Foam concrete for sewage filtration and preparation method thereof

A foamed concrete and sewage technology, applied in filtration treatment, water/sewage treatment, chemical instruments and methods, etc., can solve the problems of difficulty in purchasing sewage treatment plants, poor material durability, and easy pulverization, and improve volume stability. , Improve the compactness, reduce the effect of water-material ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Foamed concrete for sewage filtration (the product density is 300 kg), including the following raw materials: 150 kg of Po425 cement, 100 kg of silica fume, 2 kg of magnesium chloride, 2 kg of foaming agent and 150 kg of water.

[0036] Preparation:

[0037] (1) take each raw material by the weight of the above-mentioned foamed concrete that is used for sewage filtration;

[0038] (2) Add water, magnesium chloride, silica fume and Po425 cement successively in the stirring system, stir 5min with the rotating speed of 50r / min, obtain mixed slurry;

[0039] (3) The mixed slurry obtained in step (2) is transported to the mixing system through pipelines, and at the same time, the foaming agent is added to the foaming system for foaming. Mix in time to obtain a fluid product;

[0040] (4) The fluid product obtained in step (3) is pumped into the mold through a pipeline to obtain foamed concrete for sewage filtration.

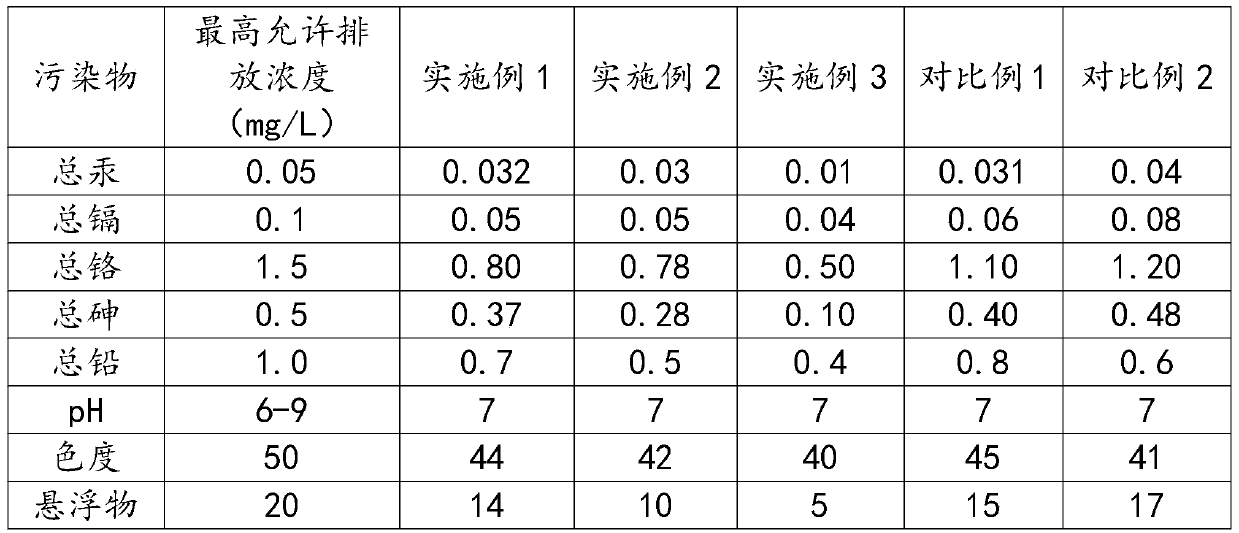

[0041] It is found through testing that compared with ...

Embodiment 2

[0043] Foam concrete for sewage filtration (the product density is 300 kg), including the following raw materials: 150 kg of cement clinker, 100 kg of slag, 2 kg of sodium chloride, 0.5 kg of gypsum, 1 kg of inorganic aluminum salt, 2 kg of foaming agent and 150kg of water.

[0044] Preparation:

[0045] (1) take each raw material by the weight of the foamed concrete that is used for sewage filtration above;

[0046] (2) Add water, sodium chloride, gypsum, inorganic aluminum salt, slag and cement clinker in sequence, and stir for 3 minutes at a speed of 100 r / min to obtain a mixed slurry;

[0047] (3) The mixed slurry obtained in step (2) is transported to the mixing system through pipelines, and at the same time, the foaming agent is added to the foaming system for foaming. Mix in time to obtain a fluid product;

[0048] (4) The fluid product obtained in step (3) is pumped into the mold through a pipeline to obtain foamed concrete for sewage filtration.

[0049]It is foun...

Embodiment 3

[0051] Foam concrete for sewage filtration (product density is 400 kg), including the following raw materials: 250 kg of Po425 cement, 100 kg of water quenching slag, 2 kg of magnesium chloride, 0.5 kg of gypsum, 1 kg of naphthalene-based water reducer, and 1 kg of inorganic aluminum salt , Foaming agent 2kg and water 210kg.

[0052] Preparation:

[0053] (1) take each raw material by the weight of the above-mentioned foamed concrete that is used for sewage filtration;

[0054] (2) Add water, magnesium chloride, gypsum, inorganic aluminum salt, naphthalene-based water reducing agent, water-quenched slag and Po425 cement in sequence, and stir at a speed of 150r / min for 2min to obtain a mixed slurry;

[0055] (3) The mixed slurry obtained in step (2) is transported to the mixing system through pipelines, and at the same time, the foaming agent is added to the foaming system for foaming. Mix in time to obtain a fluid product;

[0056] (4) pumping the fluid product obtained in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com