Process for plating cadmium on shaped steel part with deep/blind hole

A special-shaped steel, cadmium plating technology, applied in the plating of superimposed layers, metal material coating process, coating and other directions, can solve the problems of difficult solution control and maintenance, poor deep plating and coverage ability, narrow current density range, etc. , to achieve the effect of not easy natural decomposition and aging, excellent deep plating ability, and wide current density range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

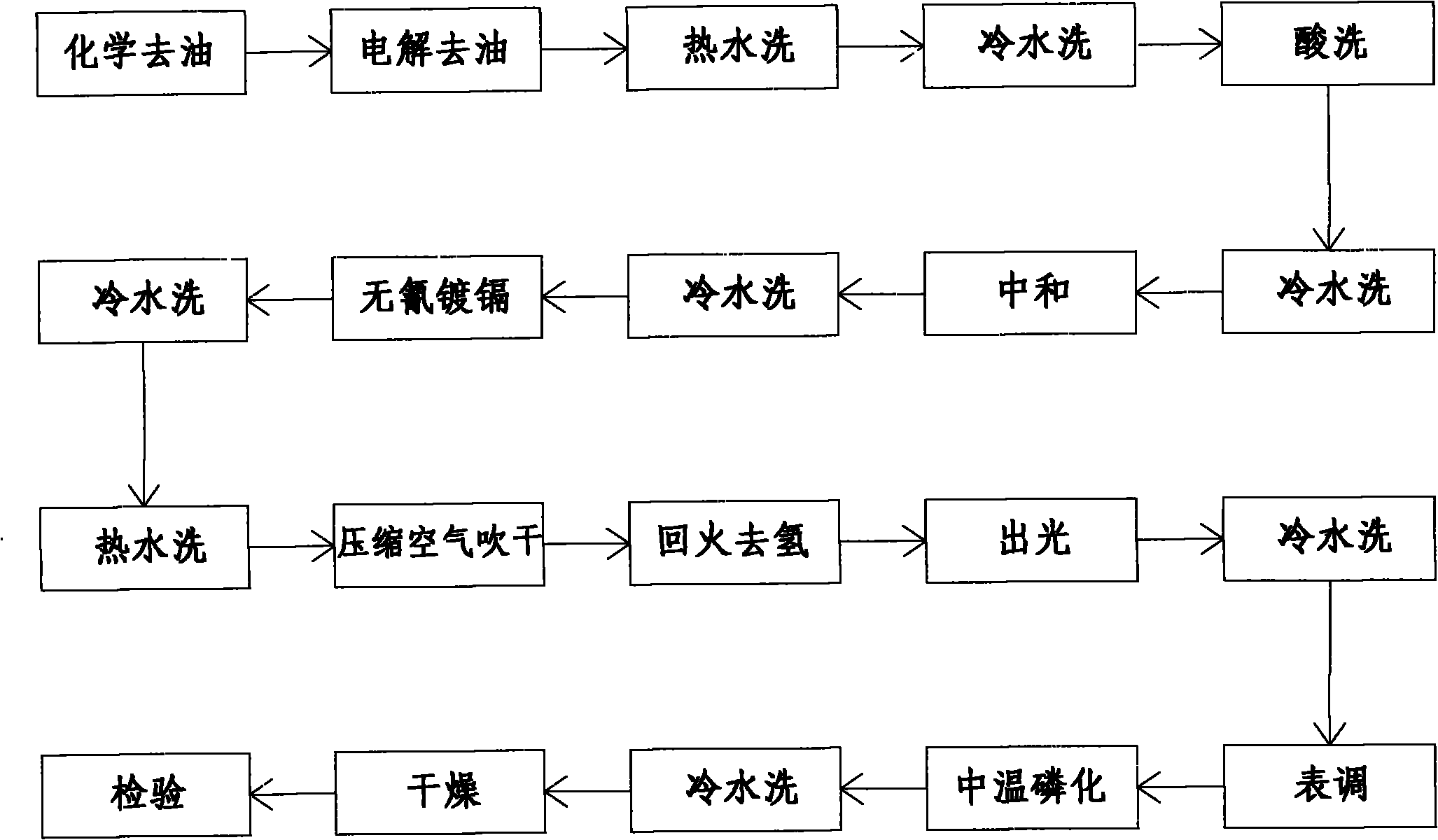

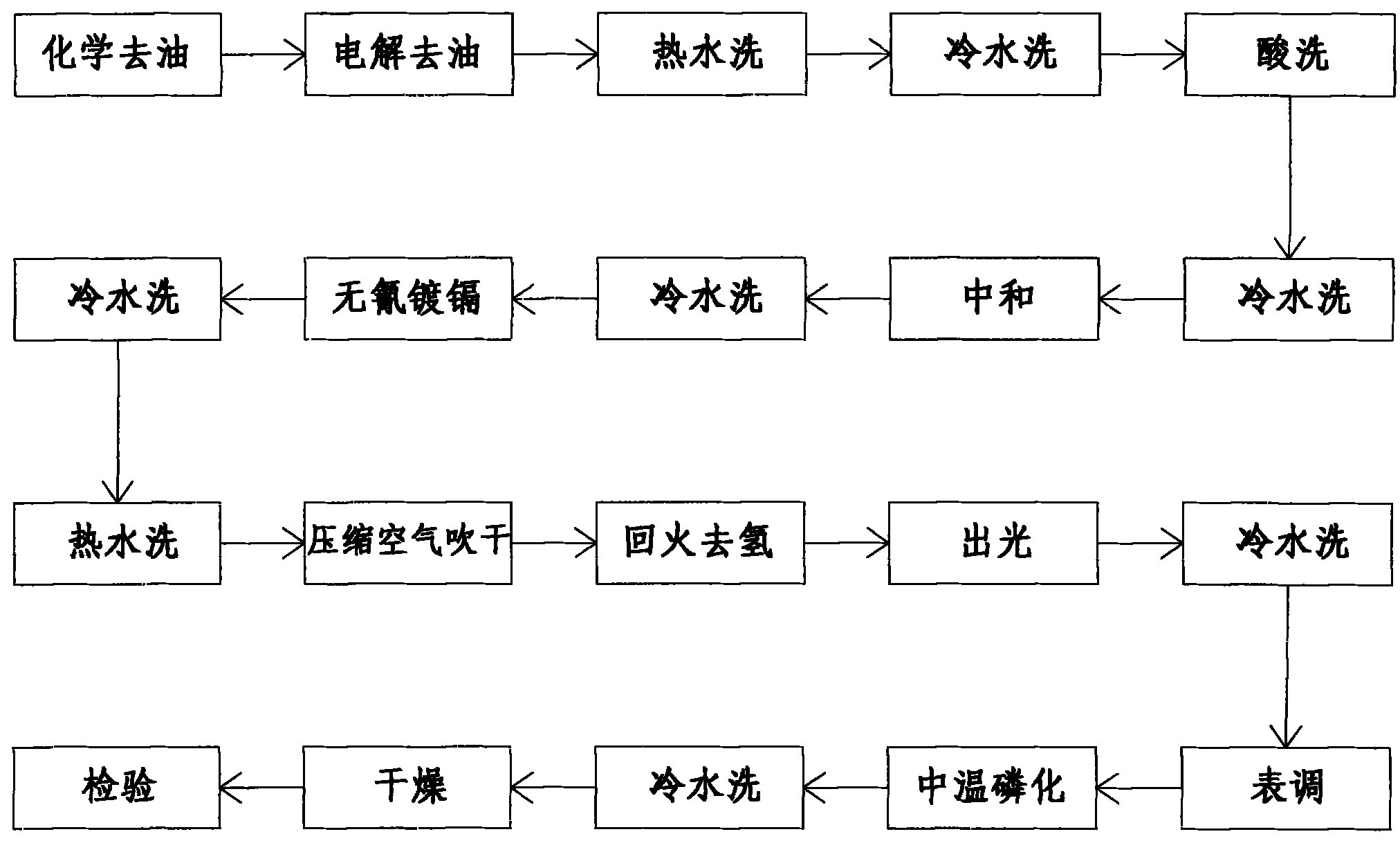

[0043] The present invention will be further described below in conjunction with the drawings.

[0044] Prepare the plating solution first, the preparation method is as follows:

[0045] First formula

[0046] (1) Weigh 210g / L of ammonium chloride and pour it into the tank, add hot water at about 80°C to one third of the tank volume, and stir to completely dissolve it;

[0047] (2) Weigh 50g / L of cadmium sulfate and add it to the ammonium chloride solution, stir to dissolve, and obtain a cadmium sulfate-ammonium chloride solution;

[0048] (3) Weigh nitrilotriacetic acid (NTA) at 70g / L, and ethylenediaminetetraacetic acid (EDTA) at 30g / L. Mix nitrilotriacetic acid and ethylenediaminetetraacetic acid in another container to make a paste Use 20% (mass) sodium hydroxide solution under constant stirring to slowly add until the solution is transparent (the pH value is about 5.8), and then add this solution to the cadmium sulfate-ammonium chloride solution;

[0049] (4) Adjust the pH value to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com