PEEK (polyether-ether-ketone) porous separator for lithium ion battery as well as preparation and application of PEEK porous separator

A technology of lithium-ion batteries and porous diaphragms, applied in secondary batteries, battery pack components, circuits, etc., can solve problems such as low heat resistance and poor wettability, and achieve good high temperature stability, fast response, and operability strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] (1) Add polyether ether ketone, methanesulfonic acid and sulfuric acid to the flask, wherein the mass ratio of methanesulfonic acid and sulfuric acid is 1:0.1, and fully stirred at 20 ° C for 8 hours to make PEEK with a mass concentration of 10%. casting liquid;

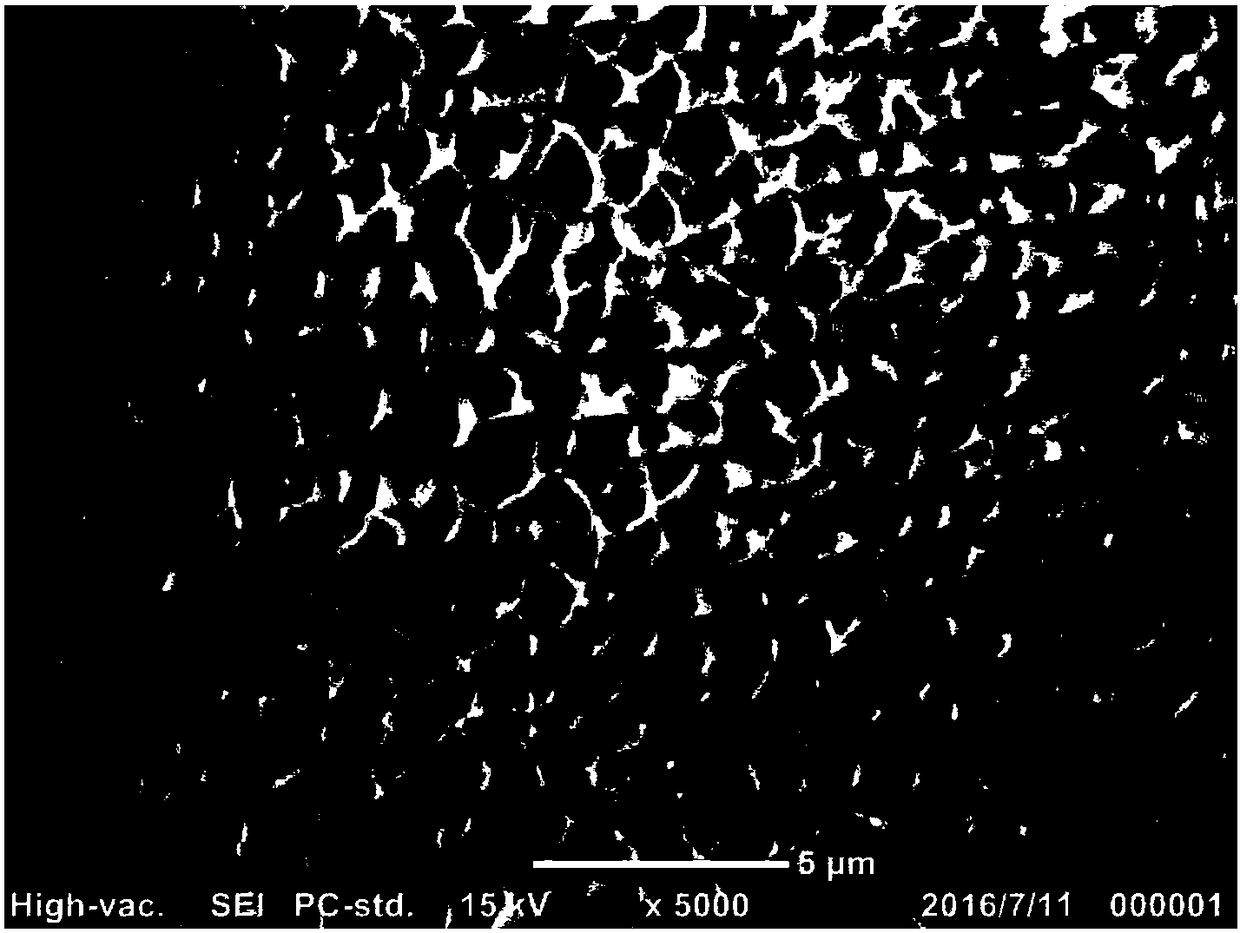

[0028] (2) pouring the uniform casting liquid prepared in step (1) on a flat plate and scraping it to make a wet film; then immersing the whole film in methanol solvent for 10 min to form a porous film, soaking in deionized water to remove residual solvent to obtain PEEK porous membrane;

[0029] (3) The PEEK porous membrane is taken out from the deionized water and dried.

[0030] The porosity test of the produced PEEK porous membrane (28um) was about 76%; the contact angle test, the result was 30°. The resulting film was tested for thermal stability, and the result was that only slight deformation occurred at 350°C.

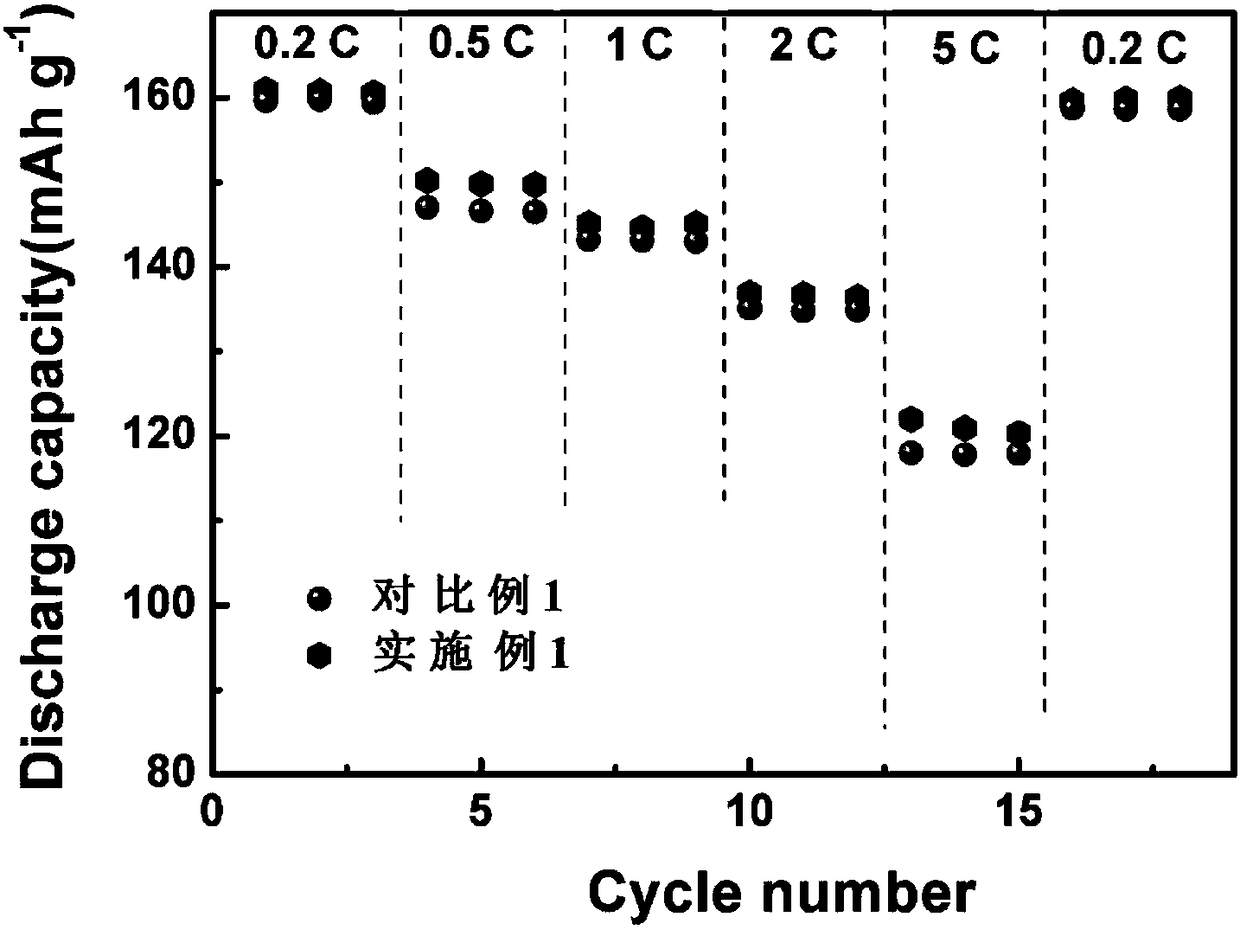

[0031] Lithium-ion battery testing using the prepared porous membrane. The negative ele...

Embodiment 2

[0033] (1) Add polyether ether ketone, methanesulfonic acid and sulfuric acid to the flask, wherein the mass ratio of methanesulfonic acid and sulfuric acid is 1:0.1, and fully stirred at 20 ° C for 18 h to make PEEK mass concentration of 12% uniform casting liquid;

[0034] (2) pouring the uniform casting liquid prepared in step (1) on a flat plate and scraping to make a wet film; then immersing the whole film in water for 15 minutes to form a porous film, soaking in deionized water to remove residual solvent to obtain PEEK porous film diaphragm;

[0035] (3) The PEEK porous membrane is taken out from the deionized water and dried.

[0036] The porosity test of the produced PEEK porous membrane (30um) was about 75%; the contact angle test, the result was 29°. The resulting film was tested for thermal stability, and the result was that only slight deformation occurred at 350°C. Then, under the same conditions as in Example 1, the prepared porous film was used to assemble a ...

Embodiment 3

[0038] (1) Add polyether ether ketone, methanesulfonic acid and sulfuric acid to the flask, wherein the mass ratio of methanesulfonic acid and sulfuric acid is 1:4, and fully stirred at 25 ° C for 12 h to make PEEK with a mass concentration of 15%. casting liquid;

[0039] (2) pouring the uniform casting liquid prepared in step (1) on a flat plate and scraping it into a wet film; then immersing the whole in an ethanol solvent for 25 min to form a porous film, soaking in deionized water to remove residual solvent to obtain PEEK porous membrane;

[0040] (3) The PEEK porous membrane is taken out from the deionized water and dried.

[0041] The porosity test of the prepared PEEK porous membrane (38um) was about 74%; the contact angle test, the result was 31°. The resulting film was tested for thermal stability, and the result was that only slight deformation occurred at 350°C. Then, under the same conditions as in Example 1, the prepared porous film was used to assemble a lith...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com