Patents

Literature

47results about How to "Wide current density range" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Multi-coordination-agent cyanide-free electrogilding liquid and electrogilding process

ActiveCN103741181AExcellent bath performanceGood coating performancePotassium hydroxidePotassium carbonate

The invention relates to multi-coordination-agent cyanide-free electrogilding liquid and an electrogilding process, which belong to the technical field of electrogilding. The electrogilding liquid is prepared from a main coordination agent, an auxiliary coordination agent, potassium hydroxide, potassium carbonate, goldpotassium chloride, combined additives and ultrapure water. The electrogilding process comprises the following steps: 1, preprocessing a substrate; 2, electroplating an intermediate nickel plating layer; 3, electrogilding, namely washing the substrate after electroplating the intermediate nickel plating layer with ultrapure water, directly feeding the substrate into a plating cell containing the multi-coordination-agent cyanide-free electrogilding liquid to be electrogilded, taking out a sample from the electrogilding liquid after the electrogilding, washing the surface of the sample by utilizing distilled water, and drying the sample through cold air. Double coordination agents are used as the coordination agents of gold ions in the electrogilding liquid, so that a cyanide-free electrogilding system which has high current efficiency, smoothness and compactness in plating layer crystallization, wide current density range, wide temperature requirement and capability of guaranteeing the golden bright appearance of the plating layer compared with those of a single coordination agent system is obtained.

Owner:HARBIN INST OF TECH

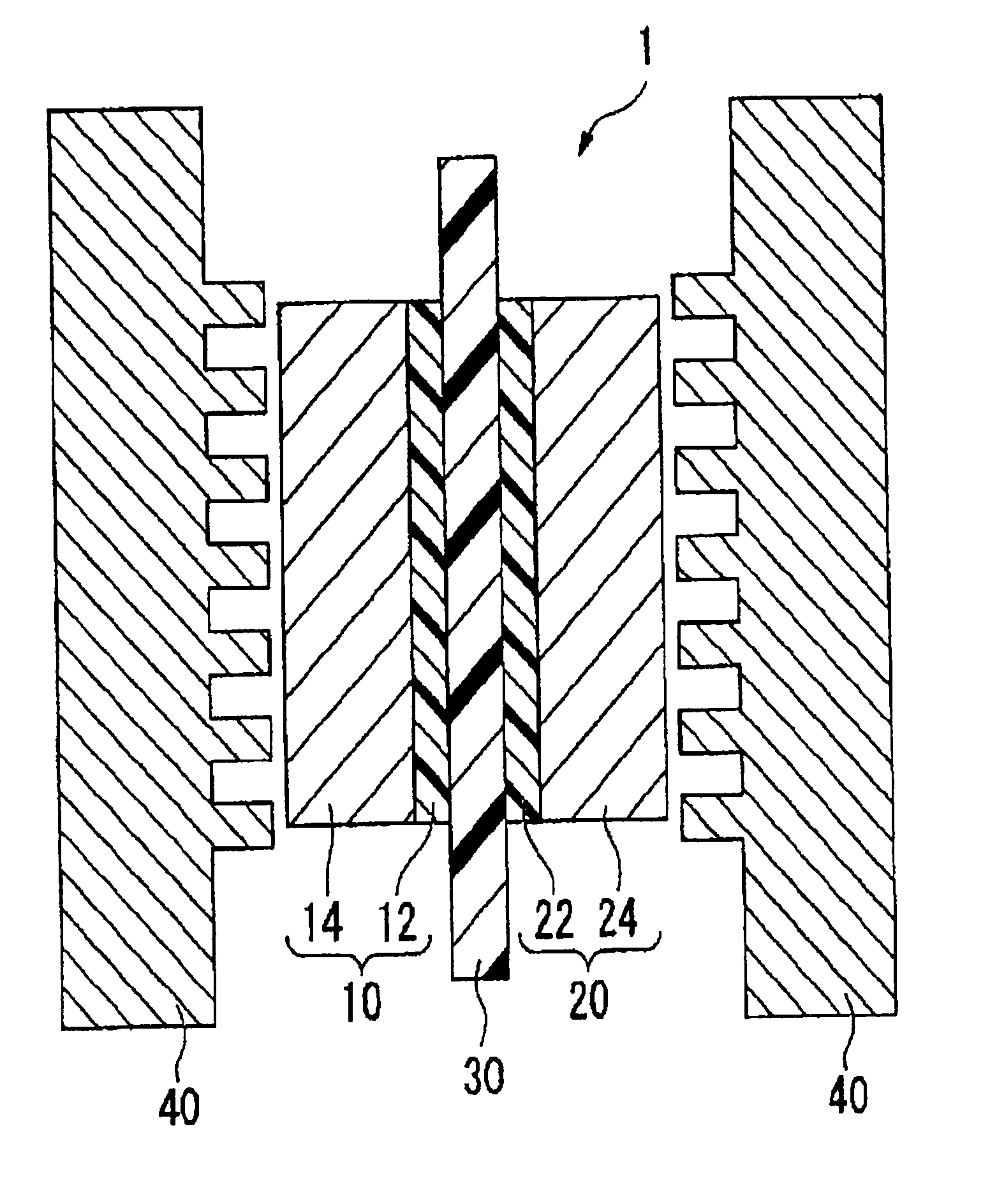

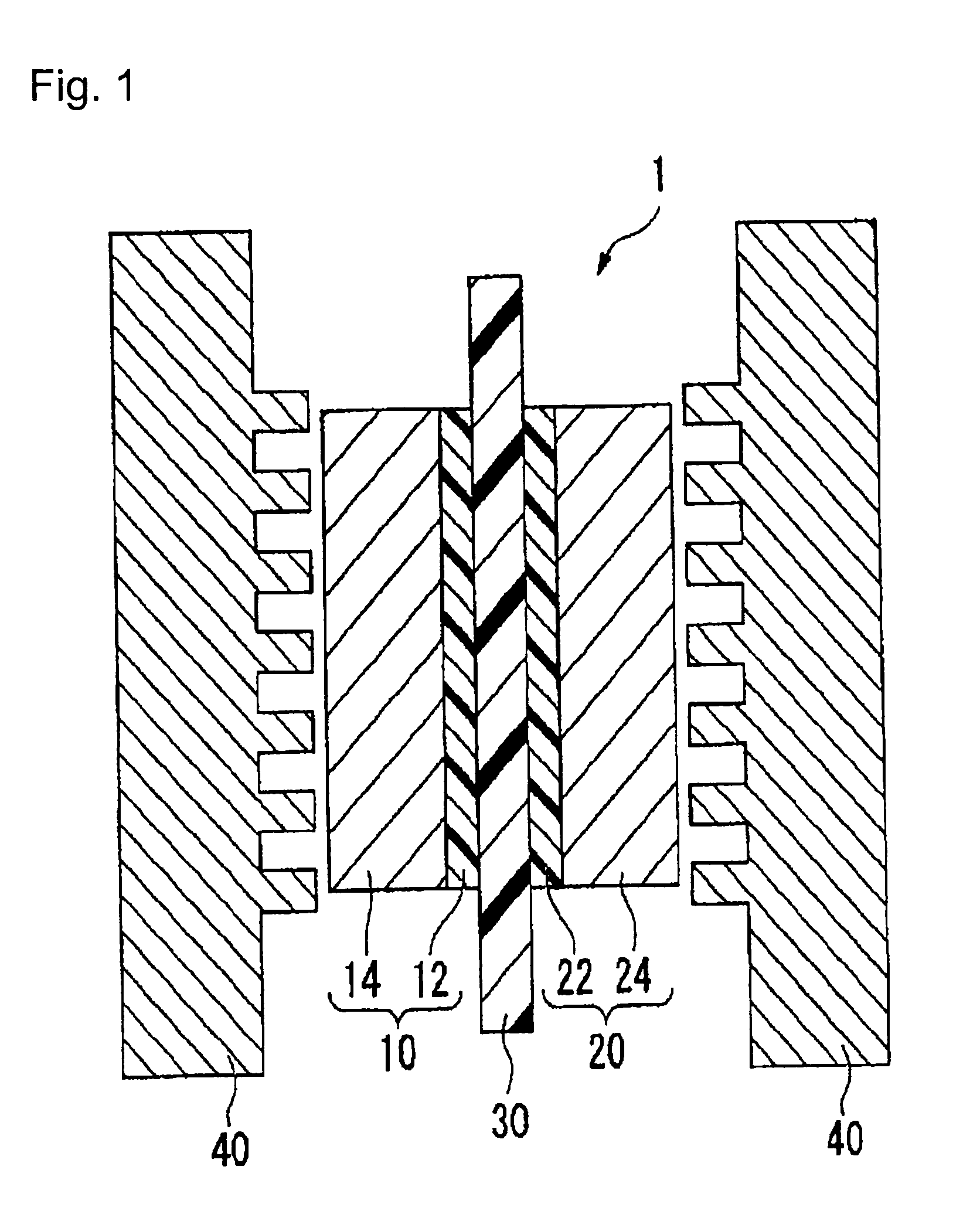

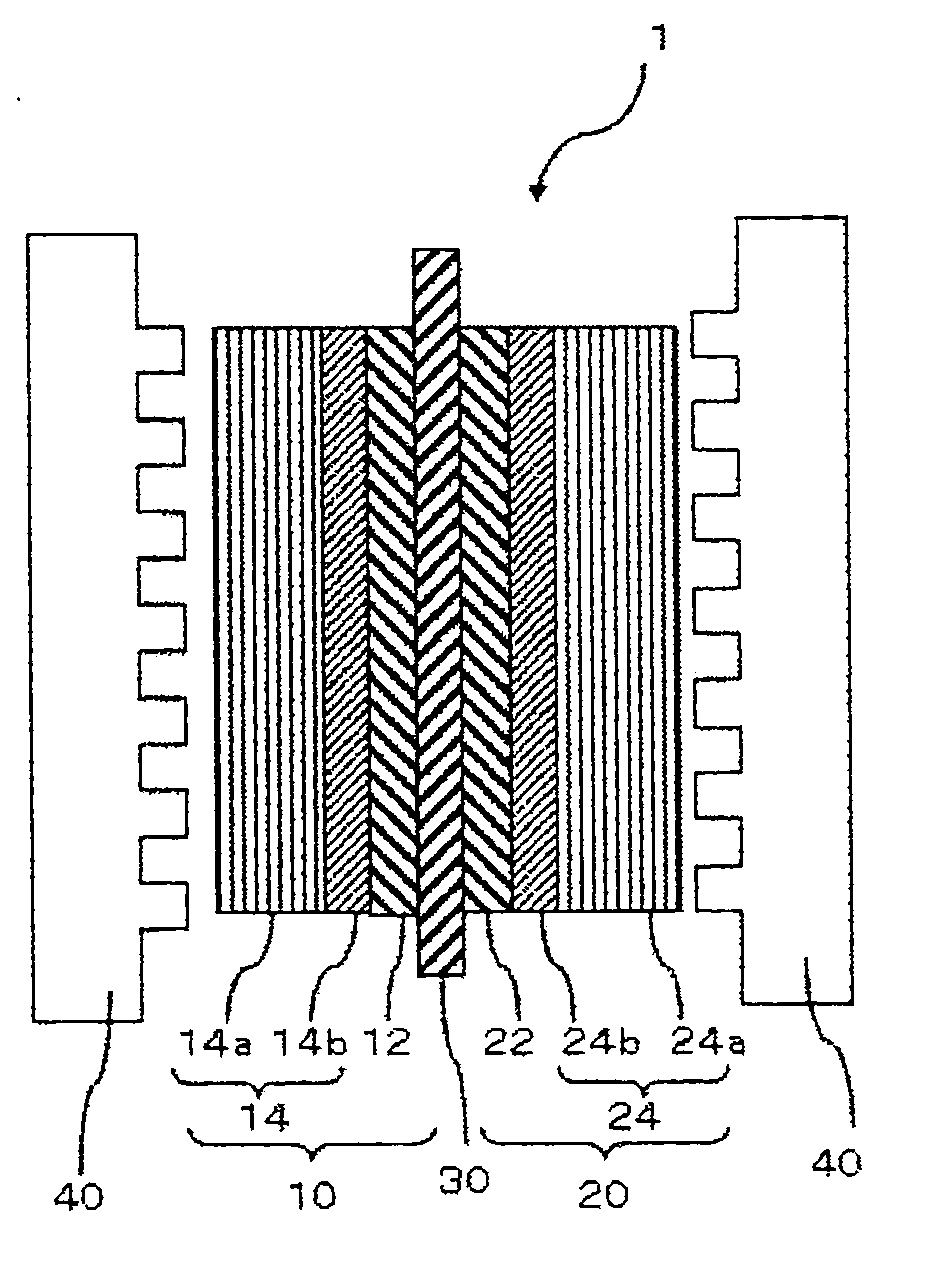

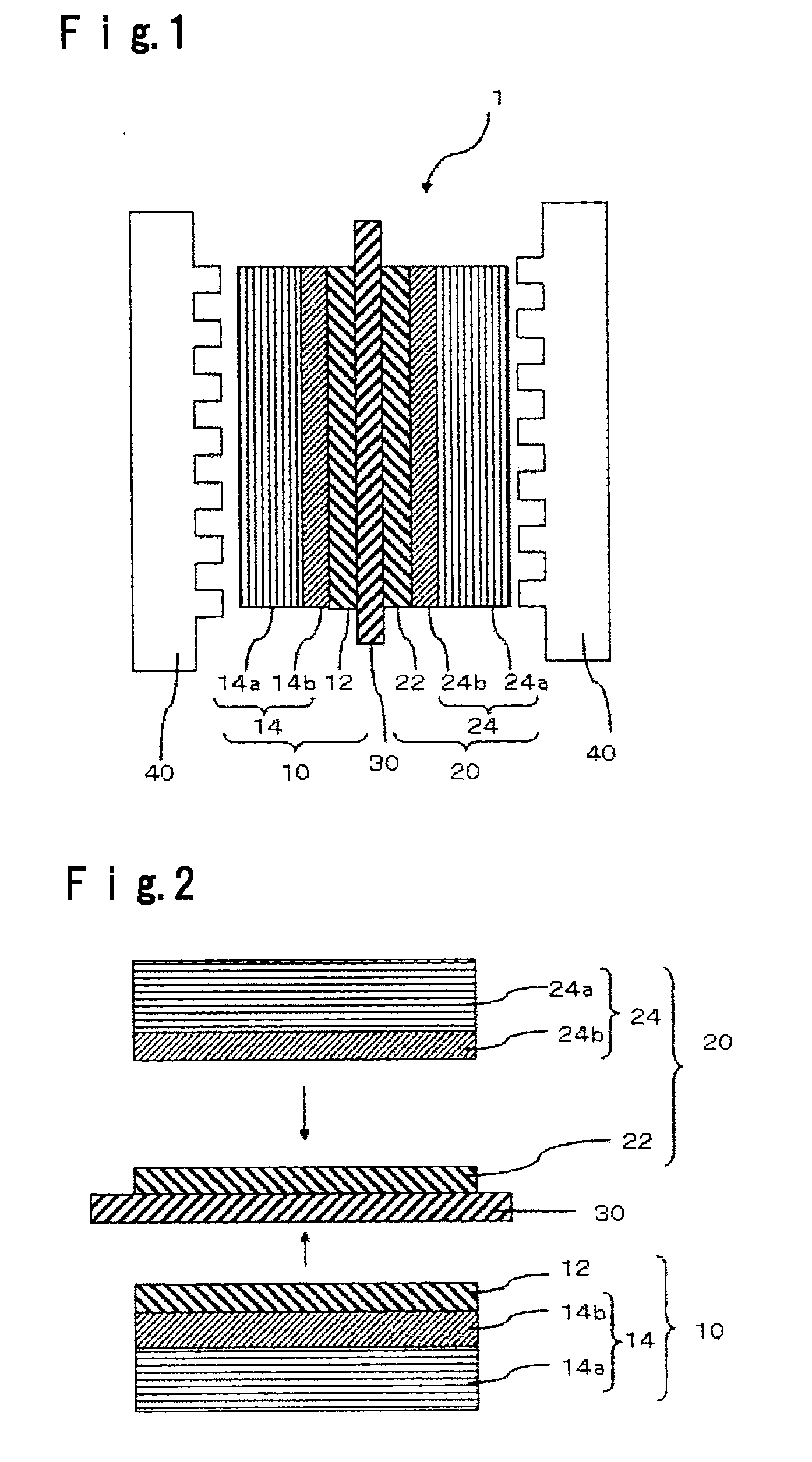

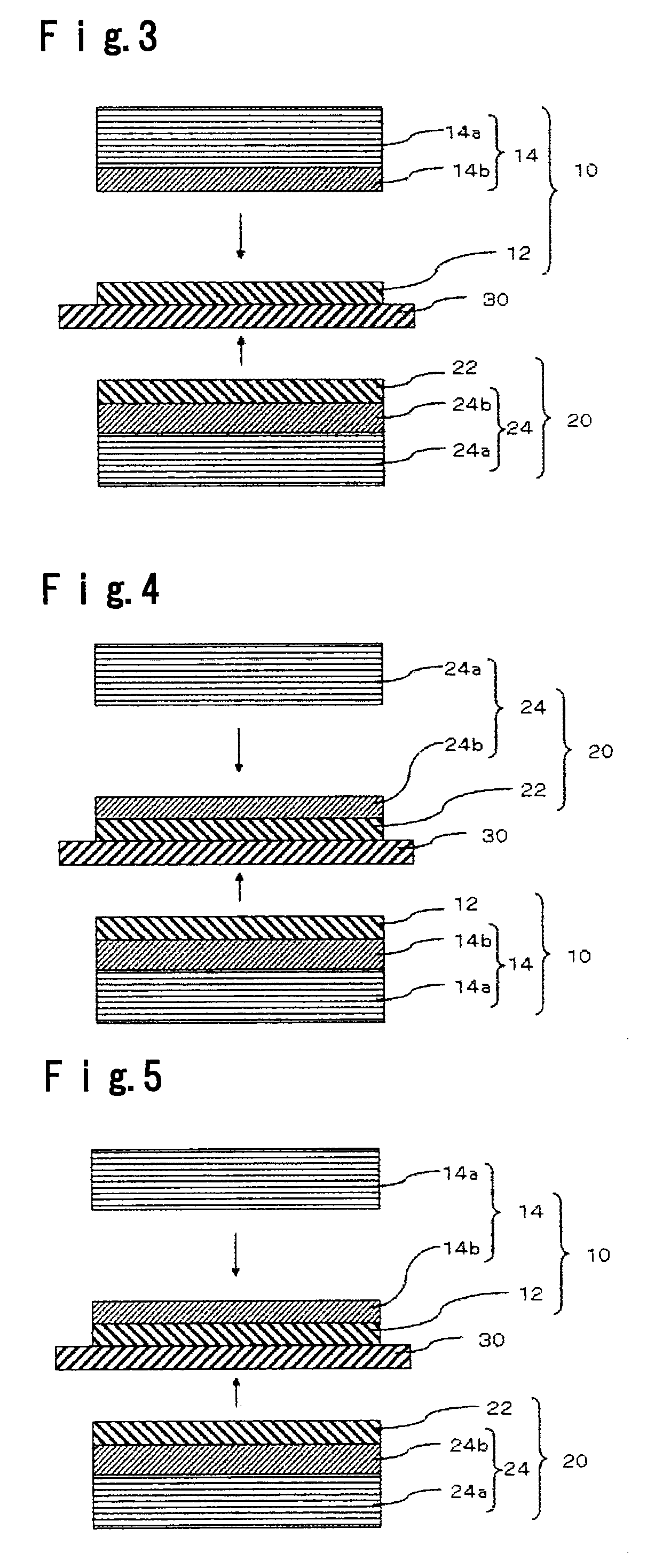

Process for producing membrane/electrode assembly for polymer electrolyte fuel cell and process for producing polymer electrolyte fuel cell

InactiveUS20100003400A1Increase the output voltageWide current density rangeFinal product manufactureCoatingsFiberCarbon fibers

Provided are a process for producing a membrane / electrode assembly for a polymer electrolyte fuel cell and a process for producing a polymer electrolyte fuel cell, capable of achieving a high output voltage in a wide current density range.At least one of an anode and a cathode in a membrane / electrode assembly for a polymer electrolyte fuel cell is formed through a catalyst layer forming step of applying a first coating fluid containing a catalyst and an ion exchange resin, onto a substrate to form a catalyst layer; a gas diffusion layer forming step of applying a second coating fluid containing carbon fibers and an ion exchange resin, onto the catalyst layer to form a gas diffusion layer to serve as an outermost layer of the membrane / electrode assembly for the polymer electrolyte fuel cell; and a peeling step of peeling the substrate off from the catalyst layer. The membrane / electrode assembly for the polymer electrolyte fuel cell is disposed between two separators each having a gas channel formed on a surface thereof so that surfaces of the outermost layers are adjacent to the respective separators, whereby the gas diffusion layer is adjacent to the separator.

Owner:PANASONIC CORP +1

Process for producing membrane/electrode assembly for polymer electrolyte fuel cell

InactiveUS20100314038A1High output voltageIncrease the output voltageLamination ancillary operationsLaminationPower flowPolymer electrolyte fuel cells

Provision of a process for producing a membrane / electrode assembly for a polymer electrolyte fuel cell which can produce a high output voltage in a wide current density range.A process for producing a membrane / electrode assembly for a polymer electrolyte fuel cell, comprising an anode and a cathode each having a catalyst layer, and an electrolyte membrane interposed between the catalyst layer of the anode and the catalyst layer of the cathode;said process comprising:a gas diffusion layer-forming step of applying a gas diffusion layer-coating fluid containing carbon fibers having a fiber diameter of from 1 μm to 50 μm and a proton conductive polymer, on a substrate to form a gas diffusion layer;a removal step of removing the substrate from the gas diffusion layer formed in the gas diffusion layer-forming step; anda step of disposing at least one such a gas diffusion layer thus prepared, on a surface of the catalyst layer of at least one of the anode and the cathode, on which the electrolyte membrane is not disposed.

Owner:ASAHI GLASS CO LTD

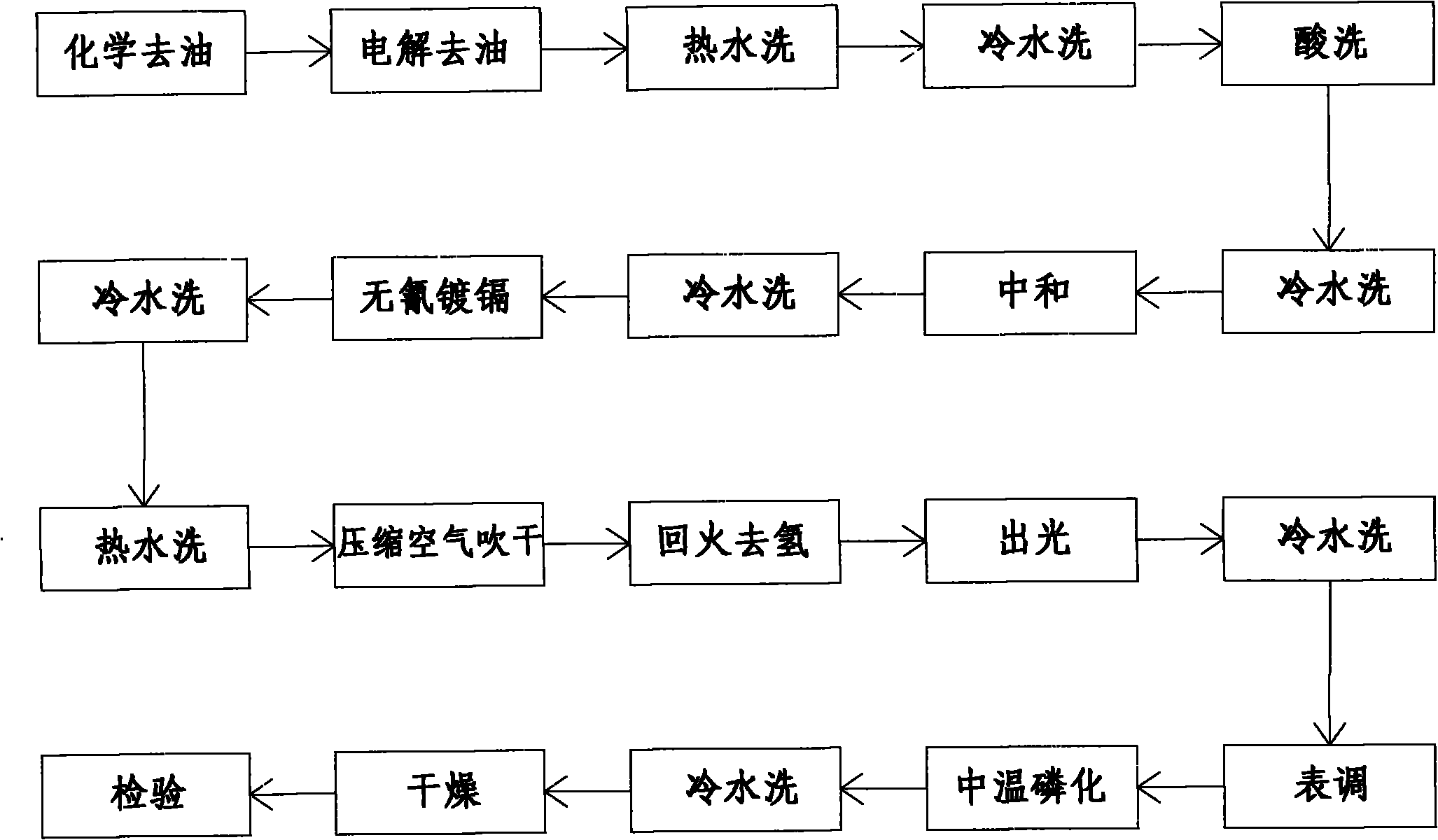

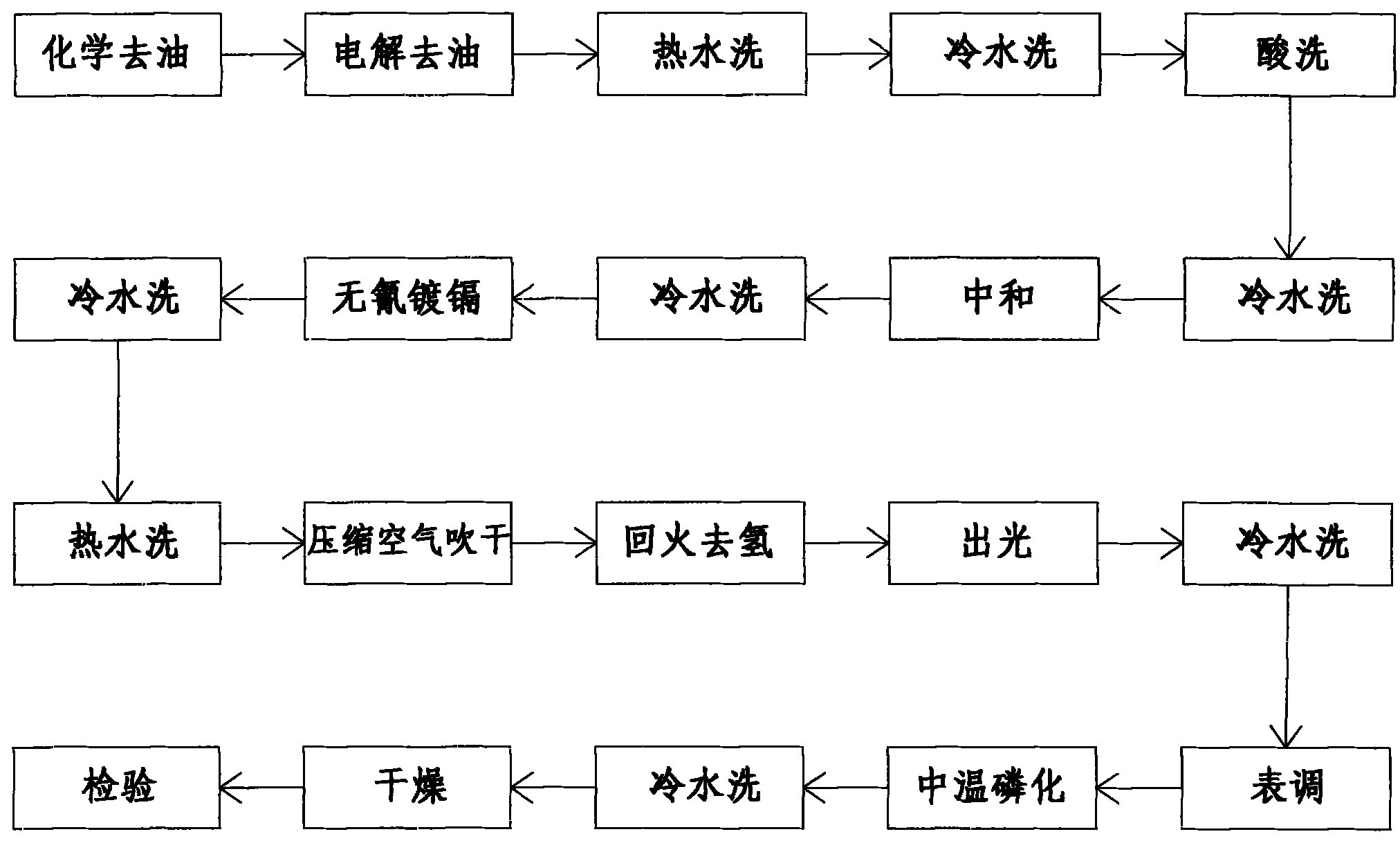

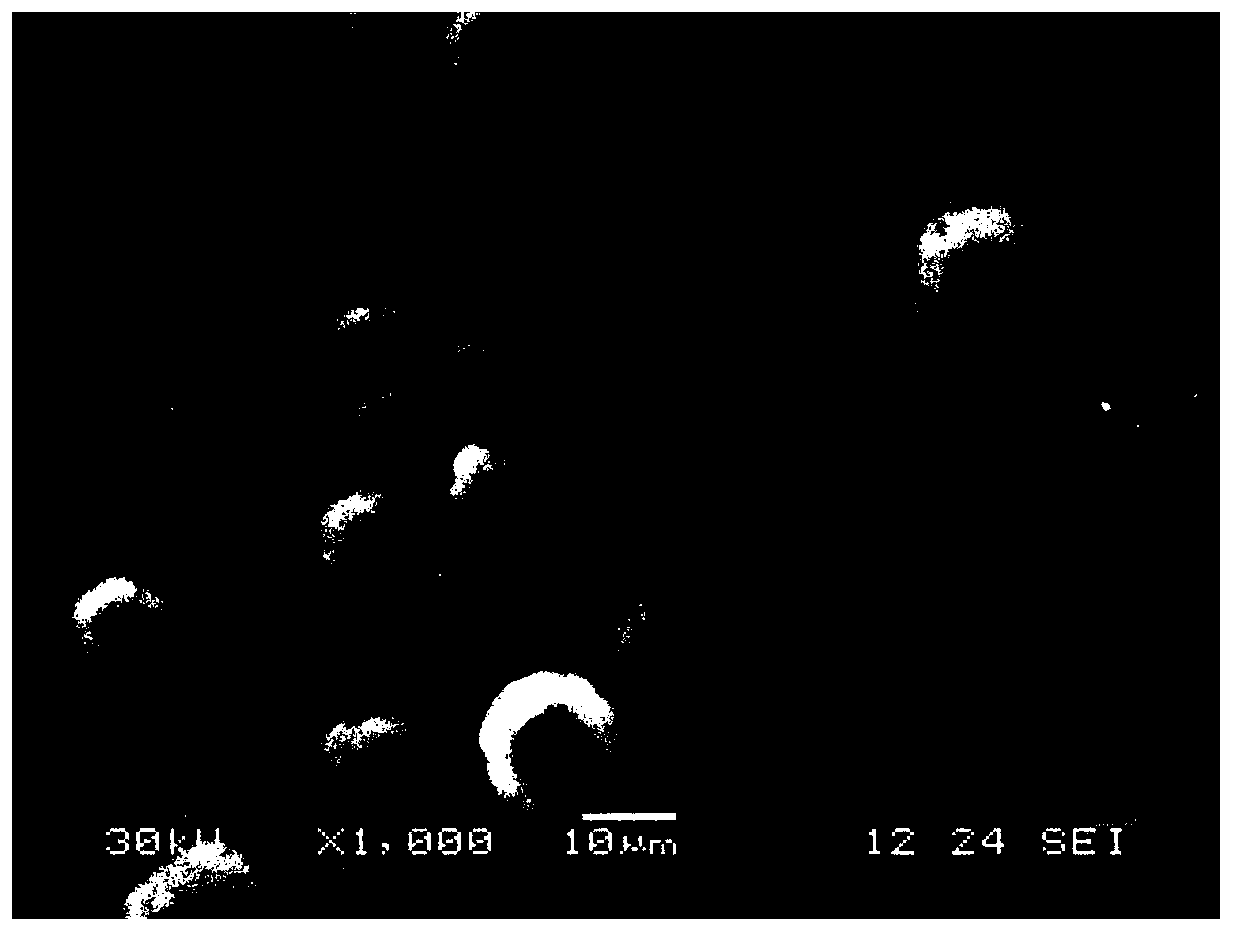

Process for plating cadmium on shaped steel part with deep/blind hole

InactiveCN101942681AWide current density rangeStrong dispersion abilitySuperimposed coating processNitrilotriacetic acidCadmium sulfate

The invention discloses a process for plating cadmium on a shaped steel part with a deep / blind hole, which comprises the following steps of: chemical oil removal, electrolytic oil removal, hot water washing, cold water washing, acid washing, cold water washing, neutralizing, cold water washing, cyanogen-less cadmium plating, cold water washing, hot water washing, compressed air drying, tempering dehydrogenizing, bright dipping, cold water washing, surface conditioning, middle-temperature phosphating, cold water washing, drying and detection, wherein the formula of each liter of electroplating liquid comprises: 40 to 50g of cadmium sulfate, 180 to 220g of ammonium chloride, 50 to 70g of nitrilotriacetic acid, 25 to 30g of ethylene diamine tetraacetic acid, a main additive, a brightener and a refiner, and the pH value is 6.2 to 6.7. The process effectively improves the quality and stability of special products, guarantees the use performance of the products and prolongs the service life of the products; and the production process is clean and environmentally-friendly, can effectively protect the environment and the physical and metal health of operators and meets the requirements of pollution-free production.

Owner:CHANGAN AUTOMOBILE (GRP) CO LTD

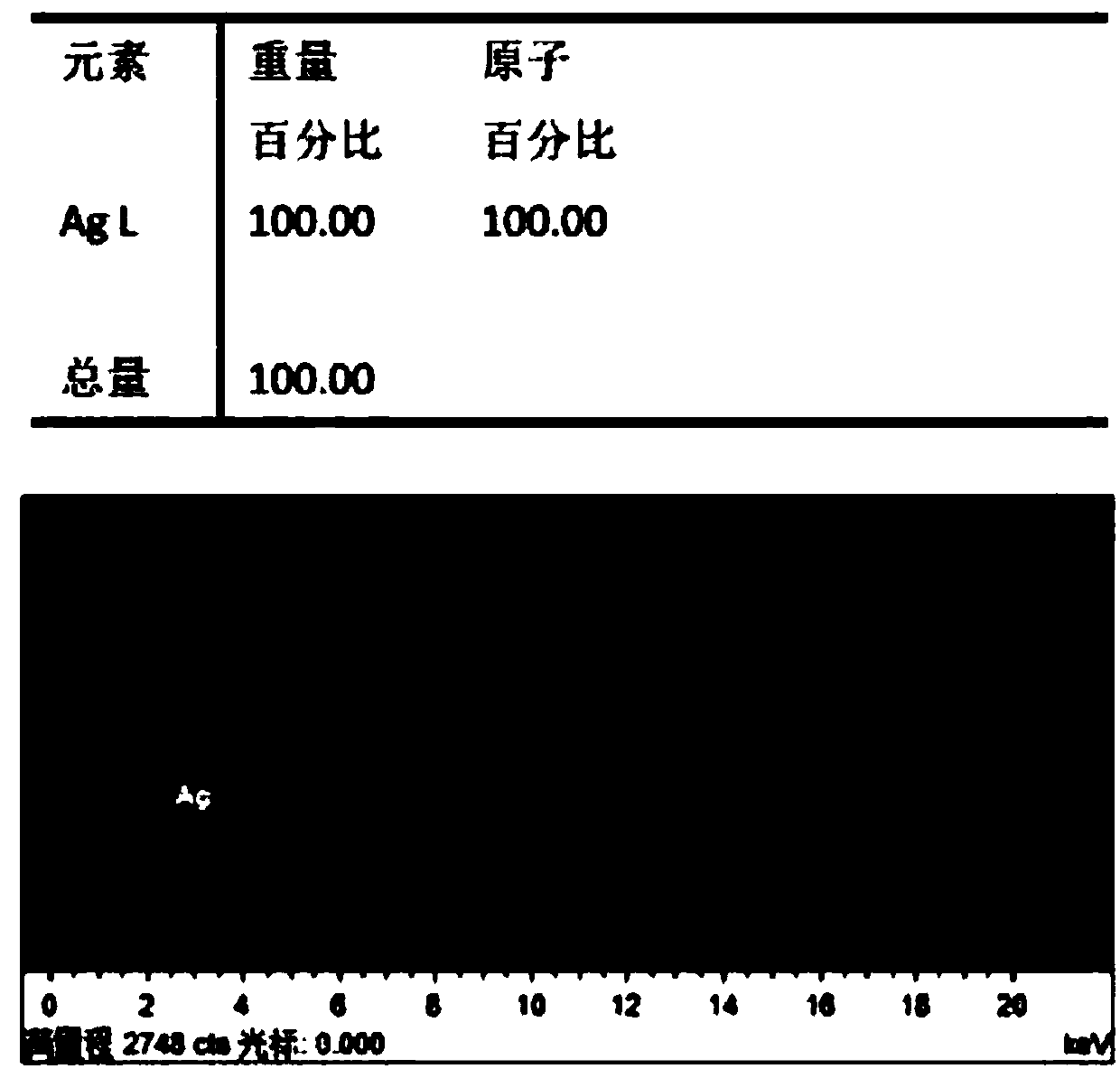

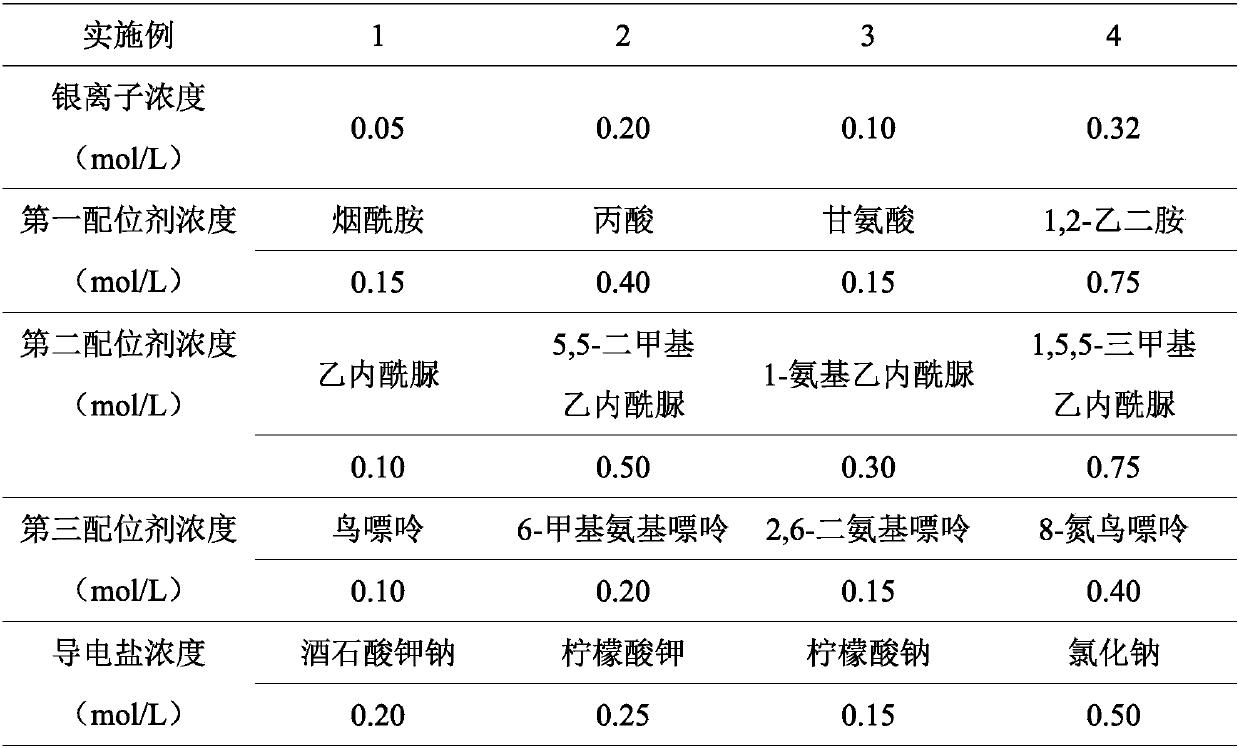

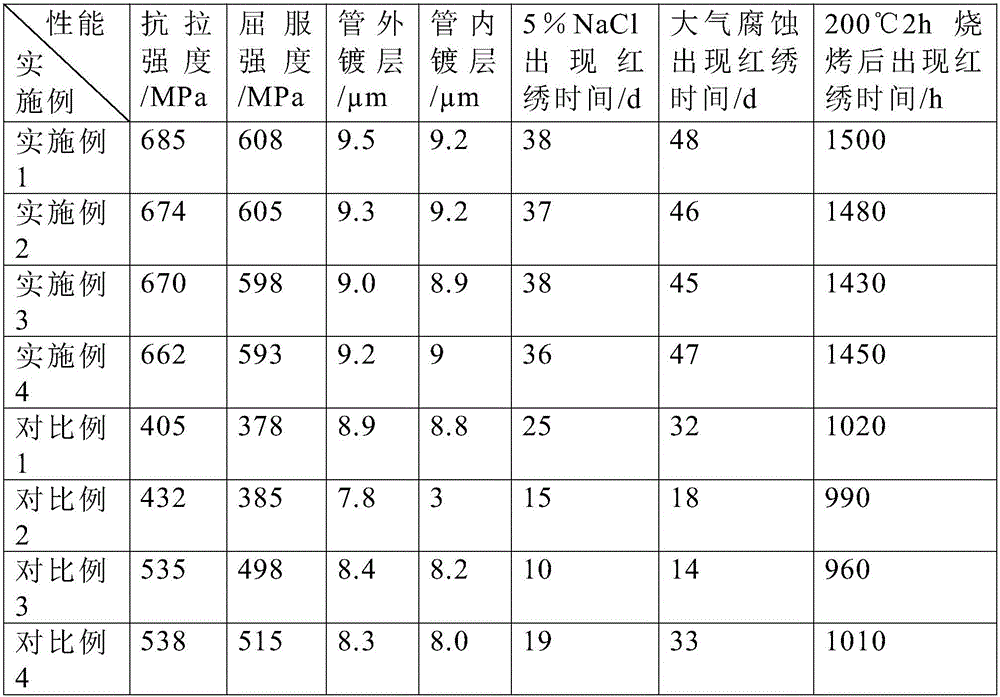

Cyanide-free silver plating liquid composition based on composite coordination system and application of cyanide-free silver plating liquid composition

The invention discloses a cyanide-free silver plating liquid composition based on a composite coordination system and application of the cyanide-free silver plating liquid composition. pH=8.5-12.5. The cyanide-free silver plating liquid composition comprises silver salt, a coordination agent, conducting salt, a pH buffer agent, an adding agent and deionized water. The coordination agent is formedby a first coordination agent, a second coordination agent and a third coordination agent. The total molar concentration ranges from 0.25 mol / L to 2.8 mol / L. The molar ratio of the silver salt to thecoordination agent is 1:5-8. The cyanide-free silver plating liquid composition is quite stable, a solution is still transparent after being put for half a year, scanning electrochemical curves are basically overlapped, plating liquid components are basically not changed, the displacement resisting capacity is high, a silver replacement layer cannot be observed when an activated copper sheet is put in silver liquid for 3 min, the depth capacity and the covering capacity are good, and silver plating layers be obtained for parts in complex shapes or with deep holes in an electroplating manner; and a cyanide-free silver plating method is based on the composite coordination system, the proper multi-coordination system is selected, the comprehensive performance is close to and even superior tothat of the cyaniding silver plating process, and the industrial application foundation is achieved.

Owner:XIAMEN UNIV

Non-cyanide electro cooper plating bath of EDTA system and use method thereof

The present invention provides a new non-cyanide electro cooper plating bath of EDTA system and use method thereof. In the electro copper plating bath, using disodium EDTA or dipotassium EDTA as main complexant, using copper sulfate or basic copper carbonate as main salt, using trisodium citrate, potassium citrate or potassium sodium tartrate as auxiliary complexant, using sodium nitrate or potassium nitrate as conductive salt, using sodium hydroxide or potassium hydrate as pH value regulator. The invention also provides a use method of the non-cyanide electro cooper plating bath. The invention has advantages: simple plating bath formula, easy control and operation, wide temperature range of plating bath using, high current efficiency, fine crystallization coating, good appearance color, stable plating bath, strong uniform plating and covering ability, low cost, easy wastewater treatment. The invention can be used for pre copper plating or direct electro-coppering instead of virulent cyaniding electro-coppering process.

Owner:KUNMING UNIV OF SCI & TECH

Processing technique of oil delivery pipe

ActiveCN106282822AFast deposition rateStable eutectoid ratioSuperimposed coating processComponents of crude oilMechanical property

The invention relates to a processing technique of an oil delivery pipe, belonging to the technical field of alloy processing. The technique comprises the following steps: machining alloy steel to obtain an oil delivery pipe blank; carrying out electroplating treatment on the oil delivery pipe blank in a 20-30-DEG C nickel-electroplating solution by an auxiliary anode electroplating technique, wherein the electroplating solution is composed of 5-7 g / L zinc oxide, 110-130 g / L sodium hydroxide, 0.6-1 g / L nickel and 150-300ml of additive; sequentially carrying out polishing treatment, passivating treatment and rust prevention treatment on the electroplated oil delivery pipe blank to obtain an oil delivery pipe semifinished product; and carrying out seal treatment on the oil delivery pipe semifinished product to obtain the oil delivery pipe finished product. The oil delivery pipe has reasonable component combination; and under the synergistic actions of the component elements, the zinc-nickel alloy is electroplated on the surface by the auxiliary anode electroplating technique, the passivating treatment and rust prevention treatment are then carried out, and finally, the seal treatment for silanization treatment is carried out to further enhance the corrosion resistance and mechanical properties of the oil delivery pipe.

Owner:NINGBO YADA METAL SURFACE TREATMENT

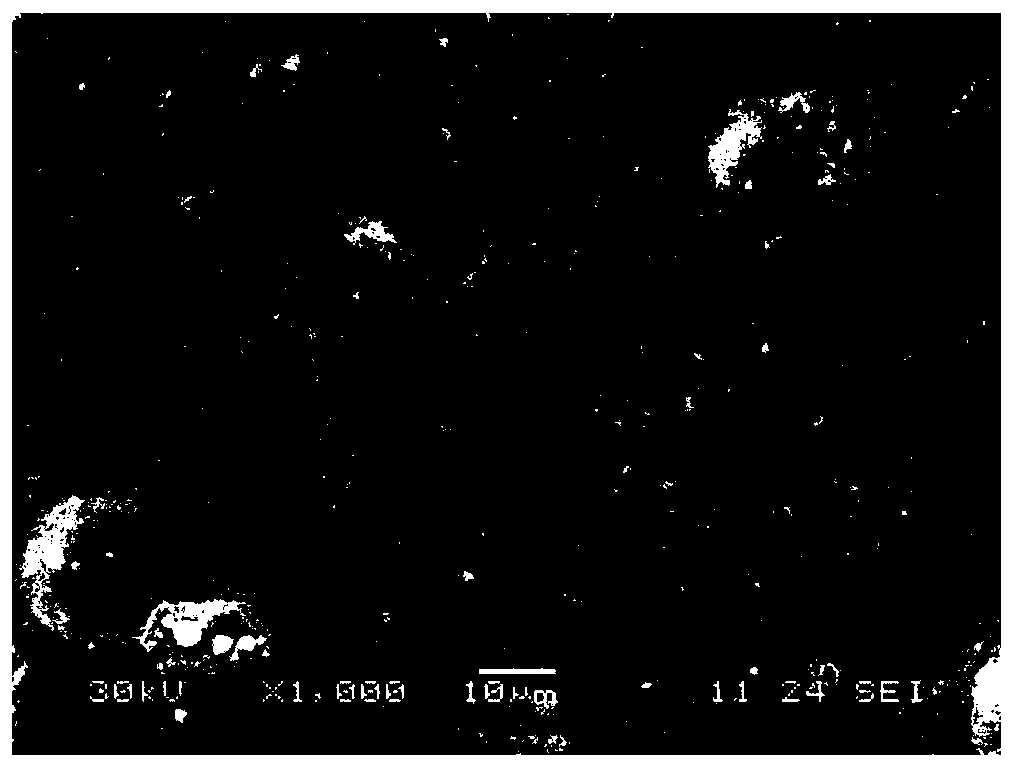

Environment-friendly cyanide-free alkaline galvanizing electroplating liquid and galvanizing technology

The invention relates to the technical field of electroplating, and discloses environment-friendly cyanide-free alkaline galvanizing electroplating liquid and a galvanizing technology. One liter of the cyanide-free alkaline galvanizing electroplating liquid comprises 10 g to 12 g of zinc, 130 g to 145 g of sodium hydroxide, 25 ml to 30 ml of a 51011 regulator, 6 ml to 8 ml of a 51012 preparing beginning agent, 1 ml to 3 ml of a 51015 brightener and 0.1 ml to 0.3 ml of a 51016 wetting agent. The brightener is prepared by polymine, imidazole propoxy condensation compounds, n-heterocyclic derivatives, modified aromatic aldehyde compounds, epoxy chloropropane and water. By means of the environment-friendly cyanide-free alkaline galvanizing electroplating liquid and the galvanizing technology, the brightness of a zinc coating is improved, the thickness can be 30 micrometers, fragility is avoided, and therefore the dispersing capacity and the covering capacity of the electroplating liquid are higher than the dispersing capacity and the covering capacity of traditional alkaline galvanizing brighteners.

Owner:广东比格莱科技有限公司

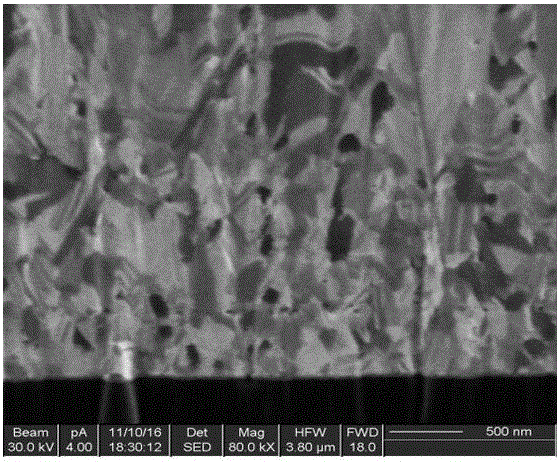

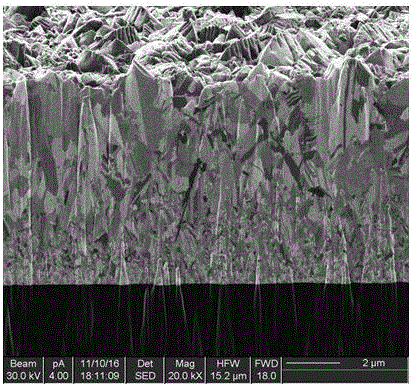

Method for producing electroplated copper layer with preferential orientation growth structure, and application thereof

ActiveCN106521573AGuaranteed reliabilityGuarantee service reliabilityCellsSemiconductor/solid-state device detailsCorrosion reactionHardness

Owner:SUZHOU SHINHAO MATERIALS

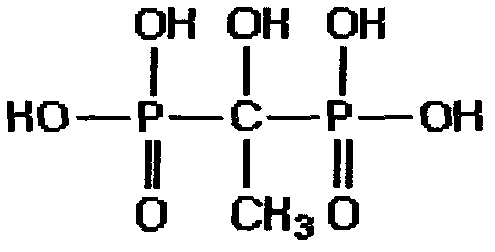

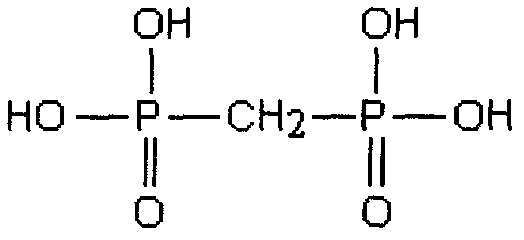

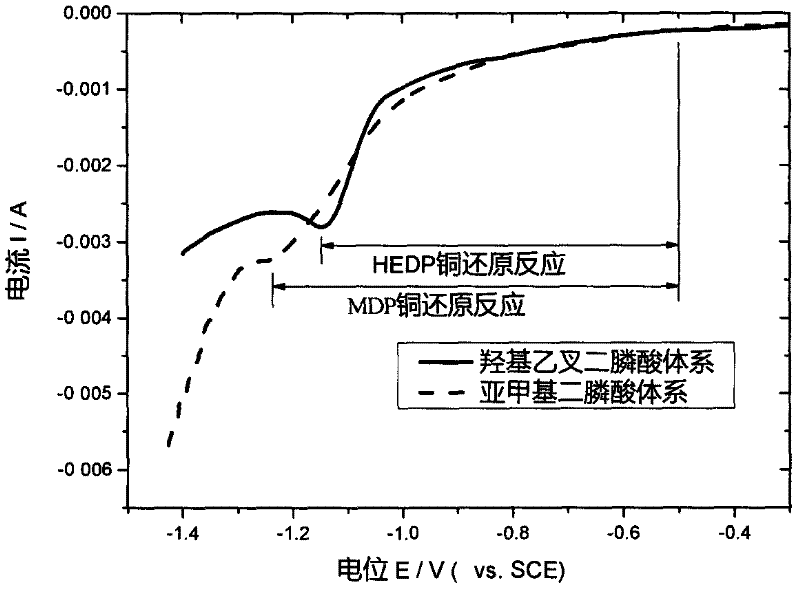

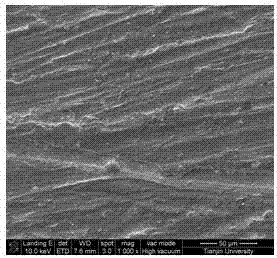

Alkaline non-cyanide copper plating solution with main coordination agent of methylenediphosphonate

The invention provides an alkaline copper plating solution with a main coordination agent of methylenediphosphonate, and relates to non-cyanide electroplating field. The plating solution comprises the following components: methylenediphosphonate (MDP) with concentration of 30-100 g / L, cupric ion with concentration of 3-25 g / L, and carbonate ion with concentration of 10-80 g / L. By using sodium hydroxide or potassium hydroxide, pH value of the solution is adjusted to 7.5-13.5. The plating solution in the invention has the characteristics of simple formula, no cyanide pollution, small concentration polarization generated in an electroplating process, good stability of the plating solution, and wide allowable current density range. By using the plating solution to plate copper on iron matrix, zinc matrix, zinc alloy matrix or aluminium zinc galvanizing directly, a copper plating layer with good bonding force with the matrix is obtained.

Owner:HANGZHOU AMAER TECH

Combination type zincate galvanizing brightener

The invention provides a combination type zincate zinc-plating brightener, wherein 13.6g of the imidazole, 10.3g of the triethylene-tetramine, 30ml of the formalin of which the concentration is 37 percent and 15ml of the water are added in a reactor, the reactor is heated up to reach the temperature of 40 DEG C, the chloroepoxy propane is dripped down at a temperature below 80 DEG C, the temperature is risen to 140 DEG C and the heat is preserved. The invention has the advantages of good physical properties of the plating coat, wide range of the current density, bright and even colors and low cost.

Owner:TIANJIN HANLONG ZINC PLATING

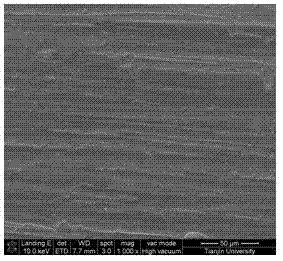

Method for electroplating zinc in neodymium iron boron magnet ionic liquid

The invention relates to a method for electroplating zinc in neodymium iron boron magnet ionic liquid. According to the method, a neodymium iron boron magnet treated before plating is used as a cathode, a zinc sheet is used as an anode, the ionic liquid is adopted as electroplating liquid, under the magnetic stirring condition, a power supply is conducted, the temperature, the current intensity and the electroplating time are controlled for electroplating, and then, bright dipping, passivation and aging treatment are carried out. The method is applied to the neodymium iron boron magnet electroplating, the process is simple, the price of medicine is low, the operation temperature is low, more importantly, the hydrogen evolution reaction is avoided, the obtained plating layer is bright and compact, the combination of the plating layer and a base body is firm, and the corrosion resistance performance is good.

Owner:TAIYUAN UNIV OF TECH

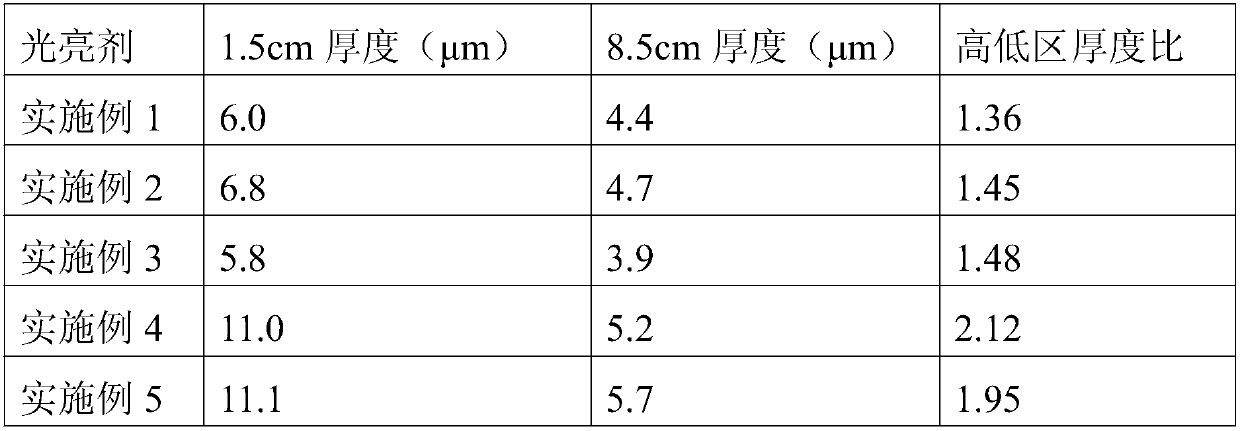

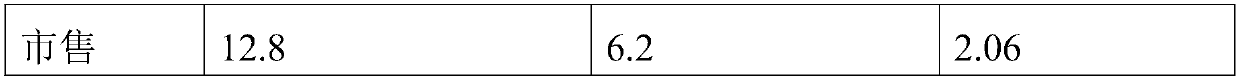

Preparation method of alkaline zincate zinc-plating brightener

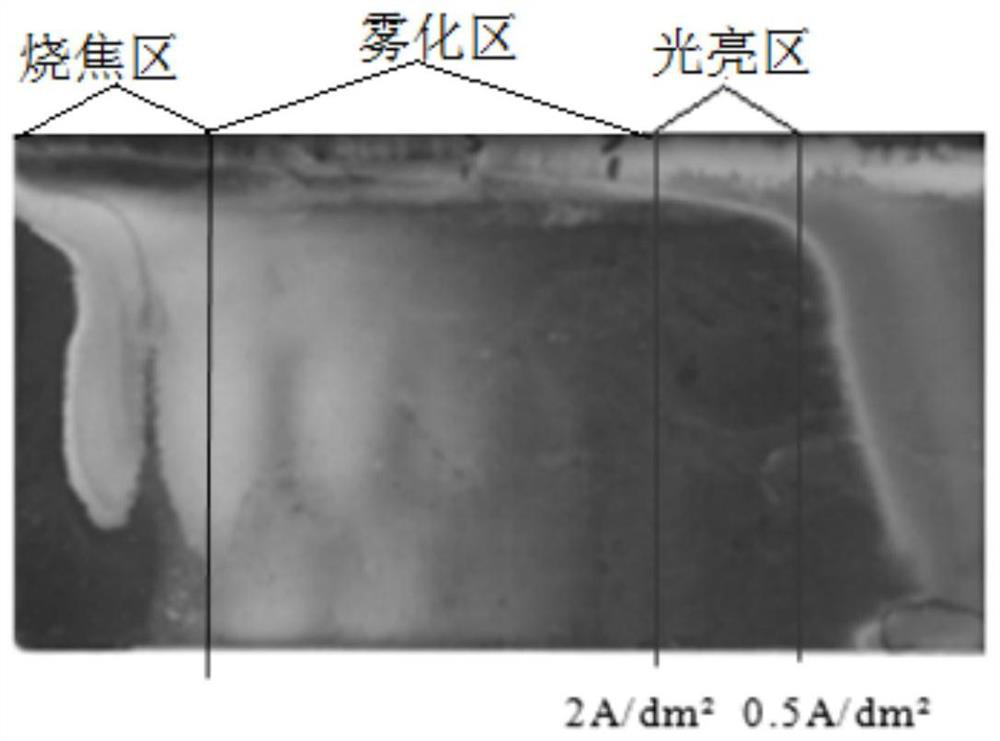

The invention discloses a preparation method of an alkaline zincate zinc-plating brightener and relates to a preparation method of a brightener, and the preparation method is used for solving the problems that the existing zincate zinc-plating brightener is narrow in bright current density range, dark in plating layer and rough in surface. The preparation method comprises the following steps of: adding 12-15g of 33wt% dimethylamine into a four-neck bottle; then heating to 23 DEG C, completely dropwise adding 12-15g of epichlorohydrin into the four-neck bottle at the speed of 3-4s / drop; after dropwise adding is finished, heating to 25 DEG C-30 DEG C, reacting for 1.5-2.5 hours, and completely dropwise adding 0.1-1g of tetraethylenepentamine into the four-neck bottle; and after dropwise adding is finished, heating to 65 DEG C-75 DEG C, and reacting for 4-5 hours, so as to obtain the alkaline zincate zinc-plating brightener. The current density of the alkaline zincate zinc-plating brightener disclosed by the invention is 0.5-10.73A / dm<2>. The alkaline zincate zinc-plating brightener disclosed by the invention is applied to the field of zinc electroplating.

Owner:HARBIN UNIV OF SCI & TECH

High-dispersibility alkaline non-cyanide zinc-plating brightener and preparation method and application thereof

The invention discloses a high-dispersibility alkaline non-cyanide zinc-plating brightener and a preparation method and application thereof and belongs to the field of surface treatment electrogalvanizing. The preparation method comprises the following steps that 5-amino-8-quinolinol and salicylic aldehyde are dissolved in an organic solvent which is mutually soluble with water at the mole ratio of 1-3:1-3, a small amount of paraformaldehyde is added as a catalyst, the temperature is raised to 80-90 DEG C, and a reflux reaction is performed for 4-5 h; after the reaction is completed, a sodiumhydroxide solution is added, the temperature is raised to 40-50 DEG C, propane sultone is dropwise added, after adding, the temperature is raised to 90-105 GEG C, after a sufficient reaction, the alkaline non-cyanide zinc-plating brightener is obtained. The mole ratio between the propane sultone and the 5-amino-8-quinolinol is 1.0-1.3:1. The current density range of a plating solution prepared from the prepared alkaline non-cyanide zinc-plating brightener is 0.5-11 A / dm<2>, when the through current is 2A, the current efficiency is higher than or equal to 80%, and the dispersive capacity reaches about 88%. The high-dispersibility alkaline non-cyanide zinc-plating brightener has good application prospect.

Owner:武汉奥邦表面技术有限公司

Environment-friendly brightener for non-cyanide alkaline zinc plating and preparation method thereof

The invention relates to the technical field of electroplating additives and discloses environment-friendly brightener for non-cyanide alkaline zinc plating and a preparation method thereof. The brightener is prepared through polymine, IMZE, nitrogen heterocyclic derivatives, modified aromatic aldehyde compounds, epoxy chloropropane and water. According to the environment-friendly brightener for non-cyanide alkaline zinc plating and the preparation method thereof, the brightness of a galvanization layer is improved, the thickness of the galvanization layer can reach 30 micrometers, the galvanization layer is free of frangibility, and the dispersing power and the covering power of plating solution exceed those of traditional alkaline zinc plating brightener.

Owner:广东比格莱科技有限公司

Low-temperature rapid black nickel water

Owner:东莞市宝中实业发展有限公司

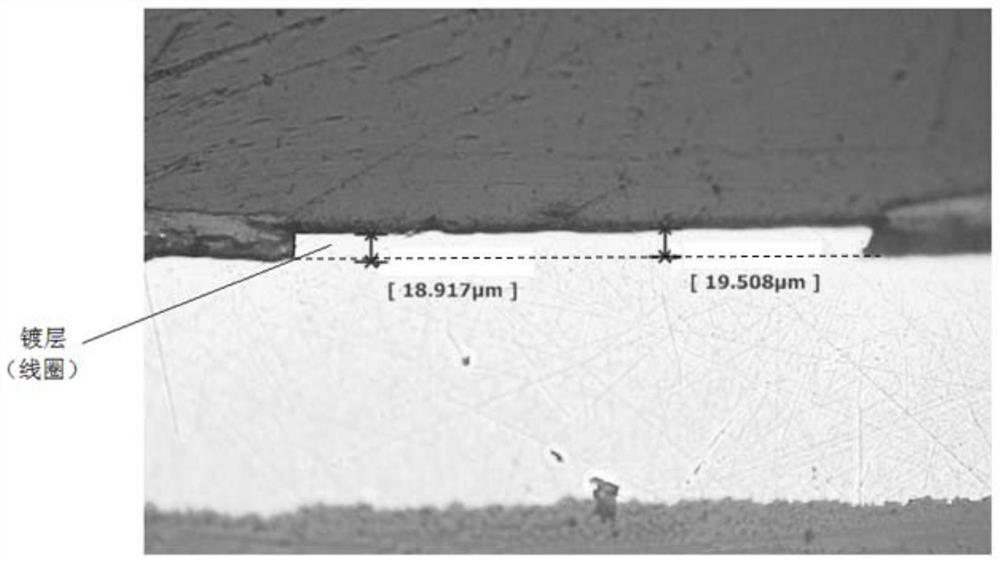

Cyanide-free copper electroplating method for reducing porosity of copper plating layer

The present invention relates to a cyanide-free copper electroplating method for reducing porosity of a copper plating layer. According to the cyanide-free copper electroplating method, a substrate is alternately subjected to a direct current electroplating unit and a pulse electroplating unit, the pH value of the electroplating solution is controlled to 12-13, the temperature is 50-70 DEG C, the cathode current density for copper electroplating in each direct current electroplating unit is 0.5-3.0 A / dm<2>, the electroplating time is 2-3 min, the pulse average current density for copper electroplating in each alternating current electroplating unit is 0.5-3.0 A / dm<2>, the duty ratio is 15%, and the electroplating time is 2-3 min. The plating layer obtained through the method has minimal porosity when the plating layer thickness is 10-20 mum.

Owner:WUXI XINSANZHOU STEEL

Cyanide-free silver-electroplating solution and electroplating method thereof

The invention discloses a cyanide-free silver-electroplating solution mainly prepared from silver nitrate, sodium thiosulfate, anhydrous sodium sulfite, ammonium acetate, potassium acetate, boric acid, nicotinic acid and deionized water. The electroplating solution disclosed by the invention contains no extremely toxic substances in components and is prepared according to a cyanide-free formula so as to reduce environment hazards. The electroplating solution contains the simply and easily obtained components so as to be relatively low in cost. The electroplating solution is relatively good in stability and free of phenomena such as sedimentation, discoloration and the like after being placed for a long term; in addition, the electroplating effect of the electroplating solution placed for a long term is same as that of a new prepared electroplating solution. The electroplating solution is also relatively good in dispersing power and throwing power, relatively wide in allowed current density range and capable of obtaining a silver electroplating layer with favorable performance within the allowed current density range. The obtained silver electroplating layer is consistent in smoothness, fine and dense in crystal, relatively strong in binding force with a matrix, smooth and bright in appearance, free of discoloration after being placed in the air for a long term, and excellent in discoloration resistance.

Owner:SUZHOU UNIV

Combination type zincate galvanizing brightener

The invention provides a combination type zincate zinc-plating brightener, wherein the urotropin, the dimcthylamine of which the concentration is 33 percent and the water are added in a reactor, the formaldehyde of which the concentration is 37 percent is dripped in the reactor and stirred for 30 minutes, the chloroepoxy propane is dripped down, the mixed liquid is heated up to the reflux temperature and the heat is preserved for 2 hours. The invention has the advantages of good physical properties of the plating coat, wide range of the current density, bright and even colors and low cost.

Owner:TIANJIN HANLONG ZINC PLATING

Aluminum plating solution, aluminum film, resin structure, porous aluminum object, and porous aluminum object manufacturing method

InactiveUS20160369418A1Wide current density rangeLower resistance3D structure electroformingHydrogen atomHalogen

Provided is an aluminum plating solution that has a wide current density range in which aluminum plating can be performed and that has a low solution resistance. The aluminum plating solution contains an aluminum halide, at least one selected from the group consisting of an alkylimidazolium halide, an alkylpyridinium halide, and a urea compound, and an ammonium salt represented by the general formula (1) below. A concentration of the ammonium salt is 1 g / L or more and 45 g / L or less.NR4+.X− General formula (1)In the general formula, R each represent a hydrogen atom or an alkyl group which may have a side chain and which has 15 or less carbon atoms, X represents a halogen atom, and R may be the same or different from each other.

Owner:SUMITOMO ELECTRIC IND LTD

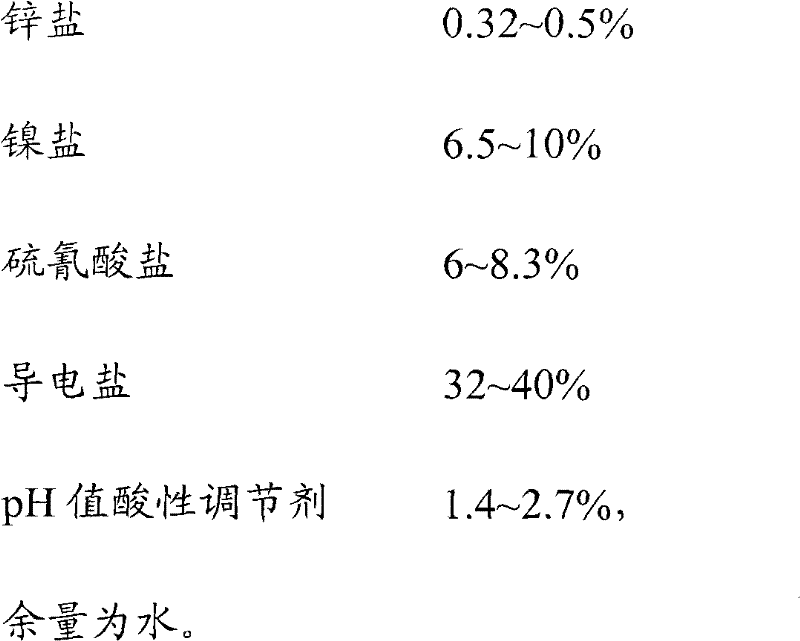

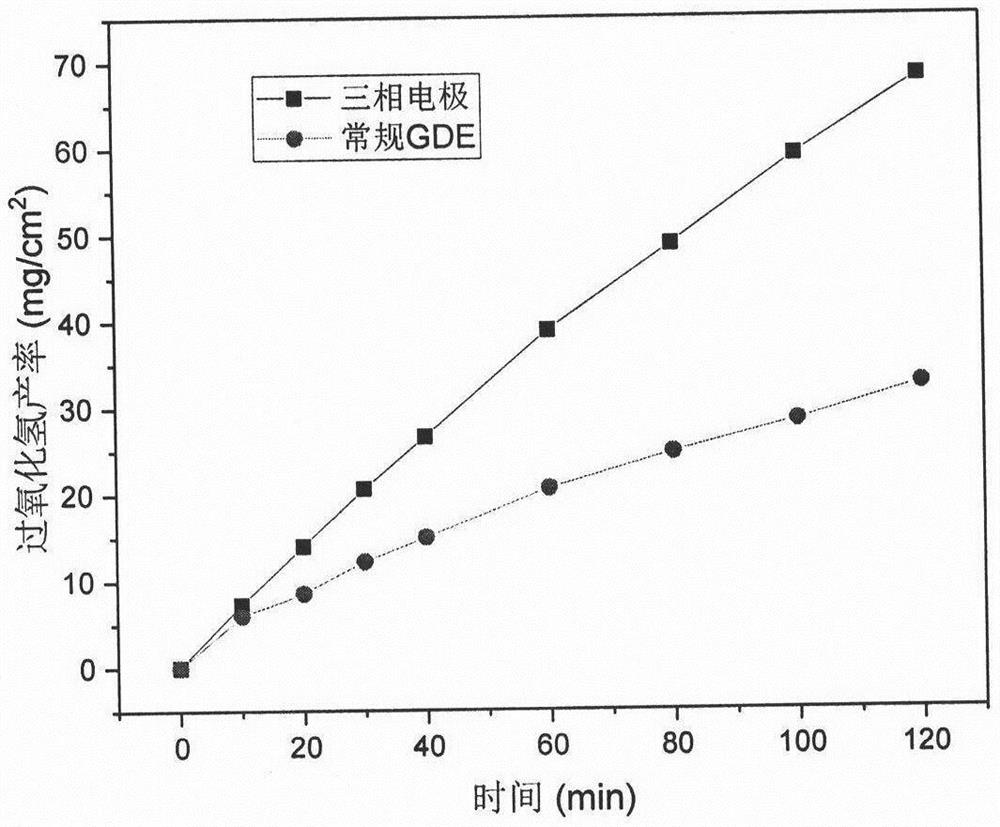

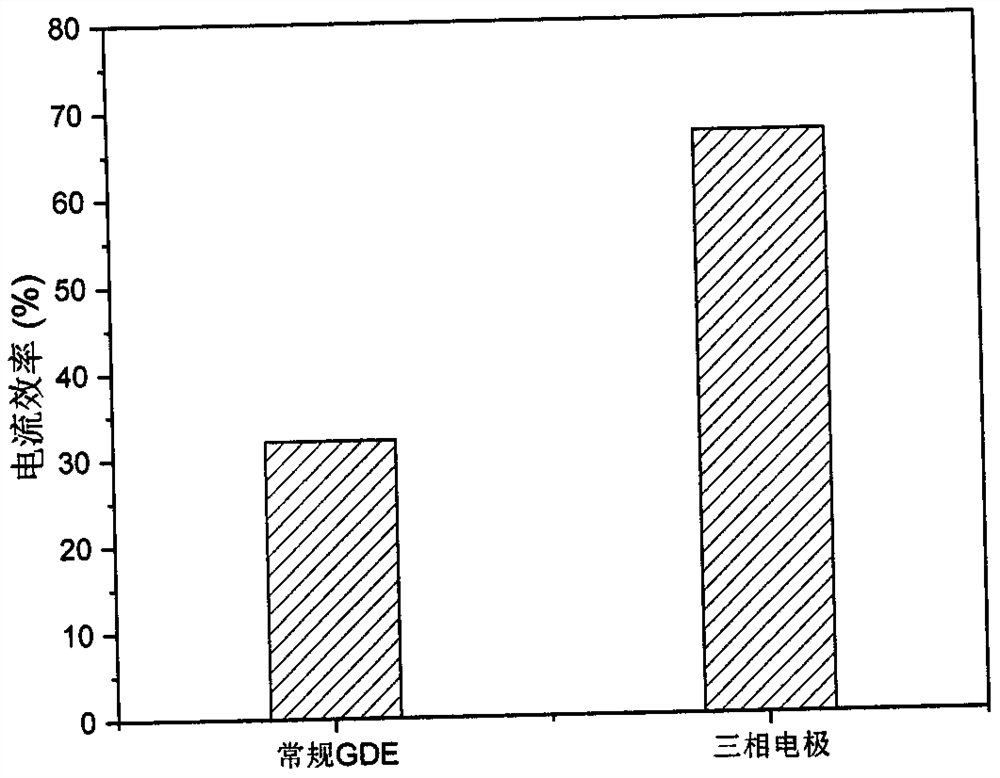

Air Active Diffusion Hydrogen Peroxide Electrochemical Generator

The invention provides an air active diffusion type hydrogen peroxide electrochemical generating device, which has the characteristics of high efficiency and energy saving. The device has a simple structure and low-cost electrode materials. Its main feature is that one side of the three-phase superhydrophobic cathode is connected to the air, and the other side is in contact with the electrolyte solution. efficient mass transfer of oxygen. Compared with the traditional device, the new hydrogen peroxide generating device saves the gas blowing equipment, can reduce the power consumption by more than 65%, and can realize the efficient preparation of hydrogen peroxide in a wide range of current density.

Owner:NANKAI UNIV

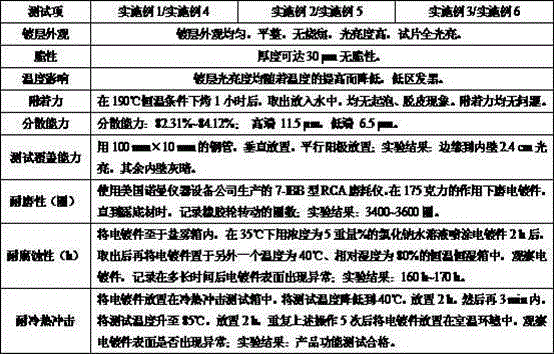

Non-cyanide alkaline silver plating method

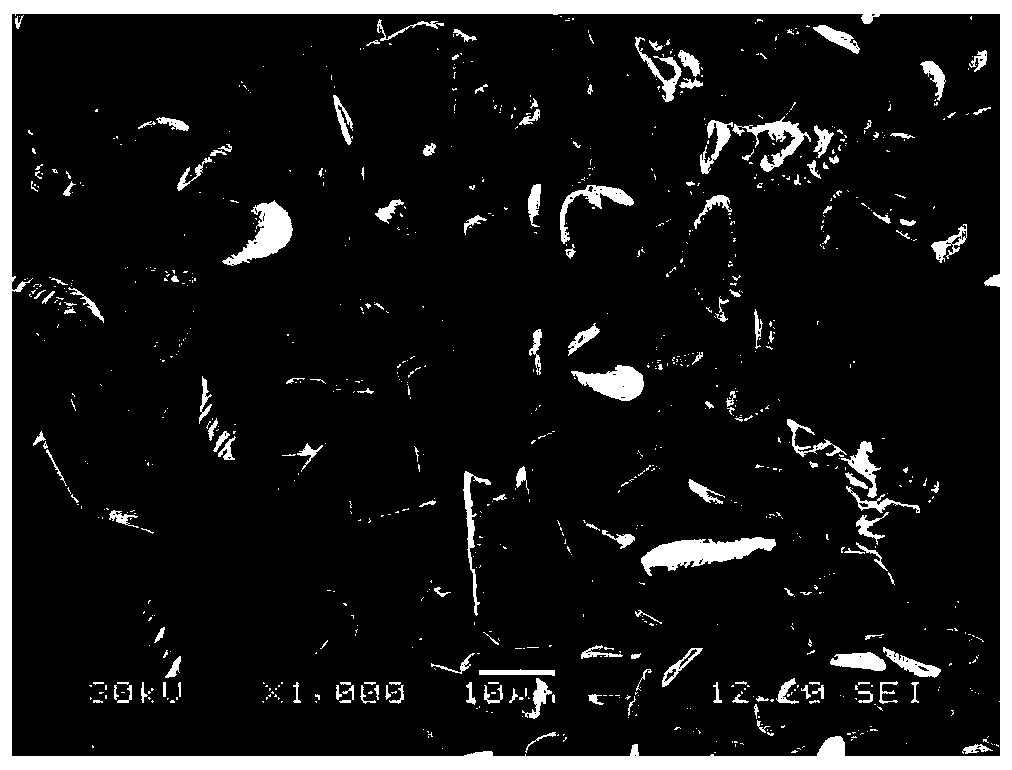

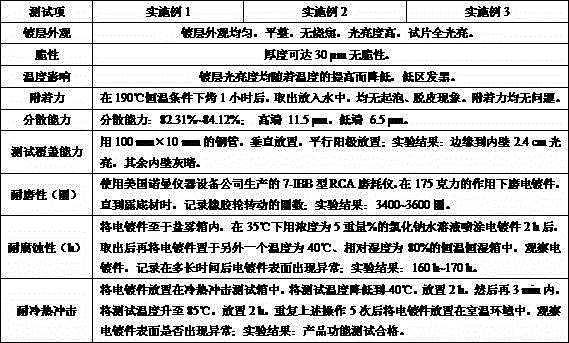

The invention provides an environmentally-friendly non-cyanide alkaline silver plating electroplating liquid having a dispersive capacity reaching up to 84.12 percent, which is considerably higher than a dispersive capacity being 59.4 percent to 72.7 percent in the same domestic industry, and is approximate to a dispersive capacity being 86.04 percent in the foreign advanced technology; a platingliquid performance is greatly improved compared with a domestic company, and the surface gloss and the stability of a plating layer are remarkably improved; compared with the foreign advanced technology, the invention still has a margin but undoubtedly has a great pioneering significance and enthusiasm on improving a domestic non-cyanide alkaline silver plating technology and breaking a foreign high-technology monopoly, and has a wide market prospect; a full silver plating layer with a bright mirror surface can be obtained, a current density range is wide, a surface is smooth, an anti-tarnishproperty is good, the corrosion resistance and the wear resistance are high, a binding force of the plating layer is good, a dispersive capacity and a covering capacity are excellent, electroplating wastewater is treated easily, the maintenance is simple, and the economy and the practicability are realized.

Owner:张达

Zincate zinc-plating brightener

The invention relates to a zincate zinc-plating brightener. The zincate zinc-plating brightener is prepared from the components by parts: 20-30 parts of amino dimethane, 28-35 parts of zinc chloride,25-30 parts of boric acid, 14-17 parts of 2.4-dichlorobenzaldehyde, 5-8 parts of polyethylene glycol single dodecane ether and 1-3 parts of sodium citrate. According to the zincate zinc-plating brightener, the sodium citrate and the polyethylene glycol single dodecane ether are added to the brightener to enhance stability of a system, the amino dimethane and the 2.4-dichlorobenzaldehyde are added,thus the brightener has the wide current density range, the zinc chloride and the boric acid are added to improve the polarization action of the brightener, the brightener does not contain addition agents of aromatic hydrocarbon and amine, environmental protection is achieved, safety and non-toxicity are achieved, performance is stable, a plating layer is uniform and compact, brightness of metalsis improved, the preparation technology is simple, the cost of raw materials is low, and the brightener has good economic benefit.

Owner:DALIAN BETRUST ENVIRONMENTAL PROTECTION TECH CO LTD

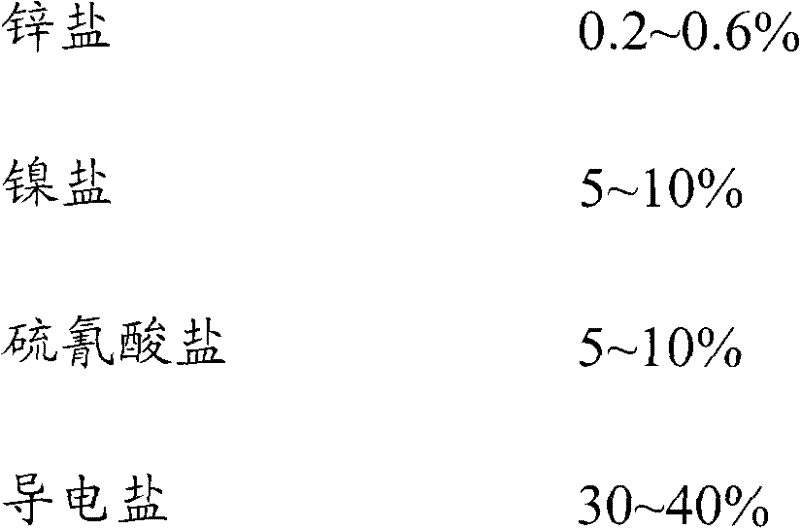

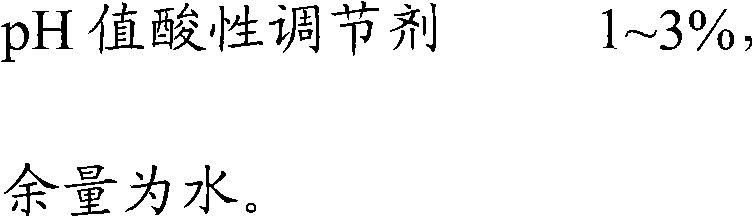

Electroplating liquid for plating surface of metal part in complex shape with zinc-nickel alloy

The invention discloses electroplating liquid for plating the surface of a metal part in the complex shape with a zinc-nickel alloy. The electroplating liquid is prepared from, by mass, 8-15 g / L zincoxide, 5-10 g / L zinc chloride, 1-3 g / L zinc sulfamate, 5-10 g / L nickel sulfate, 3-5 g / L nickel methane sulfonate, 110-150 g / L sodium hydroxide, a 20-60 g / L complexing agent, 2-5 g / L a brightener and a3-10 g / L adjuvant. The electroplating liquid is wide in current density range, has excellent dispersing capacity and even plating capacity and is especially suitable for plating of the surface of themetal part in the complex shape.

Owner:温州市展鑫新材料有限公司

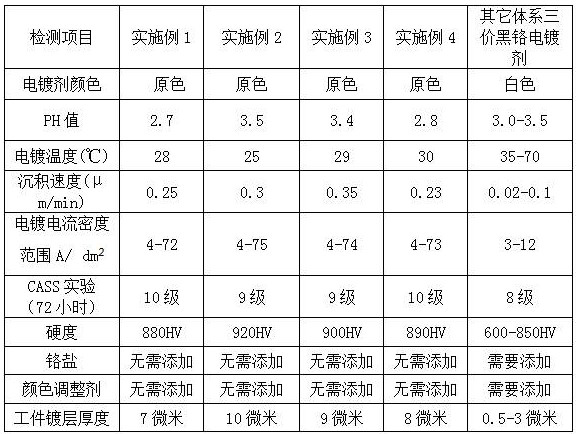

Trivalent black chromium electroplating agent easy to prepare and preparation method thereof

InactiveCN111962105ASimple processThe deployment process is simpleChloride potassiumChromium(III) chloride

A trivalent black chromium electroplating agent easy to prepare comprises potassium chloride, ammonium chloride, boric acid, chromium trichloride, potassium thiocyanate and methionine. The potassium chloride, the ammonium chloride and the boric acid are used as main materials, the chromium trichloride is added, so that the color can be changed from white to green, other additives do not need to beadded to adjust the color, and meanwhile, the mixed use of the potassium chloride, the ammonium chloride, the boric acid and the chromium trichloride can maintain the chromium concentration of a bathsolution without separately adding chromium salt in the process of preparing an electroplating solution; therefore, the preparation process can be simplified, the preparation time can be shortened, the purchase cost of raw materials can be saved, and the preparation process can be simpler and more convenient; and by adding the potassium thiocyanate and the methionine, the plating layer depositionspeed of the plating solution of the trivalent black chromium electroplating agent can be improved, the covering capacity of the trivalent black chromium electroplating agent can be improved, a chromium layer can be deposited on the surface of a workpiece plated by the trivalent black chromium electroplating agent, and the corrosion resistance of the surface of the workpiece can be greatly improved by the chromium layer.

Owner:广东涂乐师新材料科技有限公司

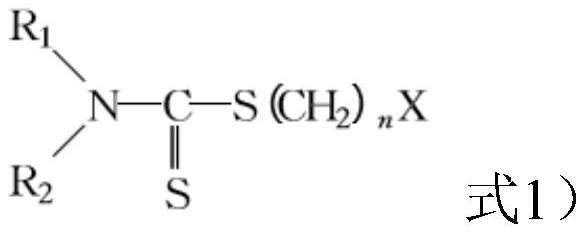

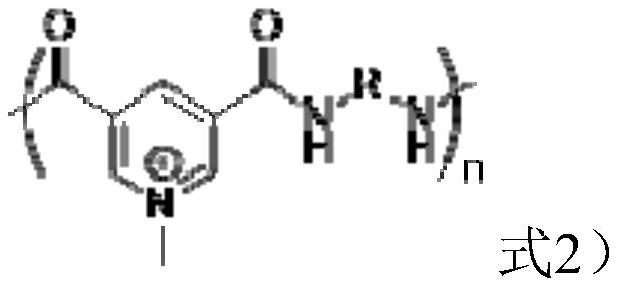

A high-speed electroplating copper additive and electroplating solution for advanced packaging

The invention discloses a high-speed electroplating copper additive and electroplating solution for advanced packaging, which comprises copper salt, acid, 20-80ppm of chloride ion, 2-2000ppm of accelerator, 5-5000ppm of carrier agent, and 3-3000ppm of leveling agent ; The copper ion content in the copper salt is 20-90g / L, and the acid content is 0.5-5.0mol / L; the accelerator is a dithiocarbamic acid derivative, and the carrier is EO- PO block copolymer, the leveling agent composition is a composition comprising a copper ion source and at least one leveling agent. The invention can effectively solve the technical problems of defects such as pits, roughness, voids, poor uniformity, poor bump appearance, and inconsistent heights at different positions that are easy to occur in advanced packaging Bump / RDL electroplating.

Owner:JIANGSU AISEN SEMICON MATERIAL CO LTD

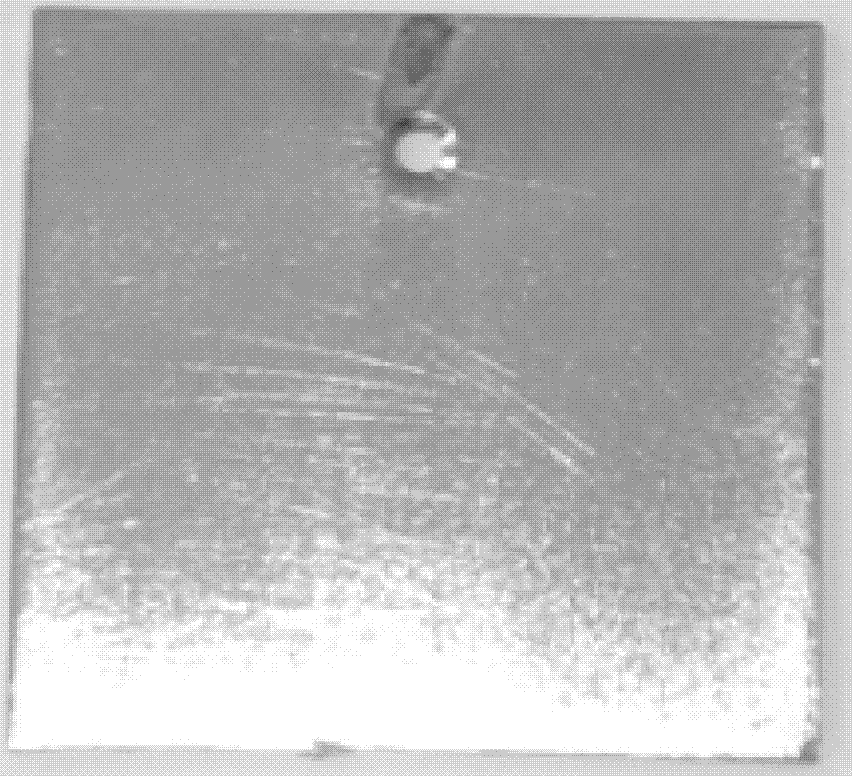

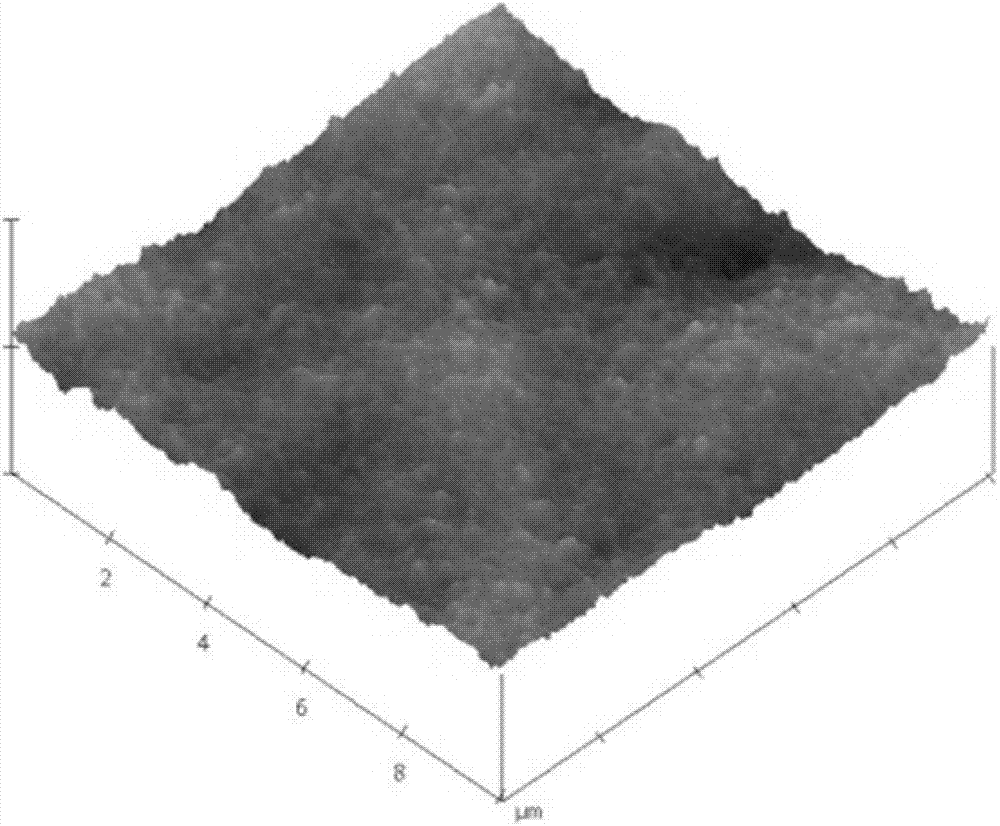

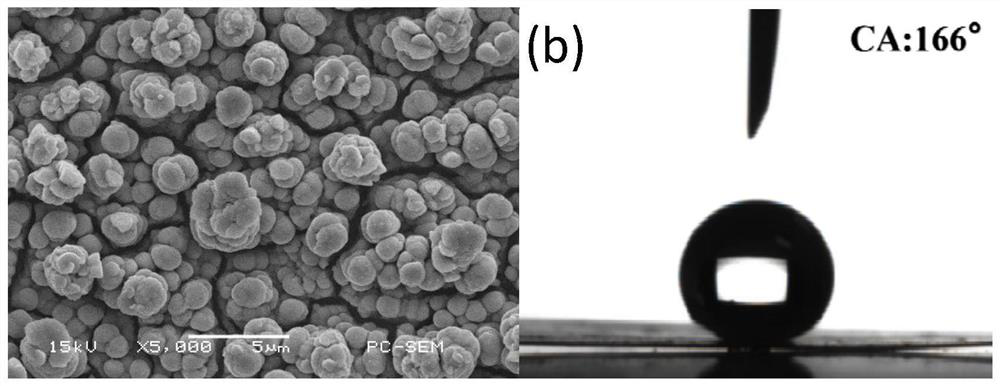

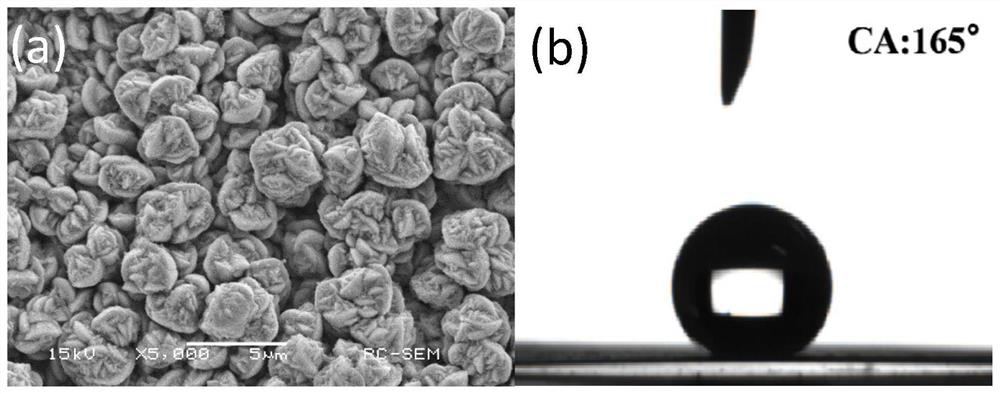

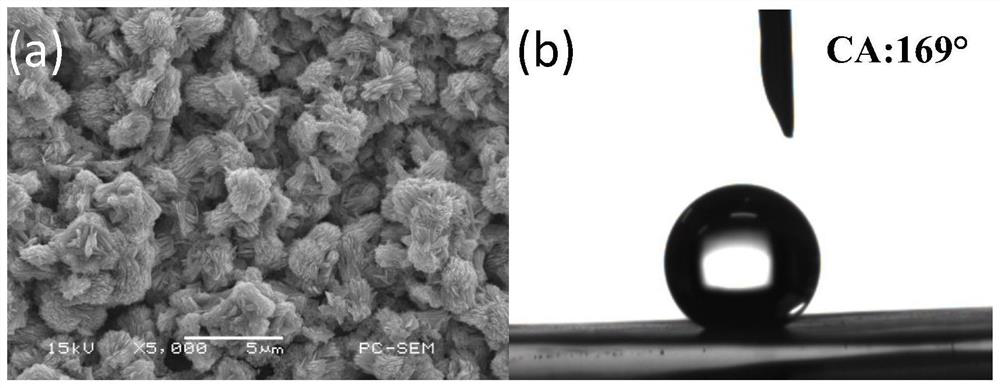

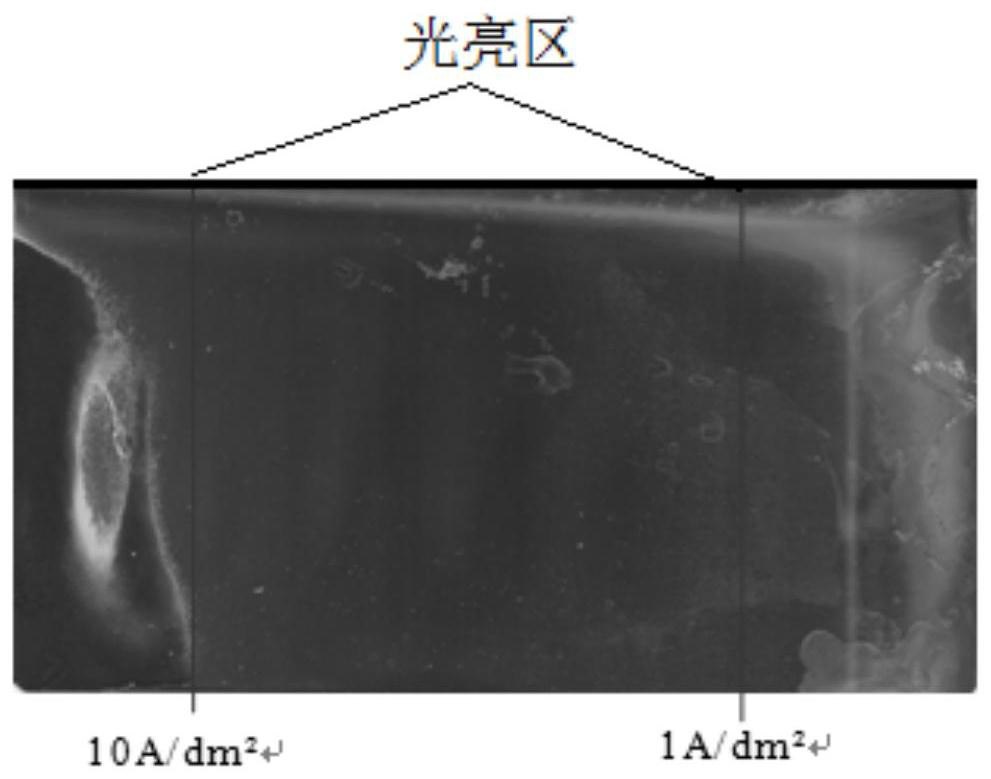

Method for preparing super-hydrophobic Zn-Fe alloy coating through electro-deposition in eutectic ionic liquid

ActiveCN113174617AControl shapeControl the ratio of zinc to ironBulk chemical productionElectrolytic agentAlloy coating

The invention relates to a method for preparing a super-hydrophobic Zn-Fe alloy coating through electro-deposition in eutectic ionic liquid, and belongs to the field of electro-deposition. According to the method, a zinc source, an iron source, a solubilizer, a viscosity reducer, a pH regulator and the like are dissolved in the eutectic ionic liquid with choline chloride and ethylene glycol being a hydrogen bond acceptor and donor to prepare electrolyte; and in the electro-deposition process, electro-deposition is carried out for 10-60min at the constant current of 10-500mA / cm<2> under the temperature of 40-90 DEG C to obtain the super-hydrophobic Zn-Fe alloy coating with good corrosion resistance. According to the super-hydrophobic Zn-Fe alloy coating, the iron content ranges from 1wt% to 20wt%, the water contact angle is greater than or equal to 160 degrees, the rolling angle is smaller than or equal to 4 degrees, and good hydrophobic performance and corrosion resistance are shown. The method is easy to operate, safe and reliable, the electro-deposition process is free of hydrogen evolution and other side reactions, the current efficiency is high, the coating does not need passivation treatment, the plating solution is easy to recycle, and the method is an environment-friendly method for preparing the super-hydrophobic Zn-Fe alloy coating.

Owner:CHANGZHOU UNIV

Weak-alkali electroplating liquid and application thereof

The invention discloses weak-alkali electroplating liquid and application thereof. The weak-alkali electroplating liquid comprises basic electroplating liquid and an additive, wherein concentration ofcopper pyrophosphate in the basic electroplating liquid is 50-100 g / L, concentration of potassium pyrophosphate in the basic electroplating liquid is 200-380 g / L, concentration of ammonia water in the basic electroplating liquid is 0.5-8 mL / L, and the pH value of the basic electroplating liquid is adjusted to 7-9 through pyrophosphoric acid; and the additive comprises the following components: abrightener with concentration of 1-20 mL / L in the electroplating liquid and an auxiliary complexing agent with concentration of 1-10 mL / L in the electroplating liquid. The weak-alkali electroplating liquid has the characteristics of current density being 1-10 A / dm < 2 >, electroplating height being 5-150 [mu] m, excellent coating uniformity and the like, does not contain any harmful compound, is green and environment-friendly, is particularly suitable for electronic elements with complex shapes, and can be used for electroplating copper on the electronic elements with diameters being 5-500 [mu] m.

Owner:SUZHOU SHINHAO MATERIALS

Non-cyanide copper-tin alloy plating solution

The invention provides a non-cyanide copper-tin alloy plating solution, wherein the copper-tin alloy plating solution comprises the following main components: stannous pyrophosphate and copper pyrophosphate, potassium pyrophosphate or sodium pyrophosphate as main complexing agent, succimide as auxiliary complexing agent, and soluble dihydric phosphate as buffering agent. The operating conditions of the non-cyanide plating solution are as follows: the pH range is 7.0-9.5; the current density is 0.3-2.5 A / dm2; and the temperature is 20-40 DEG C. The non-cyanide copper-tin alloy plating solutionhas the advantages of being low in cost, simple and convenient for operation and maintenance, and having little toxicity or no toxicity, wide density range of cathode current, high current efficiency, fine and bright plating; and the non-cyanide copper-tin alloy plating solution can satisfy the application requirements in multiple fields such as decoration plating, functional plating and the like.

Owner:FUZHOU UNIV

Electroplating liquid for electroplating treatment

The invention discloses an electroplating liquid for electroplating treatment. The electroplating liquid comprises the following compositions according to mass ratio: 9-10g / L of nickel sulfate, 0.6-0.8g / L of a hydrogen removal agent, 4-5g / L of citric acid, 4-6g / L of fluoroboric acid, 0.6-0.8g / L of lead acetate, 2-3g / L of glycol, 20-24g / L of stannous fluoborate, 6-8g / L of sulfuric acid, 5-6g / L of sodium hypophosphite and 4-6g / L of a brightening agent. After being electroplated by the electroplating liquid, the surface of a copper wire is good in corrosion resistance, excellent in conductivity, and antiwear; the nickel, lead and phosphorus elements are added, so that the diffusion of copper atoms towards the electroplating liquid can be effectively prevented; and the precipitation speed is fast, the current density range is wide, the electricity consumption is low, the electroplating quality is good, and the service life of the metal copper wire is prolonged.

Owner:MINGGUANG XUSHENG TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com