Method for preparing super-hydrophobic Zn-Fe alloy coating through electro-deposition in eutectic ionic liquid

A technology of ionic liquid and alloy coating, which is applied in the fields of anti-corrosion, electrodeposition, and surface treatment. It can solve problems such as difficulty in obtaining coatings and large differences, and achieve the effects of simple process control, easy contact with outside air, and contact with outside air.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] (1) Alkaline cleaning and degreasing: Use alkaline cleaning solution to remove the grease and organic matter on the surface of the substrate, and then wash the sample with deionized water. The components of the alkaline cleaning solution are: sodium hydroxide 15.0g / L, isopropanol 10.0g / L, nonylphenol polyoxyethylene ether 0.5g / L, sodium benzenesulfonate 0.5g / L. The alkali washing temperature is 35°C and the time is 2min.

[0050] (2) pickling activation: use pickling to remove the oxide film and metal impurities on the surface of the material, and then wash it with deionized water. The composition of pickling solution is: HCl30.0mL / L, Na 2 S 2 o 8 10.0g / L, fatty alcohol polyoxyethylene ether 1.0g / L. The pickling temperature is 25°C and the time is 1min.

[0051] (3) Dehydration: Dehydrate the matrix in absolute ethanol for 3 minutes, and set aside.

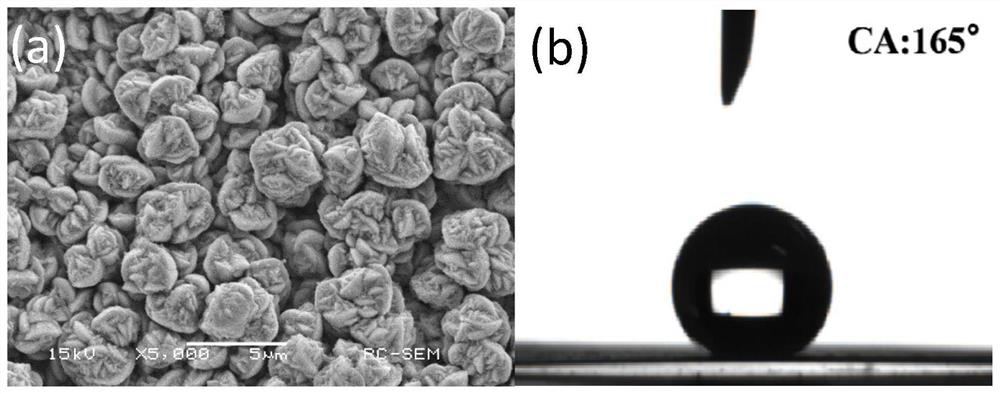

[0052] (4) Place choline chloride and ethylene glycol in a vacuum drying oven at 120°C for 24 hours and dry them fo...

Embodiment 2

[0058] (1) Repeat steps (1)-(3) in Example 1 to carry out pretreatment on the substrate.

[0059] (2) Choline chloride and ethylene glycol were dried in a vacuum oven at 120°C for 24 hours, cooled to room temperature and heated at 80°C for 4 hours with a molar ratio of 1:1.5 to form a clear and transparent solution.

[0060] (3) in the deep eutectic ionic liquid in step (2), add the zinc chloride of 20.0g / L, the ferrous chloride of 3.0g / L, then add the deionized water of plating solution total amount 3.0wt% and Add 2 wt% ethanol and 3.0 wt% methyl nonafluorobutyl ether in the total amount of the plating solution, and stir until the solution becomes clear and transparent.

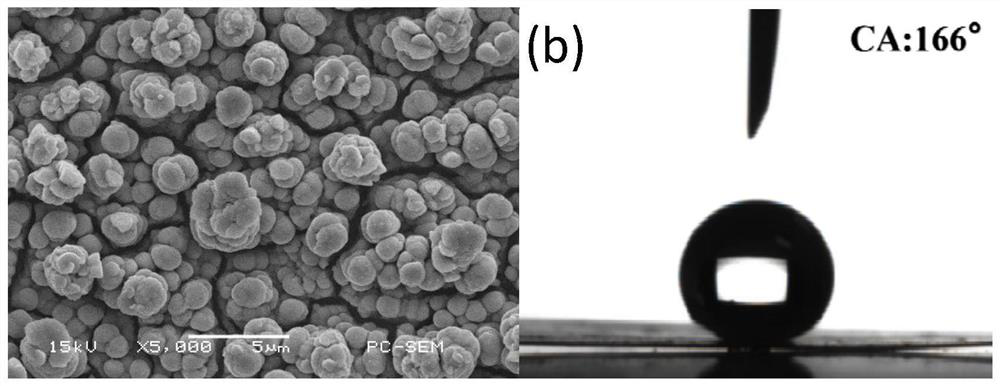

[0061] (4) Electrodeposition: The anode of electrodeposition is titanium mesh, the cathode is aluminum alloy sheet, the distance between cathode and anode is 20mm, and the current density is 250mA / cm 2 , the temperature is 70°C, the stirring speed is 300rpm, the pH of the plating solution is adjusted to 8.5...

Embodiment 3

[0065] (1) Repeat steps (1)-(3) in Example 1 to carry out pretreatment on the substrate.

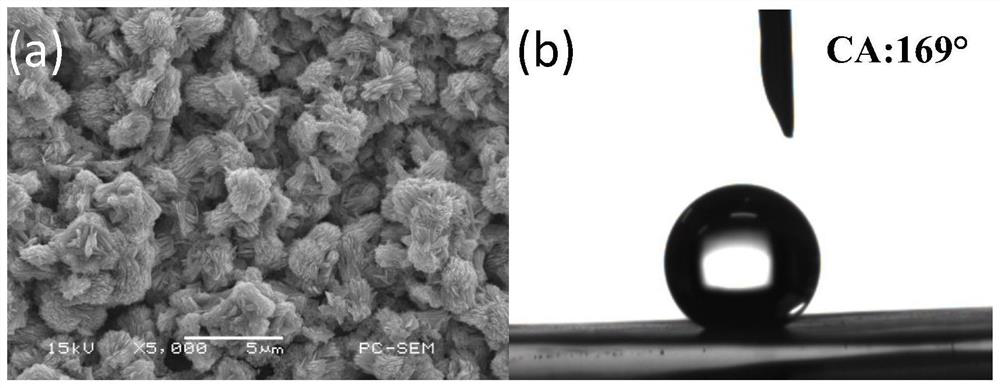

[0066] (2) Place choline chloride and ethylene glycol in a vacuum drying oven at 120°C for 24 hours, then cool to room temperature and heat them at 80°C for 4 hours with a molar ratio of 1:3 to form a clear and transparent solution .

[0067] (3) in the eutectic ionic liquid in step (2), add the zinc oxide of 15.0g / L, the ferrous chloride of 2.0g / L, add the propanol of plating solution total amount 1.0wt% and plating solution total amount again Measure 5.0wt% ethylene glycol butyl ether and stir until the solution is clear and transparent.

[0068] (3) Electrodeposition: The electrodeposition anode is a titanium plate, the cathode is a pure copper sheet, the distance between the cathode and the anode is 10mm, and the current density is 300mA / cm 2, the temperature is 80°C, the stirring speed is 500rpm, the pH of the plating solution is adjusted to 9.0 with diethanolamine, and the electr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| electric potential / voltage | aaaaa | aaaaa |

| electric potential / voltage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com