Zincate zinc-plating brightener

A zincate galvanizing and brightener technology, which is applied in the field of metal processing, can solve problems such as the speed and brightness of the light are not up to the standard, the environmental protection requirements of metal processing are not met, the quality of the coating, the brightness is not enough, etc., to achieve good economy Benefits, enhanced stability, improved brightness effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

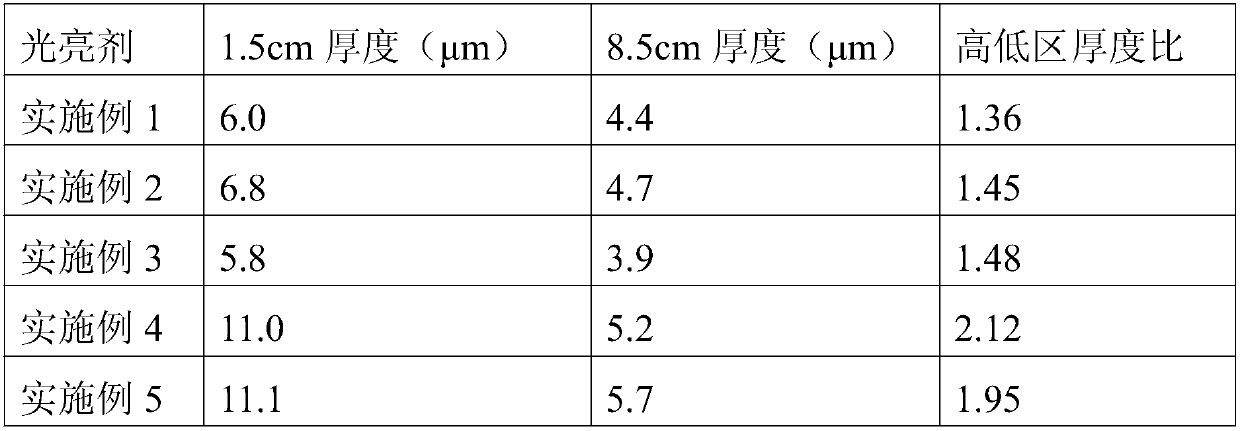

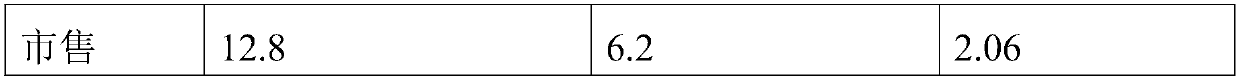

Examples

Embodiment 1

[0021] (1) Take 22 parts of aminodimethyl methane and add it into a four-neck round bottom flask, then heat it to 24°C, slowly add 15.5 parts of 2.4-dichlorobenzaldehyde dropwise, after the dropwise addition, raise the temperature to 25°C, and react for 3 hours to obtain mid product;

[0022] (2) Add 32.5 parts of zinc chloride and 27 parts of boric acid to the intermediate product, heat to 76°C while stirring, react for 4 hours, separate layers, and take the upper organic phase.

[0023] (3) Add 6 parts of polyethylene glycol monododecyl ether and 1.8 parts of sodium citrate to the organic phase, stir and react at 82° C. for 4 hours, and cool to room temperature to obtain zincate galvanized brightener.

Embodiment 2

[0025] (1) Take 25 parts of aminodimethyl methane and add it into a four-neck round bottom flask, then heat it to 25°C, slowly add 16 parts of 2.4-dichlorobenzaldehyde dropwise, after the dropwise addition, raise the temperature to 28°C, and react for 1-3h , to get the intermediate product;

[0026] (2) Add 30 parts of zinc chloride and 26 parts of boric acid to the intermediate product, heat to 80°C while stirring, react for 3.5 hours, separate layers, and take the upper organic phase.

[0027] (3) Add 5.5 parts of polyethylene glycol monododecyl ether and 1.5 parts of sodium citrate to the organic phase, stir and react at 80° C. for 4 hours, and cool to room temperature to obtain a zincate galvanizing brightener.

Embodiment 3

[0029] (1) Take 30 parts of aminodimethyl methane and add it into a four-neck round bottom flask, then heat it to 24°C, slowly add 17 parts of 2.4-dichlorobenzaldehyde dropwise, after the dropwise addition, raise the temperature to 25°C, and react for 3 hours to obtain mid product;

[0030] (2) Add 28 parts of zinc chloride and 25 parts of boric acid to the intermediate product, heat to 68°C while stirring, react for 4 hours, separate layers, and take the upper organic phase.

[0031] (3) Add 8 parts of polyethylene glycol monododecyl ether and 3 parts of sodium citrate to the organic phase, stir and react at 80° C. for 5 hours, and cool to room temperature to obtain zincate galvanized brightener.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com