Trivalent chromium electroplate liquid and preparing method thereof

A technology of electroplating solution and trivalent chromium, applied in the field of electrochemistry, can solve the problems of strict electroplating operation requirements, unsustainable thickening of the coating layer, narrow range of process parameters, etc., and achieves a wide range of current density, a simple preparation method, and a stable plating solution. good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~4 3

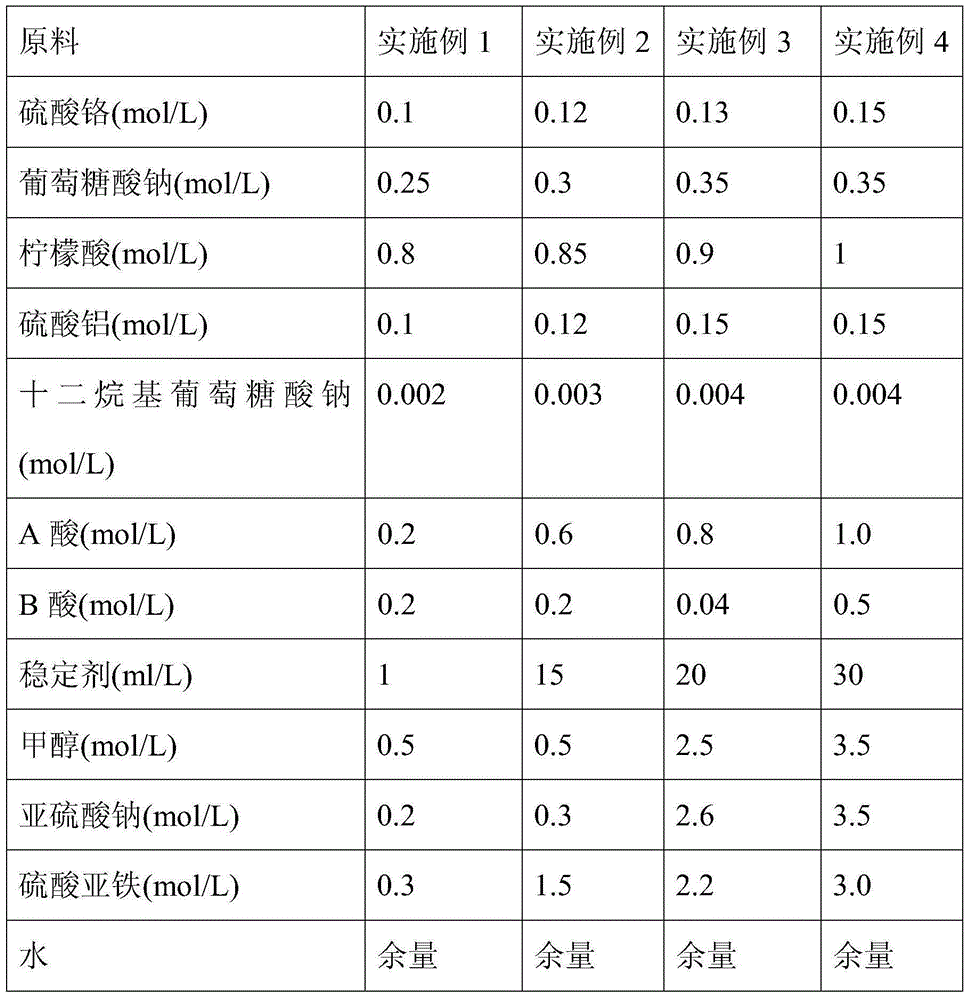

[0023] The proportioning of embodiment 1~4 trivalent chromium electroplating solution

[0024]

[0025] The compositions and proportioning ratios of the trivalent chromium electroplating solutions of the four embodiments are shown in the above table.

[0026] The preparation steps of the electroplating solution of above-mentioned four embodiments are as follows:

[0027] a. Dissolve chromium sulfate in distilled water or pure water according to the ratio in the above table, and stir until dissolved to obtain a chromium sulfate solution; dissolve citric acid in distilled water at 55°C or 60°C or 70°C or 75°C, and stir until Dissolving to obtain citric acid solution;

[0028] b. Chromium sulfate solution is mixed with citric acid solution, and complexing agent is added; since trivalent chromium aqueous solution generally exists stably in the form of a hexahydrate complex, its complexation substitution reaction with complexing agent is carried out slowly, so, After the compl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com