A high-speed electroplating copper additive and electroplating solution for advanced packaging

A high-speed electroplating, advanced technology, applied in the field of high-speed electroplating copper additives and electroplating solution, can solve the problems of inconsistent height at different positions, poor bump shape, poor uniformity, etc., to avoid voids, avoid coating burnt and rough, and coating Excellent flatness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

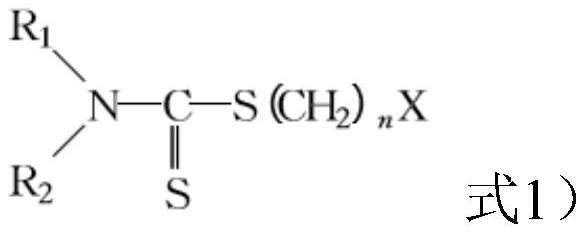

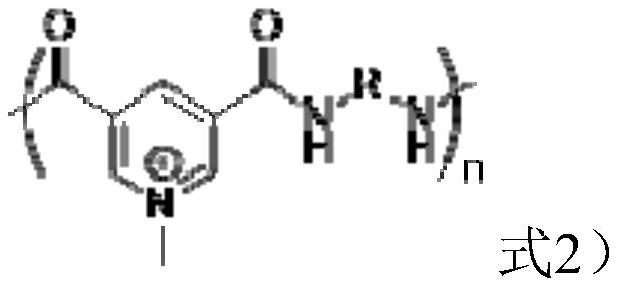

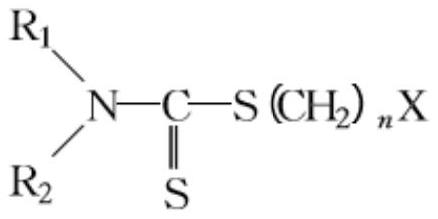

Method used

Image

Examples

Embodiment 1

[0029] Example 1, Example 2 Parameters As shown in Table 1. Sodium SPS / Wetting PEG-6000 / Of Sodium SPS / Wetting PEG-6000 / Overall Sputter Polyviimide Commonly used in the market additives As the same condition reference group 1, the reference group 2, respectively, electroplated performance test:

[0030] Table 1: Example / Reference Group Parameter Comparison of Electroplating Performance

[0031]

[0032]

[0033] Table 1 Advanced Sealing Electric Plating Copper Plating Performance Evaluation Test Method is as follows:

[0034] 1) Plating ductility test: Apply the oxide anode with titanium, the cathode uses the ground stainless steel plate, electroplating 50-80 microns, 2 h on 120 ° C for 2 hours, and the plating layer is peeled off, and it is produced into 1 cm wide strip, in pull Test the elongation and tensile strength when the plating layer is tested on the promoter. Elimination requirements> 18%, higher, tensile strength requirements 200-500MPa

[0035] 2) Coating ...

Embodiment 2

[0040] Example 2 and the reference group 2 are all copper medium temperature systems in Chinese acid, and the low current density is tested: the normal extension and tensile strength of the plating layer, the uniformity of the plating layer is good, and the appearance of the reference group is basically normal. Point a small amount of empty, the brightness is slightly poor, the plating elongation and tensile strength, uniformity are in the requirement, but it is not as good as in Example 2, and Example 2 is excellent in low current density performance, which can be applied to a small current density of 1.0ASD. .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com