Patents

Literature

166 results about "Methane sulfonic acid" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Methane sulphonic acid is considered to be natural product and is part of the natural sulphur. It is less corrosive and toxic than other mineral acids. Due to these properties methane sulphonic acid making an environmentally benign material [1].

Apparatus for high deposition rate solder electroplating on a microelectronic workpiece

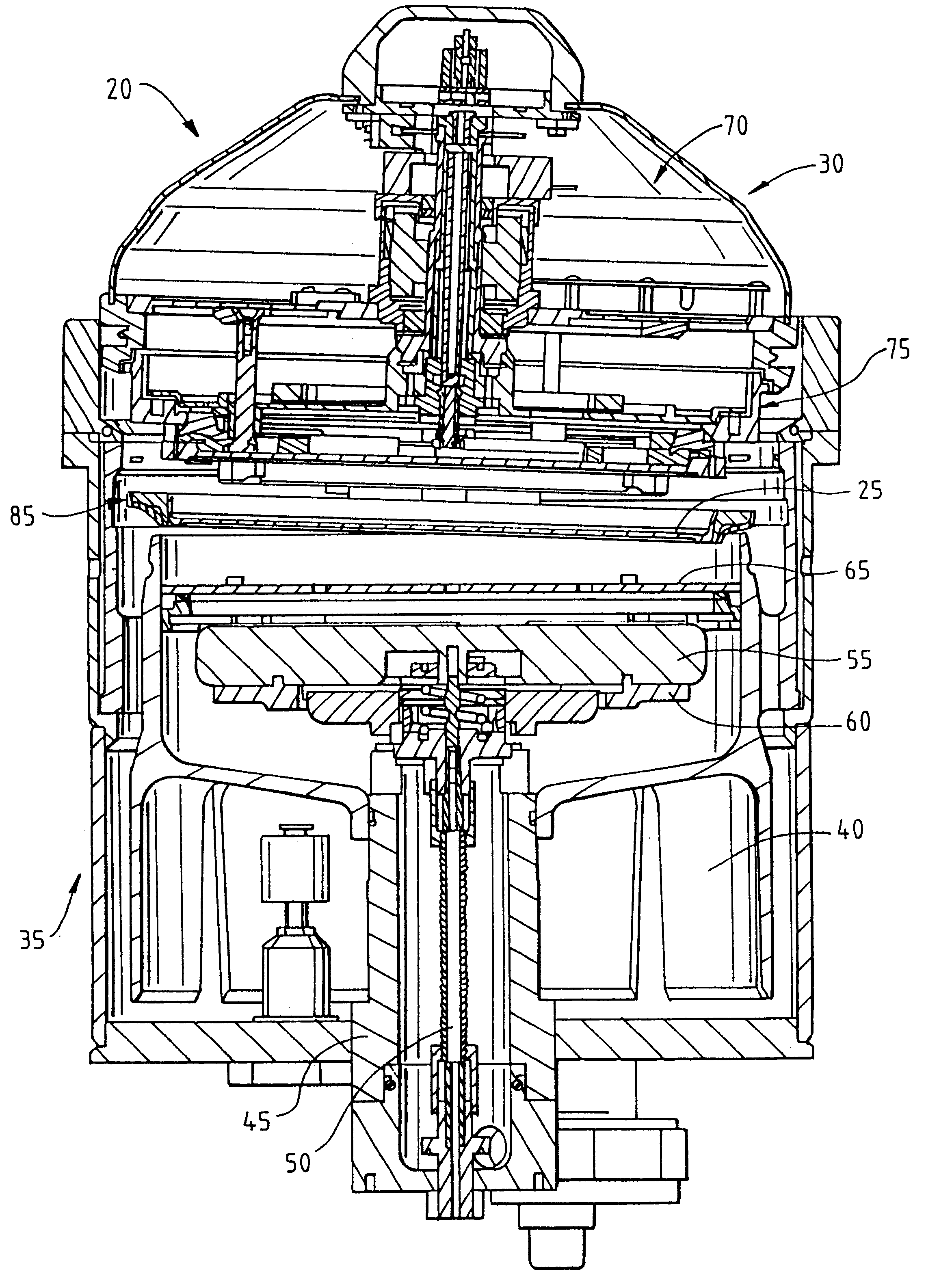

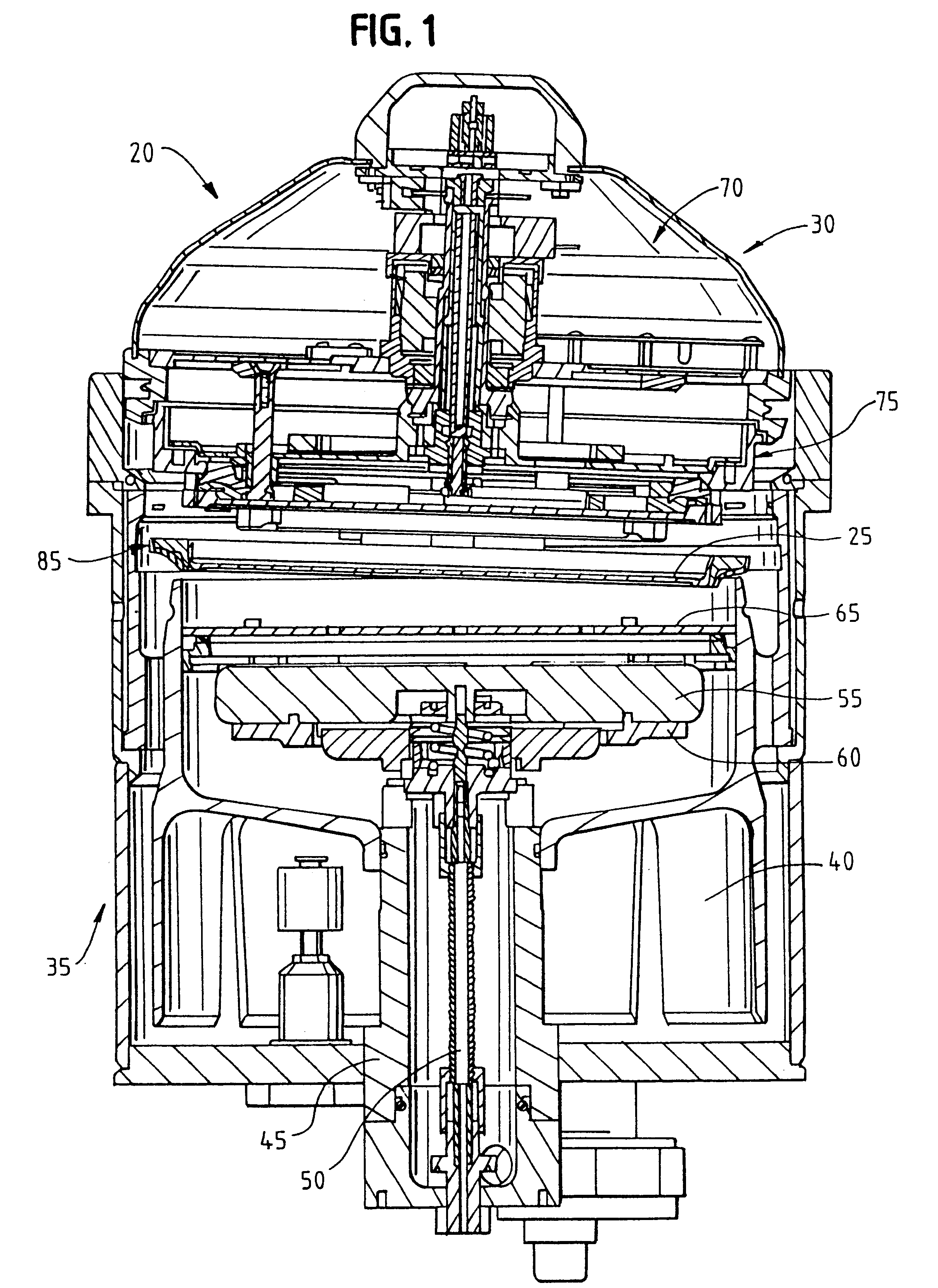

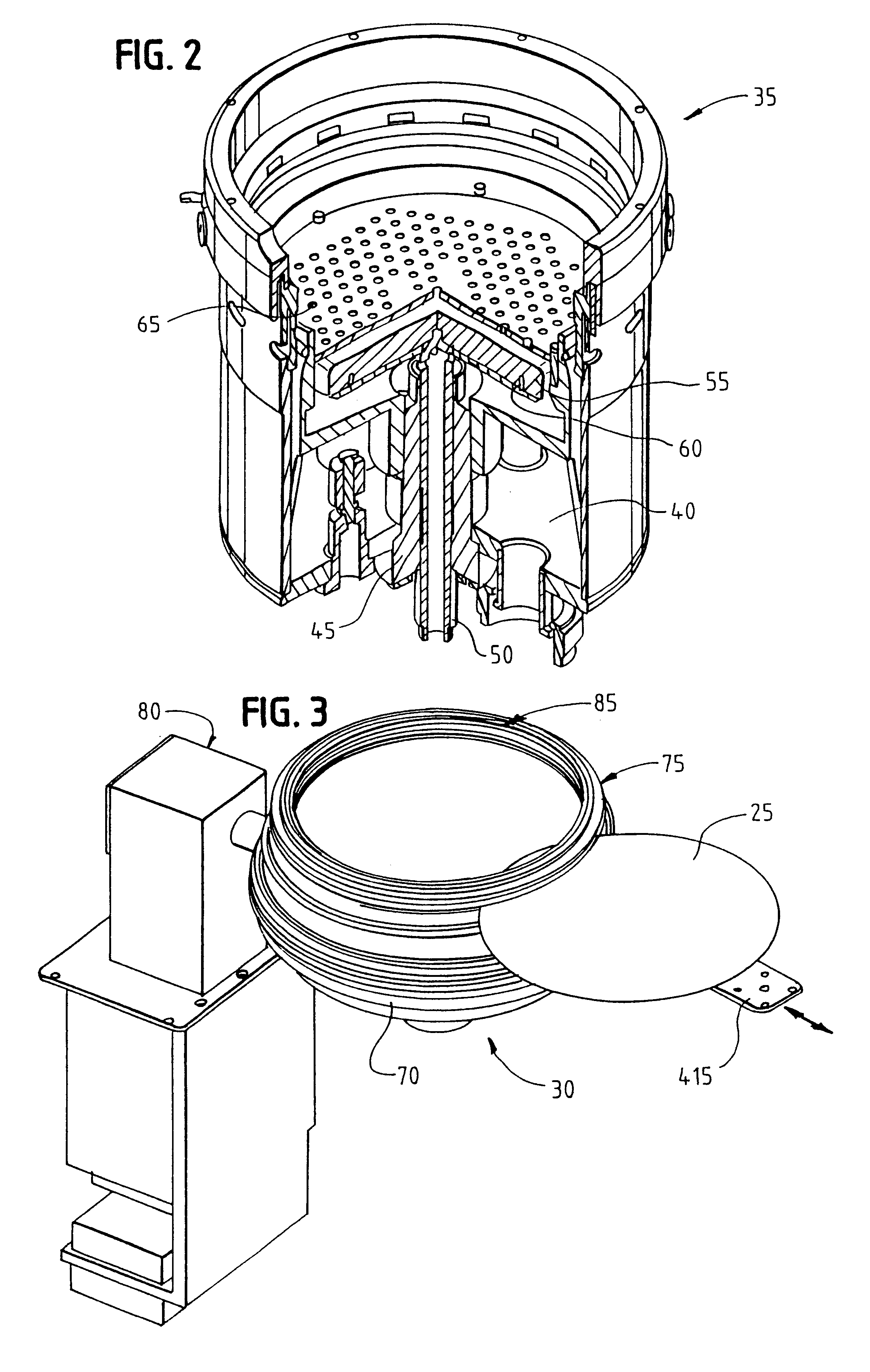

The present invention is directed to an improved electroplating method, chemistry, and apparatus for selectively depositing tin / lead solder bumps and other structures at a high deposition rate pursuant to manufacturing a microelectronic device from a workpiece, such as a semiconductor wafer. An apparatus for plating solder on a microelectronic workpiece in accordance with one aspect of the present invention comprises a reactor chamber containing an electroplating solution having free ions of tin and lead for plating onto the workpiece. A chemical delivery system is used to deliver the electroplating solution to the reactor chamber at a high flow rate. A workpiece support is used that includes a contact assembly for providing electroplating power to a surface at a side of the workpiece that is to be plated. The contact contacts the workpiece at a large plurality of discrete contact points that isolated from exposure to the electroplating solution. An anode, preferably a consumable anode, is spaced from the workpiece support within the reaction chamber and is in contact with the electroplating solution. In accordance with one embodiment the electroplating solution comprises a concentration of a lead compound, a concentration of a tin compound, water and methane sulfonic acid.

Owner:APPLIED MATERIALS INC

Method for Treating a Subterranean Formation

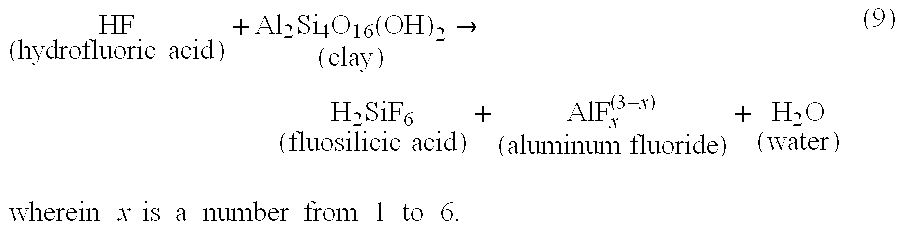

Acidizing methods for subterranean formations formed of predominantly siliceous material as well as acidizing compositions. Some methods include injecting into a predominantly siliceous subterranean formation, an aqueous acidic mixture formed by blending an aqueous liquid, a fluoride source, and an effective amount of an alkane sulfonic acid, preferably methane sulfonic acid, to adjust the pH of the fluid where the alkane sulfonic acid where the alkane group may be an unbranched, a branched or a cyclic alkyl residue. Hydrofluoric acid (HF) may not be added to the fluid in some embodiments as the fluoride source, such as the case for an HF free fluid, and, in some instances, hydrochloric acid is not added to the fluid to adjust pH. Also described are compositions containing an aqueous acidic mixture formed by blending an aqueous liquid, a fluoride source, and an effective amount of an alkane sulfonic acid to adjust pH.

Owner:SCHLUMBERGER TECH CORP

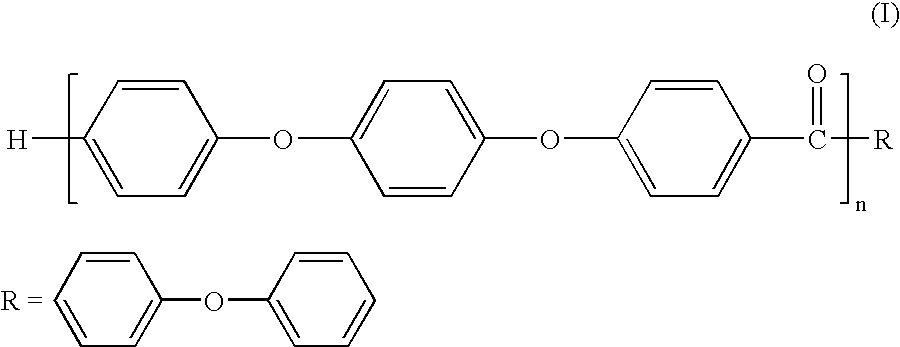

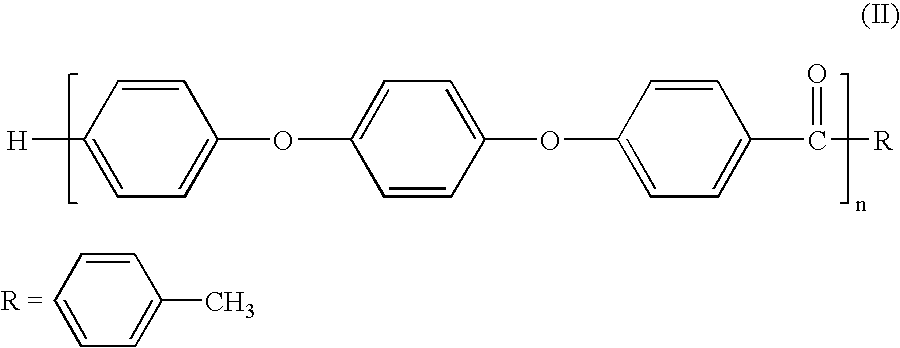

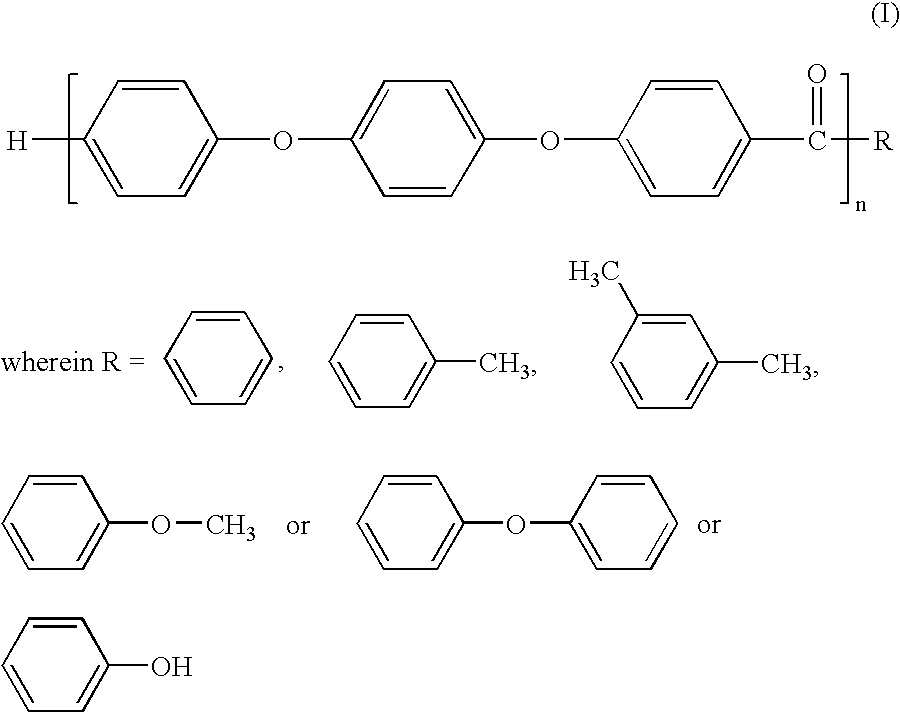

Melt processible polyether ether ketone polymer

InactiveUS6881816B2Easy to processReduce the temperatureChemical recyclingMethane sulfonic acidEnd-group

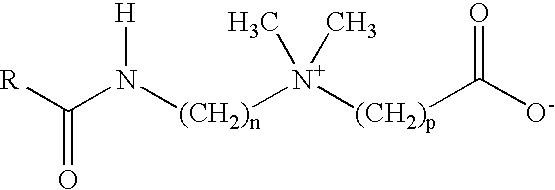

A melt processible Polyether Ether Ketone (PEEK) polymer with novel end-group structure is synthesized electrophilically using Methane Sulfonic Acid containing Methane Sulfonic Anhydride or Phosphorous Pentoxide. The product so obtained shows controlled structure with elimination of reactive end group like —COOH and is therefore melt processible by conventional techniques and exhibits high thermal and mechanical properties making it useful high temperature engineering and specialty plastics. It can be extruded into a rod, film and can also be molded into commercially useful products.

Owner:GHARDA CHEM LTD

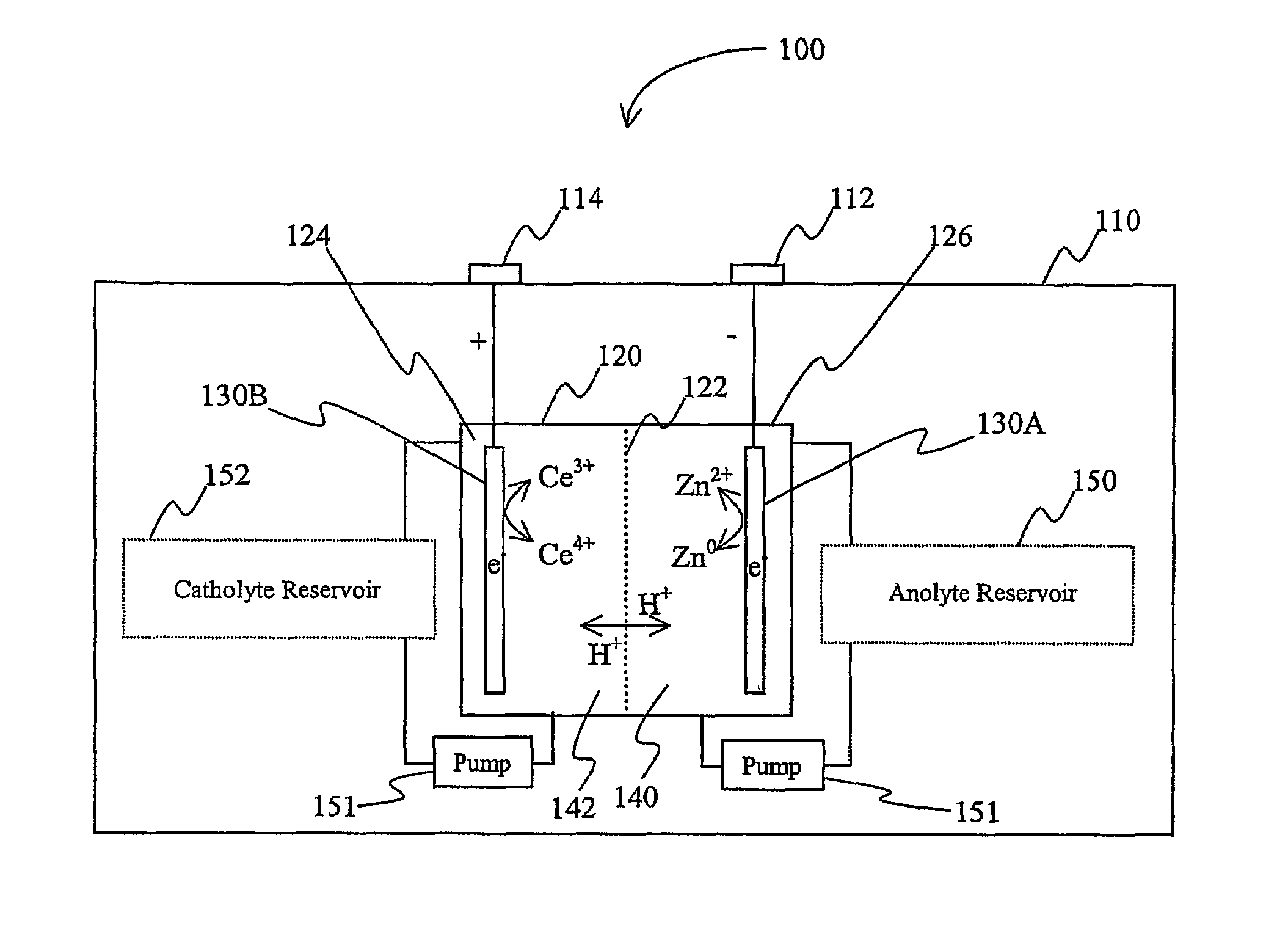

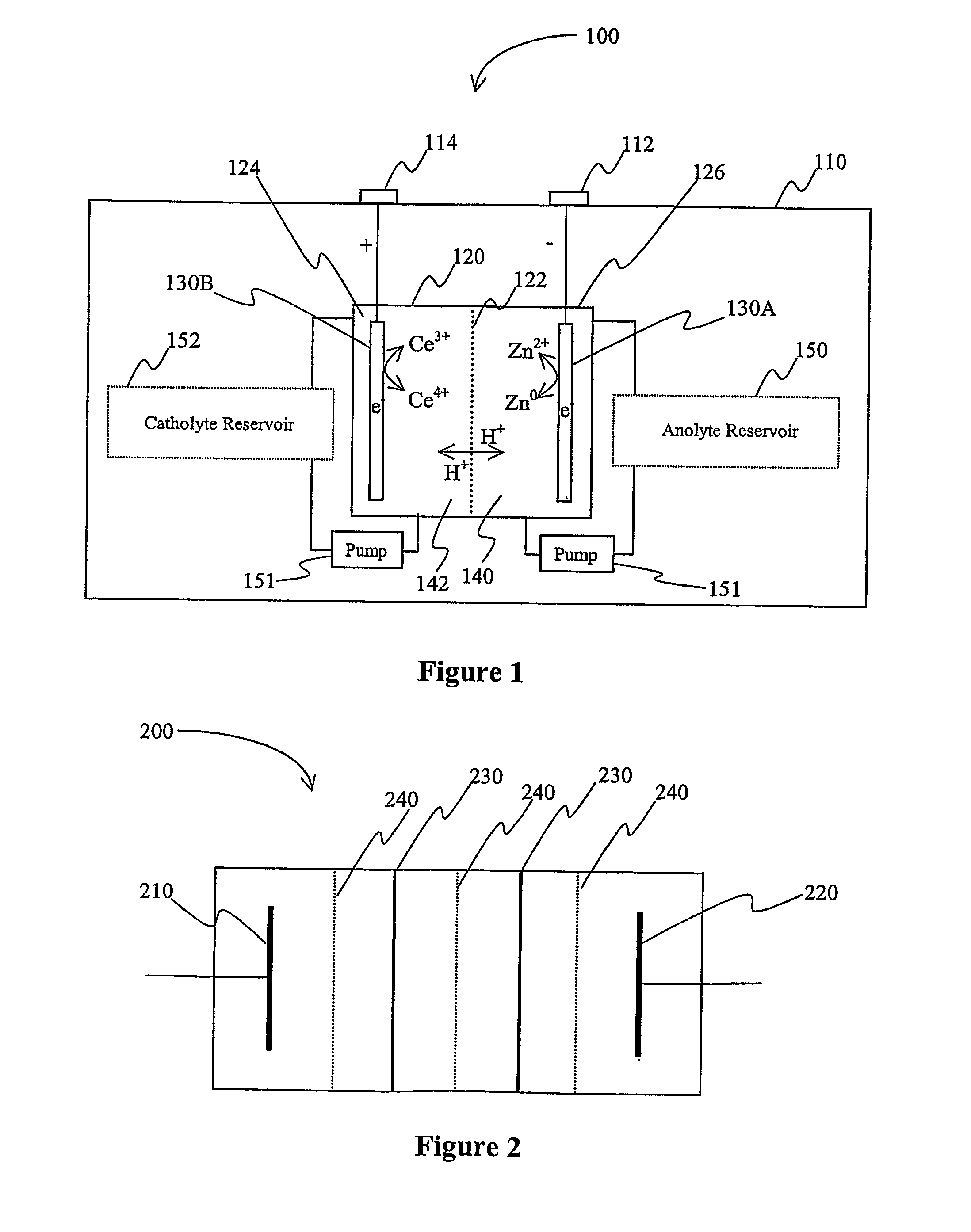

Lanthanide batteries

InactiveUS7252905B2Wide capacity rangeLarge capacityAlkaline accumulatorsSolid electrolyte cellsLanthanideCerium

A battery (100) comprises an electrolyte in which a lanthanide and zinc form a redox pair. Preferred electrolytes are acid electrolytes, and most preferably comprise methane sulfonic acid, and it is further contemplated that suitable electrolytes may include at least two lanthanides. Contemplated lanthanides include cerium, praseodymium, neodymium, terbium, and dysprosium, and further contemplate lanthanides are samarium, europium, thulium and ytterbium.

Owner:PLURION LTD

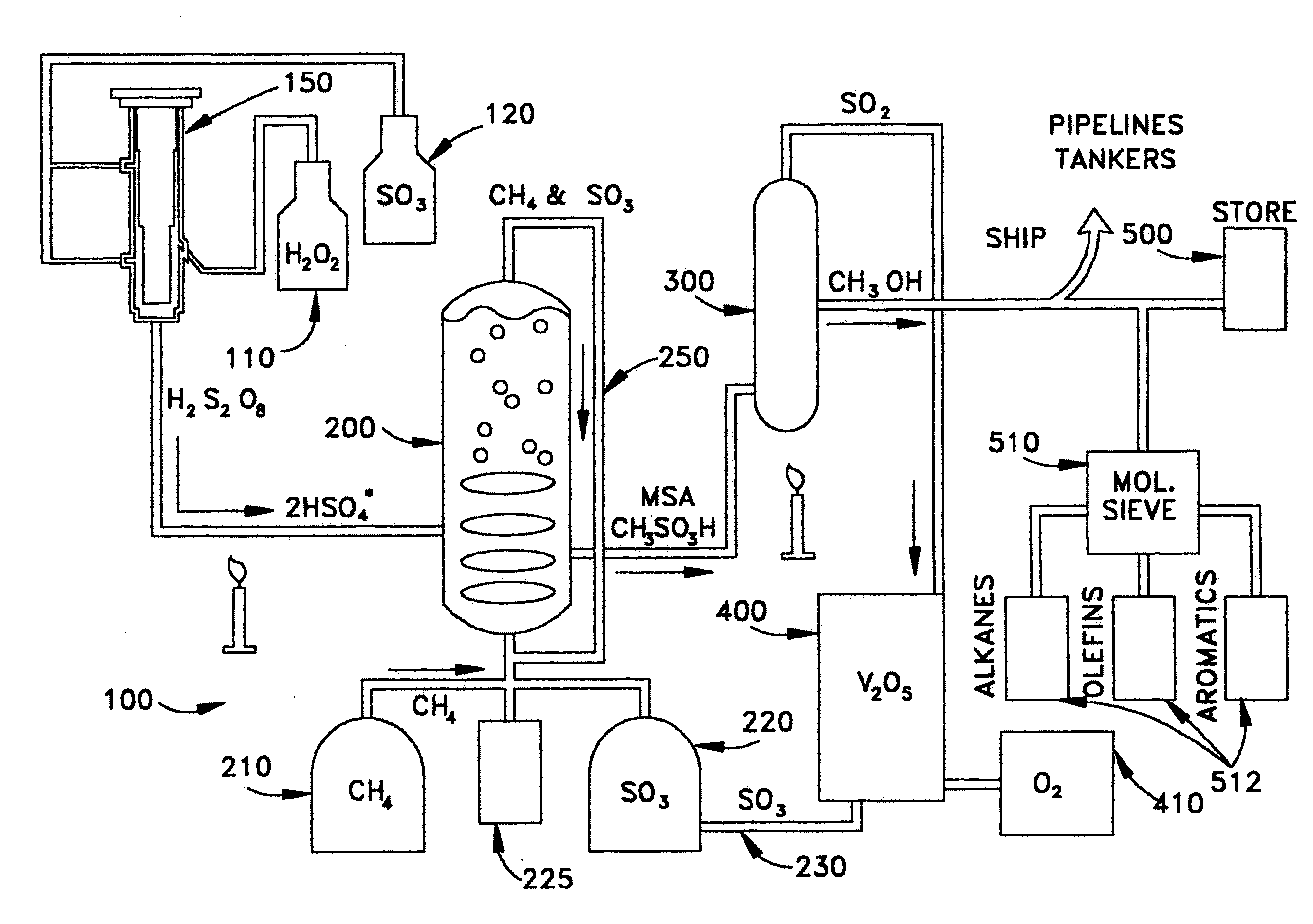

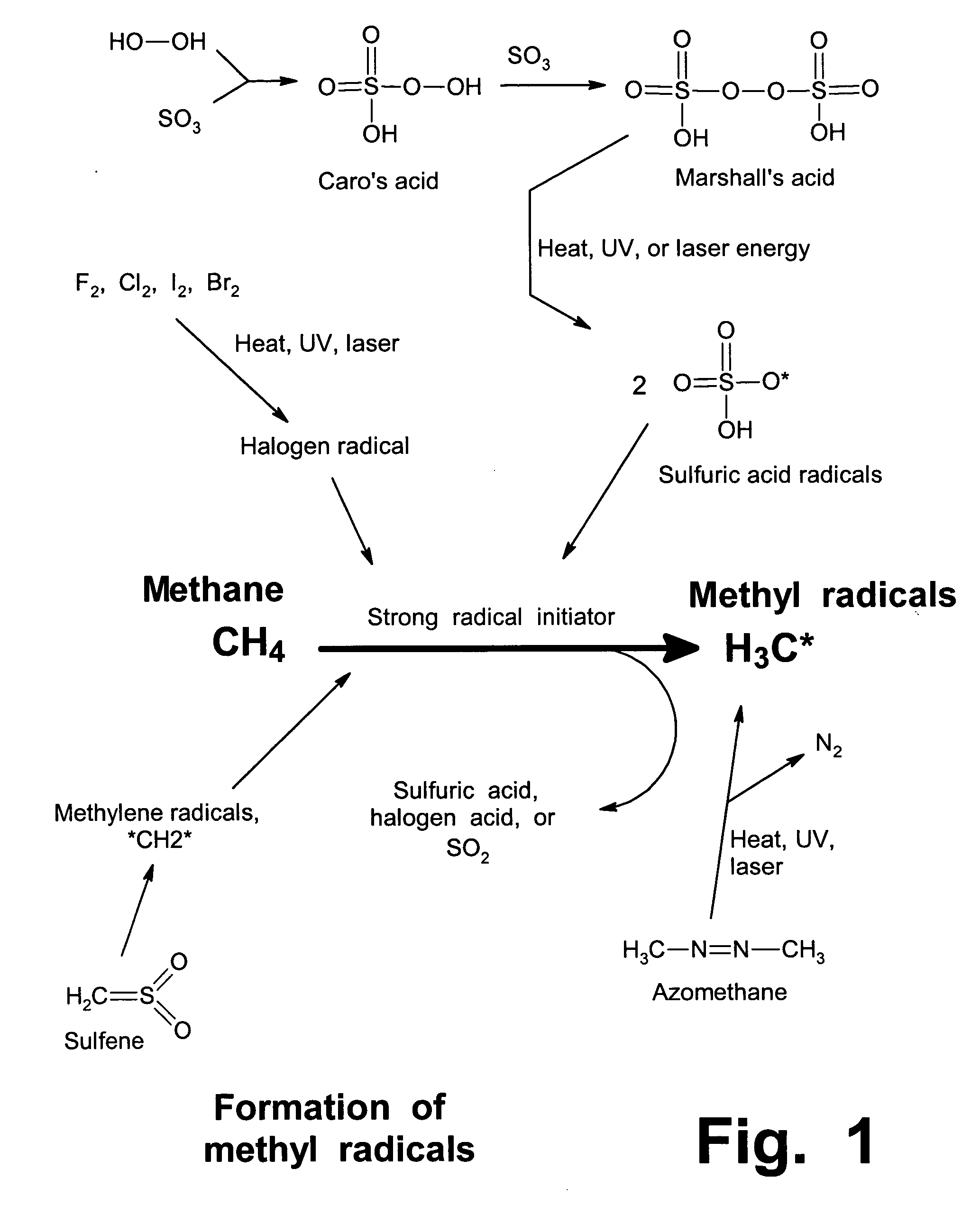

Anhydrous processing of methane into methane-sulfonic acid, methanol, and other compounds

ActiveUS20050070614A1Increases solubility and reaction rateEfficient removalHydrogenOrganic compound preparationLiquid fuelOxygen compound

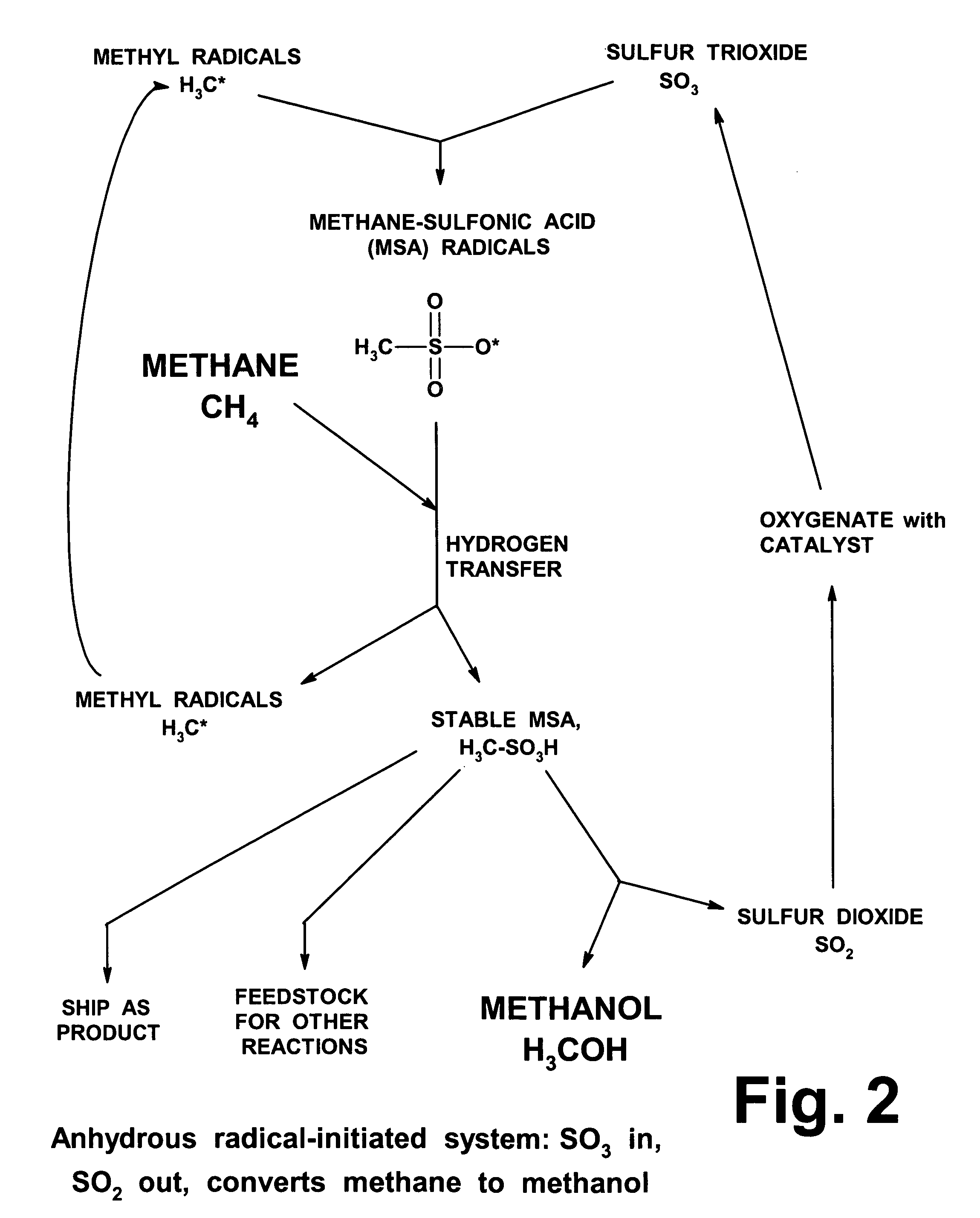

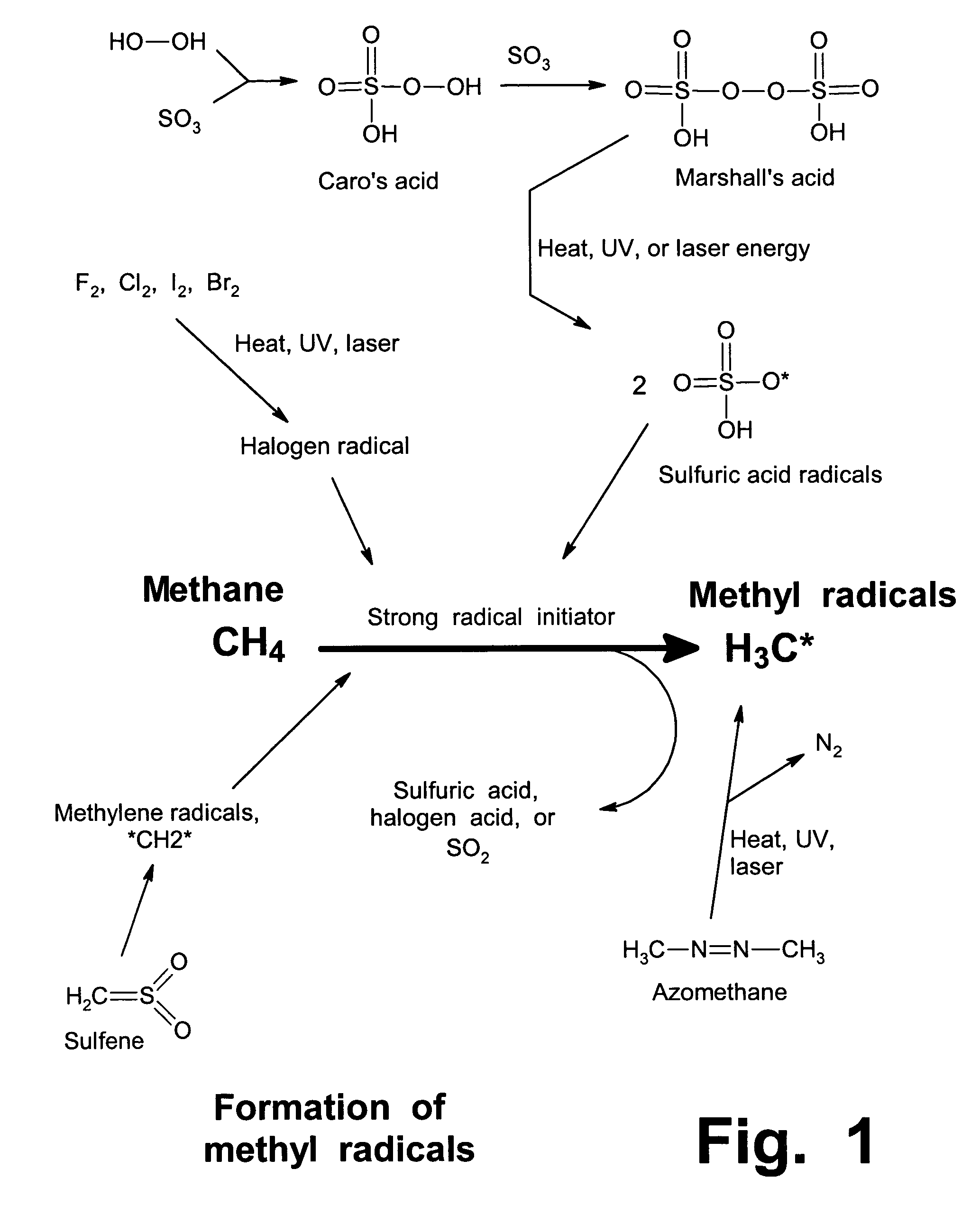

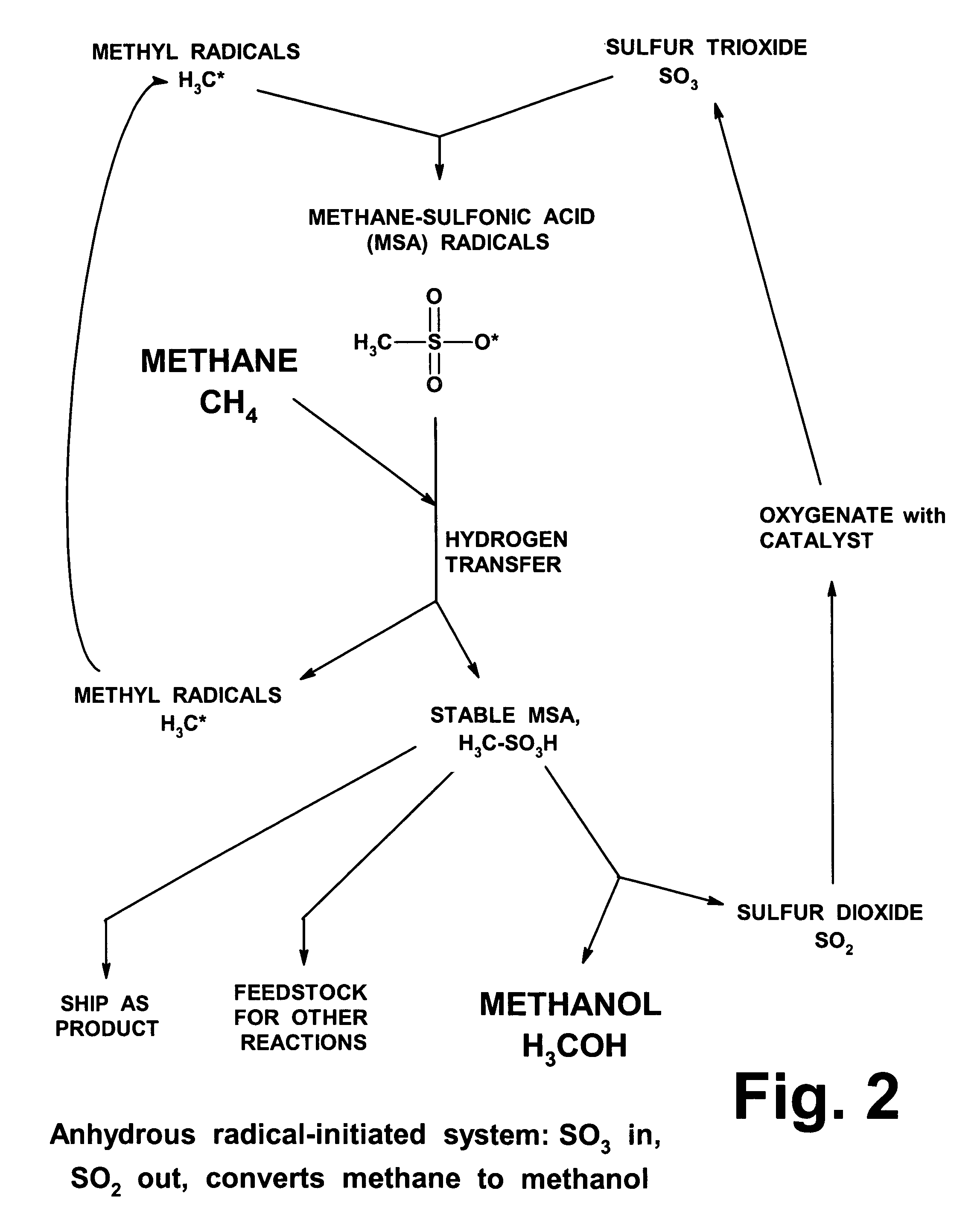

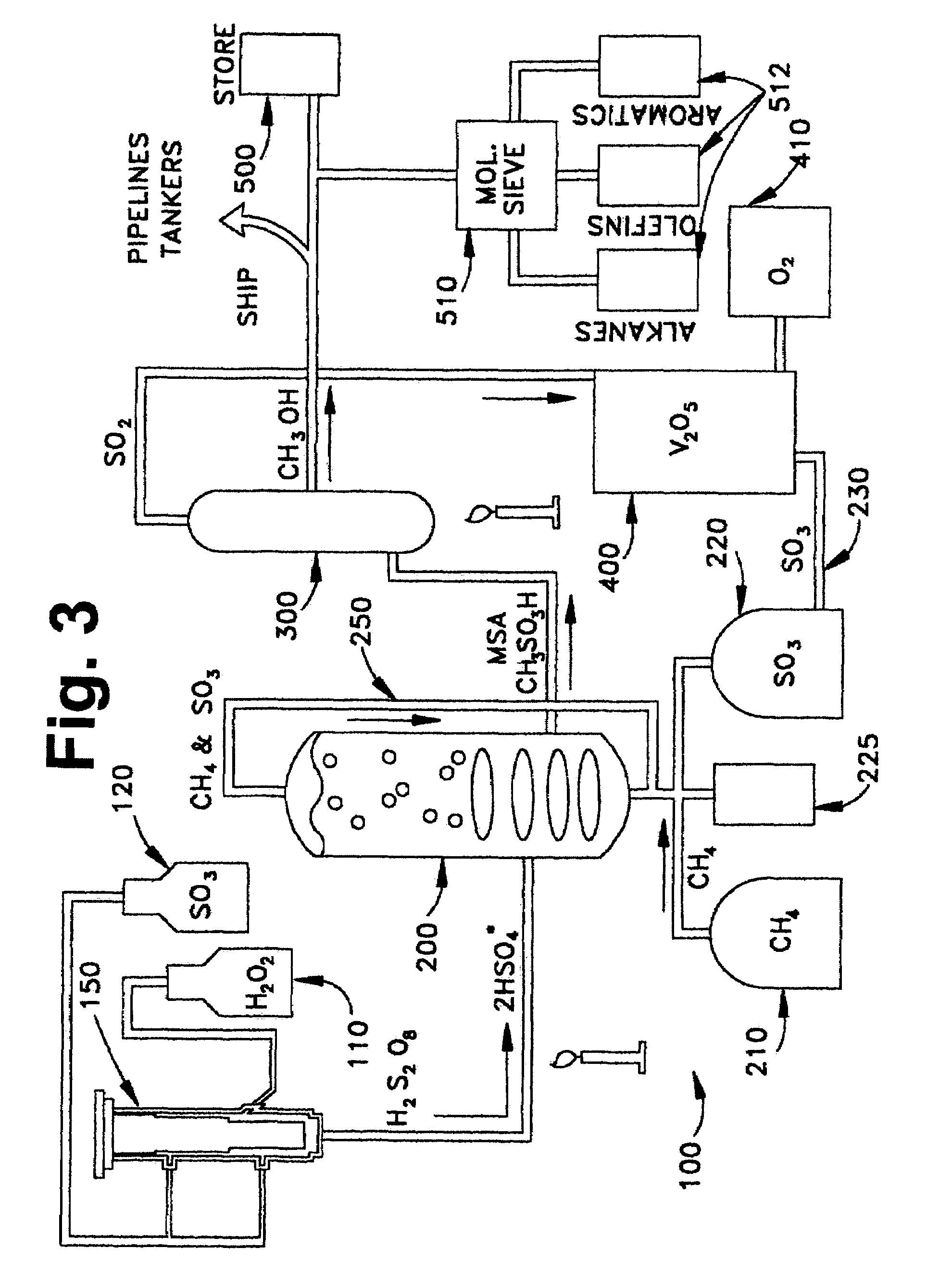

Anhydrous processing to convert methane into oxygenates (such as methanol), liquid fuels, or olefins uses an initiator to create methyl radicals. These radicals combine with sulfur trioxide to form methyl-sulfonate radicals. These radicals attack fresh methane, forming stable methane-sulfonic acid (MSA) while creating new methyl radicals to sustain a chain reaction. This system avoids the use or creation of water, and liquid MSA is an amphoteric solvent that increasing the solubility and reactivity of methane and SO3. MSA from this process can be sold or used as a valuable chemical with no mercaptan or halogen impurities, or it can be heated and cracked to release methanol (a clean fuel, gasoline additive, and chemical feedstock) and sulfur dioxide (which can be oxidized to SO3 and recycled back into the reactor). MSA also can be converted into gasoline, olefins, or other valuable chemicals.

Owner:VEOLIA NORTH AMERICA REGENERATION SERVICES LLC

Anhydrous processing of methane into methane-sulfonic acid, methanol, and other compounds

ActiveUS7282603B2Increases solubility and reaction rateEfficient removalHydrogenOrganic compound preparationSolubilityLiquid fuel

Anhydrous processing to convert methane into oxygenates (such as methanol), liquid fuels, or olefins uses an initiator to create methyl radicals. These radicals combine with sulfur trioxide to form methyl-sulfonate radicals. These radicals attack fresh methane, forming stable methane-sulfonic acid (MSA) while creating new methyl radicals to sustain a chain reaction. This system avoids the use or creation of water, and liquid MSA is an amphoteric solvent that increasing the solubility and reactivity of methane and SO3. MSA from this process can be sold or used as a valuable chemical with no mercaptan or halogen impurities, or it can be heated and cracked to release methanol (a clean fuel, gasoline additive, and chemical feedstock) and sulfur dioxide (which can be oxidized to SO3 and recycled back into the reactor). MSA also can be converted into gasoline, olefins, or other valuable chemicals.

Owner:VEOLIA NORTH AMERICA REGENERATION SERVICES LLC

D1369 d radiation curable secondary coating for optical fiber

A new radiation curable Secondary Coating for optical fibers is described and claimed wherein said composition comprises a Secondary Coating Oligomer Blend, which is mixed with a first diluent monomer; a second diluent monomer; optionally, a third diluent monomer; an antioxidant; a first photoinitiator; a second photoinitiator; and optionally a slip additive or a blend of slip additives; wherein said Secondary Coating Oligomer Blend comprises:α) an Omega Oligomer; andβ) an Upsilon Oligomer;wherein said Omega Oligomer is synthesized by the reaction ofα1) a hydroxyl-containing (meth)acrylate;α2) an isocyanate;α3) a polyether polyol; andα4) tripropylene glycol; in the presence ofα5) a polymerization inhibitor; andα6) a catalyst;to yield the Omega Oligomer;wherein said catalyst is selected from the group consisting of dibutyl tin dilaurate; metal carboxylates, including, but not limited to: organobismuth catalysts such as bismuth neodecanoate; zinc neodecanoate; zirconium neodecanoate; zinc 2-ethylhexanoate; sulfonic acids, including but not limited to dodecylbenzene sulfonic acid, methane sulfonic acid; amino or organo-base catalysts, including, but not limited to: 1,2-dimethylimidazole and diazabicyclooctane; triphenyl phosphine; alkoxides of zirconium and titanium, including, but not limited to Zirconium butoxide and Titanium butoxide; and Ionic liquid phosphonium salts; and tetradecyl(trihexyl)phosphonium chloride; andwherein said Upsilon Oligomer is an epoxy diacrylate.

Owner:DSM IP ASSETS BV

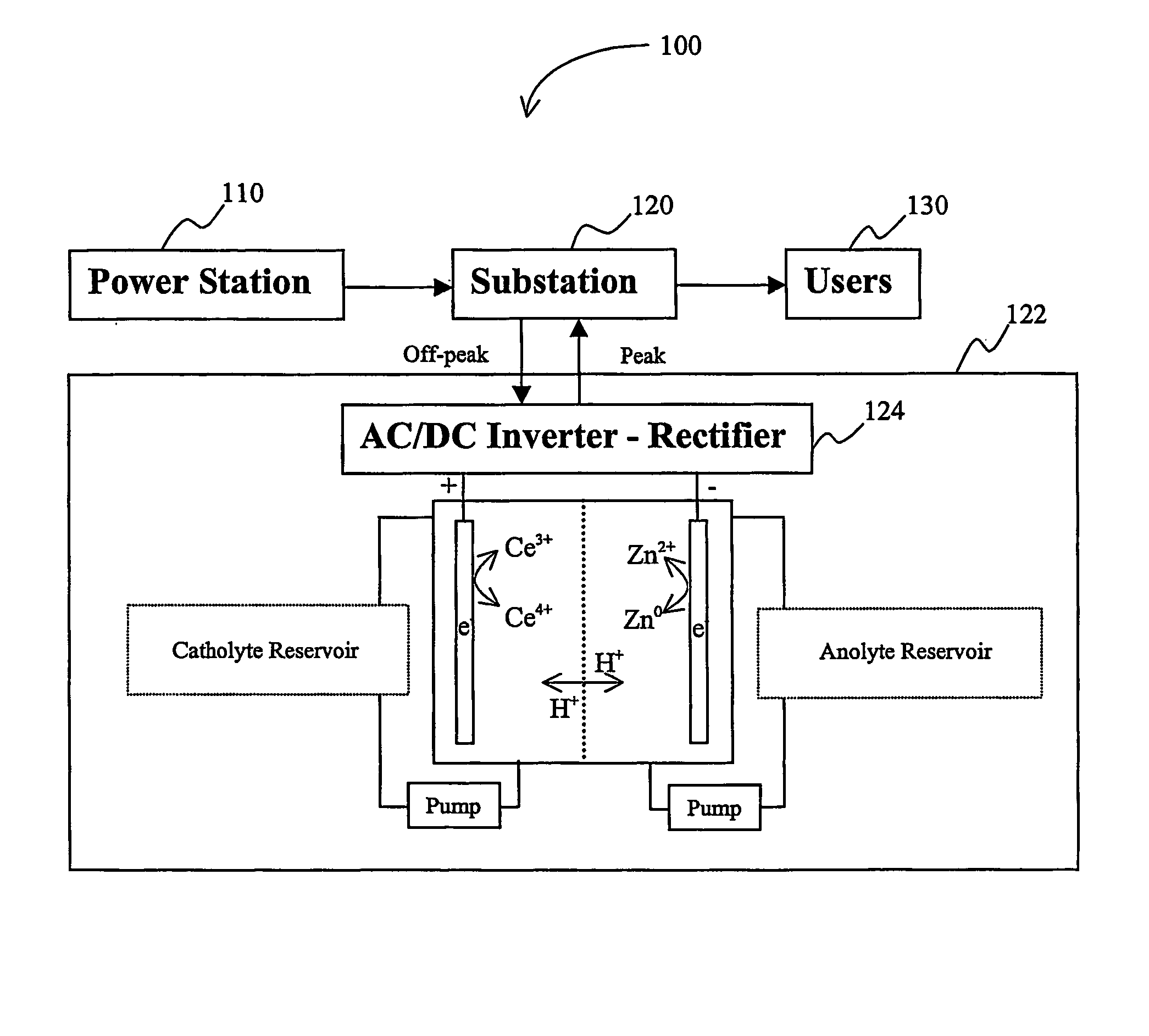

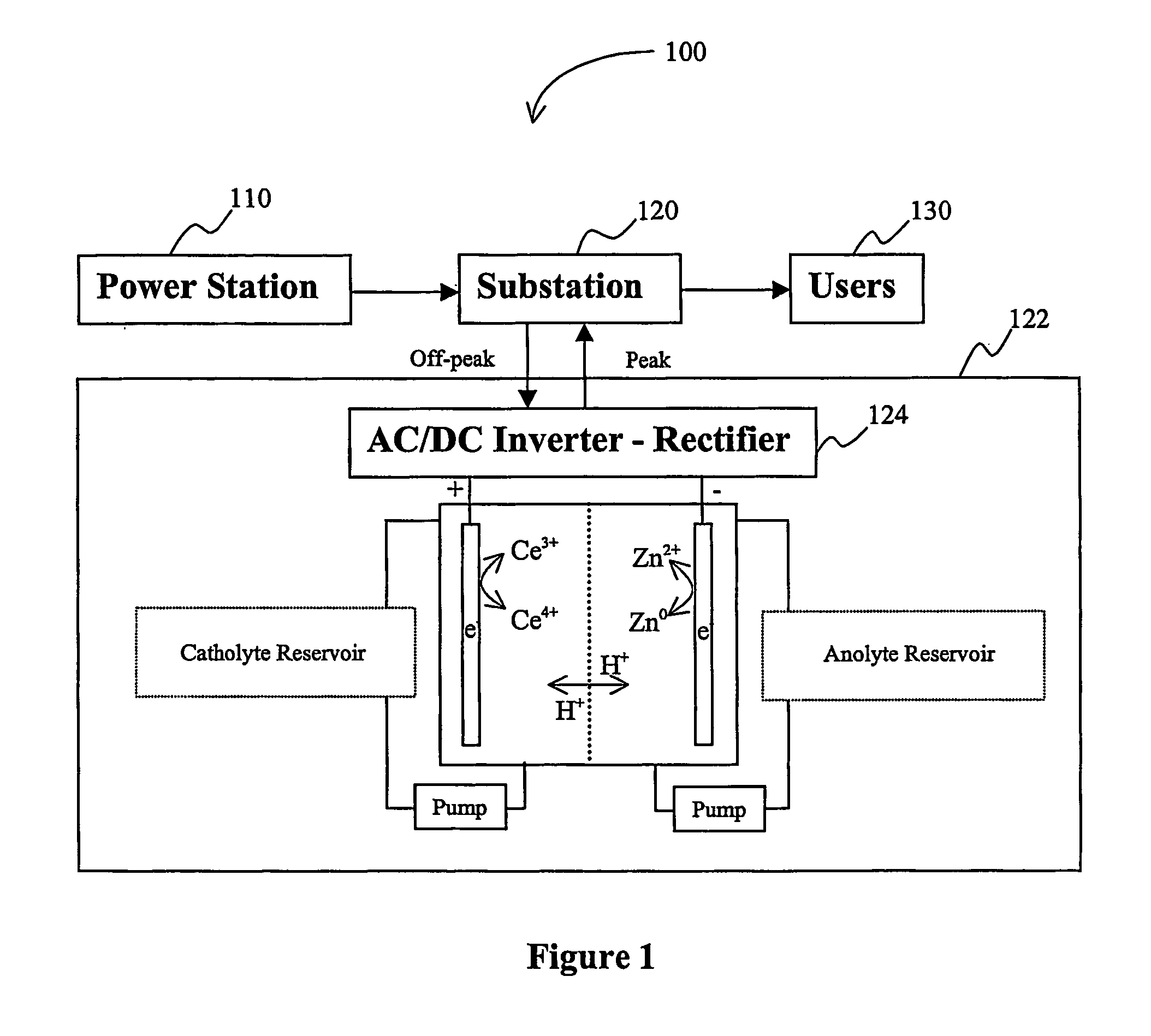

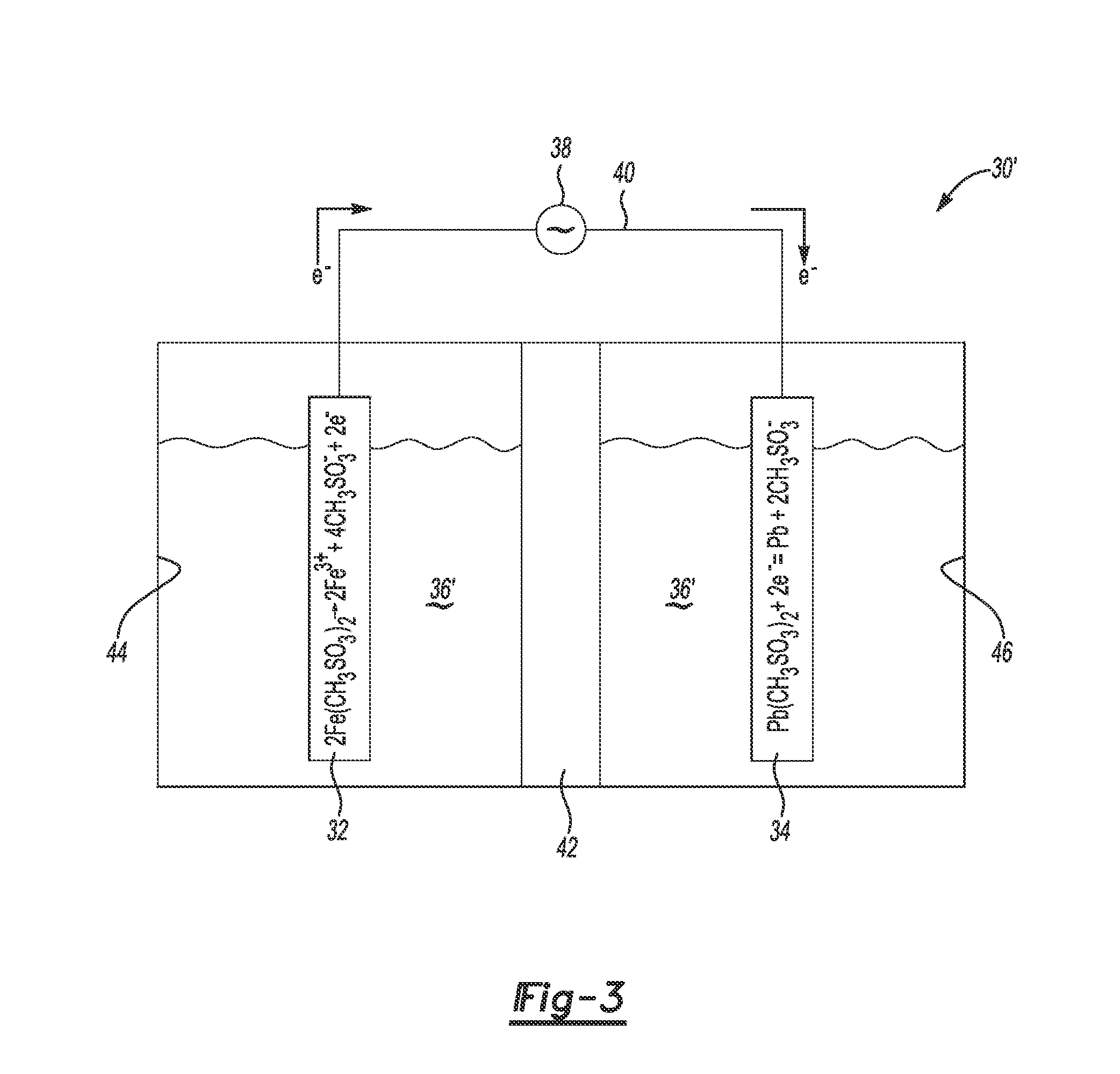

Load leveling battery and methods therefor

InactiveUS7270911B2Electrolyte moving arrangementsElectrolytic capacitorsMethane sulfonic acidCerium

A load leveling battery (122) comprising an electrolyte that includes a cerium zinc redox pair wherein preferred electrolytes are acid electrolytes, and most preferably comprise methane sulfonic acid. Contemplated load leveling batteries (122) have an open circuit voltage of at least 2.4 Volt per cell. Such batteries are useful at power grid substations (120) and commercial and industrial applications were large amounts of power are used. Preferred capacity is at least 100,000 kWh, more preferably 250,000 kWh.

Owner:PLURION LTD

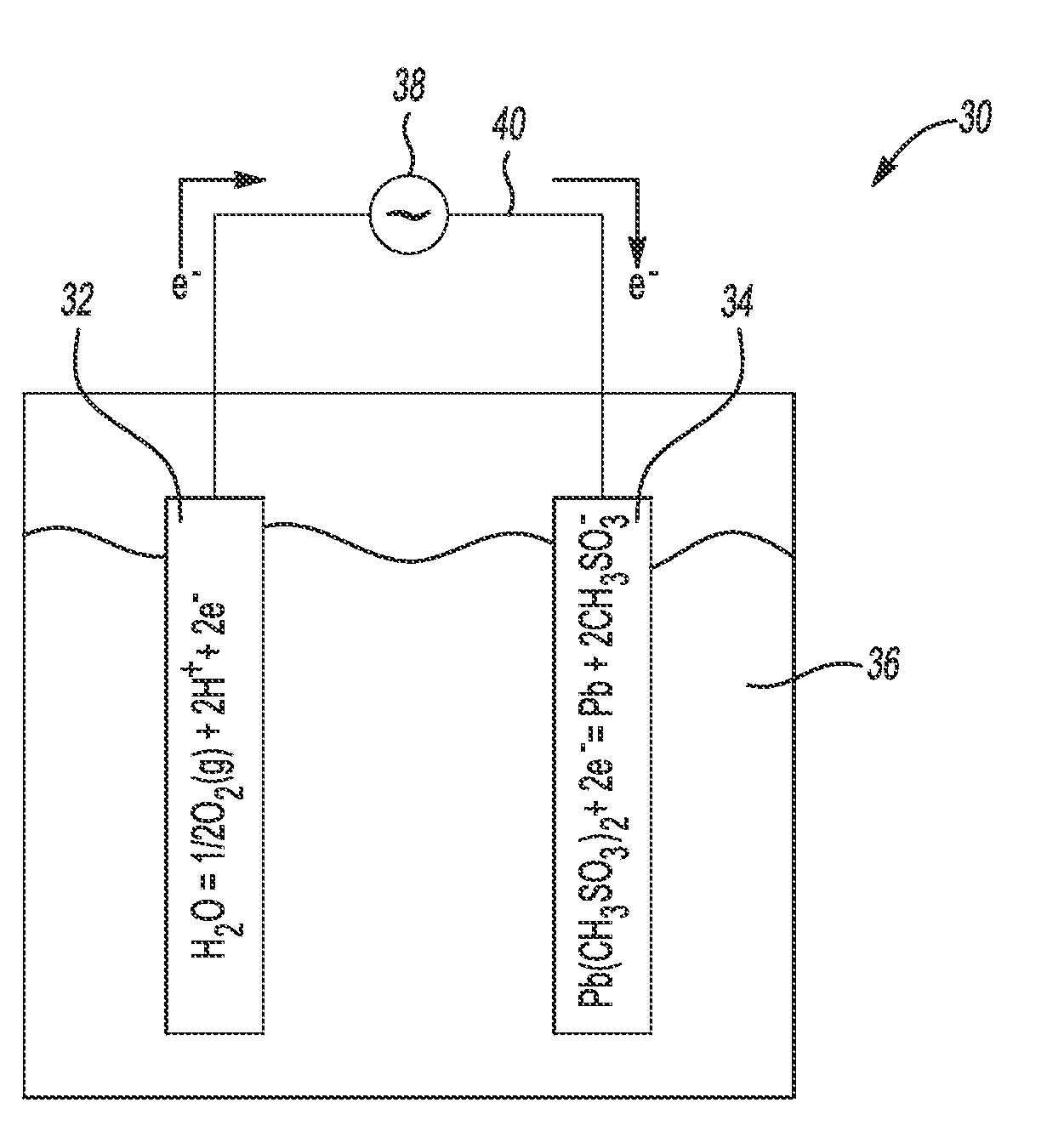

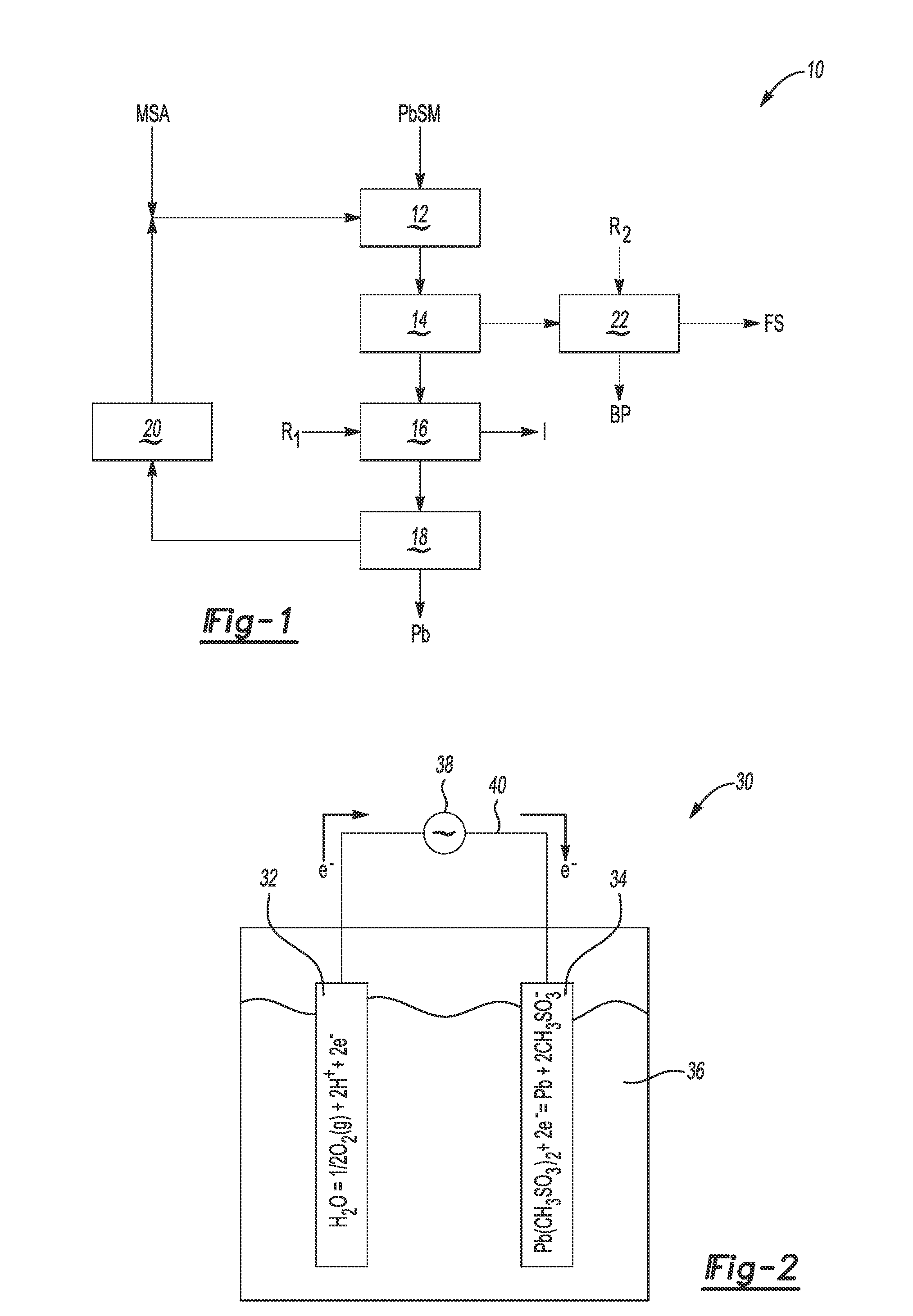

Recovering lead from a lead material including lead sulfide

In an example of a method for recovering lead from a lead material including lead sulfide, methane sulfonic acid is selected as a leaching acid for the lead material. The lead material is exposed to a solution including the methane sulfonic acid and i) ferric methane sulfonate or ii) oxygen, which leaches lead from the lead sulfide in the lead material, and generates a liquid leachate including a lead-methane sulfonate salt. The liquid leachate is purified, and lead is recovered from the purified liquid leachate using electrolysis.

Owner:THE UNIV OF BRITISH COLUMBIA

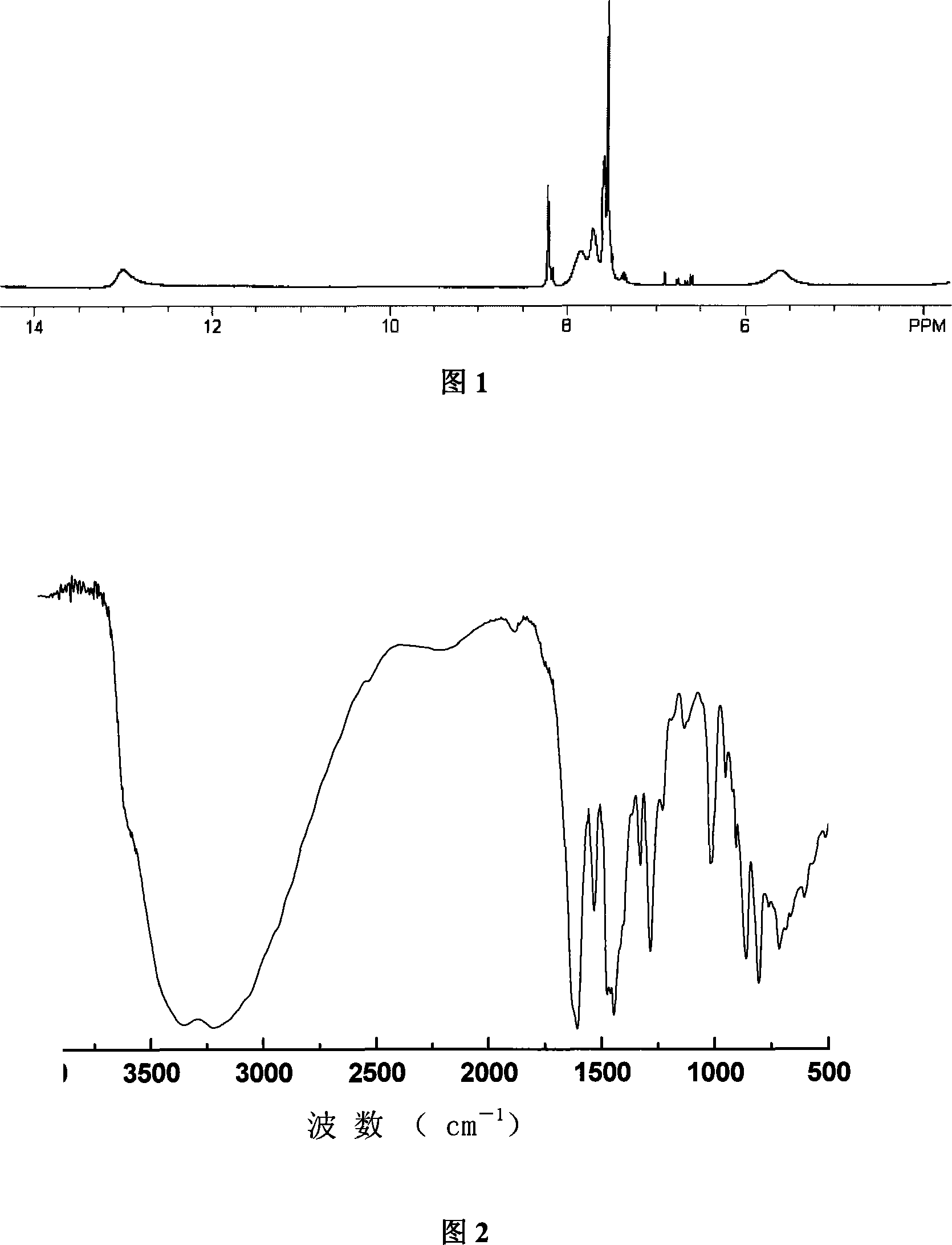

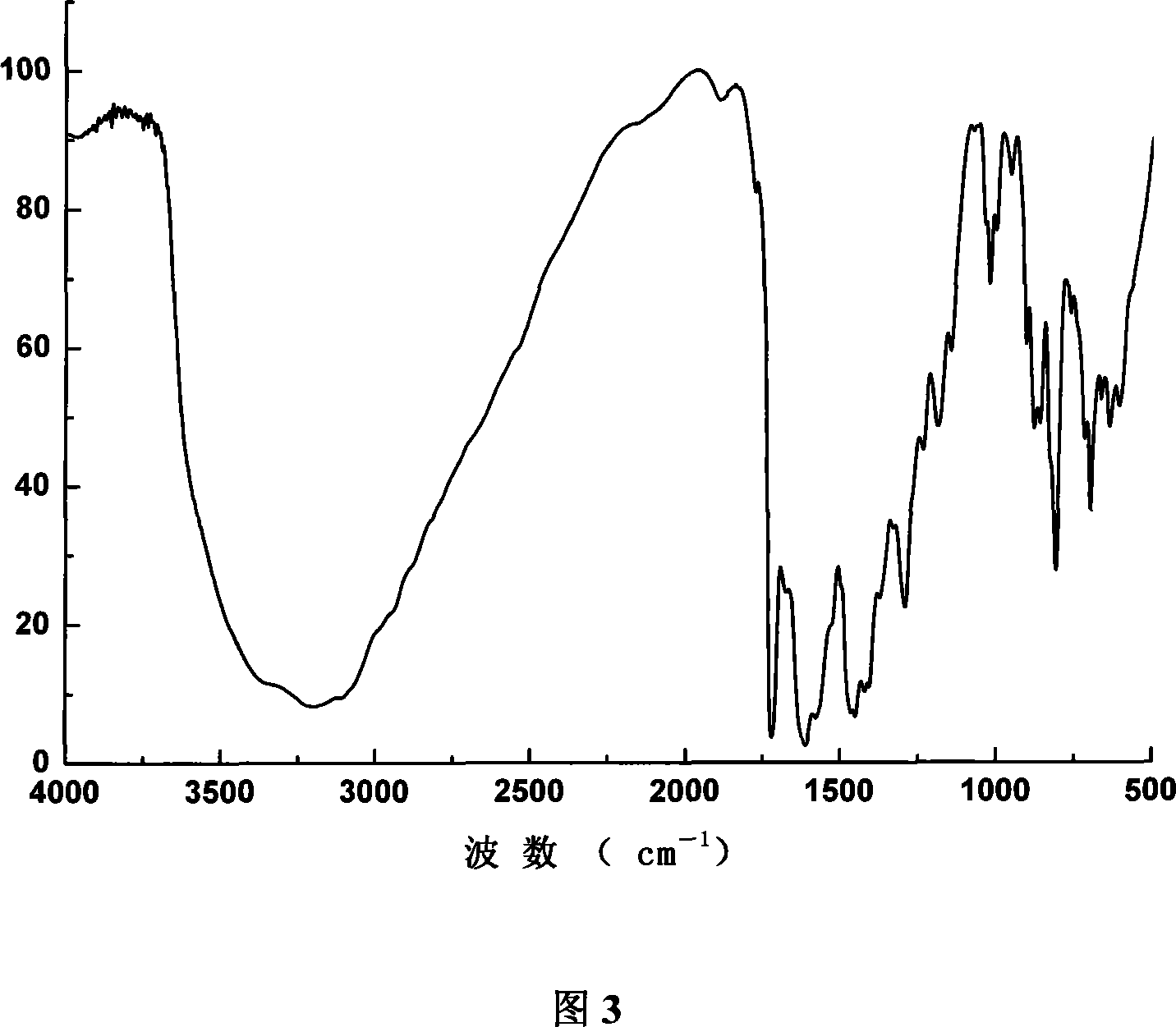

Production method for maleic anhydride modified polybenzimidazole crosslinked membrane

The invention relates to a preparation method of a maleic anhydride modified polybenzimidazole crosslinking membrane, which takes amino dibasic acid and aromatic tetraamine as monomer raw material and polyphosphoric acid as reaction medium and reaction is carried out for 5-30 hours at 150-220 DEG C under the nitrogen protection condition so as to obtain homopolymer containing amino polybenzimidazole, and takes the amino dibasic acid, nonaminonic dibasic acid and the aromatic tetraamine as the monomer raw materials so as to prepare copolymer of amino polyphosphoric under the same conditions. The prepared homopolymer and the copolymer of the polybenzimidazole have good dissolvability in solvents of dimethyl sulphoxide, N, N- dimethylacetamide, phosphate, vitriol and methane-sulforic acid, etc. and after the prepared homopolymer and the copolymer of the polybenzimidazole are dissolved in an organic solvent, reaction is carried out with the maleic anhydride to obtain maleic anhydride modified polybenzimidazole which goes through thermal crosslinking when casting into membrane, thereby obtaining the polybenzimidazole crosslinking membrane that has good mechanical property.

Owner:SHANGHAI JIAO TONG UNIV

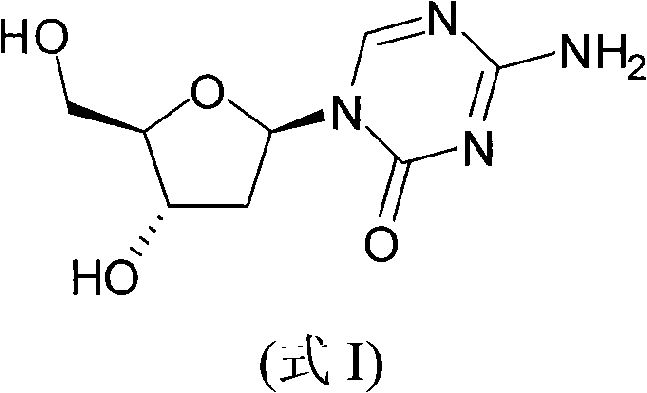

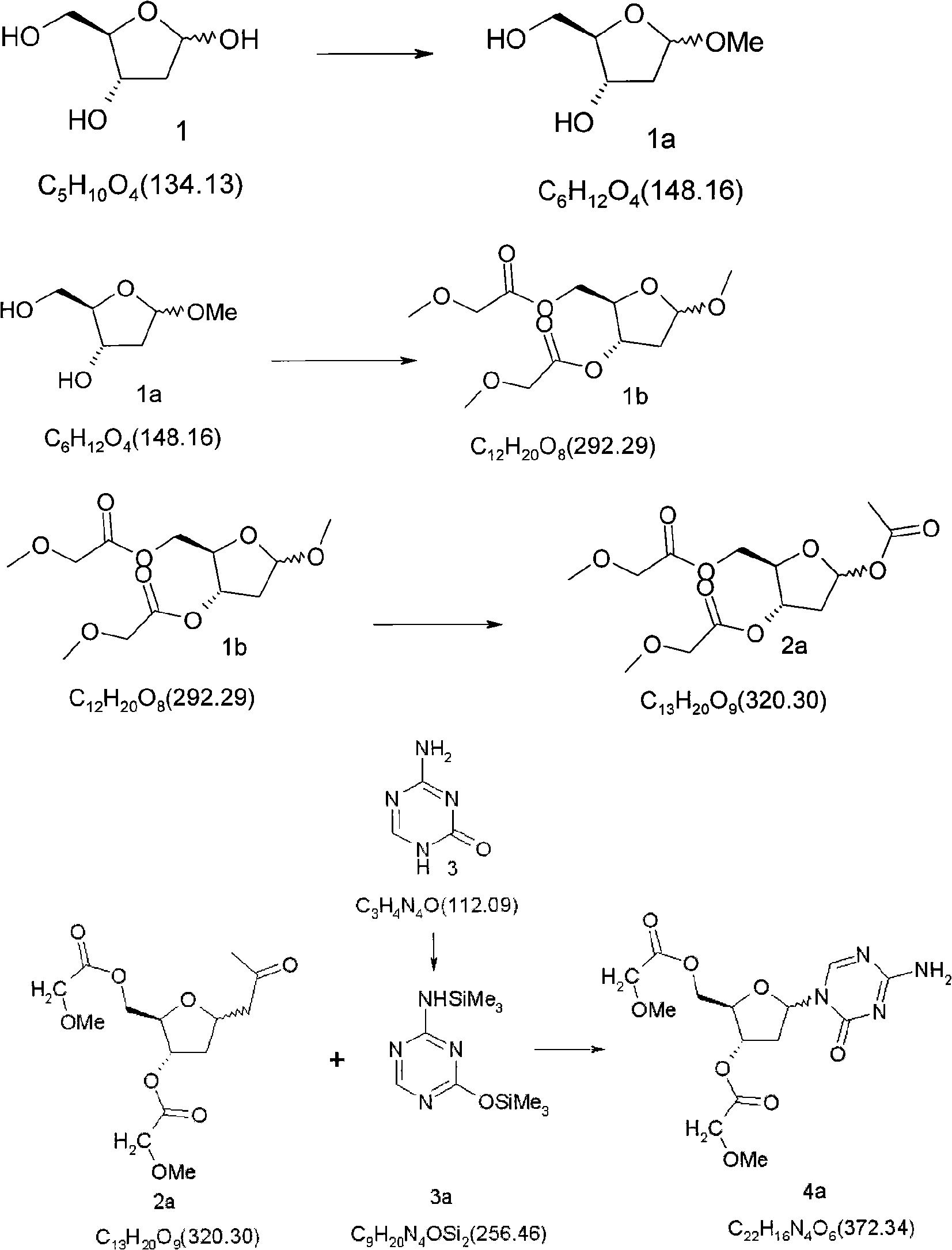

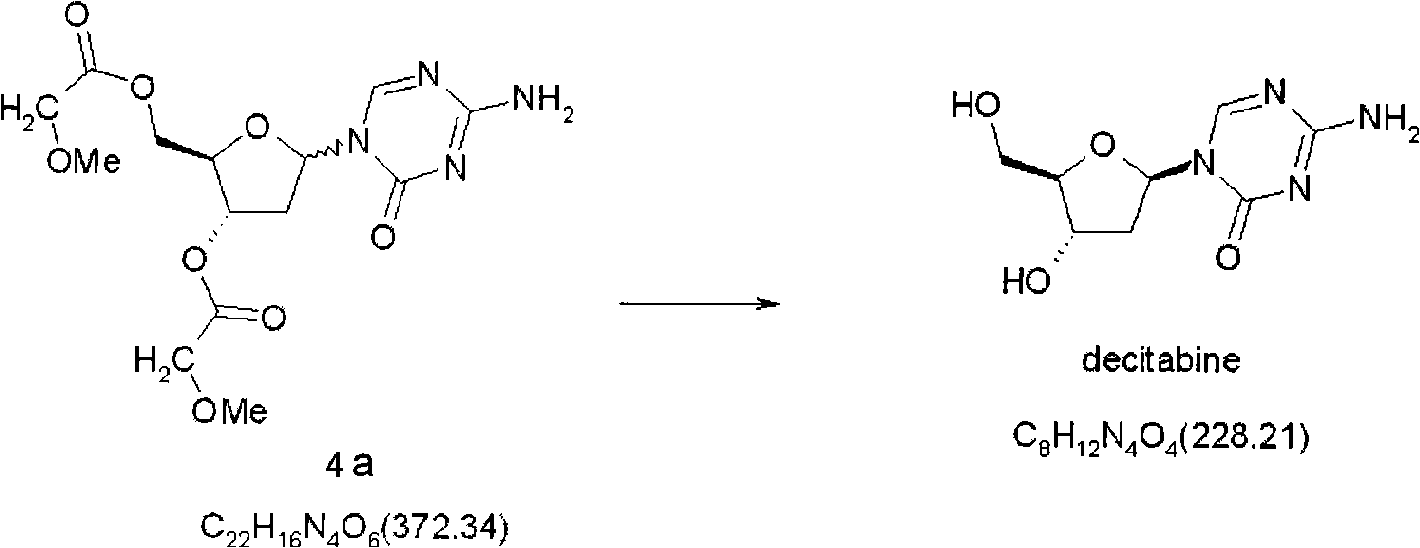

Synthetic process of decitabine

The invention relates to a method for preparing Decitabine. The particular proposal for solving the technical problem is as follows: 2-deoxidtion-D-ribose, 10 percent of HCL methanol solution, methoxyacetic acetic anhydride, HMDS, acetic anhydride, tri-silicyl tri-fluorine methane sulfonic acid ester, acetic acid amine, etc. are adopted as raw materials to synthesize the Decitabine; the target product of the Decitabine is obtained through the five steps of reactions, namely, methylation, acylation, trimethyl silication, ammoniation and deacylation with a total yield of above 18.4 percent and a product purity of above 99.7 percent.

Owner:GUIZHOU UNIV

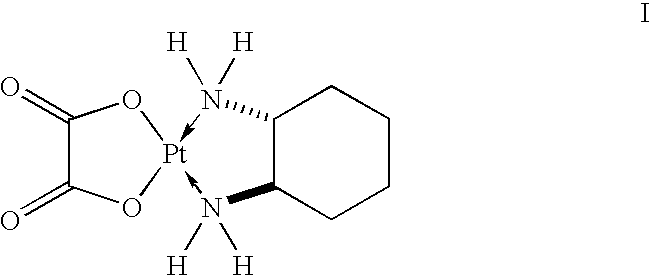

Ready-to-use oxaliplatin solutions

InactiveUS20060063833A1Not impair stability of solutionBiocideAnimal repellantsMethane sulfonic acidO-Phosphoric Acid

The invention relates to oxaliplatin solutions that also preferably contain sulfuric acid, phosphoric acid, methane sulfonic acid, ethane sulfonic acid, or para-toluene sulfonic acid. The solutions according to the invention are distinguished by high storage stability.

Owner:STADA ARZNEIMITTEL AG

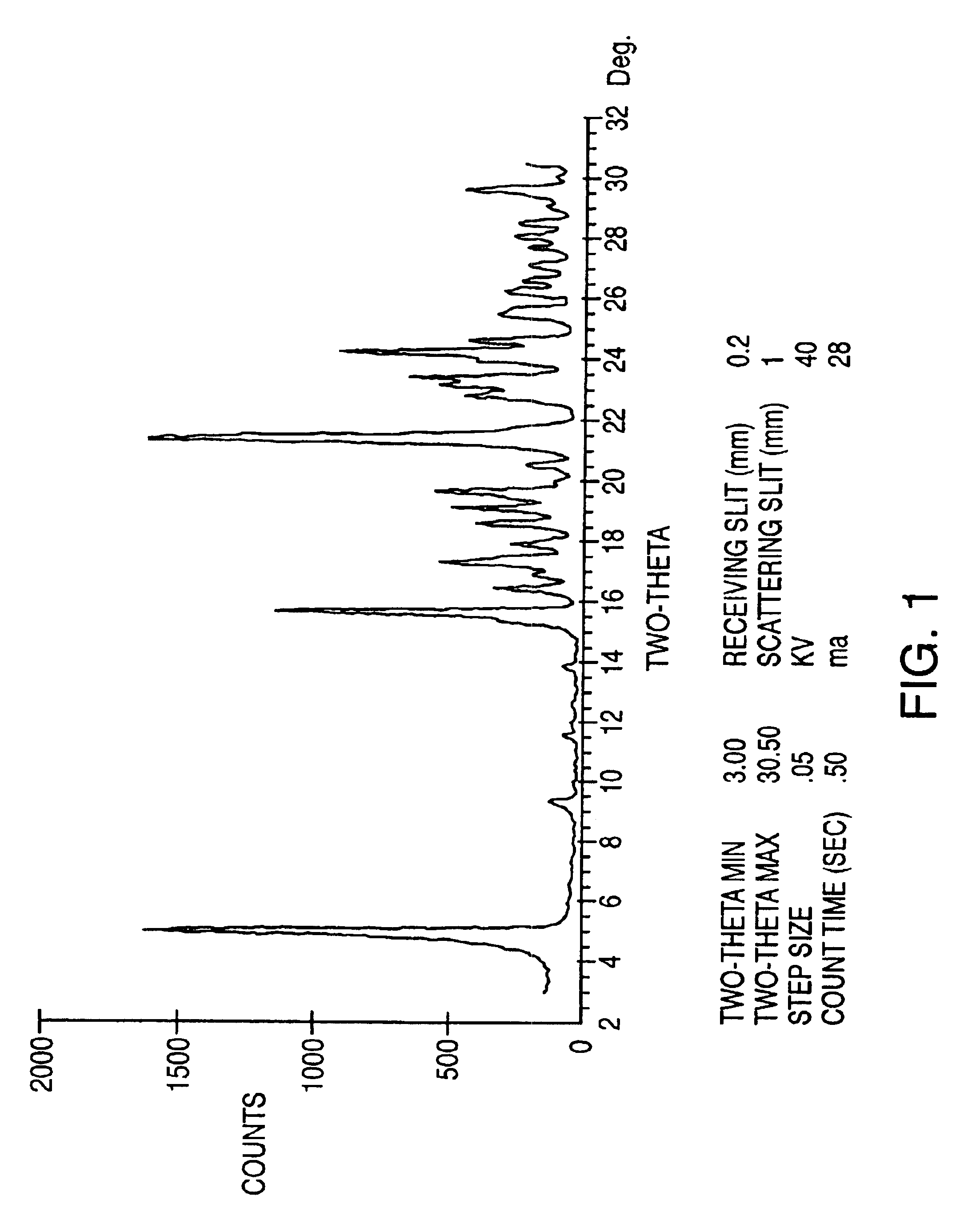

Stable Crystal Form of Imatinib Mesylate and Process for the Preparation Thereof

InactiveUS20070265288A1Stable and non-hygroscopicUseful in therapyOrganic active ingredientsBiocideMethane sulfonic acidPyridine

The invention relates to a stable, non hygroscopic alpha crystalline form of methane sulfonic acid addition salt of 4-(4-methyl piperazin-1yl methyl)-N-[4-methyl-3-(4-pyridin-3-yl) pyrimidin-2-yl amino)phenyl]-benzamide (imatinib mesylate). A process for the preparation of the crystalline form is also described.

Owner:CIPLA LTD

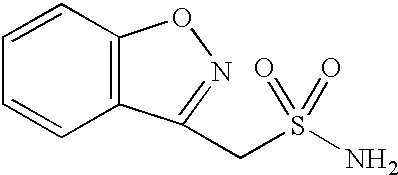

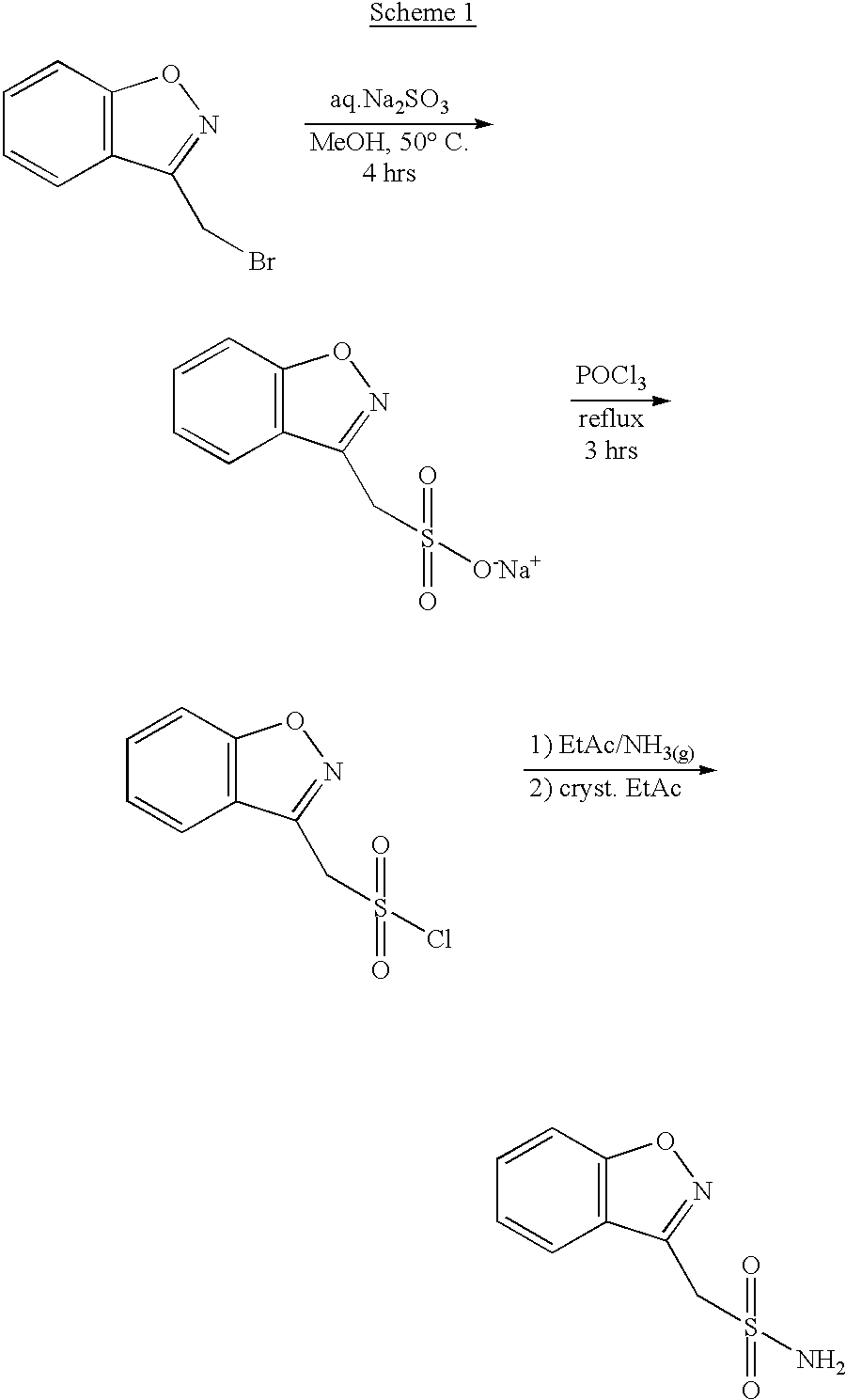

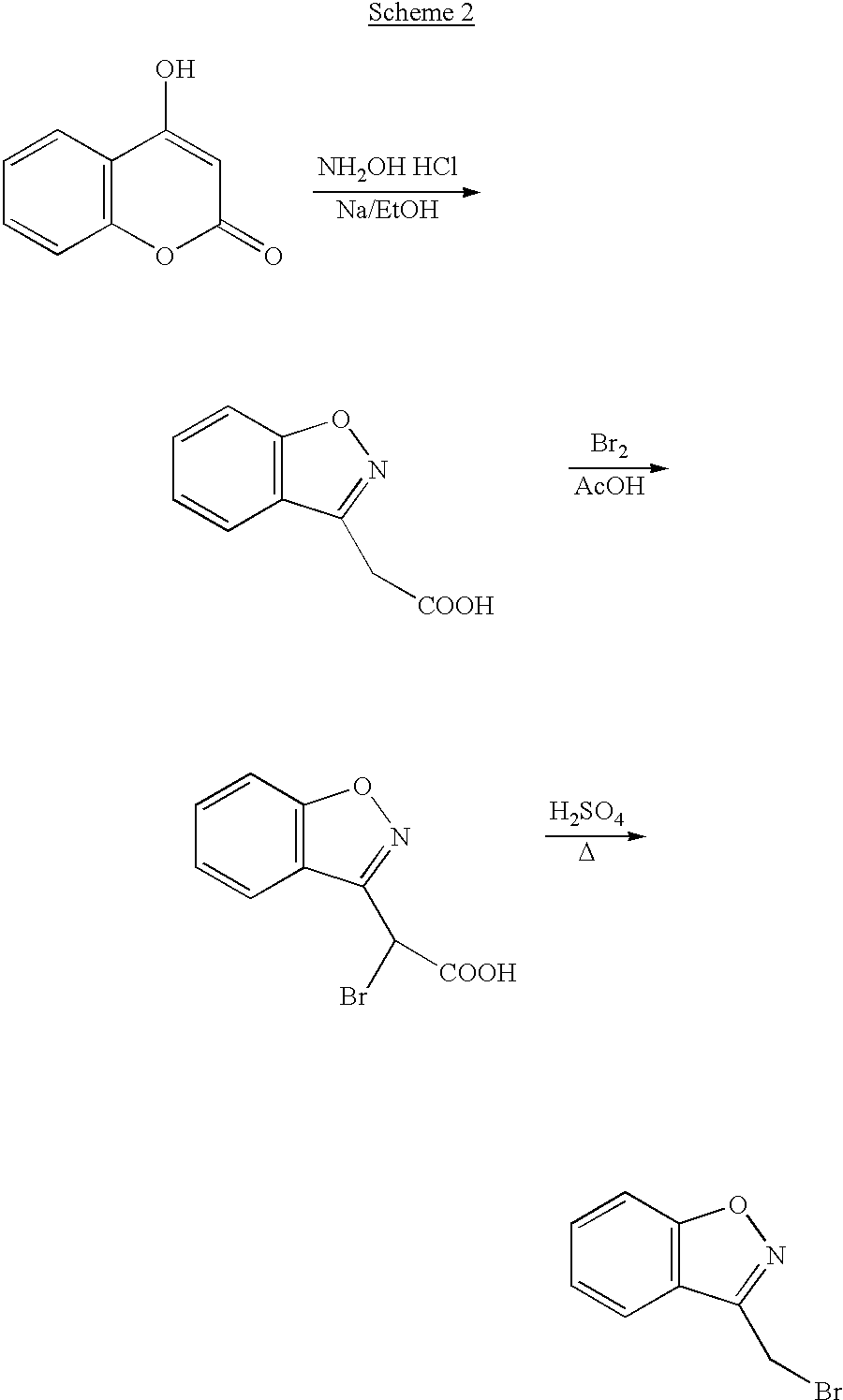

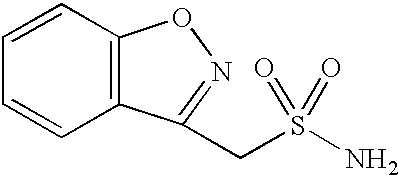

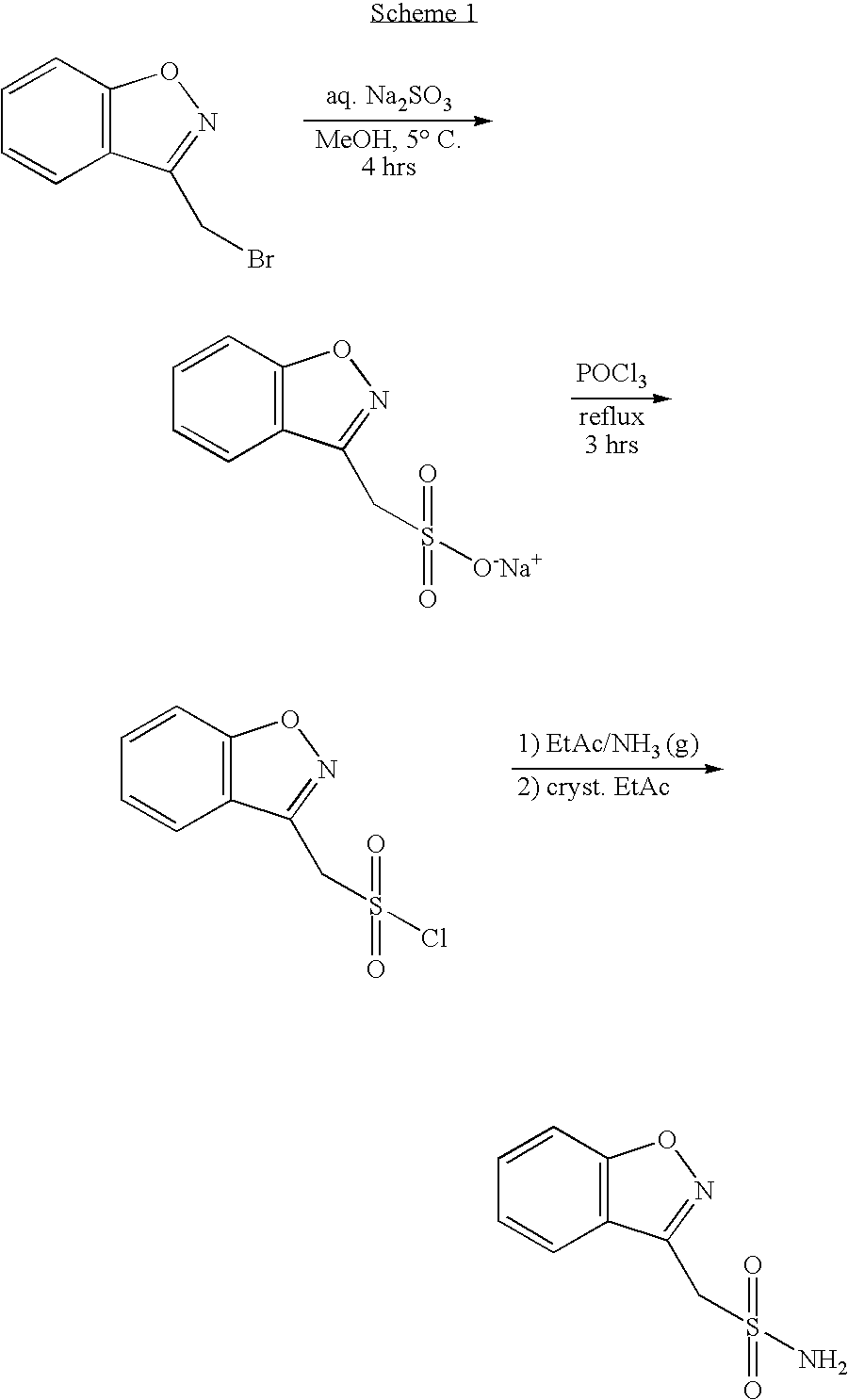

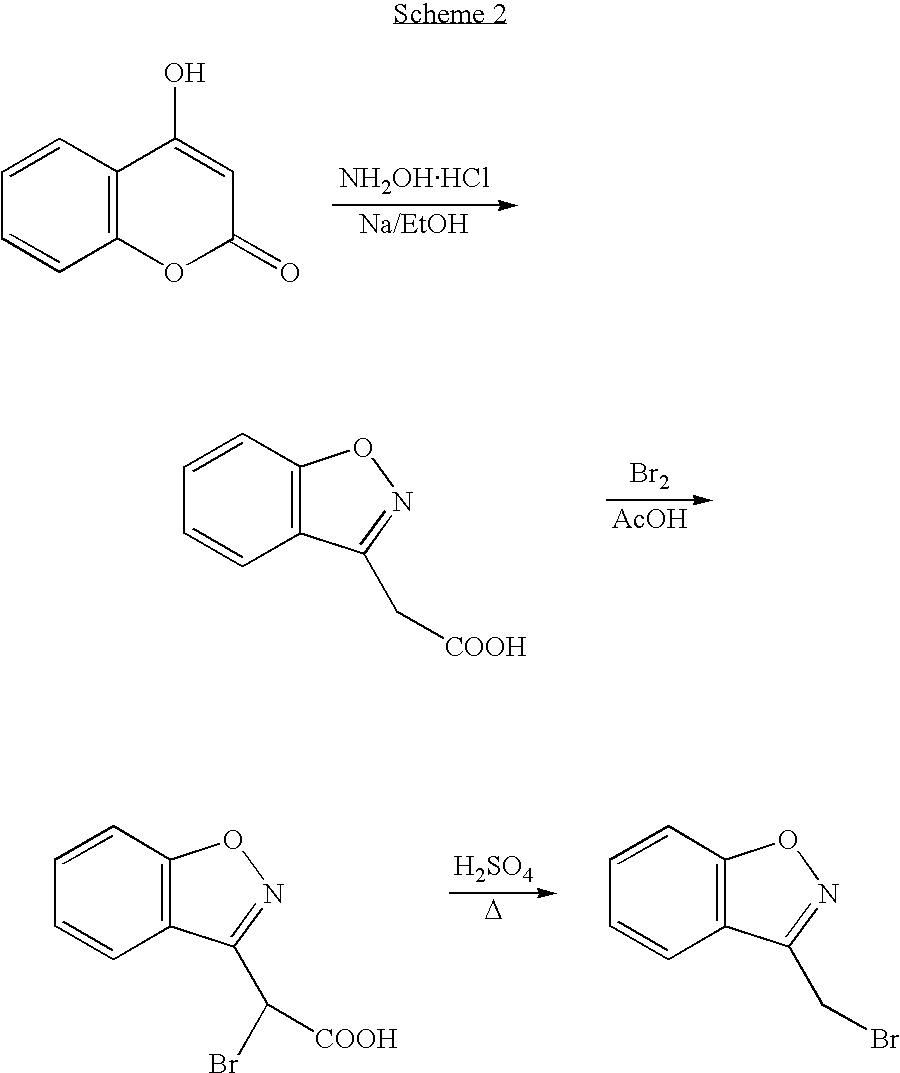

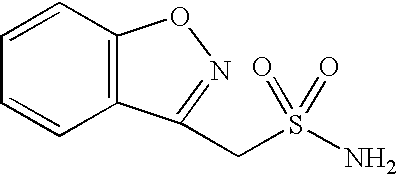

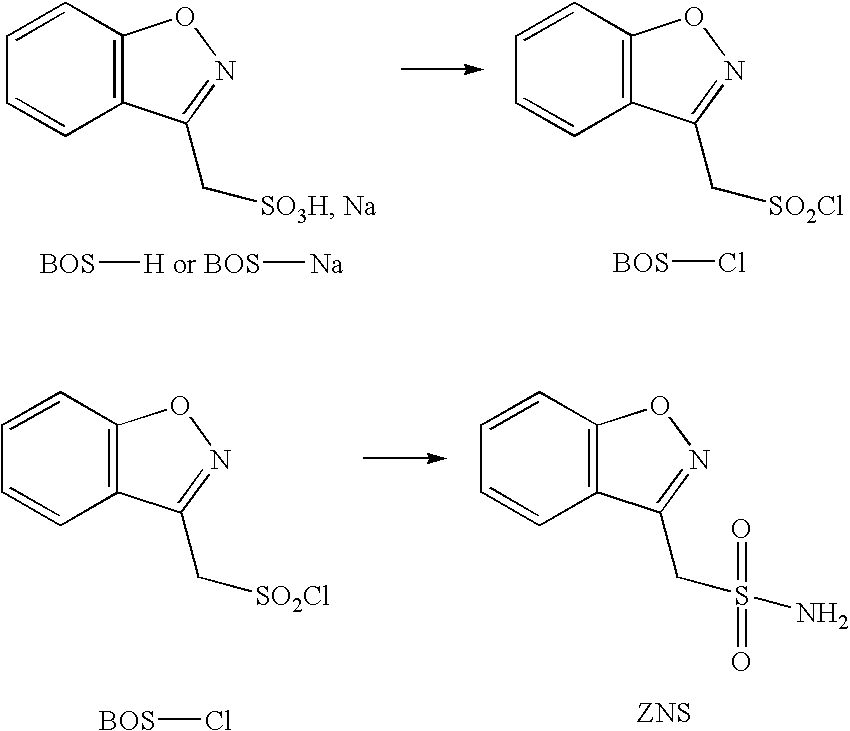

Process for the preparation of 1,2-benzisoxazole-3-acetic acid

InactiveUS20020183525A1High puritySpeed up the processOrganic chemistryAcetic acidMethane sulfonic acid

The present invention provides a process for preparing 1,2-benzisoxazole-3-acetic acid, comprising the step of reacting 4-hydroxy-coumarin with hydroxyl-amine in the presence of a base. The present invention further provides a process for preparing a salt of benzisoxazole methane sulfonic acid, comprising the steps of 1) sulfonating 1,2-benzisoxazole-3-acetic acid using chlorosulfonic acid in a solvent mixture comprising methylene chloride and sodium hydroxide; and 2) isolating the salt of benzisoxazole methane sulfonic acid.

Owner:TEVA PHARM USA INC

Silver-graphitic electrical contact composite plating layer and method of preparing the same

InactiveCN101256903AEvenly distributedFlat surfaceContact materialsConductive materialAdditive ingredientMetallic materials

Silver -black lead electrical contact composite plating and manufacture method thereof, which belongs to metallic material technology field. The steps are: confecting compound plating solution, black lead granule dispersing, and substrate preprocess, compound plating solution ingredient: methane sulfonic acid silver 0.05M / L, succinimide 0.15M / L-1.5M / L, composite plating. boracic acid 0.5M / L-0.5M / L, black lead content in solution 2g / L-50g / L. The composite plating is made up of silver and black lead, wherein the black lead volume percent is: 1-15%, silver volume fraction 85%-99%, contact resistance 1.2-2m Omega, hardness 70-100Hv, density more than 99.9%. The present invention plating solution is protection environment and non-toxic; the ultrasonic energy promoting adequate distribution of black lead granule, the produced composite plating has smooth surface and high density.

Owner:SHANGHAI JIAO TONG UNIV

Sulfonation method for zonisamide intermediate in zonisamide synthesis and their novel crystal forms

The present invention relates to a novel sulfonation of an intermediate of zonisamide. The sulfonation processes using chlorosulfonic acid as well as acetic anhydride and sulfuric acid in an organic solvent are disclosed. Crystalline forms of benzisoxazole methane sulfonic acid (BOS-H) and its salts (BOS-Na, BOS-Ca, and BOS-Ba) and their novel preparation processes are disclosed.

Owner:TEVA PHARM USA INC

Method for treating a subterranean formation

Acidizing methods for subterranean formations formed of predominantly siliceous material as well as acidizing compositions. Some methods include injecting into a predominantly siliceous subterranean formation, an aqueous acidic mixture formed by blending an aqueous liquid, a fluoride source, and an effective amount of an alkane sulfonic acid, preferably methane sulfonic acid, to adjust the pH of the fluid where the alkane sulfonic acid where the alkane group may be an unbranched, a branched or a cyclic alkyl residue. Hydrofluoric acid (HF) may not be added to the fluid in some embodiments as the fluoride source, such as the case for an HF free fluid, and, in some instances, hydrochloric acid is not added to the fluid to adjust pH. Also described are compositions containing an aqueous acidic mixture formed by blending an aqueous liquid, a fluoride source, and an effective amount of an alkane sulfonic acid to adjust pH.

Owner:SCHLUMBERGER TECH CORP

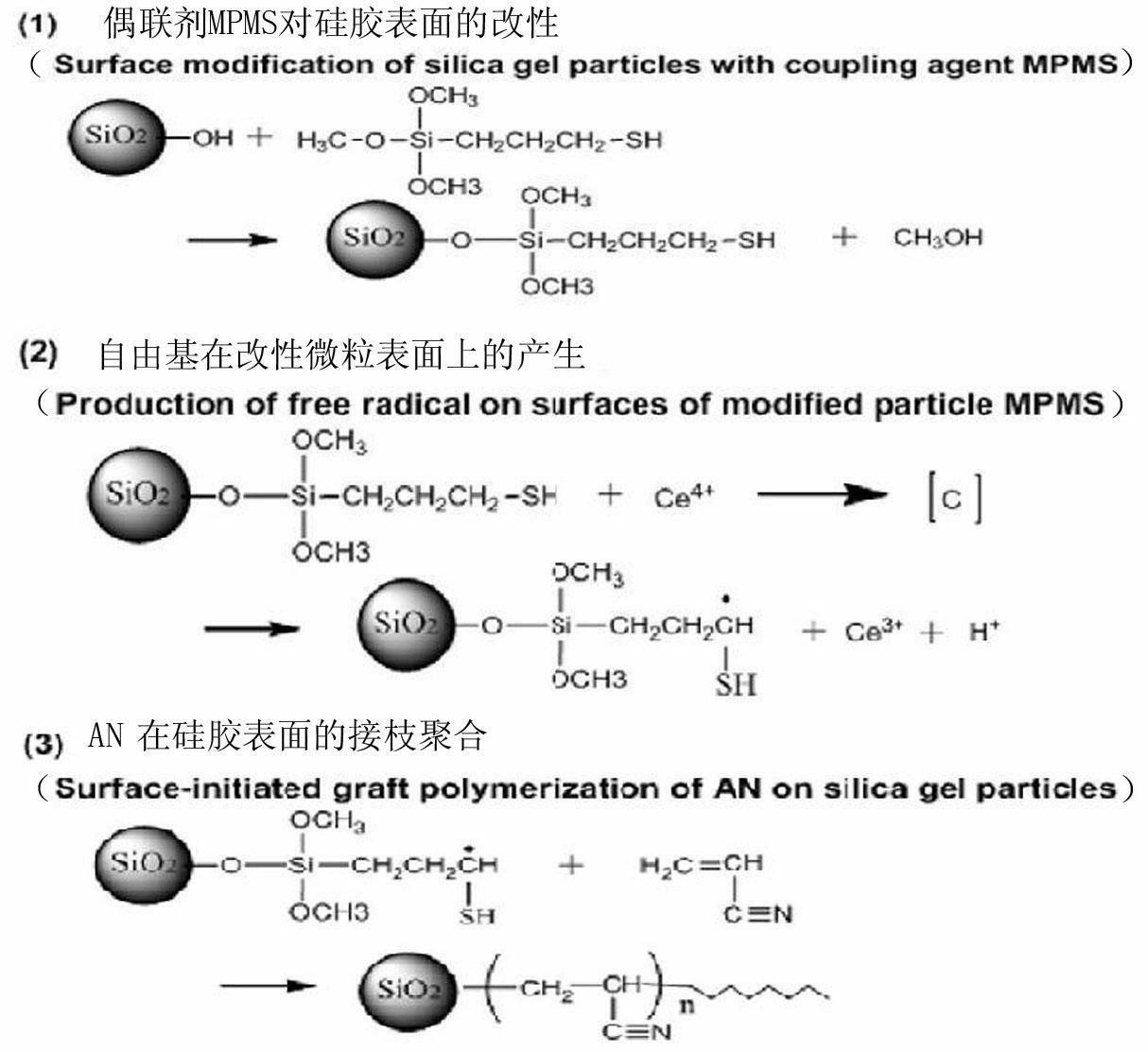

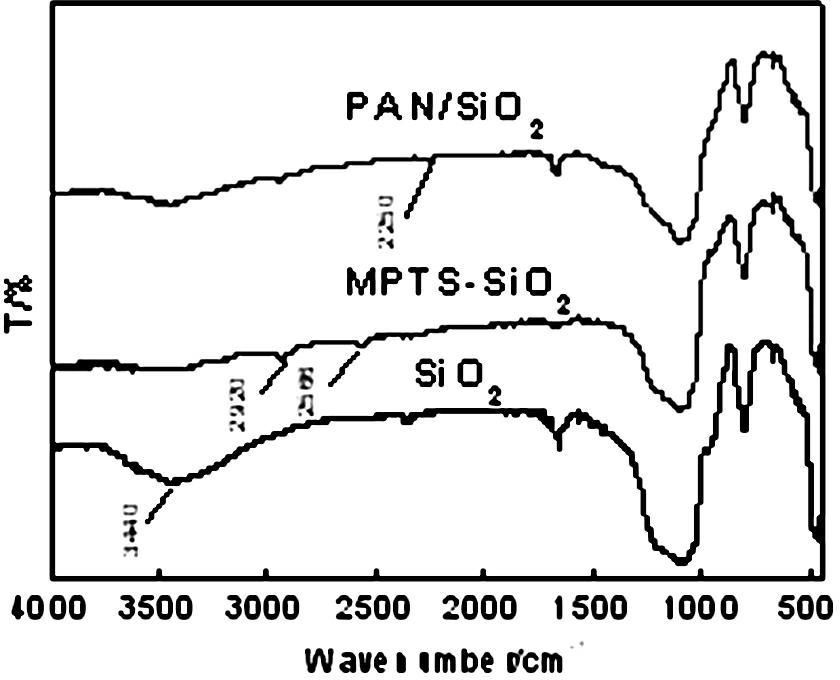

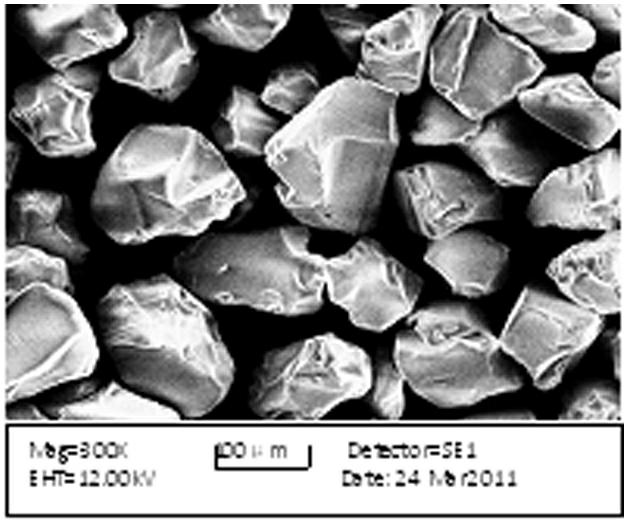

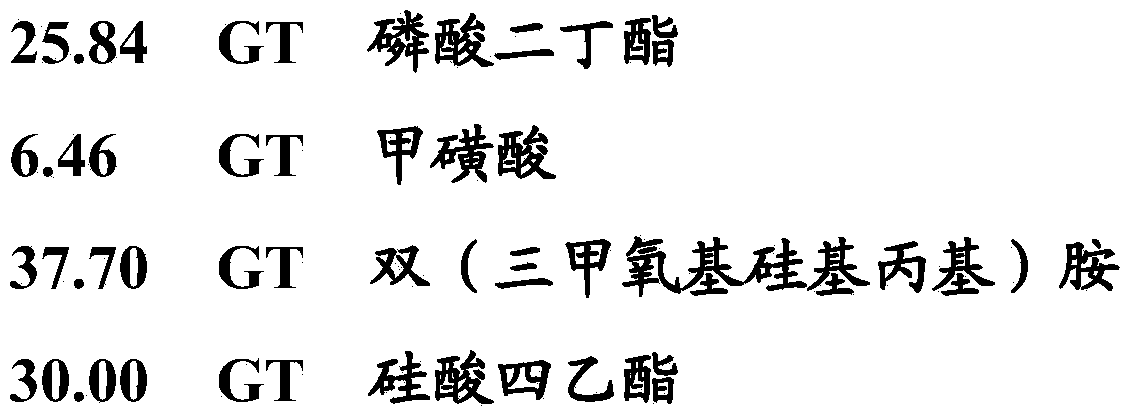

Method for realizing efficient graft polymerization of acrylonitrile on surface of silica gel microparticles by utilizing mercapto-Ce(IV) salt redox initiation system

InactiveCN102443120AGraft polymerization is effectiveIncrease the degree of graftingSilanesAcrylonitrile

The invention discloses a method for realizing efficient graft polymerization of acrylonitrile on the surface of silica gel microparticles by utilizing a mercapto-Ce(IV) salt redox initiation system. The method comprises the following steps of: (1) surface modification of silica gel by using a mercapto-containing coupling agent: reacting silica gel microparticles in a methane sulfonic acid aqueous solution, then adding activated silica gel microparticles to a toluene solvent, and adding gamma-mercaptopropyl trimethoxy silane (MPMS) as a coupling agent to prepare modified silica gel microparticles MPMS-SiO2 containing mercapto on the surface; and (2) graft polymerization of acrylonitrile: adding the modified microparticles MPMS-SiO2, DMF (dimethyl formamide) and AN (acrylonitrile) monomer to a four-neck flask, introducing nitrogen for 30 min, then adding a water solution dissolved with ammonium cerous sulfate and concentrated sulfuric acid, and reacting to obtain grafted microparticlesPAN / SiO2. In the method disclosed by the invention, the mercapto-Ce(IV) salt redox initiation system is utilized to initiate graft polymerization, and the active spots are located on the surface of acarrier, thus the method has high grafting degree and is a high-efficiency surface-initiated grafting method.

Owner:ZHONGBEI UNIV

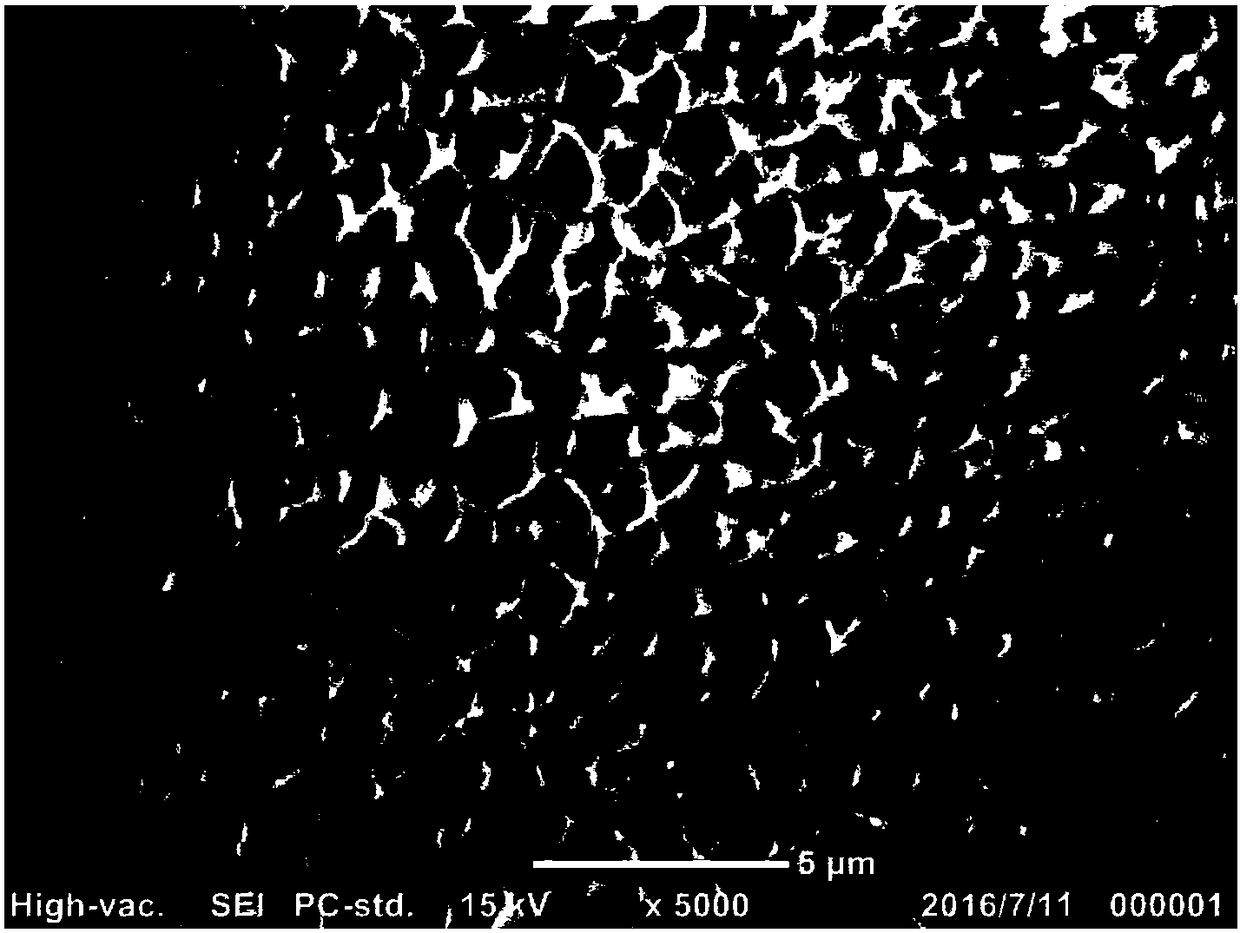

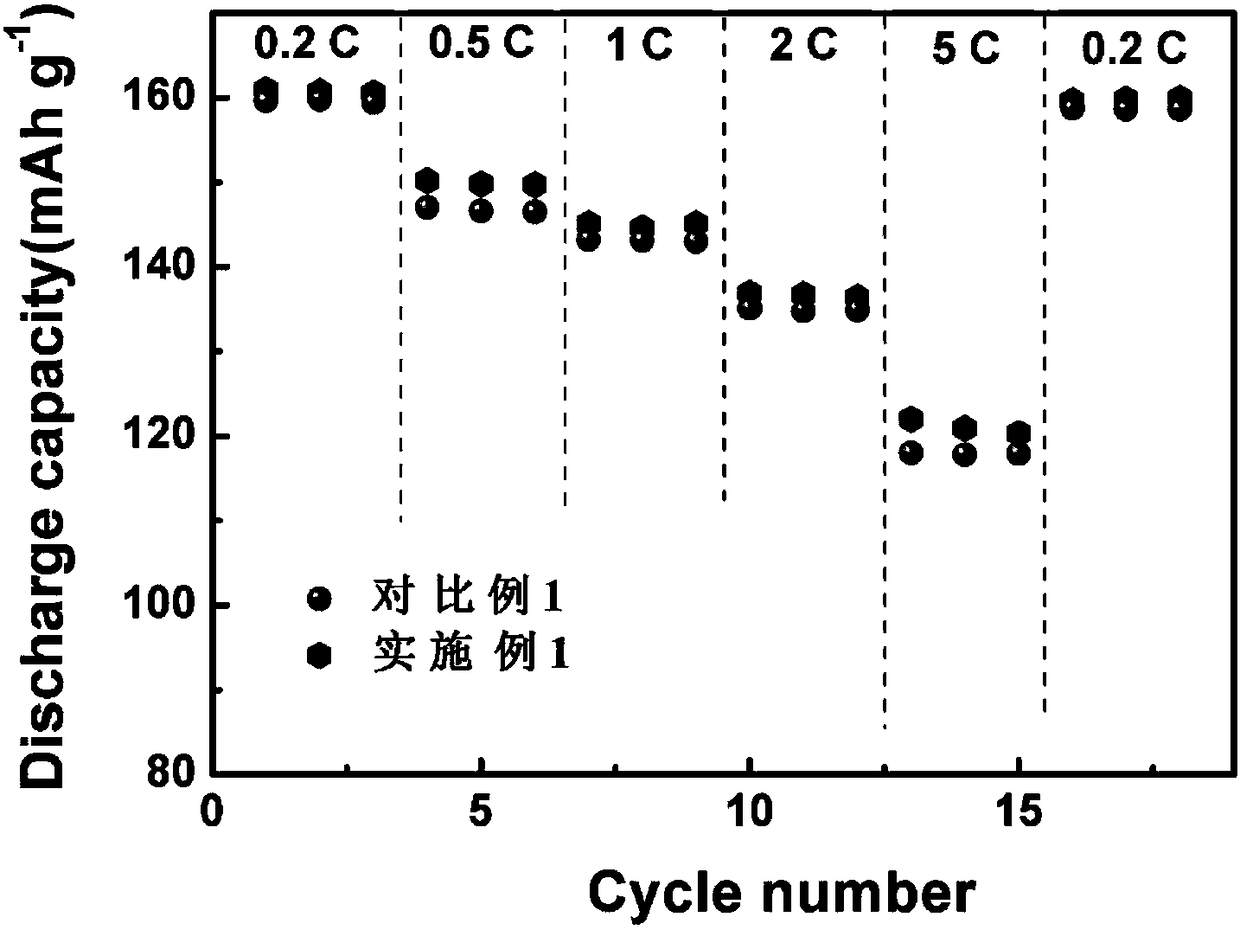

PEEK (polyether-ether-ketone) porous separator for lithium ion battery as well as preparation and application of PEEK porous separator

ActiveCN108134032AImprove thermal stabilityImprove wettabilitySecondary cellsCell component detailsPorosityOperability

The invention discloses a preparation method of a lithium-ion battery separator with good mechanical performance and high-temperature stability and an application of the lithium-ion battery separatorin a lithium-ion battery. A porous separator is prepared from heat-resisting macromolecule resin PEEK (polyether-ether-ketone) as a raw material and a sulfuric acid and methane sulfonic acid mixed solution as a solvent with a phase inversion method. The prepared porous separator is high in heat-resisting class, high in porosity and good in affinity with an electrolyte and facilitates improvement of rate capability of the battery, and safety performance of the battery is improved; compared with a traditional high-temperature melt-blowing film formation method, the phase inversion method for preparing the PEEK porous separator is simple in process, low in cost and high in operability, and further popularization and application are facilitated. The prepared PEEK porous ionic conduction film has the characteristics of good wettability, high heat-resisting class and the like and is one separator material with great application prospect.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Process for the preparation of 1,2-benzisoxazole-3-acetic acid

InactiveUS6677458B2High puritySpeed up the processOrganic chemistryMethane sulfonic acidAcetic acid

The present invention provides a process for preparing 1,2-benzisoxazole-3-acetic acid, comprising the step of reacting 4-hydroxy-coumarin with hydroxyl-amine in the presence of a base. The present invention further provides a process for preparing a salt of benzisoxazole methane sulfonic acid, comprising the steps of 1) sulfonating 1,2-benzisoxazole-3-acetic acid using chlorosulfonic acid in a solvent mixture comprising methylene chloride and sodium hydroxide; and 2) isolating the salt of benzisoxazole methane sulfonic acid.

Owner:TEVA PHARM USA INC

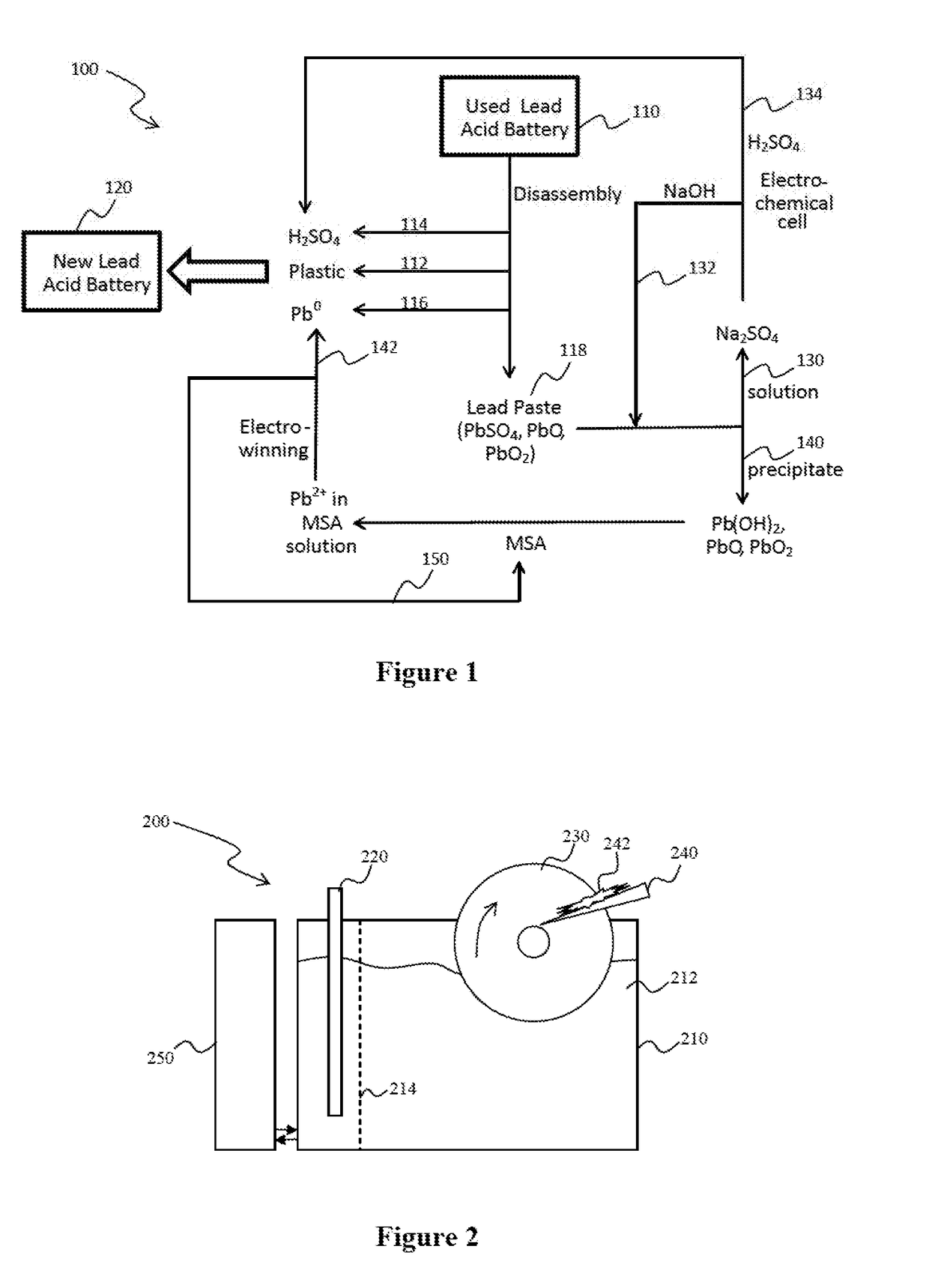

Closed Loop Systems and Methods for Recycling Lead Acid Batteries

A closed loop electrochemical process of recovery of high-purity lead uses continuous formation of adherent lead on a cathode from an electrolyte that is used to dissolve desulfated lead paste. Preferred cathodes include aluminum containing cathodes that are operated in methane sulfonic acid to produce a micro- or nanoporous mixed matrix metallic composition and lead dioxide formation at the anode is avoided using appropriate anode configurations or operating conditions

Owner:AQUA METALS INC

Stripper for cured negative-tone isoprene-based photoresist and bisbenzocyclobutene coatings

InactiveUS7183245B2Organic detergent compounding agentsSurface-active detergent compositionsMethane sulfonic acidPhotoresist

Owner:KMG ELECTRONICS CHEM

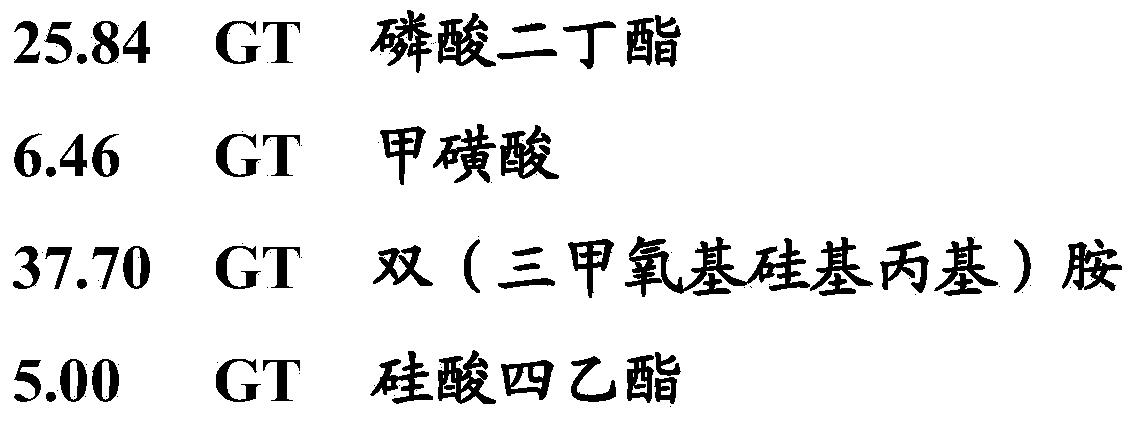

Cold-box binding agent systems and mixtures for use as additives for such binding agent systems

ActiveCN104114614AExtended shelf lifeGood storage stabilityLamination ancillary operationsFoundry mouldsMethane sulfonic acidPolymer science

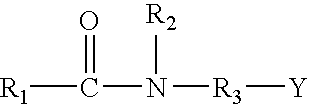

A description is provided of a mixture which is preparable by allowing the reaction of a premixture of (av), methanesulfonic acid (bv), one or more esters of one or more phosphorous-oxygen acids and (cv) one or more silanes. The invention also concerns the use of said mixtures as additives for the polyisocyanate component of a two-component binding agent system for preparation of a polyurethane resin. The invention further concerns a solution containing polyisocyanate for use as a component of a molding material binding agent system, and the use of a solution containing polyisocyanate as the polyisocyanate component of a two-component binding agent system for preparation of a polyurethane resin and corresponding two-component binding agent systems for preparation of a polyurethane resin.

Owner:HUTTENES ALBERTUS CHEM WERKE

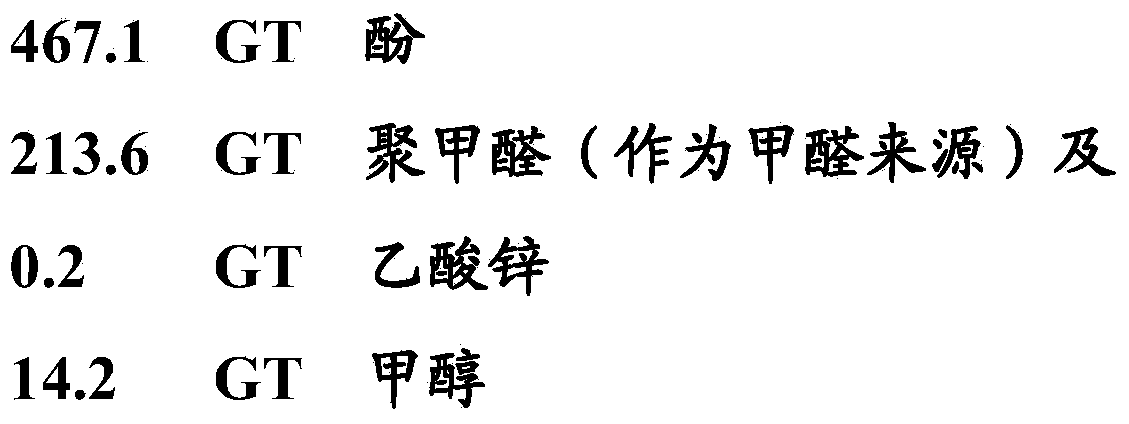

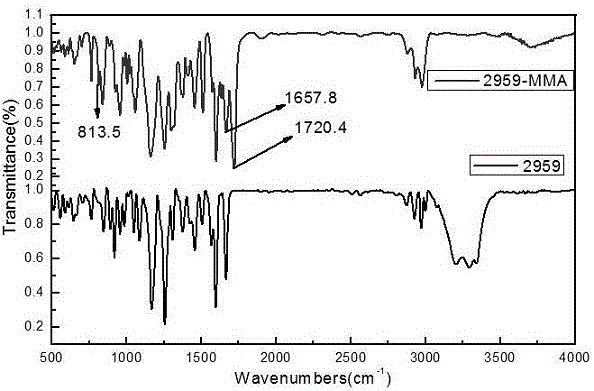

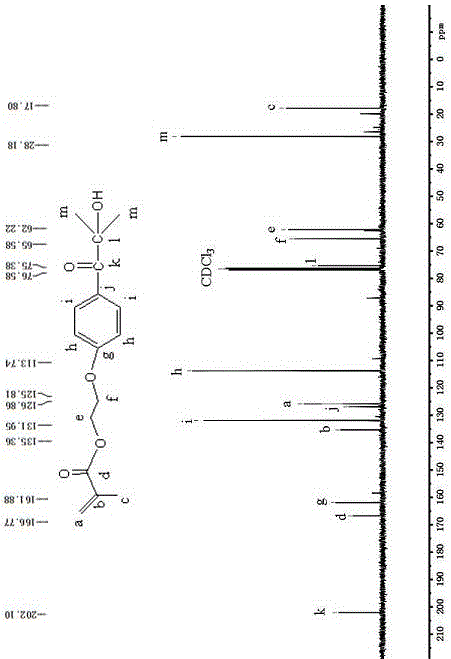

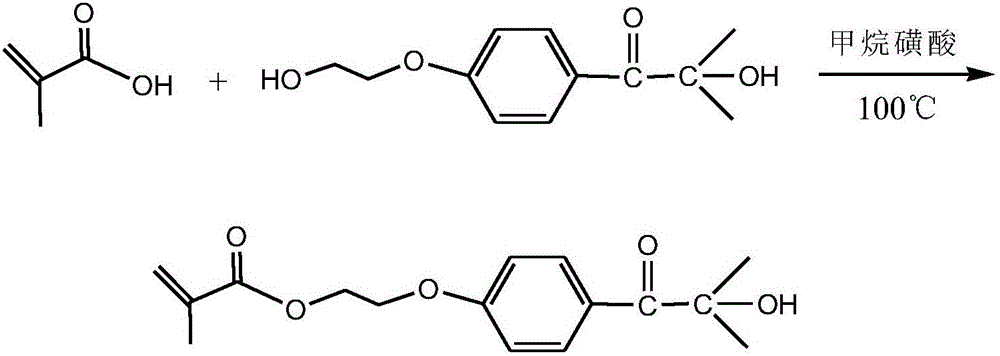

Method for preparing polymerizable photoinitiators

InactiveCN105859551AImprove migration abilityLow mobilityOrganic compound preparationCarboxylic acid esters preparationHydroxybenzoate EthersAdhesive

The invention discloses a method for preparing polymerizable photoinitiators. The polymerizable photoinitiators are prepared from methacrylic acid and 2-hydroxyl-4'-(2'-hydroxyethoxy)-2-methyl propiophenone by the aid of direct esterification processes. The use quantity of polymerization inhibitors in a reaction system accounts for 0.01%-0.5% of the mass of the methacrylic acid, the use quantity of methane sulfonic acid which is a catalyst accounts for 0.1%-2% of the mass of the methacrylic acid, and a molar proportion of the methacrylic acid to the 2-hydroxyl-4'-(2'-hydroxyethoxy)-2-methyl propiophenone is 1:1-1.2. Each polymerization inhibitor is methoxyphenol or hydroquinone or 2-tertiary butylhydroquinone, and a solvent is toluene or dimethylformamide or tetrahydrofuran. The method has the advantages that the polymerizable photoinitiators are excellent in compatibility with monomers and resin in photo-curing systems fragments obtained after the polymerizable photoinitiators are subjected to illumination pyrolysis are low in migration rate in cured films and are anti-yellowing, excellent initiation effects can be realized, and the method can be applied to the field of photo-cured coating, printing ink, adhesive and the like; the method for synthesizing the polymerizable photoinitiators is low in cost, processes for preparing the polymerizable photoinitiators are simple and convenient, and obvious application effects can be realized.

Owner:NANCHANG HANGKONG UNIVERSITY

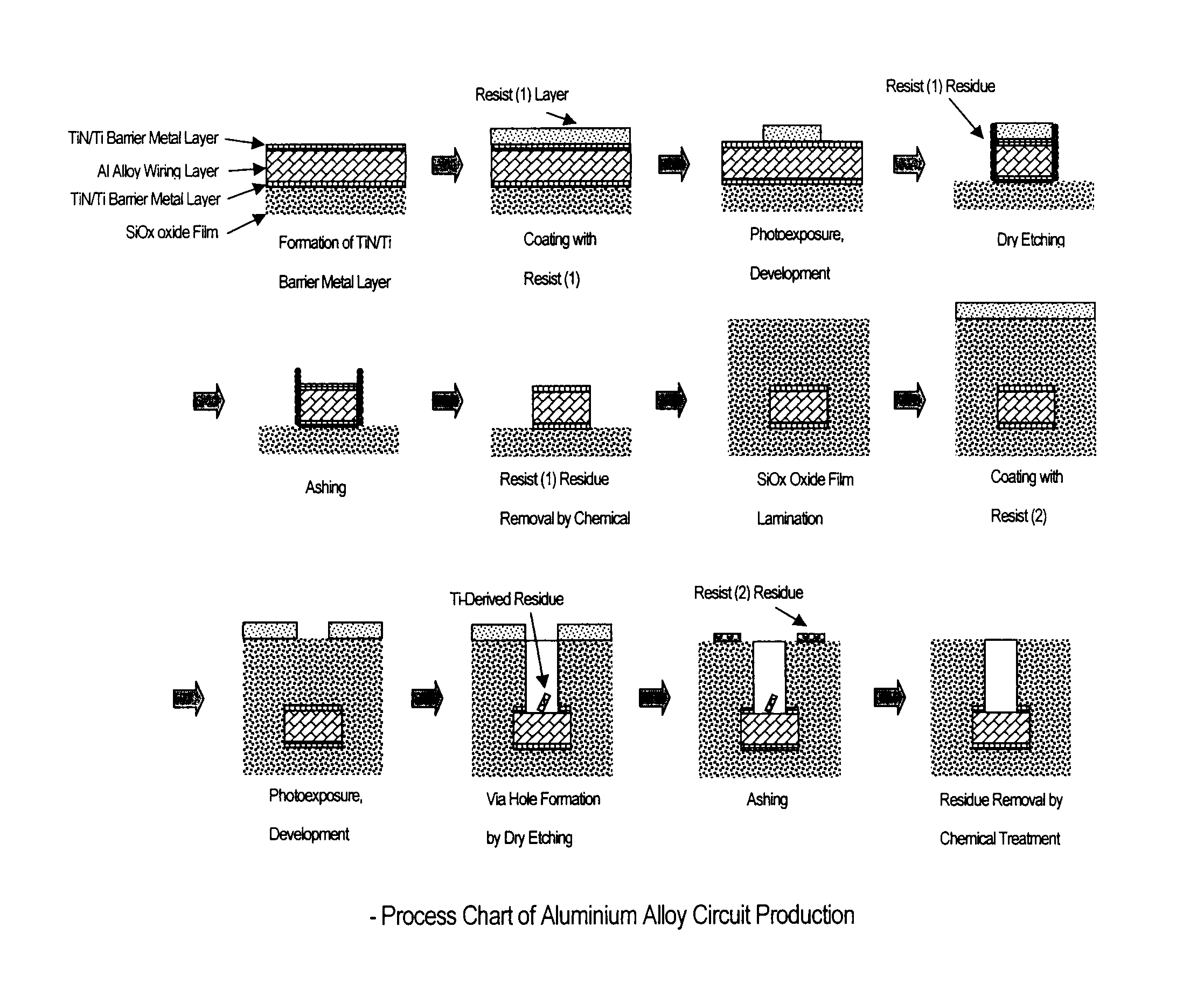

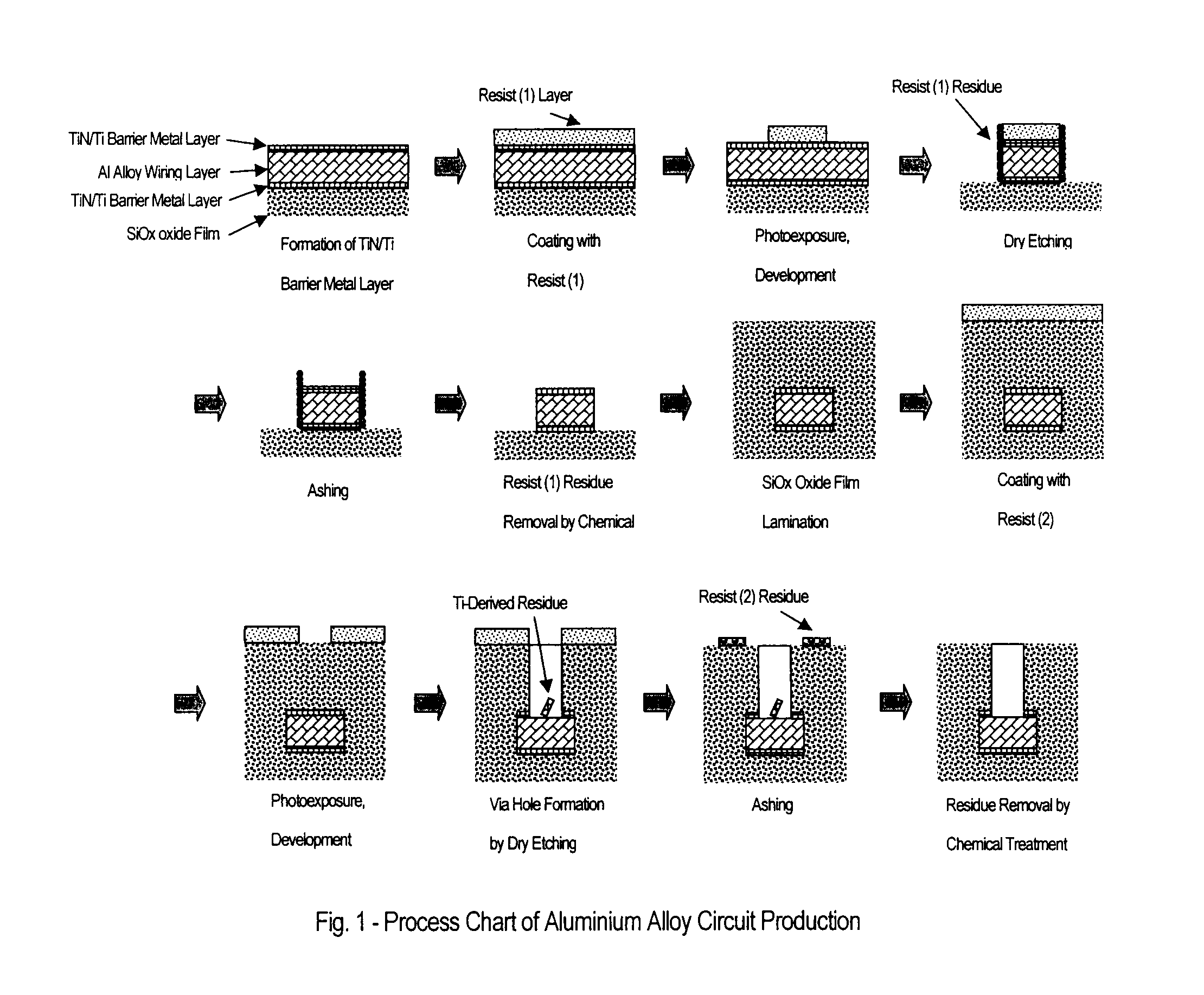

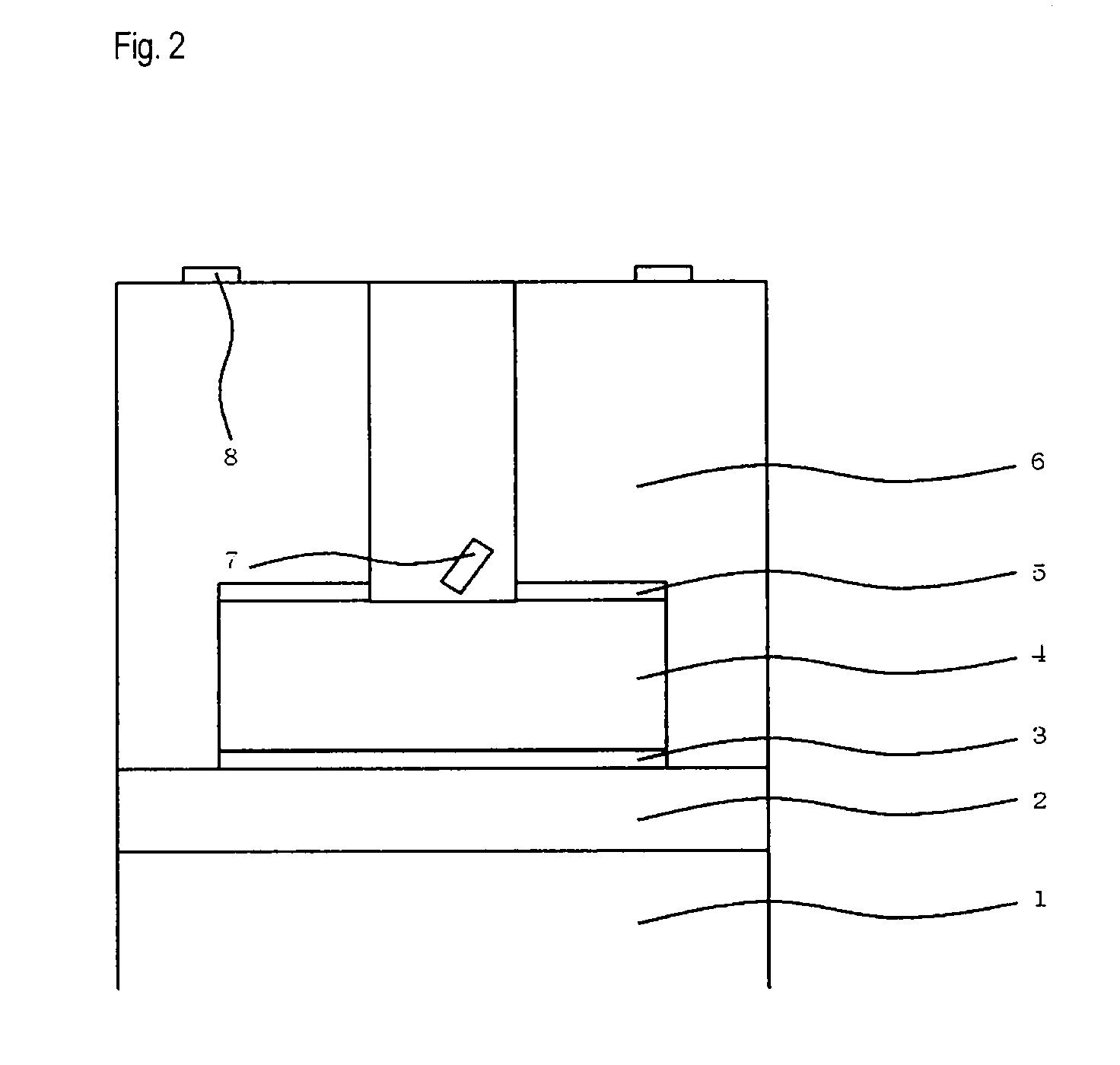

Residue removing liquid composition and method for cleaning semiconductor element using same

ActiveUS20110256483A1Improve production yieldDetergent mixture composition preparationSemiconductor/solid-state device manufacturingDevice materialAlloy

Provided are a residue removing liquid composition capable of completely removing a resist residue and a titanium (Ti)-derived residue that remains after dry etching and ashing in via hole formation in a production process for a semiconductor substrate having metal wiring of aluminium (Al) or an Al alloy, at a low temperature in a short time, not corroding parts of an interlayer insulating material, a wiring material and others, and a cleaning method for semiconductor devices using it.The residue removing liquid composition contains (A) ammonium fluoride, (B) methanesulfonic acid, (C) a carbon-carbon triple bond-having compound, (D) a water-soluble organic solvent, and (E) water, wherein the content of (A), (C), (D) and (E) in the residue removing liquid composition is from 0.005 to 2% by mass, from 0.1 to 10% by mass, from 60 to 75% by mass and from 5 to 38% by mass, respectively, and (B) is contained in an amount of from 0.9 to 1.5 times (by mol) the amount of (A).

Owner:MITSUBISHI GAS CHEM CO INC

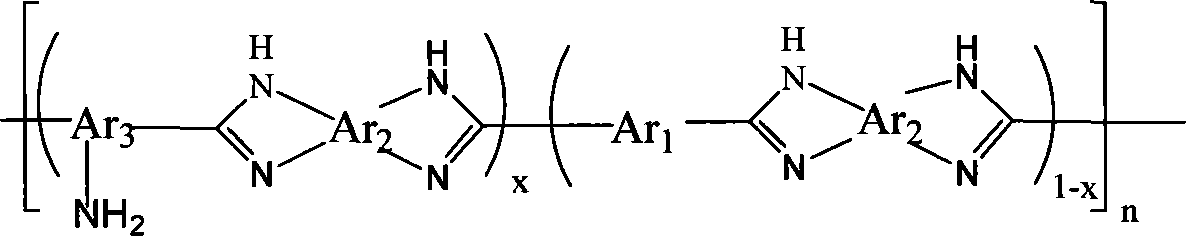

Polybenzimidazole with side groups and ether bonds and preparation method and application thereof

InactiveCN103435804AImprove solubilityGood dimensional stabilityFuel cell detailsSolubilityPolymer science

The invention belongs to the technical field of high polymer material and synthesis of a high polymer material. The preparation method comprises the following steps: carrying out the reaction between bisphenol compound and p-dihalobenzonitrile, re-crystallizing acetone to obtain dinitrile monomer with side groups and ether bonds, adding potassium hydroxide into the dinitrile monomer solution with side groups and ether bonds to carry out hydrolysis, re-crystallizing 1,4-dioxane to obtain diacid monomer with side groups and ether bonds, dissolving the diacid monomer with side groups and ether bonds and 3,3'-diaminobenzidine monomer into phosphorus pentoxide-methane sulfonic acid solution for reaction, and thus obtaining the polybenzimidazole with side groups and ether bonds after treatment. The product can be used for preparing proton conductive membranes of fuel cells. The polybenzimidazole with side groups and ether bonds prepared by the method provided by the invention has good solubility in organic solvent, is convenient to prepare membranes with high performance, and better improved in size and oxidation stability of membrane material and methanol permeability while the proton conductivity of a blend membrane is basically kept.

Owner:JILIN UNIV

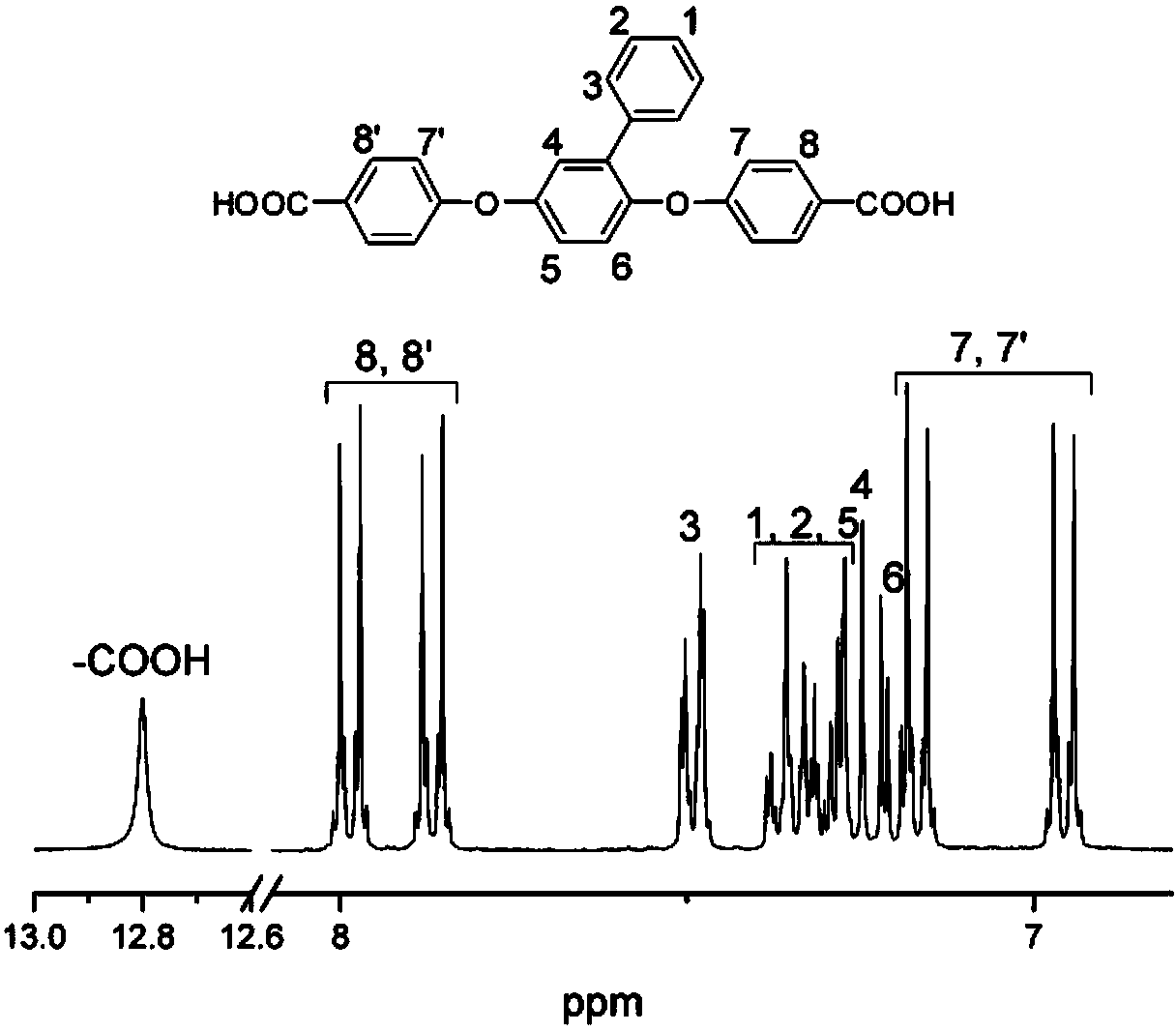

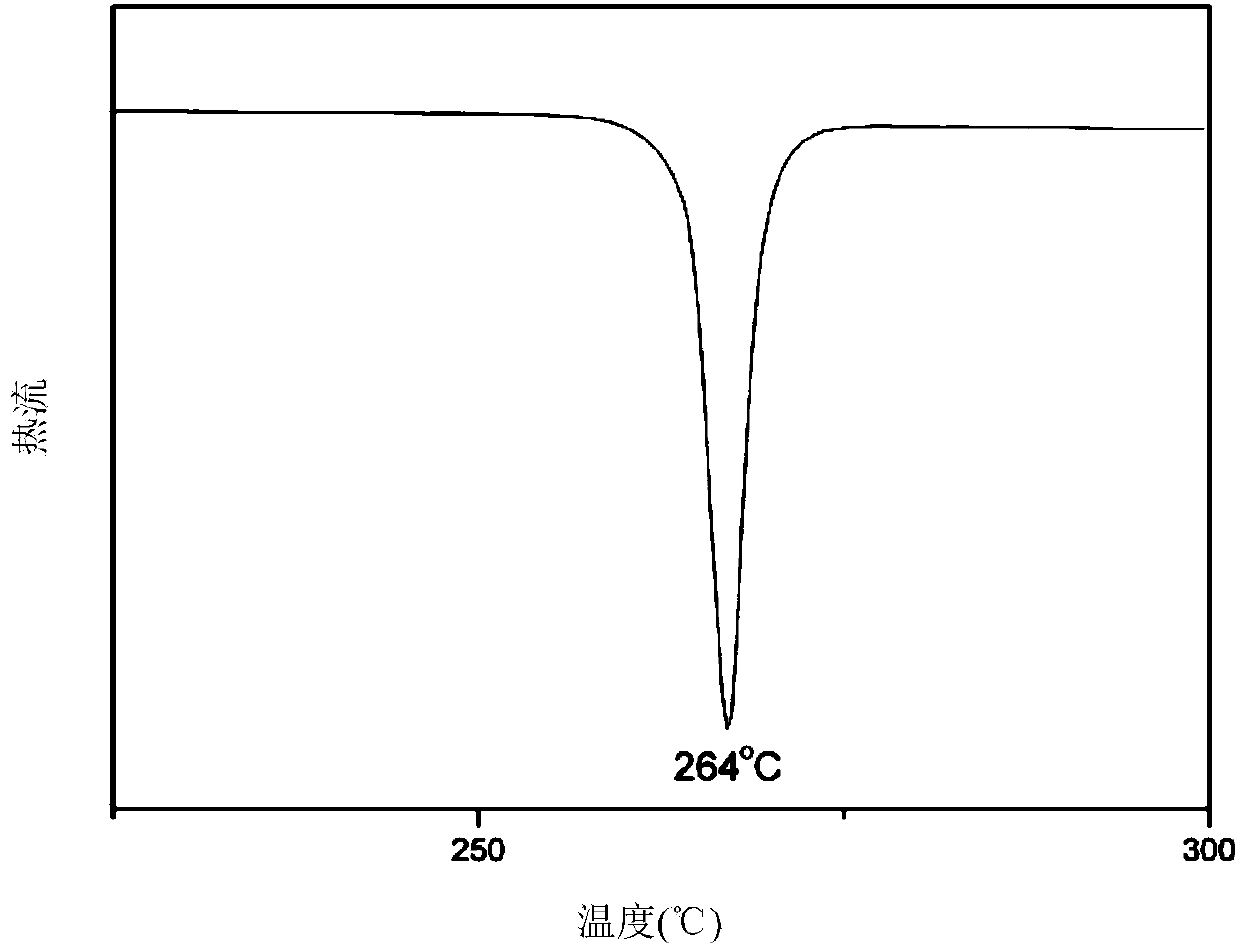

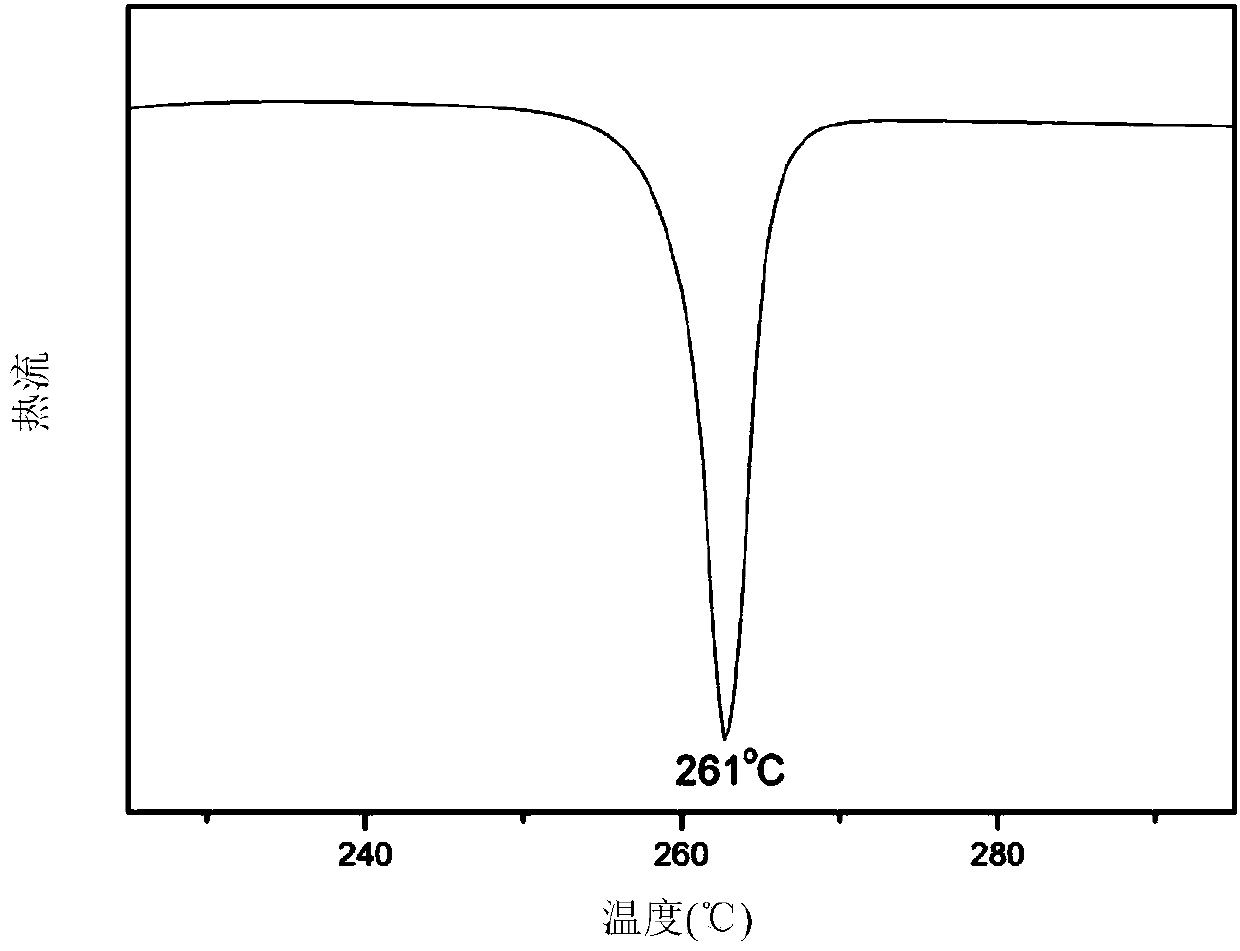

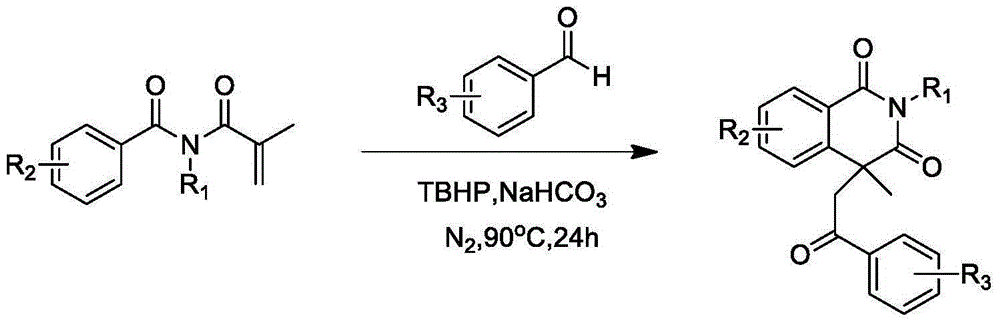

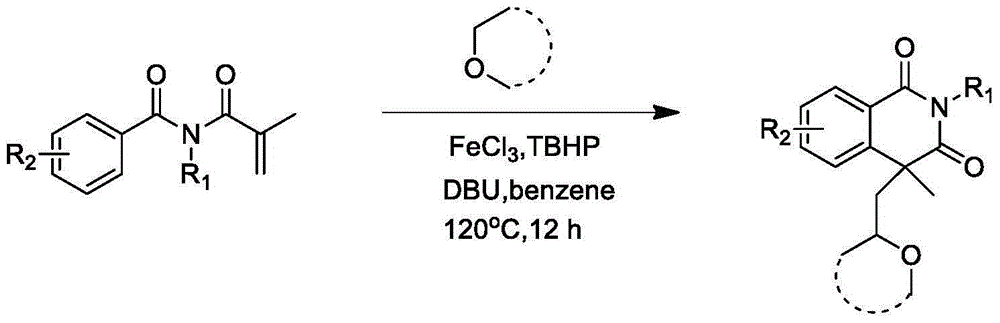

Preparation of 1,3-isoquinoline dione derivative

ActiveCN105198811AMild reaction conditionsSimple and fast operationOrganic chemistryEthyl acetateMethyl group

The invention discloses a preparation method of a 1,3-isoquinoline dione derivative. The preparation method is characterized by comprising steps as follows: (1), N-methyl-N-isobutylene acyl benzamide and methane sulfonic acid are added to acetone, 2-butanone or 3-pentanone respectively, TBHP (tert-butyl hydroperoxide) is added while stirring is performed at the room temperature, and a mixed system reacts for 2 hours at certain temperature; (2), after a reaction ends, water is added for quenching, the mixture is extracted with 20 mL of ethyl acetate twice and washed with a saturated salt solution once, and ethyl acetate is removed through spin-drying under reduced pressure; (3), the mixture is subjected to column chromatography, and a target product is obtained.

Owner:JIANGNAN UNIV

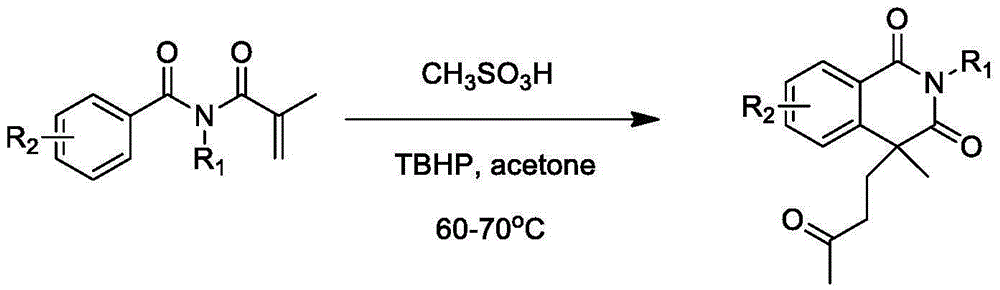

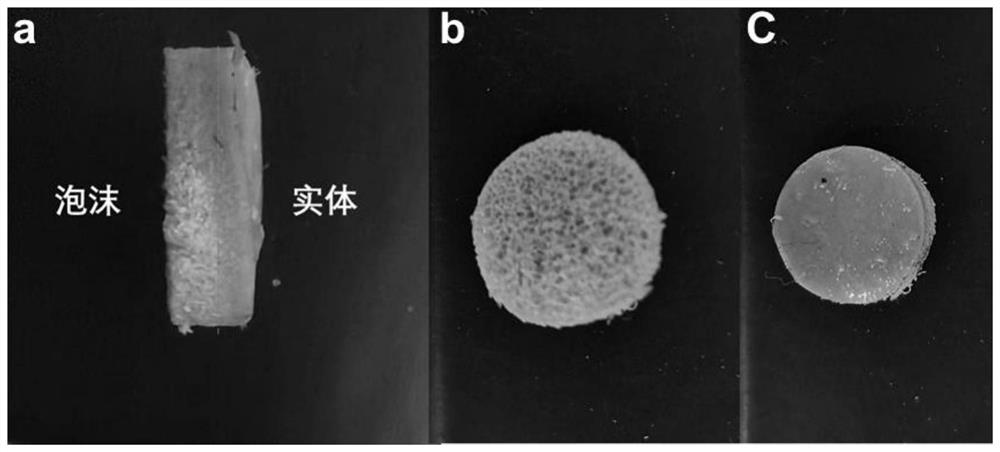

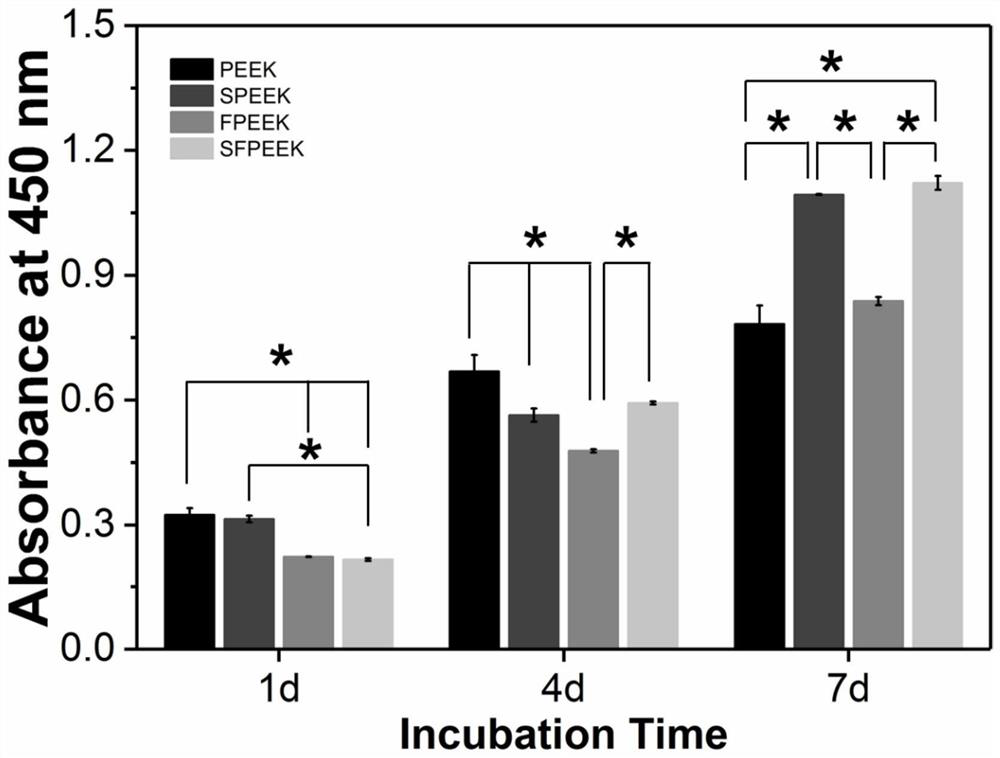

Polyether-ether-ketone bone repair material with multi-scale holes and preparation method thereof

ActiveCN112972764AImprove adhesionPromote ingrowthTissue regenerationProsthesisMicro nanoPoly ether ether ketone

The invention discloses a polyether-ether-ketone bone repair material with multi-scale holes and a preparation method thereof, and belongs to the technical field of medical biological materials. The preparation method comprises the following steps: firstly, hot-pressing polyether-ether-ketone granules into a plate, after cleaning and drying, obtaining a partially foamed polyether-ether-ketone plate in a supercritical carbon dioxide foaming device, conducting sulfonation in a mixed acid solution of concentrated sulfuric acid and methane sulfonic acid, and conducting hydrothermal treatment and vacuum drying to obtain the polyether-ether-ketone bone repair material with multi-scale holes. Small-size micro-nano holes obtained through sulfonation are beneficial to adhesion of early osteoblasts, large-size micro holes obtained through supercritical carbon dioxide foaming are beneficial to ingrowth of bone tissues in a later period, the material has a multi-scale hole structure through simple two-step operation, and bone repair is promoted. Compared with a hole-making technology using a hole-making agent, a supercritical carbon dioxide foaming technology does not have a problem that the hole-making agent is not thoroughly removed and the possibility that the material is applied to the field of biomedicine is ensured.

Owner:JILIN UNIV

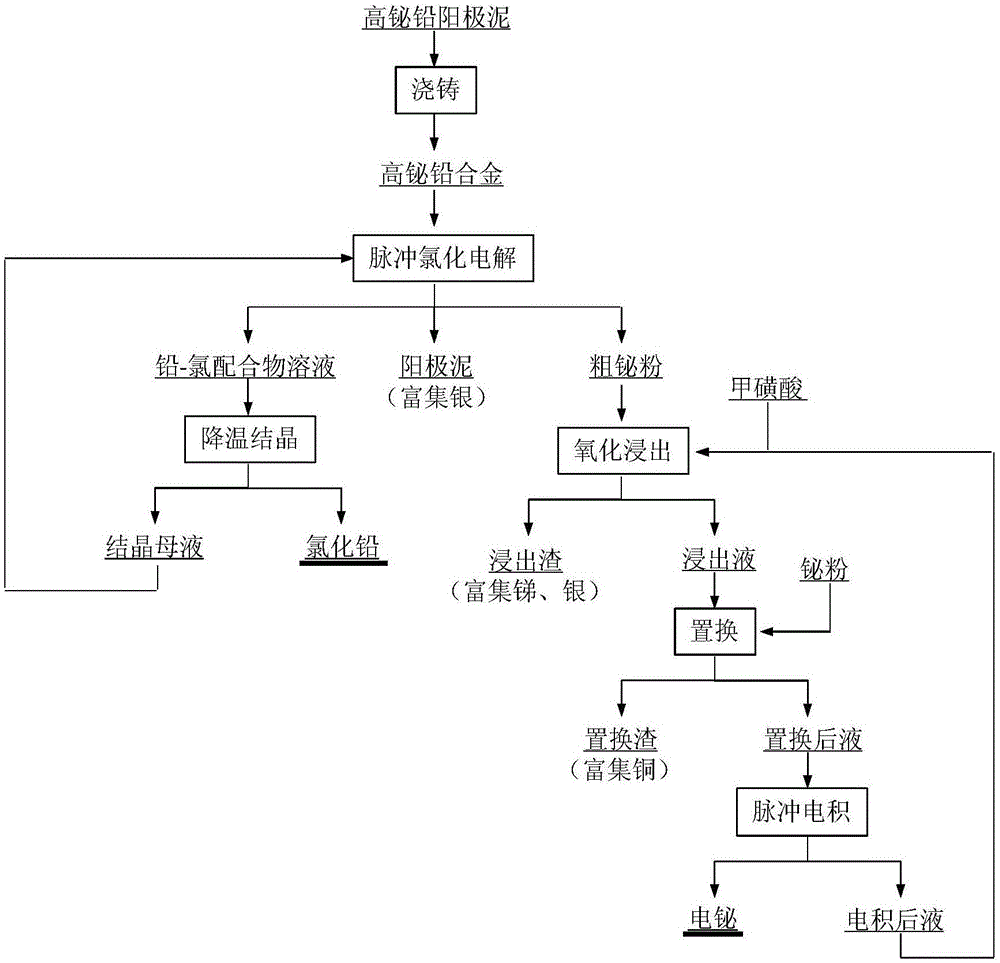

Process for separating lead and bismuth from high bismuth lead alloy

ActiveCN107177865ATo achieve full enrichmentElectrolysis componentsPhotography auxillary processesElectrolysisSlag

The invention discloses a process for separating lead and bismuth from a high bismuth lead alloy; and the process uses an alloy formed by casting high bismuth lead anode mud as an anode; and the alloy is fed in an anode bag for pulse chlorination electrolysis in a hydrochloric acid-chlorine salt system. Insoluble matters of the anode fall into the anode bag to form anode mud during electrolyzing; lead is dissolved in solution in a lead-chlorine complex form; and bismuth is separated out from a cathode in a rough bismuth powder form. The anode mud, lead chloride complex solution and rough bismuth powder are respectively obtained after electrolysis. The lead chloride solution is cooled for crystallization to obtain lead chloride; and crystallization mother liquor is returned to prepare electrolyte. The oxidation leaching is performed on the rough bismuth powder by adopting methane sulfonic acid to respectively obtain leaching liquid and leaching slag enriched with antimony and silver. The leaching liquid is replaced and purified for pulse electrodeposition to obtain electric bismuth; and electrodeposition back liquid is returned to leaching of the rough bismuth powder. The process can perform classified extraction on lead and bismuth in the high bismuth lead alloy; silver is enriched; the closed cycle of the technological process is realized; and the process has the advantages of simple technological process, high yield of valuable elements, cleanness and environmental protection.

Owner:YIYANG SHENGLI CHEM IND

Method for preparing benzisoxazole methane sulfonyl chloride and its amidation to form zonisamide

The present invention relates to a process of preparing benzisoxazole methane sulfonic acid-chloride (BOS—Cl) as an zonisamide intermediate via chlorination of benzisoxazole methane sulfonate. The present invention also discloses a process of preparing zonisamide via amidation of BOS—Cl. More particularly, the present invention provides a process of preparing zonisamide, comprising the steps of: a) chlorinating BOS, salts or esters thereof, with SOCl2 in an organic solvent and / or in the presence of a catalyst to form BOS—Cl; and b) amidating BOS—Cl in the presence of ammonia selected from the group consisting of aqueous ammonia in a biphasic system, masked ammonia and dry ammonia to form zonisamide.

Owner:TEVA PHARM USA INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com