Method for producing electroplated copper layer with preferential orientation growth structure, and application thereof

A technology of preferential orientation and electroplating copper layer, which is applied to electrodes, circuits, electrical components, etc., can solve problems such as poor thermal stability, easy chip failure, and reliability problems, and achieve a wide range of current densities, ensuring service reliability, The effect of ensuring reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

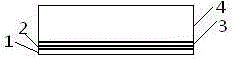

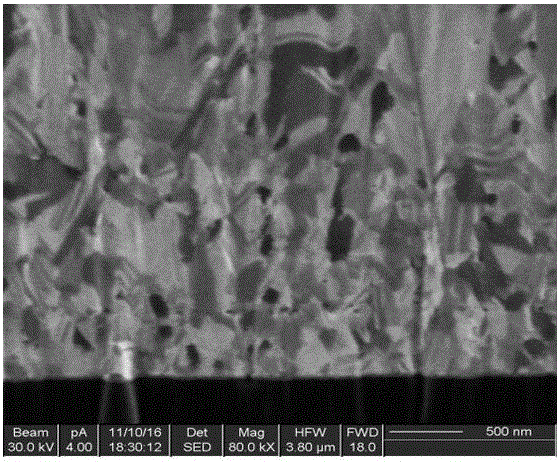

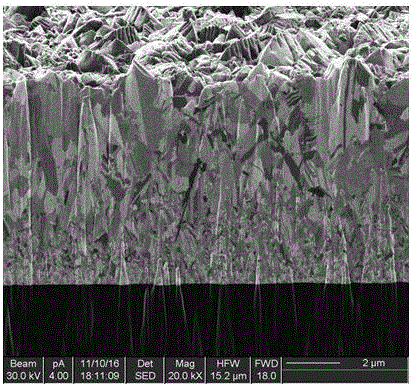

[0032] see figure 1 As shown, a copper layer with a preferential orientation growth structure in the Z-axis direction includes a wafer substrate 1, an adhesion layer 2, a copper seed layer 3 and an electroplated copper layer 4 in sequence, and the electroplated copper layer 4 contains a Z-axis The approximate columnar crystal structure grown in the preferred orientation in the Z-axis direction has a large grain size and few grain boundaries in the Z-axis direction, and the small grain size and many grain boundaries in the X-axis direction .

[0033] Preferably, the wafer substrate 1 is silicon or silicon germanium semiconductor material, or a chip or device containing silicon or silicon germanium, and the adhesion layer 2 is a titanium layer.

[0034] Preferably, the copper seed layer 3 is prepared by magnetron sputtering, and the copper seed layer 3 is connected to the electroplated copper layer 4 .

Embodiment 2

[0036] A method for preparing an electroplated copper layer with a preferred orientation growth structure, using a direct current electroplating process, the composition of the electroplating solution is copper sulfate 120-200g / L, sulfuric acid 50-150g / L, wetting agent 100-1000ppm, bright 5-50ppm agent, 40-100ppm non-dye-based leveling agent, and the rest is water;

[0037] The electroplating anode plate adopts phosphor copper plate, and the P element content in the phosphor copper plate is 0.03~150wt.%.

[0038] The current density is 1~18A / dm 2 ;

[0039] During the electroplating process, mechanical stirring is used to ensure uniform concentration in the plating solution and increase mass transfer.

[0040] Preferably, the wetting agent is polyethylene glycol or polyethyleneimine, the brightener is sodium polydithiodipropane sulfonate, and the non-dye-based leveling agent is a nitrogen-containing organic heterocyclic compound.

[0041] The electroplated copper layer with...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com