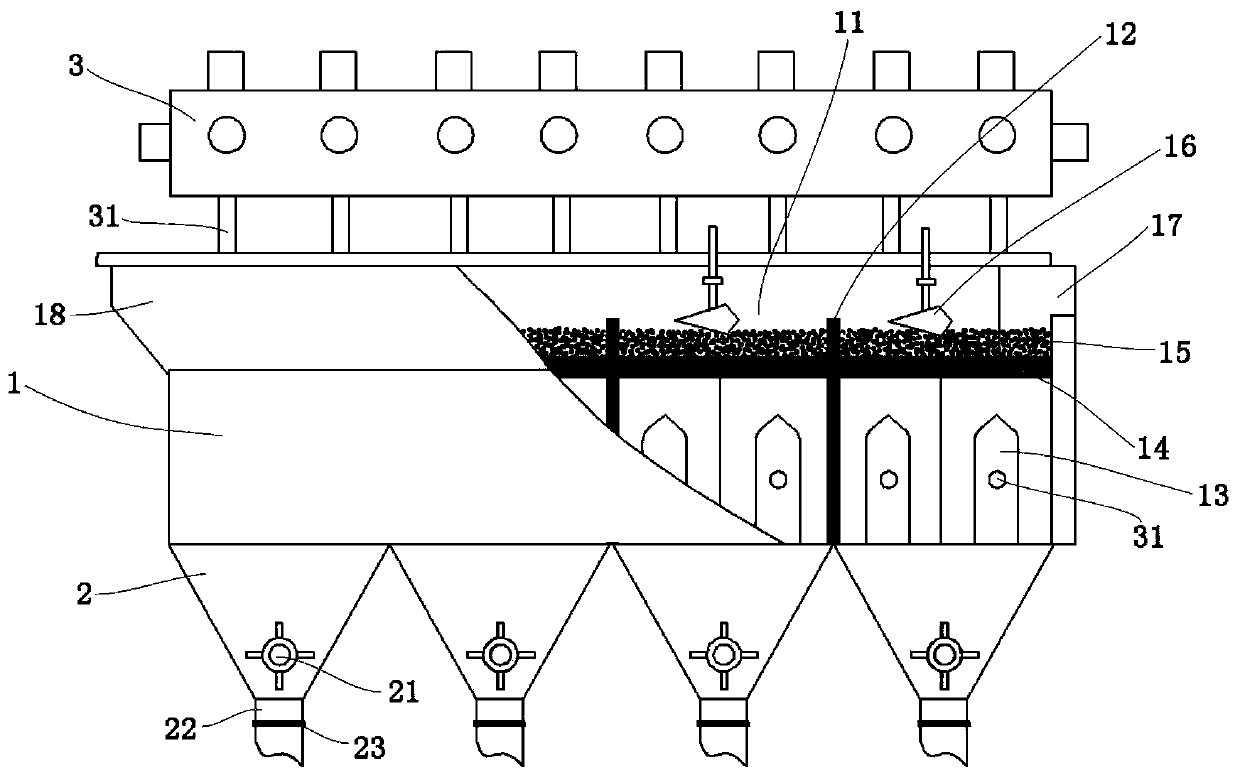

Washing method of screening type coarse slime sorting washbox

The invention discloses a washing method of a screening type coarse slime sorting washbox, and relates to the field of cleaning units. The method comprises the following steps that firstly, an artificial bed is laid, the thickness of the artificial bed ranges from 300 mm to 600 mm, the artificial bed is divided into a bottom layer, a middle layer and an upper layer, the thickness of the bottom layer ranges from 100 mm to 200 mm, the particle size of laid bed stone ranges from 10 mm to 12 mm, the density ranges from 2.1 g / cm3 to 3.6 g / cm3, the thickness of the middle layer ranges from 100 mm to200 mm, the particle size of laid bed stone ranges from 8 mm to 10 mm, the density ranges from 2.0 g / cm3 to 3.0 g / cm3, the thickness of the upper layer ranges from 100 mm to 200 mm, the particle sizeof laid bed stone ranges from 6 mm to 8 mm, and the density ranges from 1.8 g / cm3 to 2.5 g / cm3; secondly, valves at discharging openings in the bottom of the screening type coarse slime sorting washbox are closed, and a bottom dewatering screen of the screening type coarse slime sorting washbox is started; thirdly, a clean water pump is started to convey clean water to a main water pipe; fourthly, an electronic numerical control device is started, and various parameters of the electronic numerical control device are adjusted; and fifthly, coarse slime raw materials are conveyed to a raw material feeding opening of the screening type coarse slime sorting washbox to be prepared for washing. The washing method is simple in operation and high in adaptability, and the recovery rate can reach 95% or above.

Owner:西安煤科动力科技有限公司

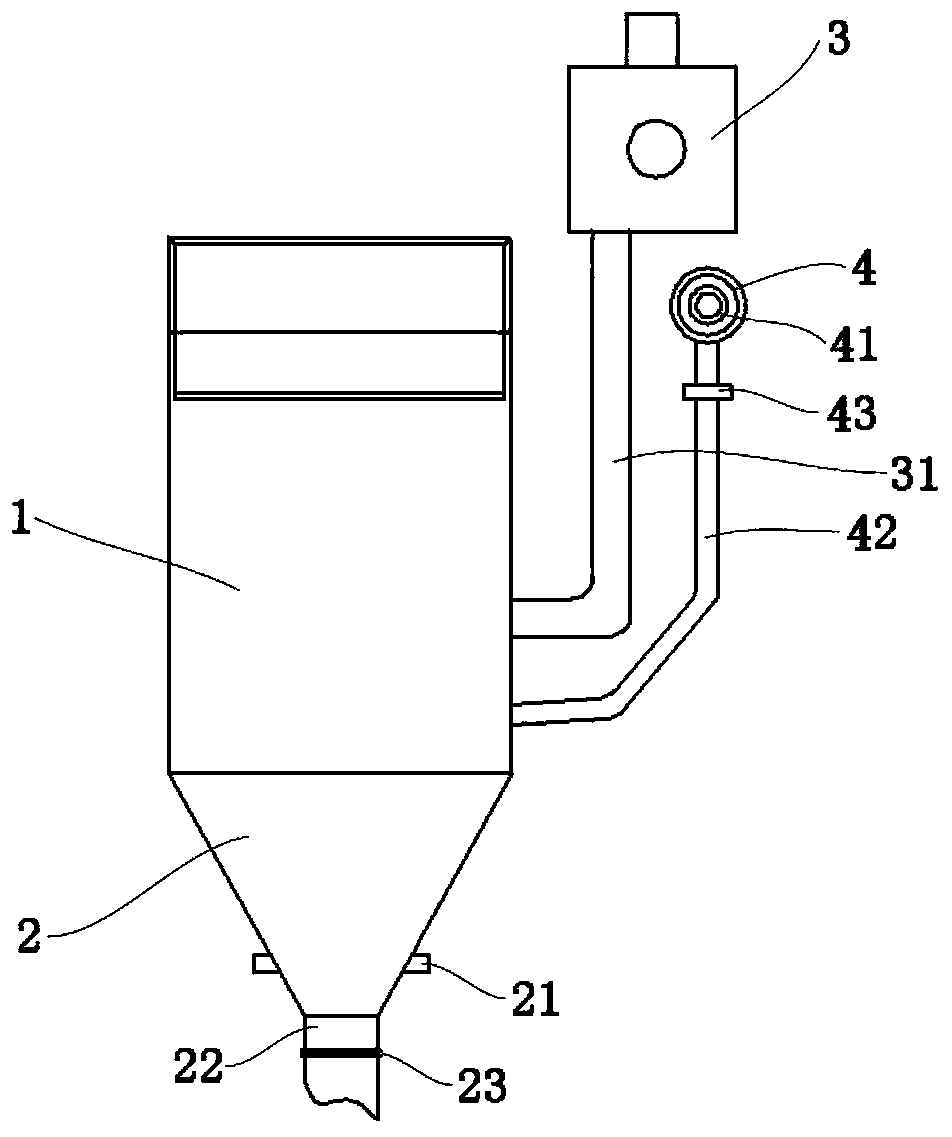

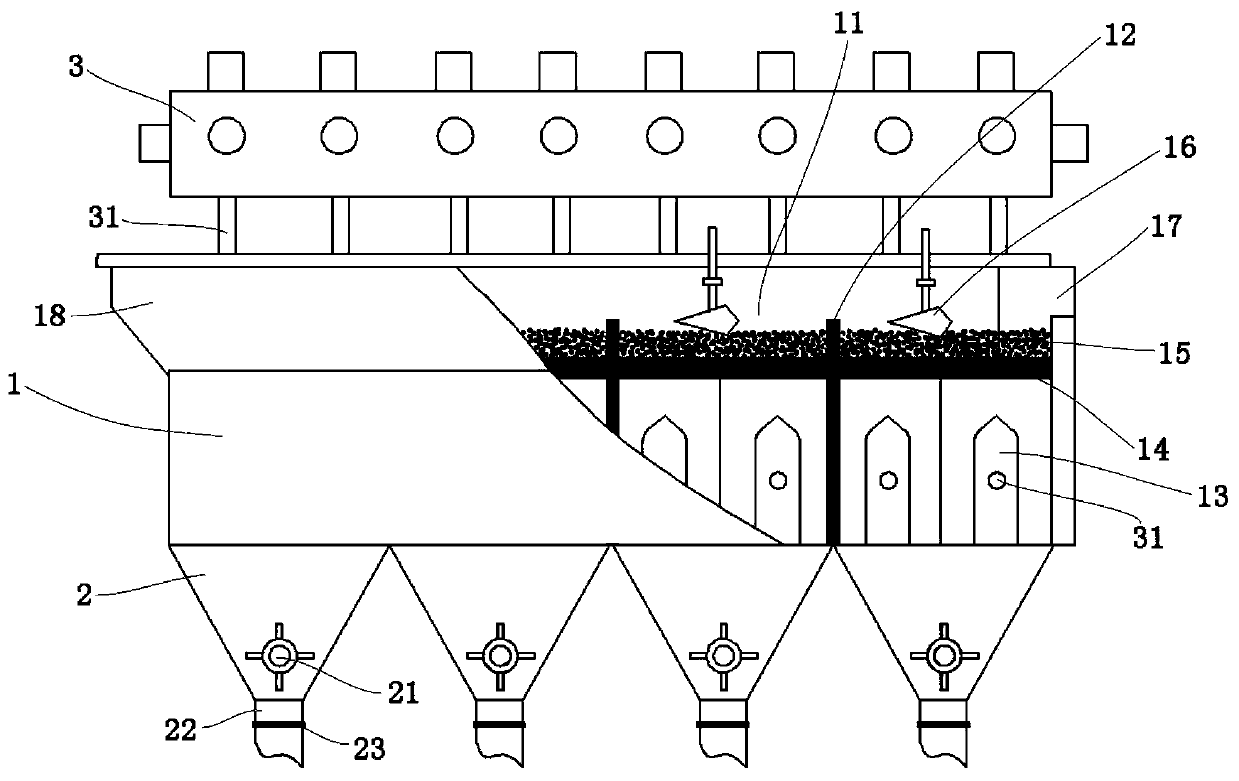

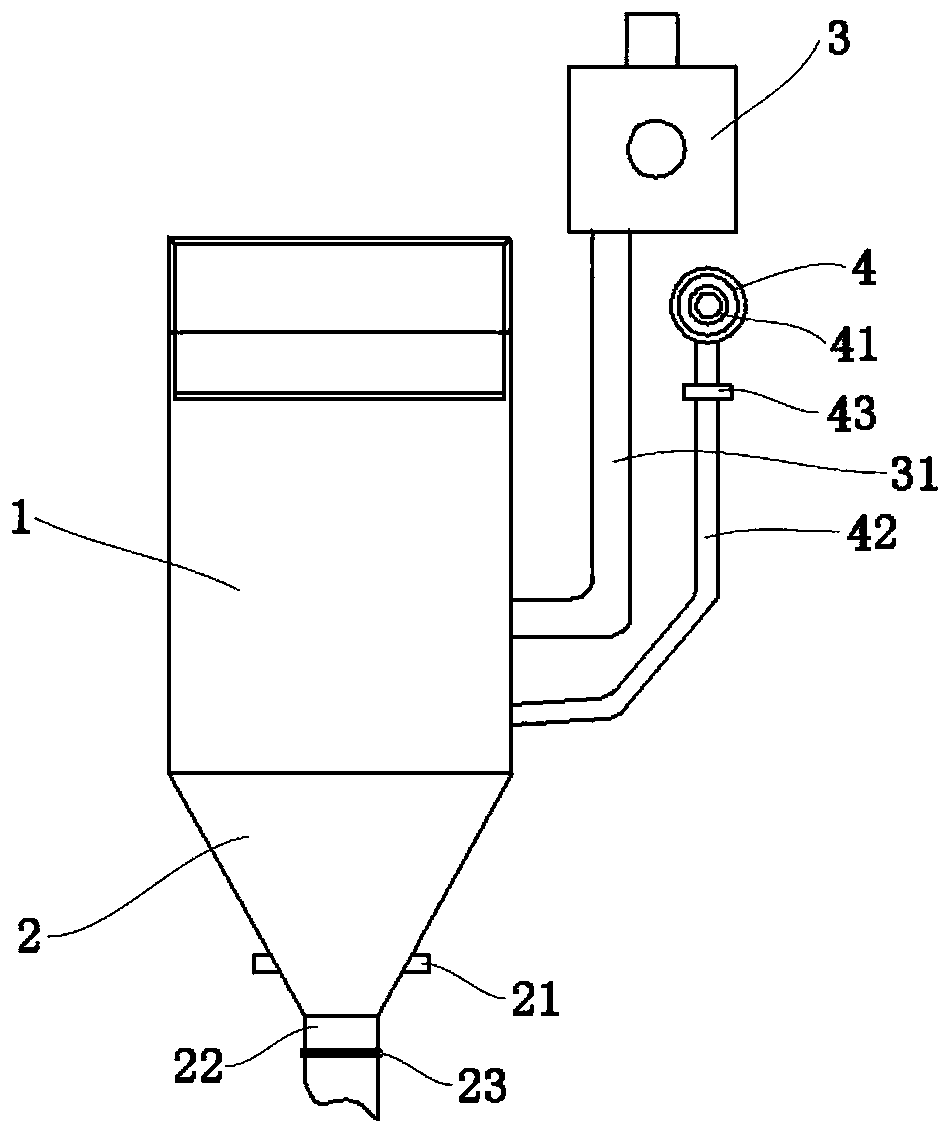

Screening type coarse slime sorting jigger

PendingCN110124843ASimple structureEasy to operateWet separationNumerical controlPulp and paper industry

The invention discloses a screening type coarse slime sorting jigger. The screening type coarse slime sorting jigger comprises an upper machine body, a lower machine body, a numerical-control air bellow and a header water tube, wherein the upper machine body is rectangular, and comprises a partition, an air chamber, a screen plate, an artificial bed layer and a buoy; the partition is used for dividing the upper machine into partition sections, each partition section is divided into 2-3 chambers, each chamber is at least provided with an air chamber which is arranged on the bottom in the uppermachine body, the screen plate is arranged at the upper end of the air chamber without an angle of inclination, the artificial bed layer spreads on the upper surface of the screen plate, and the buoyis arranged at the upper end of the artificial bed layer; a raw material charge hole is formed in one end of the upper machine body, and the other end of the upper machine body is provided with a light product overflow weir; the lower machine body is tapered, and comprises a discharge wheel, a discharge hole and a valve, the discharge wheel is arranged at the lower end of the lower machine body, the discharge hole is formed in the tail end of the lower machine body, the discharge wheel is arranged above the discharge hole, the valve is arranged at the lower end of the discharge hole, and the bottom of the upper machine body is connected to the upper part of the lower machine body; the numerical-control air bellow is mounted at the upper side of the upper machine body in a length directionof the upper machine body, and is connected to the air chamber through an air tube; and the header water tube comprises a washing water pipeline and a backwater pipeline.

Owner:西安煤科动力科技有限公司

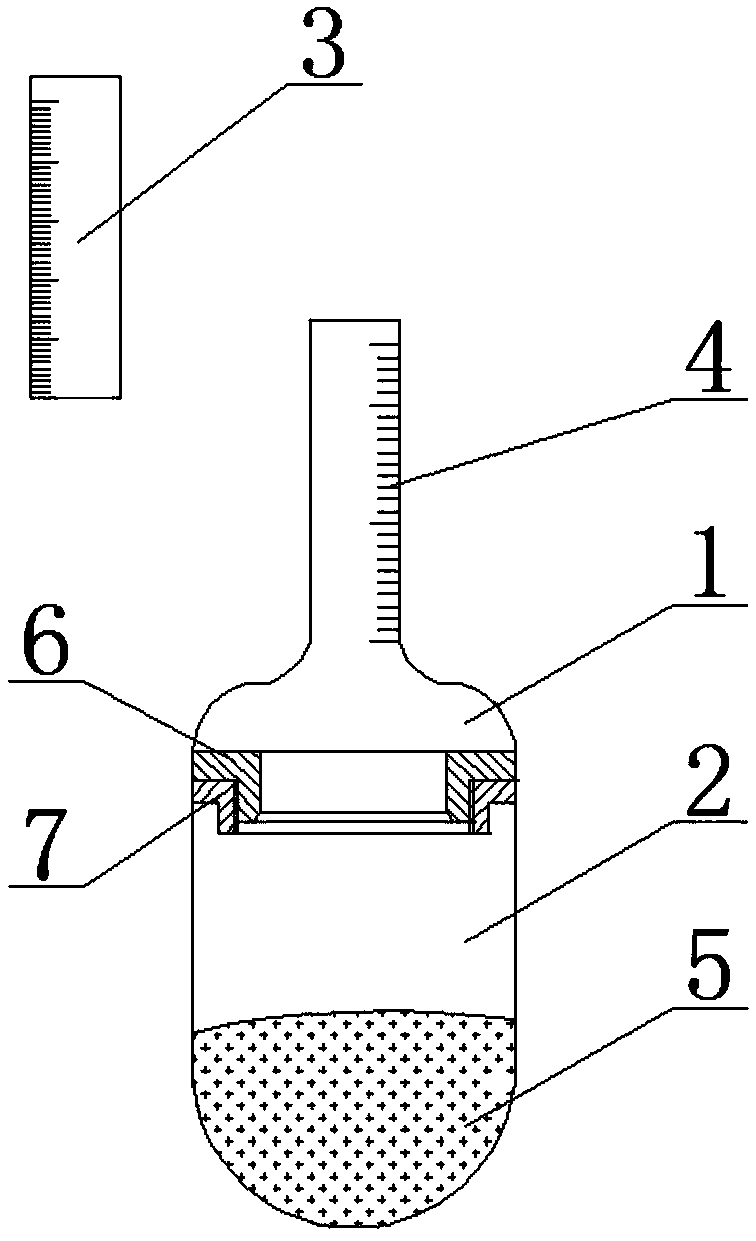

Densitometer and measurement method for measuring density of liquid

InactiveCN108169065AWide range of densitiesEasy to useSpecific gravity measurementEngineeringMechanical engineering

The invention relates to a densitometer and a measurement method for measuring the density of a liquid. The densitometer comprises a marking body, a measuring body and a plurality of density scales, the outer wall of the marking body is provided with a liquid level graduation, the density scales are movably mounted on the outer wall of the marking body, a counterweight is contained in the measuring body, the lower end of the marking body is connected with the upper end of the measuring body, and the liquid level graduation and the density scales are respectively provided with volume scale values and density scale values. The measurement method includes the following steps: immersing the measuring body in a liquid to be measured, reading the reading value on the liquid level graduation, andreading the density value of the liquid to be measured on the density scales according to the obtained volume value. The densitometer and the measurement method are adopted to simplify the measuringprocess, so the densitometer has a large measuring range, and can be easily used by measuring personnel, influences of the external environment on the densitometer are reduced, the weight of the counterweight can be changed when necessary in order to meet different measuring demands, and the densitometer and the measurement method are flexible and fast to operate.

Owner:CHINA HANGFA GUIZHOU LIYANG AVIATION POWER CO LTD

Trivalent chromium electroplate liquid and preparing method thereof

The invention discloses trivalent chromium electroplate liquid and a preparing method thereof. The trivalent chromium electroplate liquid comprises, by concentration, 0.1-0.15 mol / L of chromium sulfate, 0.25-0.35 mol / L of sodium gluconate, 0.8-1 mol / L of citric acid, 0.1-0.15 mol / L of aluminum sulfate, 0.002-0.004 mol / L of dodecyl sodium gluconate, 0.4-0.8 mol / L of a complexing agent, 15-20 mol / L of a stabilizer and the balanced solvent water. The stabilizer is a water solution which is formed by 2-3 mol / L of methyl alcohol, 2-3 mol / L of sodium sulfite and 1-2 mol / L of ferrous sulfate. Compared with the prior art, the trivalent chromium electroplate liquid has the beneficial effects that the performance is stable, the service life is long, the coating quality is good, the preparing method is simple, the operation is easy, and the great application prospect and the good use value are achieved.

Owner:WUXI QIAOYANG MACHINERY MFG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com