High-dispersibility alkaline non-cyanide zinc-plating brightener and preparation method and application thereof

A technology with high dispersibility and brightening agent, applied in the field of alkaline cyanide-free electrogalvanizing surface treatment, which can solve the problems of poor covering ability and dispersion performance, low current efficiency, and narrow current density range of alkaline cyanide-free zinc plating. , to achieve the effect of less hydrogen evolution, wide current density range and low carbon content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Take the above basic solution, the concentration of each component in the plating solution is as follows:

[0033] Zinc (g / L) 8.0

[0034] Caustic soda (g / L) 125.0

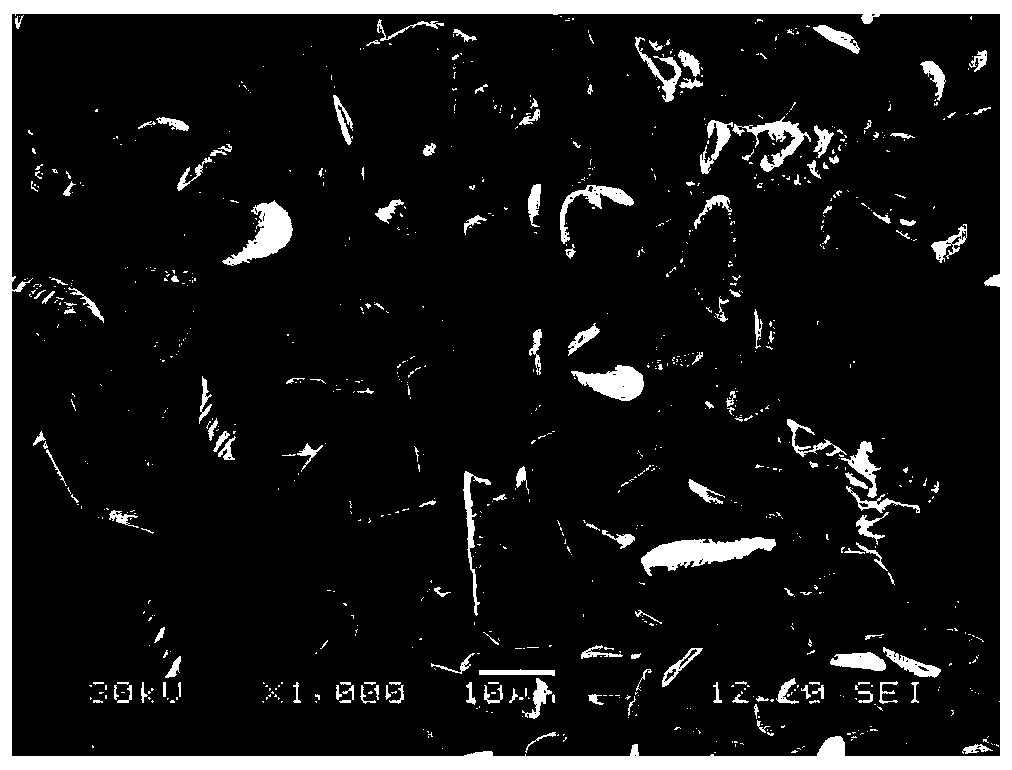

[0035] Take 500mL of the above-mentioned plating solution and add it to the Hull cell, use the zero zinc plate as the anode, and use the copper sheet (6.5cm×20cm) with a thickness of 0.3mm as the mirror surface polished by the cloth wheel as the cathode, and place the Hull cell at a constant temperature In the water bath, control the temperature of the test piece at 25°C and the current density at 0.5A / dm 2 , electroplating for 15min, a gray loose spongy coating was obtained, figure 1 Its appearance diagram.

Embodiment 2

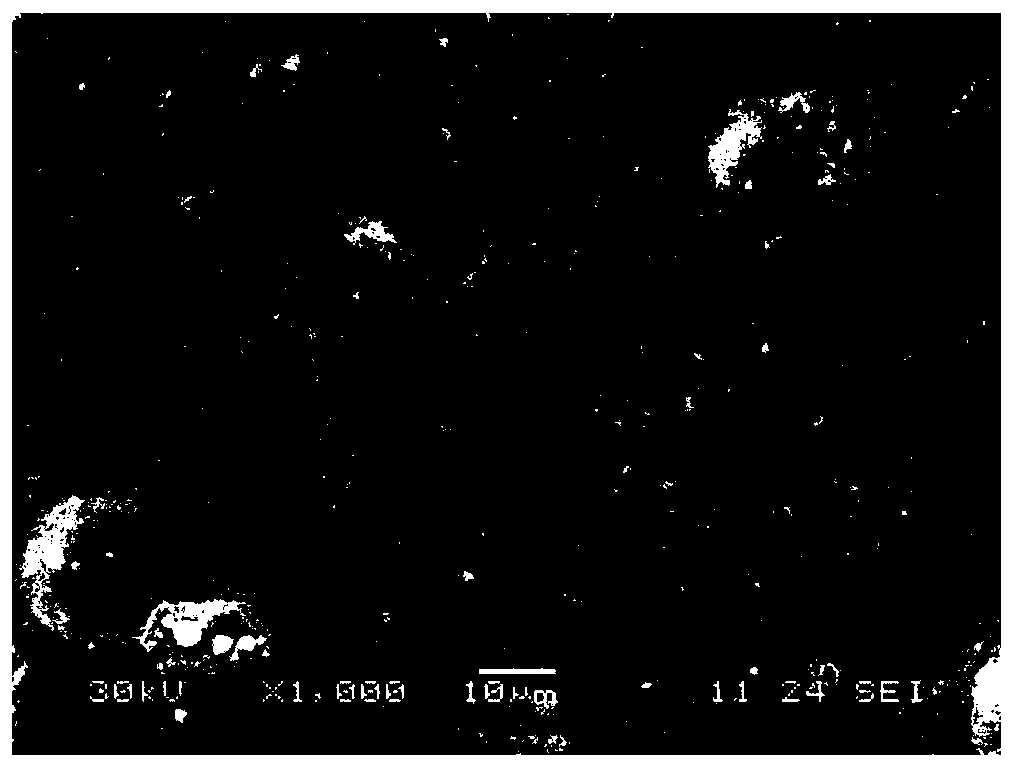

[0037] On the basis of embodiment 1 plating solution, add DPE-III+BPC-48 alkaline cyanide-free zinc plating brightener to be mixed with plating solution, the concentration of each component in the plating solution is as follows:

[0038]

[0039] Take 500mL of the above-mentioned plating solution and add it to the Hull cell, use the No. In the water bath, control the temperature of the test piece at 25°C and the current density at 0.5A / dm 2 , electroplating for 15 minutes, to obtain a bright coating on the whole piece, figure 2 Its appearance diagram.

Embodiment 3

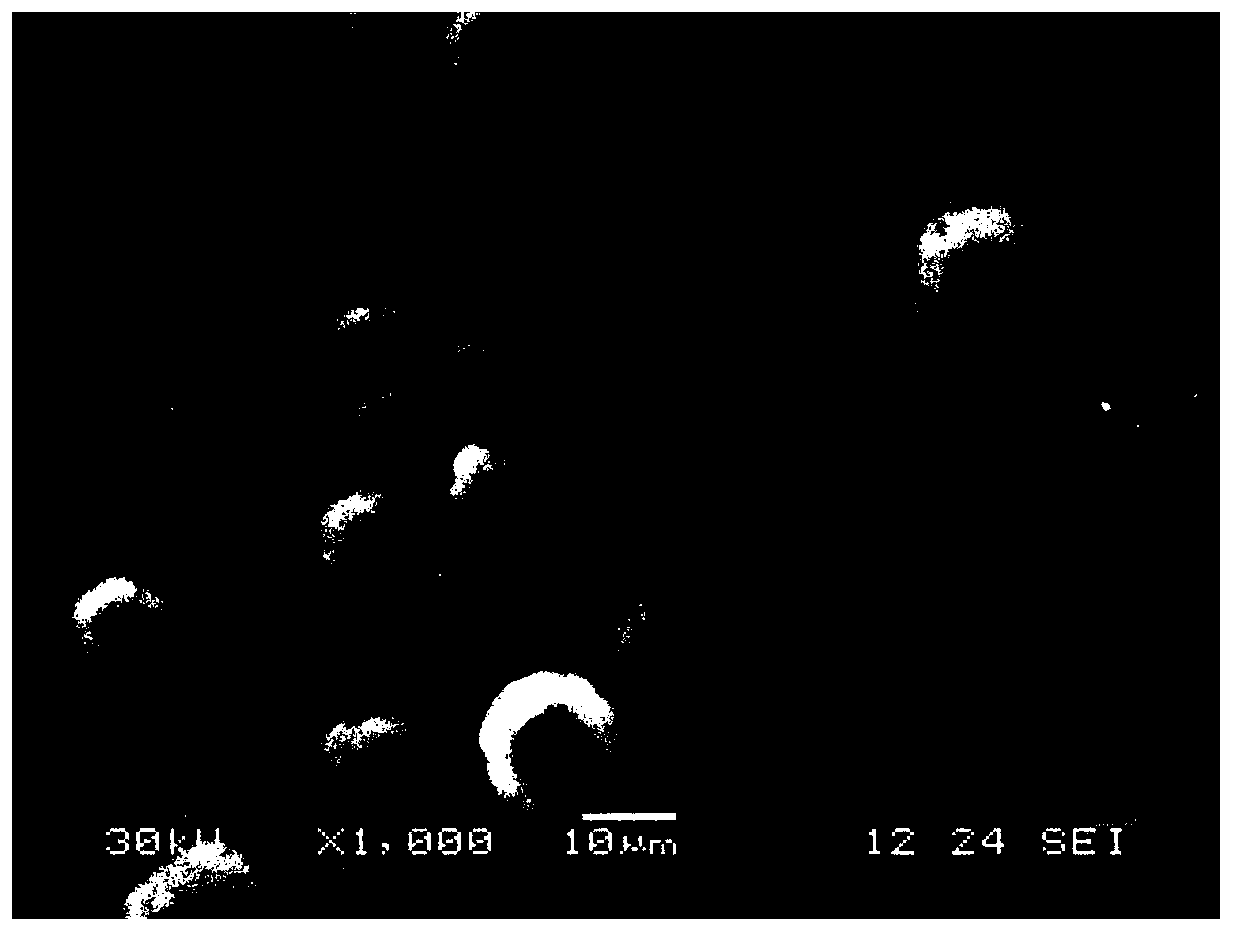

[0041]In a clean and dry 1000mL four-neck flask with stirring, heating and reflux condenser, add 160g of 5-amino-8-hydroxyquinoline, 122.2g of salicylaldehyde as a substrate and 0.085g of paraformaldehyde as a catalyst, Then add 200mL of ethanol, stir until dissolved, then raise the temperature to 90°C, and react under reflux for 4h; 122g of propane sultone was added dropwise into the bottle, and after the addition was completed, the temperature was raised to 90°C to react for 2 hours to obtain an alkaline cyanide-free zinc-plating brightener.

[0042] Get the above-mentioned alkaline cyanide-free galvanizing brightener to be mixed with plating solution, the concentration of each component in the plating solution is as follows:

[0043]

[0044] Take 500mL of the above-mentioned plating solution and add it to the Hull cell, use the zero zinc plate as the anode, and use the copper sheet (6.5cm×20cm) with a thickness of 0.3mm as the mirror surface polished by the cloth wheel ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current density | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com