Method for realizing efficient graft polymerization of acrylonitrile on surface of silica gel microparticles by utilizing mercapto-Ce(IV) salt redox initiation system

A technology of silica gel particles and graft polymerization, which is applied in the field of efficient graft polymerization of acrylonitrile on the surface of silica gel particles, can solve problems such as difficulty in introducing initiating groups, and achieve the effect of high grafting degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

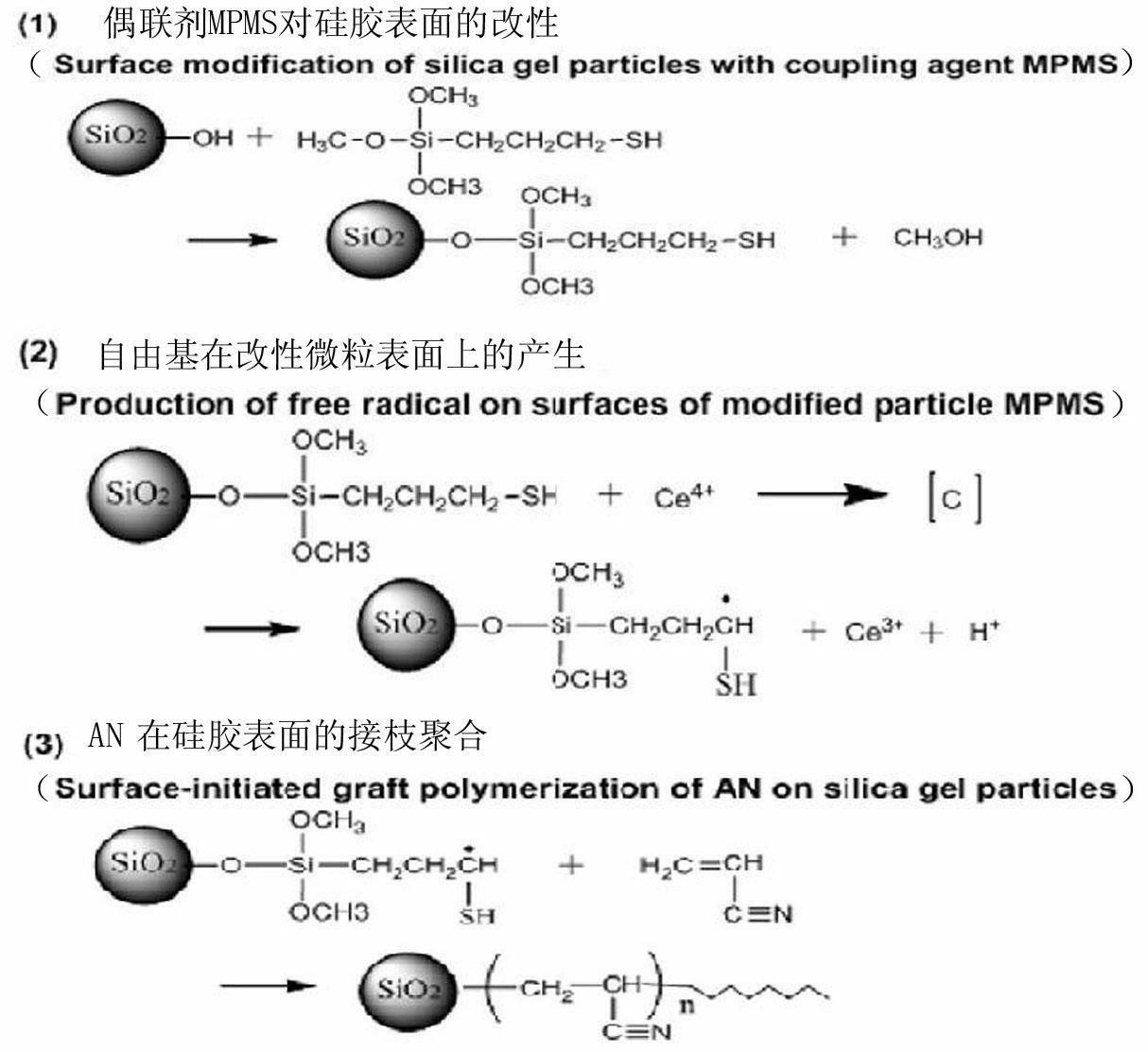

[0021] A method for realizing efficient graft polymerization of acrylonitrile on the surface of silica gel particles by using a mercapto-Ce(IV) salt redox initiation system, including the following steps:

[0022] (1) Surface modification of silica gel with a coupling agent containing sulfhydryl groups: Take 30g of silica gel particles and place them in 150 mL of a 5% methanesulfonic acid aqueous solution, stir and activate them at reflux temperature for 8 hours, and the activated silica particles Wash with distilled water repeatedly until it is neutral, filter by suction, and dry in vacuum. Then add 2.5g of activated silica gel particles to 120ml of toluene solvent, and add 2.5ml of coupling agent γ-mercaptopropyltrimethoxysilane at 110°C After reacting for 12 hours, after the reaction is finished, suction filtration, the product particles are washed with toluene first, then washed with ethanol repeatedly, and dried in vacuum to obtain the modified silica particles MPMS-SiO with ...

Embodiment 2

[0026] A method for realizing efficient graft polymerization of acrylonitrile on the surface of silica gel particles by using a mercapto-Ce(IV) salt redox initiation system, including the following steps:

[0027] (1) Surface modification of silica gel with sulfhydryl-containing coupling agent: Take 30g of silica gel particles and place them in 150 mL of methanesulfonic acid aqueous solution with a concentration of 7%, stir and activate them at reflux temperature for 10 hours. The activated silica gel particles Wash with distilled water repeatedly until it is neutral, filter with suction, and dry in vacuum. Then add 2.5g of activated silica gel particles to 130ml of toluene solvent, and add 3.5ml of coupling agent γ-mercaptopropyltrimethoxysilane, at 110℃ After reacting for 12 hours, after the reaction is finished, suction filtration, the product particles are washed with toluene first, then washed with ethanol repeatedly, and dried in vacuum to obtain the modified silica particle...

Embodiment 3

[0031] A method for realizing efficient graft polymerization of acrylonitrile on the surface of silica gel particles by using a mercapto-Ce(IV) salt redox initiation system, including the following steps:

[0032] (1) Surface modification of silica gel with a coupling agent containing sulfhydryl groups: Take 30g of silica gel particles and place them in 150 mL of a 6% methanesulfonic acid aqueous solution, stir and activate them at reflux temperature for 9 hours. The activated silica gel particles Wash with distilled water repeatedly until it is neutral, filter by suction, and dry in vacuum. Then add 2.5g of activated silica gel particles to 125ml of toluene solvent, and add 3.0ml of coupling agent γ-mercaptopropyltrimethoxysilane at 110°C After reacting for 12 hours, after the reaction is finished, suction filtration, the product particles are first washed with toluene, then repeatedly washed with ethanol, and dried under vacuum to obtain modified silica particles MPMS-SiO with s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of grafting | aaaaa | aaaaa |

| degree of grafting | aaaaa | aaaaa |

| degree of grafting | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com